Professional Documents

Culture Documents

Izing Election AND Nstallation of Ressure Elieving Evices in Efineries ART AND Election

Uploaded by

Tirta BudiawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Izing Election AND Nstallation of Ressure Elieving Evices in Efineries ART AND Election

Uploaded by

Tirta BudiawanCopyright:

Available Formats

SIZING, SELECTION,

AND

INSTALLATION

OF

PRESSURE -RELIEVING DEVICES

IN

REFINERIES, PART I-SIZING

AND

SELECTION

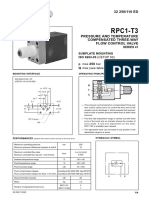

Pressure Vessel Requirements Maximum allowable accumulated pressure (fire exposure only)

Vessel Pressure

Typical Characteristics of Pressure Relief Valves

121 120-

Maximum relieving pressure for fire sizing

Maximum allowable accumulated pressure for multiple-valve installation (other than fire exposure)

116 115-

Multiple valves Maximum relieving pressure for process sizing Single-valve Maximum relieving pressure for process sizing

Maximum allowable accumulated pressure for single-valve installation (other than fire exposure)

-T _ F? B flJ 110 i : FL P 9 E 3 al 105 5 s 7 5 E R A Maximum allowable set pressure for single valve * Maximum allowable set pressure for supplemental valves (fire exposure)

(v Overpressure (maximum)

Maximum allowable set pressure for additional valves (process)

Maximum allowable working pressure or design pressure (see Note4)

if 1 0 0 6 E - 8 G -a

O- Blowdown ( t y p i c a l ) (see Note 6)

95-

Closing pressure for a single valve

Maximum expected operating pressure (see Notes 5 and 6)

90

Leak test pressure (typical)

85Notes: 1. This figure conforms with the requirements of Section VIII of the ASME Boiler and Pressure Vessel Code for MAWPs greater than 30 psi. 2. The pressure conditions shown are for pressure relief valves installed on a pressure vessel. 3. Allowable set-pressure tolerances will be in accordance with the applicable codes. 4. The maximum allowable working pressure is equal to or greater than the design pressure for a coincident design temperature. 5. The operating pressure may be higher or lower than 90. 6. Section VIII, Division 1, Appendix M of the ASME Code should be referred to for guidance on blowdown and pressure differentials.

Figure l-Pressure-Level Relationships for Pressure Relief Valves

You might also like

- Izing Election AND Nstallation of Ressure Elieving Evices in Efineries ART AND ElectionDocument1 pageIzing Election AND Nstallation of Ressure Elieving Evices in Efineries ART AND ElectionTirta BudiawanNo ratings yet

- PRV Oil Safety Valve Henry 5600Document3 pagesPRV Oil Safety Valve Henry 5600pm2013No ratings yet

- Codes & Standards: ASME Section I Boiler and Pressure Vessel Code For Fired VesselsDocument2 pagesCodes & Standards: ASME Section I Boiler and Pressure Vessel Code For Fired VesselsgnkameshNo ratings yet

- Training Program On: Pressure Relief ValveDocument71 pagesTraining Program On: Pressure Relief ValveShoaib JadoonNo ratings yet

- A Guideline For Design Pressure - Part 1Document4 pagesA Guideline For Design Pressure - Part 1Said Ahmed SalemNo ratings yet

- Project Standards and Specifications Offshore Process Design Rev01Document10 pagesProject Standards and Specifications Offshore Process Design Rev01sri9987No ratings yet

- A Guideline For Design Pressure - Part 2Document4 pagesA Guideline For Design Pressure - Part 2Said Ahmed SalemNo ratings yet

- Process Design: Norsok StandardDocument27 pagesProcess Design: Norsok StandardJason ThomasNo ratings yet

- Pages From Selection and Sizing of Pressure Relief ValvesDocument1 pagePages From Selection and Sizing of Pressure Relief Valveszohaib_farooqNo ratings yet

- Take Home From Our Facility PSV SizingDocument18 pagesTake Home From Our Facility PSV SizingConnor SailorNo ratings yet

- 1.1 PmtaDocument2 pages1.1 Pmtagabao123No ratings yet

- Relief Valves: Gases and Gas EquipmentDocument22 pagesRelief Valves: Gases and Gas EquipmentInspection EngineerNo ratings yet

- Design Conditions CriteriaDocument4 pagesDesign Conditions CriteriaJaldhi PatelNo ratings yet

- Section 30 - Relief ValvesDocument17 pagesSection 30 - Relief ValveshammamiNo ratings yet

- Guidelines On The Maintenance of Pressure Relief Valves On Board Gas CarriersDocument17 pagesGuidelines On The Maintenance of Pressure Relief Valves On Board Gas Carriers123habib123fikriNo ratings yet

- PSVDocument32 pagesPSVAhtsham Ahmad100% (2)

- Sur - Flo Turbine MeterDocument40 pagesSur - Flo Turbine MeterCheng HuangNo ratings yet

- PSV Design - Follow These Guidelines - Satsha PDFDocument2 pagesPSV Design - Follow These Guidelines - Satsha PDFPankaj TiwariNo ratings yet

- PSV Design - Follow These Guidelines - SatshaDocument2 pagesPSV Design - Follow These Guidelines - SatshaPankaj TiwariNo ratings yet

- Hot Crude Oil StorageDocument13 pagesHot Crude Oil Storagesachinumarye100% (1)

- Hose End Control Valves: Carter Ground Fueling DivisionDocument6 pagesHose End Control Valves: Carter Ground Fueling DivisionmecambNo ratings yet

- Norsok Process DesignDocument27 pagesNorsok Process DesignAlpadaniNo ratings yet

- Engineering Design Guideline Separator Vessel Rev01Document45 pagesEngineering Design Guideline Separator Vessel Rev01gad480No ratings yet

- HansenDocument4 pagesHansenBruna MacedoNo ratings yet

- Valvulas de Seguridad Hansen PDFDocument4 pagesValvulas de Seguridad Hansen PDFLuis ReinoNo ratings yet

- Lesson 03 UG98 - New2 MAWPDocument6 pagesLesson 03 UG98 - New2 MAWPVinoth Kumar SubramaniNo ratings yet

- Pressure Test ProcedureDocument11 pagesPressure Test ProcedureRolando Nicanor0% (1)

- Flow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3Document4 pagesFlow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3LibinNo ratings yet

- Understanding Double Seated Shut Off Valves: Tech Tip 12Document4 pagesUnderstanding Double Seated Shut Off Valves: Tech Tip 12AlphaNo ratings yet

- A Guideline For Design Pressure - Part 1 PDFDocument4 pagesA Guideline For Design Pressure - Part 1 PDFkrishna_nimeshNo ratings yet

- Proportional Electro-Hydraulic ControlsDocument31 pagesProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- Data Supplement For Safety and Relief ProductsDocument16 pagesData Supplement For Safety and Relief ProductsIldefonso FloresNo ratings yet

- 1083ch7 0015 PDFDocument18 pages1083ch7 0015 PDFMuhammad NaeemNo ratings yet

- NORSOK Standard For Process DesignDocument27 pagesNORSOK Standard For Process DesignM. Faisal SiddiquiNo ratings yet

- Process Design: Norsok StandardDocument27 pagesProcess Design: Norsok StandardSiddharth AthalyeNo ratings yet

- P11099-Fat ProcedureDocument5 pagesP11099-Fat ProcedureRicardoNo ratings yet

- Pressure Casing DesignDocument1 pagePressure Casing DesignJULIO CESARNo ratings yet

- Relief Valve - TypesDocument2 pagesRelief Valve - Typesyushveer002No ratings yet

- Microsoft Word - SV - Part10Document6 pagesMicrosoft Word - SV - Part10aftabulalamNo ratings yet

- Manual Valvula PCVDocument16 pagesManual Valvula PCVzamirgothNo ratings yet

- Valve Sizing - CorsbyDocument10 pagesValve Sizing - Corsbynarayanan_anoobNo ratings yet

- Actuator Sizing PrinciplesDocument2 pagesActuator Sizing PrinciplesAntonio LebrunNo ratings yet

- SB 8540.3 - 1800 and 2000 Industrial RegDocument12 pagesSB 8540.3 - 1800 and 2000 Industrial RegImam BuchairiNo ratings yet

- Seat Leakage Article Valve WorldDocument2 pagesSeat Leakage Article Valve WorldjshadwanNo ratings yet

- Max Piping Oper PressDocument8 pagesMax Piping Oper PressSandi ApriandiNo ratings yet

- PVR-108-2 Fueling Model SheetDocument2 pagesPVR-108-2 Fueling Model SheetLetycia RosalesNo ratings yet

- ASME Code Section VIII Pressure TestsDocument3 pagesASME Code Section VIII Pressure TestsAngga100% (1)

- Definitions of Pressure Vessel and PSV Design and Fabrication ValuesDocument4 pagesDefinitions of Pressure Vessel and PSV Design and Fabrication ValuesDark KnightNo ratings yet

- API Standard Title DescriptionDocument3 pagesAPI Standard Title DescriptionArpit ShahNo ratings yet

- Selection and SizingDocument2 pagesSelection and Sizing2009tamerNo ratings yet

- PSV CalculationDocument9 pagesPSV CalculationElizabeth Dean100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Reciprocating Compressors:: Operation and MaintenanceFrom EverandReciprocating Compressors:: Operation and MaintenanceRating: 4 out of 5 stars4/5 (7)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- MCWP Master Jan 21Document1 pageMCWP Master Jan 21Tirta BudiawanNo ratings yet

- Westlake ZX7045Document1 pageWestlake ZX7045Tirta BudiawanNo ratings yet

- Knuth Universal HeavyDocument9 pagesKnuth Universal HeavyTirta BudiawanNo ratings yet

- MCWP Master Jan 21Document1 pageMCWP Master Jan 21Tirta BudiawanNo ratings yet

- Lion Air Eticket Itinerary / Receipt: Rusli/Henry MRDocument4 pagesLion Air Eticket Itinerary / Receipt: Rusli/Henry MRgavinasutionNo ratings yet

- Harga BanDocument11 pagesHarga BanTirta BudiawanNo ratings yet

- 138Document4 pages138Tirta BudiawanNo ratings yet

- Lagu 2 GNR Yg BaikDocument1 pageLagu 2 GNR Yg BaikTirta BudiawanNo ratings yet

- A Presiden6Document1 pageA Presiden6Tirta BudiawanNo ratings yet

- Makmur Sentosa JayaDocument1 pageMakmur Sentosa JayaTirta BudiawanNo ratings yet

- A LG Iwan Fals A5Document1 pageA LG Iwan Fals A5Tirta BudiawanNo ratings yet

- A Lagu 2 Slank 4Document1 pageA Lagu 2 Slank 4Tirta BudiawanNo ratings yet

- A Presiden4Document1 pageA Presiden4Tirta BudiawanNo ratings yet

- Lagu 2 GNR YgcadasDocument1 pageLagu 2 GNR YgcadasTirta BudiawanNo ratings yet

- Lagu 2 GNR Yg MantafDocument1 pageLagu 2 GNR Yg MantafTirta BudiawanNo ratings yet

- Aneka Training Safety (Dep Kelautan FMIPA-UI)Document5 pagesAneka Training Safety (Dep Kelautan FMIPA-UI)Idil FitriNo ratings yet

- Hosts UmbrellaDocument1 pageHosts UmbrellaFabsor SoralNo ratings yet

- Casting MaterialsDocument42 pagesCasting MaterialsTirta BudiawanNo ratings yet

- Sweet Child O Mine 2. Don'T Cry 3. Welcome To The JunggleDocument1 pageSweet Child O Mine 2. Don'T Cry 3. Welcome To The JunggleTirta BudiawanNo ratings yet

- Casting MaterialsDocument42 pagesCasting MaterialsTirta BudiawanNo ratings yet

- Aisi 4140 From Cast MetalDocument4 pagesAisi 4140 From Cast MetalTirta BudiawanNo ratings yet

- ReadmeDocument1 pageReadmetom_heffernanNo ratings yet

- Perincian Biaya Operasional Kendaraan Merk / TipeDocument1 pagePerincian Biaya Operasional Kendaraan Merk / TipeTirta BudiawanNo ratings yet

- Report Cilacap 1 November 2013Document1 pageReport Cilacap 1 November 2013Tirta BudiawanNo ratings yet

- Flowerve PumpDocument76 pagesFlowerve PumpTirta BudiawanNo ratings yet

- Eticket TDHXYYDocument2 pagesEticket TDHXYYTirta BudiawanNo ratings yet

- Ei Practicing Final Pack IndoDocument24 pagesEi Practicing Final Pack IndoTirta BudiawanNo ratings yet

- Ei Practicing Final Pack EnglishDocument23 pagesEi Practicing Final Pack EnglishTirta BudiawanNo ratings yet

- 316 Stainless Steel Round Rod 2Document56 pages316 Stainless Steel Round Rod 2Tirta BudiawanNo ratings yet

- Energy Isolation GRACE - ElectricalDocument8 pagesEnergy Isolation GRACE - ElectricalTirta BudiawanNo ratings yet