Professional Documents

Culture Documents

SAIC-A-2025 Rev 2

Uploaded by

ரமேஷ் பாலக்காடுCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAIC-A-2025 Rev 2

Uploaded by

ரமேஷ் பாலக்காடுCopyright:

Available Formats

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Test Inspection of Pressure Vessels (All Applications, Including In-situ Testing of New Fin Fan Coolers)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2025

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

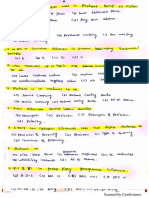

ITEM No. A

ACCEPTANCE CRITERIA Test Package Verification: Test Diagram is submitted showing the following: A) Limits of equipment to be tested incl. test manifold & equipment included in the test. B) Test pressure of the system C) Relief valve setting D) Safety Instruction Sheet Procedure has been approved & meets the detailed requirements of SAIC-A-2001 (Review Procedure - Pressure Testing) Verify drawing conformance of pressure vessel construction. Check all nozzles, supports, attachments (orientation & dimemsion) Systematically complete, verify & accept all drawings incl. details Verify complete code construction incl. support attachments. Repairs & Pick-up (ID/OD) are accepted. ASME VIII, UG-99 (a) Weld Summary Record (SAEP-1160 Welding Database) was verified to indicate completion/acceptance of all weld joints, repairs, modifications & any applicable weld inspection reqmts (visual, NDE). Verify SAIC-W-2008 & SATR-W-2008 details as applicable All required inspection & testing (RT, MT, PT, PWHT, PMI) has been completed & inspection control sheet has been signed by SA. (ASME VIII, UG-99, Para. A-2) As applicable, an SAEP-1160 Welding Database is reviewed Safety Instruction Sheet (SIS) for vessesl/equipment is complete & approved. Verify correct test pressure for system/equipment. Test Pressure at top of vessel is verified against the SIS and conforms to the following ASME Section VIII code, as applicable: A) 1.3 times MAWP for ASME D1 vessels per UG-99 (b) B) 1.25 times MAWP for ASME D2 vessels per AT-301, Div 2 Field Verification/Pre-Test Inspection of Vessel Vents are provided at all high points in the position in which it is to be tested to purge all possible air during water filling. Vessel must be adequately supported during hydrotest if it is tested out of position The strength of existing foundation/supports shall be confirmed to be adequate for additional weight of hydrotest fluid. All joints and faying surfaces, except those specifically designed and designated as removable bolted connections, are seal welded by a continuous fillet weld (external weep holes are left unwelded). Weld Summary Record was verified to indicate completion of all weld joints & applicable weld inspection reqmts (visual and NDE). Post Weld Heat Treatment (PWHT) is complete.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A1

SAES-A-004, Para. 5.6.1

A2

SAES-A-004, Para. 7.1.1 Contract drawings 32-SAMSS-004, Section 16.3.1 SAEP-1160 & SAES-W-010, Para 16.1.2

A3

A4

A5

A6

32-SAMSS-004, Section 16.3.1

A7

SAES-A-005, Para. 4.2 SAES-A-004, Para. 6.3.1 & 32-SAMSS-004, Section 16.3.8

A8

B1 B2 B3

ASME VIII, UG99, Para.(i) SAES-A-004, Para.6.3.1 SAES-A-004, Para.6.3.1 SAES-W-010, Para. 11.15.1 SAES-W-010, Para. 15.2 32-SAMSS-004, Section 16.3.2

B4

B5

B6

Page 1 of 3

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Test Inspection of Pressure Vessels (All Applications, Including In-situ Testing of New Fin Fan Coolers)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2025

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. B7

ACCEPTANCE CRITERIA Prior to final inspection & pressure test, new vessel internal and external surfaces have been thoroughly cleaned. Any slag, scale, dirt, grit, spatter, paint, oil, and construction aids are removed. Vessel Trim (associated piping) receives a strength test except in Utility services and less when a service test can be conducted. Note: Vessel Trim piping pressure tests are often overlooked Sampling piping systems are pressure tested as an integral part of the equipment to which it is connected. All welded attachments with telltale holes shall be pneumatically tested at minimum 35 kPa (5 psi) prior to heat treatment and vessel pressure testing. Telltale holes are OPEN during pressure test. This is a Bubble Leak test per SAIC-A-2005/A-2021/A-2023 Shellacs, glues, lead, etc.are not applied on gaskets during testing. Gaskets and bolting materials are as specified on data sheet. Note: Gaskets may be used as service gaskets if the bolted joint is not disassembled after testing, example: Sumps, etc. Vertical vessels tested in horizontal position are supported such that primary stresses in any part of the vessel do not exceed 90% of minimum specified yield strength of the vessel material. Horizontal vessels shall be tested while resting on their permanent support saddles without additional supports or cribbing. Equipment or parts that are clad shall be hydrotested with water having chloride content not greater than 50 ppm. Fin fan exchangers are strength tested in-situ before final acceptance for all new projects. HOLD POINT. See Attachment 1 Jacketed Vessel exams & hydrotest sequence are planned and detailed in design & during hydrotesting (per test procedure). A) Inner vessel construction & hydrotesting is completed prior to outer jacket installation and hydrotesting. B) Construction sequence allows 100% visual inspection of welds during hydrotest. Jacket design & installation is carefully planned. [Reference: ASME VIII, UG-99 sect. (e)]

REFERENCE 32-SAMSS-004, Section 16.2.9 SAES-L-150, Para. 5.3 SAES-L-150, Para. 5.3 32-SAMSS-004, Section 16.3.3 32-SAMSS-004, Section 16.3.4 32-SAMSS-004, Section 16.3.6 32-SAMSS-004, Section 16.3.11 32-SAMSS-004, Section 16.3.12 32-SAMSS-031, Para. 10.2.1 SAES-A-004, Para. 6.4.5.1

PASS

FAIL

N/A

RE-INSP DATE

B8

B9

B10

B11

B12

B14

B15 B16 B17

B18

SCH Q, Attachment VI PROCEDURE DETAILS

REMARKS: REFERENCE DOCUMENTS: 1. SAES-A-004, General Requirements for Pressure Testing, (30 March, 2005) 2. SAES-A-005, Safety Instruction Sheet, (28 February 2005) 3. SAES-D-008, Repairs, Alterations, and Re-rating of Process Equipment (30 November, 2003) 4. SAES-L-150, Pressure Testing of Plant Piping and Pipelines (30 September, 2003) 5 SAES-W-010, Welding Requirements for Pressure Vessels (14 November 2005) 6. 32-SAMSS-004, Manufacture of Pressure Vessels (30 March, 2005) 7. ASME Section VIII, Division 1 - Rules for Construction of Pressure Vessels (2002 Edition) 8. ASME Section VIII, Division 2 - Rules for Construction of Pressure Vessels, Alternative Rules (2002 Edition)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 2 of 3

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Test Inspection of Pressure Vessels (All Applications, Including In-situ Testing of New Fin Fan Coolers)

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2025

1-Dec-06

MECH-

Attachment 1 - IN-SITU TESTING & CARE OF FIN FAN COOLERS

1. Follow these simple guidelines to assure good test results. 2. Make certain Fin Fans (on arrival) were treated very carefully. 3. Inspect the load on arrival for proper preservation & damage

The internals of exchangers shall be protected from corrosion by use of a non-toxic vapor phase corrosion inhibitor such as CORTEC VCI-309 or 307 or equivalent, applied at a rate of 0.1 kg/m fogged into the space. The inhibitor selected must be appropriate for the metallurgy of the exchanger. Exchangers must be sealed vapor tight for the inhibitor to be effective. Alternatively, nitrogen blanketing or temporary coatings in accordance with MIL-C-16173-D Grade IV (example Tectyl 846) may be used. Corrosion inhibitors for use on exchangers with stainless steel & monel tubes must be chloride free, suitable for its intended use & not result in crevice corrosion. 32-SAMSS-011, Sect. 11 Stainless steel exchangers shall be protected from salt water and salt water spray during shipment. 32-SAMSS-011, Sect. 11

4. Fin Fan Coolers can "twist" if improperly lifted. BEWARE!!!

Properly equipped cranes with "spreader" bars are used for unloading. NEVER ALLOW FORK TRUCK UNLOADING. Follow detailed manufacturer handling and preservation requirements ... OR YOU CAN COUNT ON ADDED COST DUE TO TUBE/TUBESHEET LEAKS!!!

5. First thing, before it leaves the truck it arrives on! Inspection (camera) a) Look at the top row of tubes. They should be VERY, VERY STRAIGHT! b) If they aren't straight, i.e., bowed ... MAJOR PROBLEM! c) Don't even let it be unloaded BEFORE YOU TAKE PICTURES. d) Look at underside of the tubes, specifically the tube supports. e) Severe shipping damage will result in "dislodged" support members. 6. Transit & erection clips & fasteners are checked closely for damage. MAKE YOUR CLAIM RIGHT AWAY! TAKE EXTRA* PRECAUTIONS!

* The first one arrived damaged ... YOU CAN COUNT ON ALL OF THEM COMING THIS WAY "UNLESS YOU ACT QUICKLY". * All the Quality intentions in the world won't fix a badly mishandled Fin Fan Cooler.

*PLAN Proactive supervision at handling points to assure they arrive ok. 7. UNLOAD & STORE ON HARD & EXTREMELY LEVEL SITES ALWAYS. a) Use good blocks (no nails). Make sure extra support is there & level. b) NEVER exceed more a few meters between blocks. 8. Plan staging areas close to Units to minimize handling

OK, YOU DIDN'T DO SO WELL ... ORDER EXTRA PLUGS & PRAY!!! OK, YOU MADE IT THIS FAR OK ... NOW PRESERVATION EFFORT 9. Corrosion Inhibitors can solidify, beware of opening these up. 10. Limit opening for "fit up" & piping work to good dry weather. 11. Keep system closed except when absolutely necessary. 12. Plan Test at test pressure on Manufacturer's Stamp.

If Chemical Cleaning (usually around 90 psi) is req'd, utilize this opportunity to meet the reqmt. (it's usually close enough) Perform testing in accordance with good lay-up practices. Be Prepared to pull plugs and allow Proponent a visual exam. Water removal after testing at low points can be assured by spool dropouts. Test as close to start-up as practical. ALWAYS HAVE EXTRA PLUGS ON HAND (OR OVERNIGHT ACCESS AVAILABLE) IN THE EVENT OF TUBE/TUBESHEET LEAKS.

Page 3 of 3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Saudi Computer Exam For QC WeldingDocument4 pagesSaudi Computer Exam For QC Weldingரமேஷ் பாலக்காடு100% (1)

- Online Reg Certfct PDF PDFDocument2 pagesOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுNo ratings yet

- Air Carbon Arc Gouging: ElectrodeDocument1 pageAir Carbon Arc Gouging: Electrodeரமேஷ் பாலக்காடுNo ratings yet

- Welding Processes ModuleDocument27 pagesWelding Processes Moduleரமேஷ் பாலக்காடு100% (1)

- Codes Standards and SpecificationsDocument15 pagesCodes Standards and Specificationsரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Duties of A Welding Inspector 1Document12 pagesDuties of A Welding Inspector 1ரமேஷ் பாலக்காடுNo ratings yet

- Online Reg Certfct PDF PDFDocument2 pagesOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுNo ratings yet

- SA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02Document62 pagesSA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02ரமேஷ் பாலக்காடுNo ratings yet

- Gouging 01Document2 pagesGouging 01ரமேஷ் பாலக்காடுNo ratings yet

- Responabilities of A Welding InspectorDocument13 pagesResponabilities of A Welding Inspectorரமேஷ் பாலக்காடுNo ratings yet

- Pew205 Slide ShowDocument23 pagesPew205 Slide Showரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-E-2001 Rev 2Document7 pagesSAIC-E-2001 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNo ratings yet

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNo ratings yet

- API 510 Examination Sample ItemsDocument3 pagesAPI 510 Examination Sample ItemsMagira PasaribuNo ratings yet

- SAIC-D-2022 Rev 2Document5 pagesSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- 0 Wis10 Contents ListDocument1 page0 Wis10 Contents ListSangram RoutarayNo ratings yet

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNo ratings yet

- SAIC-F-2007 Rev 2Document1 pageSAIC-F-2007 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Vedic Maths TutorialDocument12 pagesVedic Maths TutorialNitin Jain100% (15)

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- Practical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTDocument362 pagesPractical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTrodrigoperezsimoneNo ratings yet

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-E-2002 Rev 2Document7 pagesSAIC-E-2002 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDocument1 pageSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- FlexEJ Brochure Elaflex 10 2011Document41 pagesFlexEJ Brochure Elaflex 10 2011harlyganNo ratings yet

- Archaea 2016 PDFDocument73 pagesArchaea 2016 PDFDr. Farokh Rokhbakhsh-Zamin50% (2)

- What Is A Fatigue Test?: High Cycle Fatigue (HCF)Document4 pagesWhat Is A Fatigue Test?: High Cycle Fatigue (HCF)Taif AlhashimNo ratings yet

- Filter Elements, Parts for Compressors and EnginesDocument2 pagesFilter Elements, Parts for Compressors and Enginespgm900No ratings yet

- Flax 7Document7 pagesFlax 7Rajyalakshmi MNo ratings yet

- 2593Document9 pages2593Zaid AhmadNo ratings yet

- Kluebersynth GEM 4 N GB enDocument6 pagesKluebersynth GEM 4 N GB enIvan MarijanovićNo ratings yet

- Successful Intraoral RadiographyDocument19 pagesSuccessful Intraoral RadiographyMonica Agustine HartonoNo ratings yet

- CHM1207 Lab 3 2023 - DRAKES, Tameica (1042436) PDFDocument6 pagesCHM1207 Lab 3 2023 - DRAKES, Tameica (1042436) PDFNikoli MajorNo ratings yet

- Lecture 4 - Reinforced Concrete - Bond, Development LengthDocument55 pagesLecture 4 - Reinforced Concrete - Bond, Development LengthChristopher PaladioNo ratings yet

- Introduction To R.T.P.P: 1.1 GeneralDocument12 pagesIntroduction To R.T.P.P: 1.1 GeneralSairam Kumar ChowdaryNo ratings yet

- Slurry Pumps Parastaltic PumpsDocument9 pagesSlurry Pumps Parastaltic Pumpsmtl40No ratings yet

- Application News: Infrared Spectra of Polyvinyl ChlorideDocument2 pagesApplication News: Infrared Spectra of Polyvinyl ChlorideRudiyansah RudiyansahNo ratings yet

- BS en 1393 1997Document18 pagesBS en 1393 1997karthikkumar T RNo ratings yet

- BioreactorsDocument32 pagesBioreactorskhadeeja vjfndnNo ratings yet

- Cosmetics 09 00063 v2Document44 pagesCosmetics 09 00063 v2maizhafiraNo ratings yet

- The Effect of Size Thickness and Type of The Bonding Interlayer On Bullet Proof Glass As Per EN 1063Document4 pagesThe Effect of Size Thickness and Type of The Bonding Interlayer On Bullet Proof Glass As Per EN 1063Anonymous hk1fhAkwyNo ratings yet

- Acid RainDocument35 pagesAcid RainAshish Deotale100% (4)

- Cassida Chain Oil 150-SdsDocument5 pagesCassida Chain Oil 150-SdsInggil Budi PekertiNo ratings yet

- LCGC Europe 2001Document4 pagesLCGC Europe 2001Jhonattan BaezNo ratings yet

- Advantages and disadvantages of mechanical fasteners and adhesive bondingDocument6 pagesAdvantages and disadvantages of mechanical fasteners and adhesive bondingYankie Mike PaPa100% (1)

- Sans 10137 2011Document107 pagesSans 10137 2011Pamps Mangampo50% (2)

- Preslia 68 - MSDSDocument12 pagesPreslia 68 - MSDSFraNo ratings yet

- 1 Formulae Equations and Amount of Substance Iedxcel TDocument25 pages1 Formulae Equations and Amount of Substance Iedxcel TBest ProgressNo ratings yet

- RN FDocument52 pagesRN Fhassan SardarNo ratings yet

- PERCENT BY MASS OF HYDROGEN PEROXIDE (H2O2) IN AGUA OXIGENADA (A Post-Laboratory Report)Document10 pagesPERCENT BY MASS OF HYDROGEN PEROXIDE (H2O2) IN AGUA OXIGENADA (A Post-Laboratory Report)Angel Ombid100% (1)

- Amarex KRT8041eDocument36 pagesAmarex KRT8041eRui Alves da Silva100% (1)

- Selig Sealing ProductsDocument60 pagesSelig Sealing Productslaurentiu29No ratings yet

- Dalma Mall's Industrial Plastic Pipes and FittingsDocument24 pagesDalma Mall's Industrial Plastic Pipes and FittingsashishNo ratings yet

- Comparison of Triode and Diode Ion PumpDocument7 pagesComparison of Triode and Diode Ion PumpAarkayChandruNo ratings yet