Professional Documents

Culture Documents

Actividades Soldadura

Uploaded by

KiukStaksOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Actividades Soldadura

Uploaded by

KiukStaksCopyright:

Available Formats

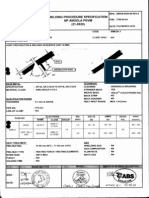

Prototype welding process of sheet metal cabinets, it includes but was not limited to define the most adequate

process flow, layout of the line for the product welding assembly, define the best practices to welding the products in order to improve cycle time, costs and space; provide the tools and templates (fixtures, pokayokes and other special devices) necessary to accomplish the quality expectations from our clients. Also I have to generate documentation required such as visual aids, quality alerts (when apply), training direct personnel until transferring the project to the manufacturing team. During the NPI process some reports were necessary to be generated and updated daily such a DFM Report in order to have a record of problems found during welding process and weekly reviewed with our customers to determine solutions.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Arc Gouging GuideDocument44 pagesArc Gouging Guidedirtylsu0% (1)

- Arc Gouging GuideDocument44 pagesArc Gouging Guidedirtylsu0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Aw StandartsDocument12 pagesAw StandartsKiukStaksNo ratings yet

- Calg CDDocument92 pagesCalg CDMilutinMMNo ratings yet

- Welding GaugeDocument11 pagesWelding GaugeDevesh ChauhanNo ratings yet

- Welding GaugeDocument11 pagesWelding GaugeDevesh ChauhanNo ratings yet

- AWS Certification for Robotic Arc Welding OperatorsDocument26 pagesAWS Certification for Robotic Arc Welding OperatorsKiukStaksNo ratings yet

- Iso 3834 2 2005 en PDFDocument6 pagesIso 3834 2 2005 en PDFRamamoorthy SundarNo ratings yet

- Weld Metal CalculationDocument1 pageWeld Metal CalculationKiukStaksNo ratings yet

- Vendor Document RequirementsDocument6 pagesVendor Document RequirementsAnonymous LLLK3pqNo ratings yet

- 027 ITP For Pre Cast Concrete PDFDocument27 pages027 ITP For Pre Cast Concrete PDFlinga2014No ratings yet

- 6GR WPS PQRDocument15 pages6GR WPS PQRKiukStaks100% (6)

- Resume Structural Design EngineerDocument3 pagesResume Structural Design Engineerazizhamidfar60% (5)

- Electric-Powered Wheelchair With Stair-Climbing Ab PDFDocument13 pagesElectric-Powered Wheelchair With Stair-Climbing Ab PDFYogita ChoudharyNo ratings yet

- Single V Butt Weld With Both Plates Prepped at Same Angle: Select ProcessDocument1 pageSingle V Butt Weld With Both Plates Prepped at Same Angle: Select ProcessKiukStaksNo ratings yet

- Requirements GatheringDocument96 pagesRequirements Gatheringswanzon100% (3)

- Safety Risk Assessments - Pls and SilsDocument44 pagesSafety Risk Assessments - Pls and SilsopreamihNo ratings yet

- Girder-Slab System Design Guide v3.2Document32 pagesGirder-Slab System Design Guide v3.2dalocivilNo ratings yet

- Plant Identification (KKS)Document75 pagesPlant Identification (KKS)Taladron LekNo ratings yet

- E8-E8M-09-Standard Test Methods For Tension Testing of Metallic Materials EspecimenDocument1 pageE8-E8M-09-Standard Test Methods For Tension Testing of Metallic Materials EspecimenKiukStaksNo ratings yet

- E8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialDocument1 pageE8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialKiukStaksNo ratings yet

- E8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialsDocument1 pageE8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialsKiukStaksNo ratings yet

- PubCat 2013Document1 pagePubCat 2013KiukStaksNo ratings yet

- E8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialsDocument1 pageE8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialsKiukStaksNo ratings yet

- E8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialsDocument1 pageE8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialsKiukStaksNo ratings yet

- Linde q1 Feb1march31Document12 pagesLinde q1 Feb1march31KiukStaksNo ratings yet

- Weight of Weld Metal in KG/M of Weld TriangleDocument5 pagesWeight of Weld Metal in KG/M of Weld TriangleKiukStaksNo ratings yet

- Metric MeditionDocument4 pagesMetric MeditionKiukStaksNo ratings yet

- Cord OnesDocument1 pageCord OnesKiukStaksNo ratings yet

- Cord OnesDocument2 pagesCord OnesKiukStaksNo ratings yet

- SR - No. Name of The Book SpecificationDocument7 pagesSR - No. Name of The Book SpecificationKiukStaksNo ratings yet

- Enter Data:: Weld Size (Leg) MM Unit Weld Length MDocument2 pagesEnter Data:: Weld Size (Leg) MM Unit Weld Length MKiukStaksNo ratings yet

- Riel LigeroDocument6 pagesRiel LigeroHenrry MendozaNo ratings yet

- Taking Your Weld's Temperature-1Document6 pagesTaking Your Weld's Temperature-1KiukStaksNo ratings yet

- Crane Rails1Document3 pagesCrane Rails1Cw TanNo ratings yet

- Weld Consumable CalculatorDocument2 pagesWeld Consumable CalculatorKiukStaksNo ratings yet

- Heat Input CalculatorDocument2 pagesHeat Input CalculatorKiukStaksNo ratings yet

- Placas SawDocument1 pagePlacas SawKiukStaksNo ratings yet

- Catagog 2013Document48 pagesCatagog 2013KiukStaksNo ratings yet

- Progress ReportDocument20 pagesProgress ReportPeter Jean-jacquesNo ratings yet

- Design and Performance Considerations of The Continuos Four-Roll Bender: A Precision Machine For The Roller Bending of PlatesDocument2 pagesDesign and Performance Considerations of The Continuos Four-Roll Bender: A Precision Machine For The Roller Bending of PlatesWilliam VanruselNo ratings yet

- Dtu Placement BrouchureDocument25 pagesDtu Placement BrouchureAbhishek KumarNo ratings yet

- Technical Handbook Version 11 - 5Document72 pagesTechnical Handbook Version 11 - 5Rodrigo100% (1)

- Autodesk Inventor Course and CNC Machining RequirementsDocument3 pagesAutodesk Inventor Course and CNC Machining Requirementsbrar352100% (1)

- Author Guidelines of Journal of Civil Engineering and Architecture ResearchDocument6 pagesAuthor Guidelines of Journal of Civil Engineering and Architecture ResearchCristian GhindeaNo ratings yet

- XLPE Insulated Low Voltage CablesDocument40 pagesXLPE Insulated Low Voltage CablesAnzad AzeezNo ratings yet

- Fresh Concrete PropertiesDocument24 pagesFresh Concrete PropertiesvolminkNo ratings yet

- PRINCIPLES OF MANAGEMENT (FIRST EDITION) - Pages-6-105Document100 pagesPRINCIPLES OF MANAGEMENT (FIRST EDITION) - Pages-6-105AlinaasirNo ratings yet

- Mechanical Engineering Curriculum for Diploma CourseDocument219 pagesMechanical Engineering Curriculum for Diploma CoursekrishanNo ratings yet

- CSTE Subjective QuestionsDocument3 pagesCSTE Subjective Questionsvenkysh2uNo ratings yet

- MME 9617 - Energy Conversion: Department of Mechanical & Materials EngineeringDocument4 pagesMME 9617 - Energy Conversion: Department of Mechanical & Materials EngineeringMohamed Al-OdatNo ratings yet

- Geo Risk 2017 Preliminary ProgramDocument8 pagesGeo Risk 2017 Preliminary ProgramRoy JariNo ratings yet

- Deep FoundationDocument61 pagesDeep FoundationAlfaizs Vi Afkara100% (1)

- Monitor Module PDFDocument2 pagesMonitor Module PDFKalpa Helitha SilvaNo ratings yet

- B e IemDocument385 pagesB e IemMega MegaNo ratings yet

- 02-1-Development Process-PDD PDFDocument17 pages02-1-Development Process-PDD PDFChandan MishraNo ratings yet

- PID Control Design For A Temperature Control SystemDocument6 pagesPID Control Design For A Temperature Control SystemChemesAlliouaNo ratings yet

- E-6 Group F (Roof Plan)Document1 pageE-6 Group F (Roof Plan)Anonymous n6jJt1gANo ratings yet

- LBT .No VAT .No. Dealer NameDocument303 pagesLBT .No VAT .No. Dealer NameShashi SukenkarNo ratings yet