Professional Documents

Culture Documents

Thread Selection

Thread Selection

Uploaded by

Jiraiya El SabioCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thread Selection

Thread Selection

Uploaded by

Jiraiya El SabioCopyright:

Available Formats

American & Efird, Inc. 2007. All Internatioal Rights Reserved.

Selection Logic & Charts

Selection Logic & Charts

Introduction

There is no perfect thread for all applications; however, there is a perfect thread for the specific application. In order to select the right thread for a specific application, there are three elements you should consider: 1. Fiber Type 2. Thread Construction 3. Thread Size American & Efird offers a thread education workshop, called Threaducation, on how to select the best thread for a specific application. This seminar is not about how we make thread but how to select the best fiber type, thread construction and size for a specific application. The information on this page is a summary of that seminar. Most people who are involved in the selection of thread make their decision based on one or all of the following reasons:

Sewability (Process ability) Seam Performance (Seam strength, seam durability, etc.) Seam Appearance (Color, color fastness, stitch appearance, etc.) Availability (Is the product available to meet my needs?) Cost (Cost includes both the price and the hidden costs associated with the above)

Thread Selection by End Use is intended to help you ask important questions about thread and then guide you in the selection of the best fiber type, thread selection, and thread size for a specific application. A&E Sales Representatives and Technical Service Team are also available to answer specific questions about thread application and share with you their experience of what is the best thread to use.

04/26/07

Page 1

American & Efird, Inc. 2007. All Internatioal Rights Reserved.

Selection Logic & Charts

Example One of Thread Application and Selection

Let's say you are making a men's dress shirt or ladies blouse and the fabric is light-weight and susceptible to seam puckering. You know that automatic sewing equipment will be used on some operations and thread breakage is common on these machines. You also would like the thread to match the fabric it is being sewn in to and have good color fastness characteristics. What thread type and size would you recommend? Looking at the Thread Selection Charts, you will find the following:

Sewability Questions

Seam Puckering? Are there any Automatic Multi-directional Lockstitch Machines? Cotton Wrapped Core or Polyester Wrapped Core Cotton Wrapped Core or Polyester Wrapped Core Polyester or Vat Dyed Cotton Thread Size T-18, T-21, T-24,T-26 (Shirt, Blouses, & Tops)

Seam Appearance Questions?

Color fastness? Light Weight?

Thread Application & Size Questions?

Looking under the Fabric Weights & Thread Sizes section, you will find that for 2 to 4 oz. goods, you would generally use a Tex 16, 18, 21, or 24 thread size. If you read the description under Corespun Thread Construction, it says corespun threads:

Sew on all types of sewing equipment with minimum sewing problems. Sew on automatic multidirectional sewing machines. Have a higher strength per size than spun polyester threads. (Allows the use of a smaller thread size to help minimize seam puckering. See our Technical Service Bulletin #3 on Minimizing Seam Pucker.) Have a fibrous surface giving a soft hand, low sheen appearance. Have a high elongation for greater seam strength and seam elasticity. PW Core threads have very good color fastness, chemical resistance & enzyme resistance. They are less expensive than cotton wrapped core.

Therefore the correct selection would be a T-18 or T-24 Poly Wrapped (PW) Core thread.

04/26/07

Page 2

American & Efird, Inc. 2007. All Internatioal Rights Reserved.

Selection Logic & Charts

Example Two of Thread Application and Selection

You are making a Tee Shirt that is primarily sewn with a overedge stitch construction. You want a thread with good chemical resistance and a thread should be as inexpensive as possible.

Sewability Questions

Overedge & Coverstitch? Spun or Textured Polyester Thread Size T-18, T-21, T-24,T-27 (Shirt, Blouses, & Tops)

Seam Performance?

Chemical Resistance? Light Weight?

Thread Application & Size Questions? Textured Thread Construction?

High "fluff" thread for excellent seam coverage and seam elasticity. Lowest purchase price. Textured Polyester - for knit garments like Tee Shirts, fleece.

Therefore T-18 Textured Polyester thread would be recommended. A T-21 Spun Polyester might be required if there are any sewing operations requiring greater ply security like sewing on a pocket with a single needle lockstitch machine.

04/26/07

Page 3

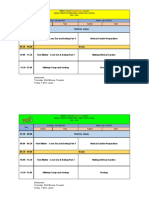

Selection Logic & Charts: Sewability,

Performance, & Appearance

Sewability, Performance, & Appearance Sewability Questions?

Apparel? Are there any Automatic Multi-directional Lockstitch? Lockstitch? Buttonsew? Buttonhole? Overedge, Coverstitch? Excessive needle heat? Are Special fabrics being sewn like microfiber, poplins? Seam puckering? Needle Cutting on Knits? Are extra small needles required? Heavy Non-Apparel? Spun, Core, Air Entangled, Textured CW Core or PW Core Corespun, Spun, or Air Entangled Spun or Textured Cotton or CW Core Perma Core - Fine Tex Size CW Core or PW Core Small as Possible Tex Size Small Tex Size Multifilament, Monocord

Seam Performance Questions?

Chemical Resistance? Abrasion Resistance? UV Resistance? Long-term Heat Resistance? Short-term Heat Resistance? Stone Wash Resistance? Minimize Cut-Stitch? Seam Elasticity? Polyester Nylon or Polyester Polyester DuPont Nomex Cotton or DuPont Kevlar Polyester CW Core or PW Core PW Core, Spun Poly, Textured

Seam Appearance Questions?

High Sheen Appearance? Low Sheen Appearance? 100% Cotton Garment Overdye? Color Fastness? Bold Size for Contrast Stitching? Seam Coverage? Filament Corespun & Spun Cotton & Lyocel Polyester, Vat dyed Cotton Large Tex Size Textured

(DuPont, Kevlar, and Nomex are registered Trademarks of E.I. du Pont de Nemours and Company and are used under license to A&E.)

04/26/07

Page 4

Selection Logic & Charts: FIBER

Fiber Types 100% Cellulose Fiber Threads

Cotton Application Low strength per size Low elongation Not as durable as synthetics Used for overdye or garment dye programs Colorfastness not as good as polyester Good Heat resistance Wrap for CW Core Only available in staple Polyester Application High strength per size - high elongation Excellent chemical resistance Very good color fastness Very good abrasion resistance Very good UV resistance Used in most apparel applications Available in staple or continuous filament Rayon Application Medium strength Low elongation Low-wet modulus Used for embroidery High sheen Only available in continuous filament Lyocell Application Low strength Low elongation Recommend for use in Tencel fabrics that are overdyed & subjected to enzymes Only available in staple

Synthetic - Thermoplastic

Nylon Application High strength per size - high elongation Excellent abrasion resistance Good chemical resistance More elastic than polyester Used for industrial applications like furniture, shoes & boots, luggage, etc. Only available in continuous filament from A&E

Synthetic - Thermoplastic

Polyester Application Nylon Application

High strength per size - high elongation Excellent chemical resistance Very good color fastness Very good abrasion resistance Very good UV resistance Used in most apparel applications Available in staple or continuous filament

High strength per size - high elongation Excellent abrasion resistance Good chemical resistance More elastic than polyester Used for industrial applications like furniture, shoes & boots, luggage, etc. Only available in continuous filament from A&E

04/26/07

Page 5

Selection Logic & Charts: CONSTRUCTION

Thread Construction Air Entangled Thread Construction

Made from 100% polyester continuous filaments - Magic Sews on all types of sewing equipment (lockstitch, chainstitch, overedge, etc.) High initial modulus for excellent loop formation Does not have as soft a "hand" as spun polyester Less expensive than Corespun & spun threads Excellent seam durability - high loop strength For all types of garment and home furnishing applications

Corespun Thread Construction

Sews on all types of sewing equipment with minimum sewing problems (lockstitch, chain, overedge, etc.) Sews on automatic multidirectional sewing machines Higher strength per size than spun polyester Fibrous surface - soft hand, no sheen, low friction High elongation for greater seam strength & seam elasticity Approx. 60% polyester core - more uniform than spun Allow use of smaller thread size but maintain seam strength

PW Core:

CW Core:

Cotton wrapped - D-Core Has good needle heat resistance Wash down look For denim garments, pants, etc.

Polyester wrapped - Perma Core Very color fast, chemical & enzyme resistant Highest strength per size - smaller thread can be used Less expensive than CW Core For all types of garment applications

Monocord Thread Construction

Made from 100% continuous filament nylon - Anecord Nylon - bonded only Flat and ribbon-like Excellent abrasion resistance Excellent seam durability High tenacity Generally industrial sewing applications: furniture, leather goods, footwear, luggage, sporting goods Prewound bobbins have higher yardage More expensive - limited color line Made from a single end of 100% continuous filament nylon - Clearlon Translucent so it blends in with many colors Not recommended for seams that lay adjacent to the skin Inexpensive compared to other thread types

Monofilament Thread Construction

04/26/07

Page 6

Selection Logic & Charts: CONSTRUCTION

Spun Thread Construction

Made from 100% staple Fibrous surface - soft hand, low sheen, low friction Sews on most types of sewing equipment (lockstitch, chain-stitch, overedge, etc.) Less expensive than Corespun threads High elongation for greater seam strength & seam elasticity

Spun Polyester:

Perma Spun- For all types of garment applications

Spun Cotton:

Anecot Plus - For garment dye programs.

Textured Thread Construction

Made from 100% continuous filament, polyester or nylon Sews on overedge, coverstitch, and chainstitch machines (but no on 301 lockstitch machines) High bulk thread for excellent seam coverage and seam elasticity High sheen Lowest purchase price Textured Polyester: Textured Nylon: Wildcat Plus- For knit garments like tee Best Stretch- For foundation garments, shirts, fleece, or serging woven garments lingerie, high stretch fabrics used in bicycle & exercise apparel

Twisted Multifilament Thread Construction

Made from 100% continuous filament - Anefil Nylon & Anefil Polyester - soft or bonded Excellent abrasion resistance Excellent seam durability High tenacity - greater strength per size Generally industrial sewing applications: furniture, footwear, luggage, sporting goods More expensive - limited color line

04/26/07

Page 7

Selection Logic & Charts: APPLICATION

& SIZES

Thread Applications & Sizes Weight

Extra Light Light Medium Medium Heavy Heavy Extra Heavy

Tex Size

T-18, T-21, T-24 T-24, T-27, T-30 T-30, T-35, T-40 T-50, T-60, T-70 T-80, T-90, T-105 T-120, T-135

Application

Sheer Blouses, T-Shirts Dress Shirts, Dresses, Knit Tops Chinos Pants, Fleece Sweat Shirts Light Weight Denims, Coveralls Heavy Denims, Parkas Heavy Denims - Stretch

Needle Applications & Sizes Weight

Light Medium Heavy

Needle Size (M)

65, 70, 75 80, 90, 100, 110 110, 120, 140, 160

Application

Shirts, Blouses, Tops Slacks, Chinos, Jackets Denim Garments, Heavy Coats, Jackets, etc.

Fabric Weights & Sizes Oz./Sq. Yd.

2-4 oz. 4-6 oz. 6-8 oz 8-10 oz. 10-14 oz

Thread Tex Size

Tex 16, 18, 21, 24 Tex 24, 27, 30 Tex 30, 35, 40, 50 Tex 40, 45, 50, 60 Tex 60, 80, 90, 105, 120, 135

04/26/07

Page 8

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Halloween Puppets: CrochetDocument3 pagesHalloween Puppets: Crochet1_teachNo ratings yet

- Itch To Stitch Uvita Top PDF Sewing Pattern Instructions V1 2 - 5f9f32167917a PDFDocument29 pagesItch To Stitch Uvita Top PDF Sewing Pattern Instructions V1 2 - 5f9f32167917a PDFsoleisolei100% (1)

- Isabella MadrigalDocument18 pagesIsabella MadrigalAlexis100% (5)

- Trends Trade Fairs ForcastingDocument20 pagesTrends Trade Fairs ForcastingMunu SagolsemNo ratings yet

- Types of Cotton Yarn and CountDocument8 pagesTypes of Cotton Yarn and CountMohammed Atiqul Hoque ChowdhuryNo ratings yet

- H&M - Marketing PlanDocument17 pagesH&M - Marketing Plancris addunNo ratings yet

- Fabric Embellishment: Shazmah Basharat Ph.D. Scholar Textiles & Clothing College of Home EconomicsDocument22 pagesFabric Embellishment: Shazmah Basharat Ph.D. Scholar Textiles & Clothing College of Home EconomicsKriti Rama Mani100% (1)

- Fashion Futures 2025Document12 pagesFashion Futures 2025digitalhandeln100% (4)

- Marketing Case Study: GucciDocument26 pagesMarketing Case Study: Gucciclaudi7zaNo ratings yet

- Home Economics: Quarter 4 - Module 4 DressmakingDocument25 pagesHome Economics: Quarter 4 - Module 4 DressmakingKishly ConcepcionNo ratings yet

- Denkard, The Acts of Religion, Book FiveDocument44 pagesDenkard, The Acts of Religion, Book FivepayamkianiNo ratings yet

- Seasonal Catalogue Spring 2020-En PDFDocument33 pagesSeasonal Catalogue Spring 2020-En PDFZsuzsaNo ratings yet

- Weekly 20-21 July 2023Document3 pagesWeekly 20-21 July 2023Sioe LieNo ratings yet

- Cabled Legwarmers: From Knit Picks Design TeamDocument2 pagesCabled Legwarmers: From Knit Picks Design TeamglezglezmonicaNo ratings yet

- High Quality Used Traditional Attires: TradiduluDocument1 pageHigh Quality Used Traditional Attires: TradiduluAHMAD IMRANNo ratings yet

- 11.contoh Soal Chapter 11 Special DaysDocument5 pages11.contoh Soal Chapter 11 Special Dayspriyo cirebonNo ratings yet

- Senior GIRLtopia Companion Guide 11.22.11Document14 pagesSenior GIRLtopia Companion Guide 11.22.11Heather Brown Hopkins100% (1)

- Permission Letter 2Document1 pagePermission Letter 2Bee LNo ratings yet

- Silk Exports PDFDocument32 pagesSilk Exports PDFyug dewanganNo ratings yet

- Line Balancing For Improving Apparel Production by Operator Skill MatrixDocument7 pagesLine Balancing For Improving Apparel Production by Operator Skill MatrixSmriti GoelNo ratings yet

- 2012 Fall Trafalgar Square Publishing General TradeDocument276 pages2012 Fall Trafalgar Square Publishing General TradeIndependent Publishers GroupNo ratings yet

- Hashir ThesisDocument30 pagesHashir ThesisSyed NafeesNo ratings yet

- Kanika Resume 2Document3 pagesKanika Resume 2ShivaniNo ratings yet

- Global FairsDocument18 pagesGlobal FairsDhaval ShahNo ratings yet

- 53ce66cb926b1 Elizabeth JohnDocument2 pages53ce66cb926b1 Elizabeth JohnVishal MokalNo ratings yet

- Sweet Li L Scarfette v2Document2 pagesSweet Li L Scarfette v2nornarte creacionesNo ratings yet

- The Feasibility of Pineapple (Ananas Comosus) Fiber: An Investigatory ProjectDocument8 pagesThe Feasibility of Pineapple (Ananas Comosus) Fiber: An Investigatory ProjectJohn Caezar YatarNo ratings yet

- One Man GuyDocument141 pagesOne Man GuymarchbuanaNo ratings yet

- DoL ChangelogDocument36 pagesDoL ChangelogAgsg df sdf asNo ratings yet

- Fashion Knits Ali VisionDocument4 pagesFashion Knits Ali Visionsalman712100% (1)