Professional Documents

Culture Documents

Central Heating

Uploaded by

sumit11235Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Central Heating

Uploaded by

sumit11235Copyright:

Available Formats

Annexure A to this office NIT NO.

MHCHD/TS /2013-14/ Dated: -

/ e-tendering:

SCOPE OF WORK The scope of providing central heating system for Govt Unani Hospital, Shalteng, Srinagar includes supply, installation, testing & commissioning of (but not limited to) the following: HSD fired water boilers with chimneys, heat exchanger etc. M.S.C Class Piping, Insulation, Control Valves, Pumps, gauges of sorts etc. Hot water steel panel Radiators. Expansion tank, fuel tanks etc. including their piping, insulation etc ( The tanks will be provided by the department) Painting & final finishing of various works. Any other work not covered above to make complete system comply with the full intent of this contract. Firm shall be responsible for attaining the conditions as per design parameters given below : Room/Corridor Temperature:- 22oC against Ambient Temperature:2 Air Changes Per Hour -6oC

Air Changes per hour :1. WATER BOILER

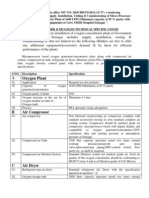

DETAILED TECHNICAL SPECIFICATIONS Water boilers each of 4 Lac Kcal/hr rating at MSL shall be fully automatic, horizontal, water tube/fire tube, preferably three pass, oil fired, pre-insulated, packaged hot water generator with allied mountings, accessories and attachments in accordance with the requirements of the system and as provided by the OEM and further complying with the following specifications. The firm shall submit civil foundation details/ drawings to this department duly recommended by OEM Burner Assembly: The mono block diesel oil fired burner shall be of international repute, highly efficient, reliable giving controlled combustion at very low noise as approved by the OEM of water boiler. Water boiler foundation: The water boiler should be mounted on a foundation as recommended by the manufacturer. Water boiler sub-panel: The electric control panel for the water boiler shall be user friendly, easy to operate, pre-wired and should be reliable having precise control of temperatures. Accessories & mountings: The water boilers should be complete with all accessories including but not limited to the items as approved the OEM. Water boiler testing: The water boiler shall be tested at hydraulic pressure of 10 kg/cm2 (pn1.0) or double the working pressure whichever is higher. Necessary test shall be carried to check proper operation of the water boiler safety devices. Tools: The water boiler should be provided with all sorts of tools and tackles as provided by the OEM. CVT: The water generator shall be provided with 0.37 Kva CVT for smooth functioning. Feed Water Pump: Feed water pump of the rating as approved by the manufacturer has to be provided with the Hot Water Generator and the rate shall be inclusive of all the items required for the complete installation of Hot Water Generator. 2. HOT WATER BOILER CHIMNEY. The water boiler shall be provided with an independent self-supporting flue gas chimney for exhaustion of the combustion gases. The chimney shall be about 12 meters high & fabricated out of 5 mm thick mild steel plates as per the OEM of Hot Water Generators. All joints between the connecting sections shall be provided with M.S flanges & duly fastened with nuts & bolts. The top of the chimney shall be provided with an M.S. sheet canopy and wire mesh to prevent the ingress of birds etc. An inspection window shall have to be provided in the bottom portion of the chimney. The chimney shall have 10 mm thick M.S. bottom plate to support the weight. A reinforced cement concrete foundation of suitable size shall be laid for the chimney provided with duly grouted steel foundation bolts of 20mm diameter, 300mm long; at about 160 mm distance from center to center. The reinforcement shall be of tor steel rods of 12 mm & 10 mm and rings made out of 8 mm tor steel for holding the matrix of steel rods in the foundation block. The chimney shall be connected to the boilers through two flanged circular tube section flue gas ducts, to be fabricated out of M.S. plate of 5 mm thickness and of dia as per the OEM of Hot Water Generators. The length of the flue gas duct shall be as per site requirements. The duct connection between the water boiler outlet and the chimney should be at an angle of not less than 45o .Two numbers of sockets of 15 mm size shall be provided in the flue gas duct at a distance of 1 meter from the flue gas outlet flange of the unit. The design / erection of the chimney shall be as recommended by the boiler manufacturer and also subject to J&K Pollution Control Board norms. The chimney shall be provided with two coats of red oxide primer followed by two coats of Heat Resistant paint of approved shade & brand. The firm shall submit drawings of chimney recommended by OEM to this department for approval before execution of work. The firm shall also submit civil foundation details/ drawings to this department duly recommended by OEM. 3. PLATE HEAT EXCHANGER. The job comprises of supply, installation, testing and commissioning of heat exchanger having heat output not less than 4 lac Kcal/hr. The heat exchanger must be plate type with plate thickness not less than 5mm,gasketted with Alloy-316,sealing material EPD/MP CLIP-ON and flange rating of ASME 150.The heat exchanger should be able to maintain the secondary circuit water temp. at 65C /75C i.e., 10C temp. drop with water primary circuit 80C /70C having LMTD OF 5.

SL. No 1 2 3 4 5

Specification Minimum Volume flow rate Inlet Temperature Outlet Temperature Design Pressure (minimum) Test Pressure (minimum)

Unit m3/hr o C o C bar bar

Primary 20 80 70 10 13

Secondary Side 55 65 75 10 13

The heat exchanger should withstand a pressure of 10 kg / cm 2 .or double the working pressure. The heat exchanger be mounted on a base frame fabricated out of ISMC. Necessary connection shall also be provided for mounting of temperature gauges, pressure gauges & air. The firm shall produce a certificate from the manufacturer to the effect that the heat output of the heat exchanger is 4lac Kcal/Hr at above parameters and complete set of manuals containing specifications, operation and maintenance procedures/details. 4. HOT WATER CIRCULATION PUMP The hot water circulation pumping unit should be coupled to 7.5 HP electric motor to ensure efficient circulation of hot water through each radiator. The pumping unit shall be suitable for operation at a temperature up to 90 oC. The other specifications of the pumping unit are: Dynamic Head Discharge Suction / Delivery Type Electric Supply Motor Rating Speed 24M 15 LPS 80 mm /65 mm Centrifugal, Mono-block 410 +10% V, 50 +3% Hz, 3Phase 7.5 HP 2900 RPM

The motor should be able to withstand a sustained overload of 10%. The pump and motor units shall be mounted on a common base frame fabricated out of ISMC100,5mm & further installed on cement concrete block or as approved by the site in-charge. 5. RAW WATER PUMP Raw water pumps should be centrifugal mono block type with rated capacity of 50 LPM each at 15 meters dynamic head, coupled to 1 HP electric motor, single phase, 220 Volt, 50 Hz, 2900 rpm mounted on a common base frame fabricated out of ISMC100, 5mm & further installed on cement concrete block or as approved by the site in-charge and connected to the water piping circuit. 6. OIL TRANSFER PUMP Oil transfer pumps should be gear type, positive displacement, coupled to 2.25KW/ 3 HP, 3 phase electric motors, mounted on a common base frame fabricated out of ISMC100, 5mm. The pumps should be suitable for output discharge of 50 LPM each. The suction / delivery of the pumps shall be 25mm x 25mm, complete with inlet, outlet valves on flanged nipples. The pumps shall be connected to the oil piping circuit. 7. BULK OIL STORAGE TANK Bulk oil storage tank of 15 K L capacity shall be provided by the department. The tank shall be provided with full scale, flanged, float type level indicator for continuous and reliable fuel level measurement in bulk oil tank. The float type level indicator shall be designed for the sump/underground application, which shall further be provided with the vapor/liquid seal assembly. The material of the float shall be preferably SS304/SS316 or as per the design standard of the manufacturer. The float type level indicator shall be calibrated for 15KL capacity bulk oil tank. A separate 25 mm fuel suction line each fitted with an NRV and a suitable valve of required size shall be provided with the tank. An MS tubular ladder of suitable size shall be provided with the tank. One dip stick duly calibrated shall be provided with the tank. The job includes earth work excavation. The tank is to be laid underground on 50mm mud-mat followed by laying of RCC raft 150mm thick in M-20 grade. The left over space in excavated trench shall be filled with sand and top of the tank shall be laid with 100mm thick RCC slab of even dimensions in M-20 Grade with duly finished top surface and a suitable gradient for easy draining of rain water etc. The installation of the tank shall be strictly as per IOCL(State owned oil company) norms. 8. DAY OIL SERVICE TANK The day oil service tank of 750 lts capacity shall be provided by the department. The tank shall be laid on pedestal block fabricated out of ISA 50x50x5mm & (100Kgs approx.). The tank shall be provided with a glass gauge complete with necessary gauge cocks. The tank shall have a suitable manhole with hinged cover. An MS tubular ladder of suitable size shall have to be provided by the firm. 9. EXPANSION TANK. The expansion tank of 500 lts capacity shall be provided by the department. The tanks shall have to be connected to the primary and secondary circuit of the system. The tanks are to be insulated on all sides with 50 mm thick glass wool and covered with alumunium cladding as per site requirement and directions of site incharge. The tank shall be mounted on an M.S pedestal made out of ISA 50x50 x 5 & 40x40x5mm(70kgs approx.) such that the bottom of the tank is at least 1M above the highest point of the hot water piping system to provide room for expansion. 10. RAW WATER STORAGE TANK

An ISI marked HDPE storage tank (horizontal/vertical; to be decided as per the site conditions), 1KL capacity for raw water compete with hinged cover shall be provided and installed. The job also includes providing and fitting of ball-cock valve assembly. The tank shall be located inside the plant room and connected by GI B class pipes of 25mm dia. along with necessary fittings etc for inlet, outlet connections. The raw water storage tank shall be connected to the raw water pump set, softener plant and expansion tank. 11. WATER SOFTENER PLANT. Supply installation testing and commissioning of Water softener plant with metallic body having a maximum capacity of delivering 1500 lts per hour and pressure range between 1.5 to 5kgf/cm2. A centrifugal pump of 0.75KW/1 HP capacity, 20M head along with a base frame to be provided and fitted with the softener plant. This plant should be able to soften the available water at site and render it viable for use in circuit of the central heating system. The plant shall be complete with pump set, PVC brine tank, resin filled tank, valves and piping grid to deliver the continuous treated water. A sample of raw water as well as treated water shall be got tested by the contracting agency from Kashmir PHE Departments Water Testing Laboratory, Zainakote and the charges on account of this test shall be born by the contracting agency. The results shall be accompanied with an authenticated certificate. 12. PIPE WORK. The scope shall comprise supply, installation, testing and commissioning of M S C Class Hot water piping including fittings such as bends, shoe bends, flanges, nipples, sockets, unions, nuts, bolts, washers etc complete in all respect. All civil works such as making openings in walls / floor / ceilings, finishing and restoration of the same and other damages, caused during execution of work at the site, to its original decor are in the scope of this job. The pipes shall be welded together by means of electric arc welding conforming to the relevant IS standards & using electrodes of repute. All hot water piping shall be E.R.W Mild steel (Black Steel) heavy class conforming to IS 1239-79, Part-1 with amendments thereafter, if any. The contractor shall ensue that the pipes are laid to comply /maintain the design standards set by the department. SUPPORTS: Pipe supports, made out of various structural steel sections like ISA6565,6mm or ISA 5050,5mm or ISA4040,5 mm, etc. shall be provided for the suspended outdoor piping wherever required to prevent shaking or sagging duly provided with wooden saddles beneath pipe work. Supports shall be further reinforced at places where fittings are provided to avoid stress on the pipeline. Angle supports/ ceiling hangers etc. shall be fixed to the walls/ ceiling by means of metallic dash fasteners as per site requirements or as approved by the site incharge. Angular supports must be smooth duly applied with two coats of primer. Pipe supports for indoors shall clamps made out of M.S. flat (not less than 32mm) as per the directions of Engineer incharge. Spacing of the pipe supports shall not be more than following: Pipe size (in mm) 20 / 25 32 / 40 / 50 / 65 80/100/125/150 Maximum spacing (in meters). 2.00 2.50 3.00 a)

b) SCHEMATIC PIPE LAYOUT: The piping shall be installed in a uniform manner, parallel to or perpendicular to walls or ceilings and all changes in direction shall be made with fittings. The horizontal piping shall be run at right angles. Bull heading, diagonal crossing over other piping and across the rooms should be avoided. All the piping shall be carefully installed to provide for proper alignment, slope and expansion. c) TESTING: Tests shall be applied to piping before connection of equipment and appliances. In no case piping shall be subjected to pressures exceeding their testing ratings. The tests shall be completed and approved by the site engineer, before any insulation is applied. Testing of the segments of pipes laid shall be permitted, provided that all open ends are first closed by blank-offs or flanges. After tests have been completed the system shall be drained and flushed 3 to 4 times and cleaned off all dust and foreign matter. All the strainers, valves and the fittings shall be cleaned off all dirt, filings, if any. All the piping shall be tested to a hydraulic test pressure of at least one and a half times the maximum operating pressure, but not less than 10kg/cm2 for a period of not less than 24 hours. All the leaks & defects in the joints revealed during the testing shall be rectified to the entire satisfaction of the engineer-in-charge. d) DRAIN PIPING: The drain piping shall be medium class galvanized steel conforming to IS 1239/1979. The drain line shall be provided at all the lowest points in the system upto the nearest drain trap and pitched towards the trap. f) FITTINGS: The fittings shall confirm to IS: 1239-part-II unless & otherwise indicated in the specifications. All bends shall be ready made, heavy duty of appropriate class. All fittings such as branches, reducers etc. in all sizes shall be fabricated from the same material as that of pipes of similar dia. and thickness used in the circuit. The reducers shall be eccentric type. To avoid pressure drop, shoe bends wherever required shall be preferred. The length of the reducers must be twice the dia. of the pipes. While laying offsets, 45 angles over 90 angles shall be preferred. g ) FLANGES: All flanges, if required, shall be of mild steel slip-on type conforming to IS: 6392 / 71 and welded to the pipe. Flange thickness shall suit class-I pressure. Flanges may be tack welded into position, but all final welding shall be done with joints dismounted, 3-mm thick fibre

reinforced rubber gaskets shall be used with all flanged joints. Flanged pairs shall be used on all such equipment, which is required to be dismantled for service. h) PAINTING: All pipes shall be applied with two coats of red oxide primer and followed by two coats of bituminous paint. 13. INSULATION: a) Above Ground Glass Wool (Pipe Section): The insulation for hot water piping shall be of glass wool pipe section. The insulating material shall be non-combustible with following specifications: Insulation Operating fluid temperature. 90 C Thermal Conductivity Kcal/hr.mC 0.045 Average Density Kg/m3 64

Glass Wool

The insulating material must be fixed with the piping with the help of chicken mesh. Hot water piping after insulation must be cladded with aluminum sheet of 22 gauge thickness properly screwed. All joints of adjoining section shall be staggered in relation to each other. The insulation of hot water piping shall be provided and fixed as per the specification and diameter of the piping below: Pipe diameter 150mm 125 mm 100 mm 80 mm 65 mm 50 mm 40 mm 32 mm 25 mm 20 mm Thickness of Insulation 65mm 65 mm 65 mm 50 mm 50 mm 50 mm 32 mm 32 mm 25 mm 25 mm

b. Insulation for Indoors Cross linked closed cell Polyethylene insulation with UV filling (Fire Retardant). The insulation for hot water piping shall be of Cross linked closed cell Polyethylene insulation with UV-Filling (Fire retardant) in conduits and shall be fixed over the piping with the help of OEM approved adhesive suitable to withstand temperatures upto 105 C. Insulation Cross linked closed cell Polyethylene insulation with UV Filling (Fire Retardant). Surface temperature. 105 C Thermal Conductivity Kcal/hr.mC 0.031 Average Density Kg/m3 33

The longitudinal/circular joints of the insulation tubing shall also be provided with 50 mm wide X 3mm thick OEM approved self adhesive plain tape and metallic adjustable clamps matching the colour of the insulating material shall be provided at intervals of 2 meter. The insulation of hot water piping shall be provided and fixed as per the specification and diameter of the piping below: Pipe diameter 20mm 25mm 32mm Thickness of Insulation 9 mm 9 mm 9 mm

ii) Insulation for Underground piping a) Glass Wool (Pipe Section) The insulation for underground hot water piping shall be of glass wool. The insulating material shall be non-combustible with the following specifications:

Insulation

Operating fluid temperature. 90 C

Thermal Conductivity Kcal/hr.mC 0.045

Average Density Kg/m3 64

Glass Wool

The job includes the trench work and insulating material be fixed with the piping with the help of chicken mesh. Hot water piping after insulation must be polythene wrapped and cladded with tar-felt. The pedestals made of brick masonery be provided at a distance of 3meters in the trench for hot water piping. 14. VALVES / GUAGES. (ISI MARKED) a) BALL VALVES: Ball valves up-to and including 32 mm dia. shall be screw type suitable for 10 kg / cm 2 test pressure (PN1.0), full bore design, provided with forged brass hard chrome plated ball. b) BUTTERFLY VALVES: All butterfly valves of 40 mm dia. and above shall be flanged type having Cast Iron body with EPDM integrally moulded body lining suitable for pressure & temperature of 10 kg / cm2 (PN1.0) & 80 0C respectively. c) AIR VENTS: Automatic Air vent valves of rating (PN1.0) shall be provided at all higher points in the piping system. D) GUAGES. Suitable Pressure Gauges (Glycerine filled) in a range of 0-20bars and Temperature Gauges in a range of 0- 1200C. 15. RADIATORS. The capacity of each radiator shall be measured at heat output 75 oC mean water temperature (75 /650C) during the winter season at a room temperature of 22oC. The radiators shall be provided with concealed brackets, air vents and plugs. Each radiator shall be provided with OEM or equivalent makes air purging & radiator control valves (inlet valve open type & outlet valve lock shield type). The bleed valve shall rotate around a fixed point. The radiator shall be provided with a drain plug at the bottom with inlet & outlet manifolds for two pipe system on both the sides. The radiator shall be complete with top grill and end/side panels with rounded bottoms for user safety with no visible screws. The radiators shall be joined to the main piping by MS connections as per site conditions. The radiators should be clearly marked/embossed with the manufacturers hologram. A certificate, from manufacturer/an accredited laboratory, to the effect that the heat output of radiators conforms to DIN EN442 standard shall be submitted by the firm before installation. The radiators should be able to withstand operating pressure of 10Kg/cm 2. The allowable heat output of the radiators should be as under: S.No. 1 2 3 4 5 6 7 Type Double Panel (22-PKKP) Double Panel (22-PKKP) Double Panel (22-PKKP) Double Panel (22-PKKP) Triple Panel (33-DKEK) Triple Panel (33-DKEK) Triple Panel (33-DKEK) Required Heat Output (kCal/hr) 1500 2000 2500 3000 3500 4000 4500 Height of Radiators 500 mm 500 mm 500 mm 500 mm 500 mm 500 mm 500 mm

Note: Width of the radiators shall be as per the manufacturers standard. The firm shall install radiators of equal or higher capacity within the contract value depending on the availability.

AEE MH&CH SUB DIVISION-3rd

EXECUTIVE ENGINEER MHCHD Srinagar

Accepted Seal & Sig. of Tenderer

You might also like

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Hal Ahu BoqDocument16 pagesHal Ahu Boqmdalt9180100% (1)

- Solenoid Valves BasicsDocument47 pagesSolenoid Valves BasicsGary8100% (6)

- CHWDocument11 pagesCHWdeepakajaydasNo ratings yet

- Chilled Water PumpsDocument8 pagesChilled Water PumpsssarangNo ratings yet

- Trane Submittal Centrifugal Water ChillersDocument10 pagesTrane Submittal Centrifugal Water Chillersjun005No ratings yet

- Schneider Price ListDocument34 pagesSchneider Price ListscribddaduNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Genset Inst Manual Feb 08Document16 pagesGenset Inst Manual Feb 08rt1973100% (2)

- HWG PDFDocument8 pagesHWG PDFsumit11235No ratings yet

- HWG PDFDocument8 pagesHWG PDFsumit11235No ratings yet

- Variable Refrigerant Flow Systems Vs ChillerDocument38 pagesVariable Refrigerant Flow Systems Vs ChillerMilton Rebello50% (2)

- Sunny EngineersDocument4 pagesSunny EngineersSivakumar ThangavelNo ratings yet

- TS Fire Hydrant Wet SystemDocument9 pagesTS Fire Hydrant Wet System123agattarNo ratings yet

- SOLAR WATER HEATING EQUIPMENTDocument7 pagesSOLAR WATER HEATING EQUIPMENTngarinyagaNo ratings yet

- Bhatia Gummidipoondi WHRSG O&m Manual FinalDocument224 pagesBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadNo ratings yet

- Husk Based Power Plant 6T 32 KG FBC With Single Stage Turbine - For Finance, Subsidy & Project Related Support Contact - 9861458008Document28 pagesHusk Based Power Plant 6T 32 KG FBC With Single Stage Turbine - For Finance, Subsidy & Project Related Support Contact - 9861458008Radha Krishna SahooNo ratings yet

- Fire Protection System (Hydrant System)Document6 pagesFire Protection System (Hydrant System)adilmomin45No ratings yet

- HWG - Boq-1Document13 pagesHWG - Boq-1Prashant Singh ChauhanNo ratings yet

- Solar Hot Water System SpecificationsDocument22 pagesSolar Hot Water System Specificationspsn_kylmNo ratings yet

- O M Manual W818 PDFDocument71 pagesO M Manual W818 PDFmujeebmehar100% (1)

- Part A - Hvac Technical Specifications 1. Hot Water GeneratorDocument25 pagesPart A - Hvac Technical Specifications 1. Hot Water GeneratorAnand_HvacNo ratings yet

- Yk Maxe Chiller MEP-10100 SM BLVD: EneralDocument7 pagesYk Maxe Chiller MEP-10100 SM BLVD: EneralSevero SeveroNo ratings yet

- Boiler SpecificationDocument15 pagesBoiler Specificationjrri16No ratings yet

- Marathahalli Project - BlankDocument12 pagesMarathahalli Project - BlankSajad ManjadikkalNo ratings yet

- HVAC system for hospital and collegeDocument17 pagesHVAC system for hospital and collegeAnkush NayarNo ratings yet

- C.I. Mould Chain Conveyor Suitable For 176-180 Moulds: Dear SirDocument8 pagesC.I. Mould Chain Conveyor Suitable For 176-180 Moulds: Dear SirSatyaranjan SahuNo ratings yet

- 35,000 kg/hr Water-Tube Boiler Design & Construction SpecDocument7 pages35,000 kg/hr Water-Tube Boiler Design & Construction SpecRabindranath Hendy TagoreNo ratings yet

- Modern Cane Sugar Boiler Purchase OrderDocument15 pagesModern Cane Sugar Boiler Purchase OrderSupratik RoyNo ratings yet

- Turn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsDocument18 pagesTurn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsKarim Galal IsmailNo ratings yet

- Keston 170 Boiler ManualDocument54 pagesKeston 170 Boiler ManualPaul HendersonNo ratings yet

- Spcification Fo DG SetDocument6 pagesSpcification Fo DG Setnirmalb21No ratings yet

- Baxi Solo 2 40rs Gcno.41-077-77Document42 pagesBaxi Solo 2 40rs Gcno.41-077-77sjallandNo ratings yet

- SpecificationDocument51 pagesSpecificationArjun VinayakumarNo ratings yet

- SECTION 3.3 - WET RISER SYSTEM Rev. 1Document33 pagesSECTION 3.3 - WET RISER SYSTEM Rev. 1يوسف محمد صالحNo ratings yet

- CSI Spec EXN-SGO-07Document5 pagesCSI Spec EXN-SGO-07davidvranaNo ratings yet

- Detailed Specification of Item No. of BOQDocument2 pagesDetailed Specification of Item No. of BOQsmithNo ratings yet

- JamJoom Pharma - Technical Offer - 113Document8 pagesJamJoom Pharma - Technical Offer - 113Ramy MahmoudNo ratings yet

- Technical Specifications OF Multi Purpose Tender (LCV 100 HP Chassis)Document23 pagesTechnical Specifications OF Multi Purpose Tender (LCV 100 HP Chassis)Naushad WadiaNo ratings yet

- HVAC Pumps and Pressurization UnitsDocument6 pagesHVAC Pumps and Pressurization UnitskdpmansiNo ratings yet

- Brian LadeDocument36 pagesBrian LadeMatteo CafieroNo ratings yet

- Technical GuideDocument6 pagesTechnical Guidesajay2010No ratings yet

- Detail of PumpDocument6 pagesDetail of PumpPrashant Singh ChauhanNo ratings yet

- Technical Specifications OF Multi Purpose Tender (16 Ton 150 HP Chassis)Document11 pagesTechnical Specifications OF Multi Purpose Tender (16 Ton 150 HP Chassis)Naushad WadiaNo ratings yet

- Spec 5da STP AwfDocument2 pagesSpec 5da STP AwfDimas BagasworoNo ratings yet

- Bmcu Specs 3-5 KLDocument24 pagesBmcu Specs 3-5 KLElumalai NarayananNo ratings yet

- Flash Tank Heat Recovery SpecificationDocument3 pagesFlash Tank Heat Recovery SpecificationMerisaNo ratings yet

- Dynaforce Hot Water 300 5000Document3 pagesDynaforce Hot Water 300 5000Oscar Dario Villada LopezNo ratings yet

- 2011 R22 DX Type Screw ChillerDocument41 pages2011 R22 DX Type Screw ChillerDiêm Công ViệtNo ratings yet

- Bfit Model BFIT Condensing Hot Water Boiler SpecificationDocument8 pagesBfit Model BFIT Condensing Hot Water Boiler SpecificationjoeNo ratings yet

- Feed Tank and Pressure SizingDocument4 pagesFeed Tank and Pressure SizingodvutNo ratings yet

- Tuty Court Genset ESTIMATES NewDocument42 pagesTuty Court Genset ESTIMATES NewRajaDurai RamakrishnanNo ratings yet

- En Installation Manual Heater Type EJKDocument10 pagesEn Installation Manual Heater Type EJKخالد بنسالمNo ratings yet

- Delta Performance MVDocument36 pagesDelta Performance MVJosé MacedoNo ratings yet

- Steam and Condensate Piping and Pump SystemsDocument7 pagesSteam and Condensate Piping and Pump SystemsOsamah AlzubadiNo ratings yet

- Artistic Milliners W.H.R.boiler Simplex (JGS-320)Document13 pagesArtistic Milliners W.H.R.boiler Simplex (JGS-320)EngrSaimaAskariNo ratings yet

- NT 664Y2500 B HeaMaster 71-101-201 EN PDFDocument44 pagesNT 664Y2500 B HeaMaster 71-101-201 EN PDFalex_cristiNo ratings yet

- Section 2 Water Chilling Unit (Screw) GeneralDocument5 pagesSection 2 Water Chilling Unit (Screw) GeneralmatzoyekNo ratings yet

- Boiler SpecificationsDocument34 pagesBoiler SpecificationsHenry CoronadoNo ratings yet

- Installation, Commissioning and Maintenance Guidelines: For Electrohydraulic SystemsDocument0 pagesInstallation, Commissioning and Maintenance Guidelines: For Electrohydraulic Systemsanta77100% (1)

- Specification of Distribution Transformer 33 KV Cap. 100 KVADocument16 pagesSpecification of Distribution Transformer 33 KV Cap. 100 KVAzulryNo ratings yet

- Rowan University Design Guide 2013Document2 pagesRowan University Design Guide 2013zeliteNo ratings yet

- TPAP Aalborg BoilerDocument11 pagesTPAP Aalborg BoilerAayush AgrawalNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- CAD1Document1 pageCAD1sumit11235No ratings yet

- GA 30 90 Brochure India 2015Document9 pagesGA 30 90 Brochure India 2015sumit11235No ratings yet

- Hep PDFDocument6 pagesHep PDFsumit11235No ratings yet

- GA 30 90 Brochure India 2015Document9 pagesGA 30 90 Brochure India 2015sumit11235No ratings yet

- 5 CPCB-II 320-625 kVADocument4 pages5 CPCB-II 320-625 kVAsumit11235No ratings yet

- LiftDocument1 pageLiftsumit11235No ratings yet

- Unbalanced 15% Below Additional Performance Security of 3%Document5 pagesUnbalanced 15% Below Additional Performance Security of 3%sumit11235No ratings yet

- Oxygen Plant: B Air CompressorDocument3 pagesOxygen Plant: B Air Compressorsumit11235No ratings yet

- Konkurencieschopnosť KrajínDocument1 pageKonkurencieschopnosť KrajínJana ČevelováNo ratings yet

- Leypower Specification (10-500kva)Document4 pagesLeypower Specification (10-500kva)balajiboss005No ratings yet

- Independence Series SpecDocument1 pageIndependence Series Specsumit11235No ratings yet

- Manufacturing solutions for commercial laundriesDocument8 pagesManufacturing solutions for commercial laundriessumit11235No ratings yet

- Aqua MaticDocument2 pagesAqua Maticsumit11235No ratings yet

- Coin-Op: Washer ExtractorsDocument4 pagesCoin-Op: Washer Extractorssumit11235No ratings yet

- Particle Dark Matter Evidence Candidates and ConstraintsDocument144 pagesParticle Dark Matter Evidence Candidates and ConstraintsJosé Galisi FilhoNo ratings yet

- Manufacturing solutions for commercial laundriesDocument8 pagesManufacturing solutions for commercial laundriessumit11235No ratings yet

- Contracts Systems and ProceduresDocument68 pagesContracts Systems and ProcedureskapsicumNo ratings yet

- Aqua MaticDocument2 pagesAqua Maticsumit11235No ratings yet

- Etovos PDFDocument21 pagesEtovos PDFsumit11235No ratings yet

- EtvosDocument5 pagesEtvossumit11235No ratings yet

- Aqua MaticDocument2 pagesAqua Maticsumit11235No ratings yet

- Truss Design ConsiderationsDocument8 pagesTruss Design Considerationsitaliaunita2470No ratings yet

- Contracts Systems and ProceduresDocument68 pagesContracts Systems and ProcedureskapsicumNo ratings yet

- Pectherm Private Limited Quotation for Thermax Spare PartsDocument1 pagePectherm Private Limited Quotation for Thermax Spare Partssumit11235No ratings yet