Professional Documents

Culture Documents

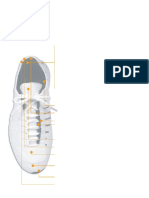

Shoe Bottom

Uploaded by

Devin HarrisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shoe Bottom

Uploaded by

Devin HarrisCopyright:

Available Formats

OUTSOLE This is where the rubber hits the road.

Generally, the outsole is made of a generic rubber compound and must be both flexible and durable. Different colors may signify different textures or densities of rubber. For example, rubber may be thicker in the heel than in the forefoot. FLEXGROOVES: Areas in the forefoot of the outsole that allow the forefoot to flex easily when walking and running. HERRINGBONE TREAD (zig-zag pattern): A fishbone-like tread pattern in the rubber of the outsole. Designed for self-cleaning, herringbone patterns release clay from the grooves when the shoe is flexed. HARDCOURT TREAD: More about durability than tread patterns, hardcourt treads can have a combination of herringbone and added thicknesses in the ball-of-foot and medial heel areas. SHANK: Located under the midfoot or arch area of the foot for support, the shank is often made of Thermal Plastic Urethane. Some shoes use a shank plate or TPU, attempting to reduce weight and retain torsional rigidity while other shoes just fill the shank area with EVA. MIDSOLE Providing knees with more comfort the midsole is a shoe's predominant cushion support. The softer section sandwiched between the outsole and upper, the midsole can consist of several densities and materials such as: EVA (Ethyl Vinyl Acetate): The most common form of midsole cushioning, an EVA midsole helps reduce a shoe's weight. The trade-off is that the material tends to break down faster than Polyurethane, but not significantly. EVA usually falls within two categories: Sheet EVA is typically used on lower end, less expensive shoes that are cup sole construction ($50 and less); molded EVA enhances a shoe's appearance because it is compressed into a more stable, permanent shape and typically used in shoes priced $55 and higher. PU (Polyurethane): This material is stronger, more durable and lasts longer than EVA, but adds weight. It is also prone to yellowing and hardening and breaks down with water.

You might also like

- ShoetopDocument1 pageShoetopRizkTimbNo ratings yet

- Components of ShoeDocument28 pagesComponents of ShoeucssNo ratings yet

- Happy Trails!: Categories of Hiking FootwearDocument7 pagesHappy Trails!: Categories of Hiking FootwearAtul RajanNo ratings yet

- SOLESDocument2 pagesSOLESMuhammad Huzaifa NajeebNo ratings yet

- Khulna University of Engineering & TechnologyDocument49 pagesKhulna University of Engineering & Technology17044 AZMAIN IKTIDER AKASHNo ratings yet

- Done By: Hyder Ali .S M.Tech (FE&M)Document12 pagesDone By: Hyder Ali .S M.Tech (FE&M)ahyder40No ratings yet

- SHOE ComponentsDocument15 pagesSHOE ComponentsVishnu TejaNo ratings yet

- A Seminar PresentationDocument10 pagesA Seminar PresentationRonik JNo ratings yet

- Launchof New Product (Shoes)Document50 pagesLaunchof New Product (Shoes)majiclover75% (16)

- Business PlanpdfDocument25 pagesBusiness PlanpdfRAISA SHANAVAS N PNo ratings yet

- Product Design: BT19MME002Document10 pagesProduct Design: BT19MME002Akarshit NandeshwarNo ratings yet

- 1.unit 1.fashion Accessories 1.0Document25 pages1.unit 1.fashion Accessories 1.0Aadhavan ParthipanNo ratings yet

- Best Insoles For Hiking BootsDocument10 pagesBest Insoles For Hiking BootsahsanNo ratings yet

- Construction MethodDocument104 pagesConstruction MethodKaustubh Gupta80% (5)

- New Microsoft Office Word DocumentDocument17 pagesNew Microsoft Office Word DocumentTanya GautamNo ratings yet

- Introduction To Shoe LastDocument99 pagesIntroduction To Shoe LastGurprashadSharma100% (1)

- Shoe Construction and ModificationDocument21 pagesShoe Construction and ModificationjohnjkjkNo ratings yet

- Unit 2Document17 pagesUnit 2Garvit GargNo ratings yet

- Mussie AssignmentDocument8 pagesMussie Assignmentgeachew mihiretuNo ratings yet

- Shoe Making CompressDocument29 pagesShoe Making CompressSalih MohammedNo ratings yet

- Nama: Khoirun Nisa Sahid NIM: 3335120351 Mata Kuliah: Bahasa Inggris The Function of ShoesDocument2 pagesNama: Khoirun Nisa Sahid NIM: 3335120351 Mata Kuliah: Bahasa Inggris The Function of ShoesKhoirunnisaSahidNo ratings yet

- A-Z Terms Related To Footware ProductionDocument80 pagesA-Z Terms Related To Footware ProductionSharoon S RaoNo ratings yet

- Shoe MakingDocument29 pagesShoe Makingrohitmba100% (4)

- TechnicalDocument17 pagesTechnicalfekadeNo ratings yet

- SRC Training Phases For New Employees Updated May 2023Document10 pagesSRC Training Phases For New Employees Updated May 2023api-666792021No ratings yet

- Unit 2 Introduction To Lasting: StructureDocument18 pagesUnit 2 Introduction To Lasting: StructurePrabu Sankar100% (1)

- Materials For Shoe SolesDocument6 pagesMaterials For Shoe SolesLawrence Theunissen100% (1)

- Pictionary-Footwear: by Sakshi Wadgaye Faculty - VF Priyanka Kochar BDESF2020037Document33 pagesPictionary-Footwear: by Sakshi Wadgaye Faculty - VF Priyanka Kochar BDESF2020037sakshi wadgayeNo ratings yet

- GUMBOOTDocument5 pagesGUMBOOTNariya MutaharaNo ratings yet

- Shoe and Foot OrthosisDocument9 pagesShoe and Foot Orthosis楊畯凱No ratings yet

- Victor Badminton Shoes 2016Document19 pagesVictor Badminton Shoes 2016Stephane HoNo ratings yet

- Glossary of Shoe TermsDocument35 pagesGlossary of Shoe TermsVishnu TejaNo ratings yet

- Amazon DiscriptionDocument4 pagesAmazon DiscriptionyameenayargondalNo ratings yet

- Shoemarketingproject KPDocument6 pagesShoemarketingproject KPapi-546981834No ratings yet

- What Goes Into Safety FootwearDocument4 pagesWhat Goes Into Safety FootwearBeshoy RedaNo ratings yet

- Types of Sports FootwearDocument22 pagesTypes of Sports FootwearRuthik Prince100% (1)

- Basic of ShoesDocument5 pagesBasic of ShoesVishnu TejaNo ratings yet

- The LastDocument15 pagesThe LastPrashant Dargan100% (2)

- Footwear & Its ClassificationDocument6 pagesFootwear & Its ClassificationEtu piaNo ratings yet

- Formal Shoes (Men's) : OxfordsDocument15 pagesFormal Shoes (Men's) : OxfordsA VatsyaNo ratings yet

- Styles of Shoes 09Document6 pagesStyles of Shoes 09ashu tkNo ratings yet

- Danner F09 CatalogDocument27 pagesDanner F09 Catalogmonkist100% (1)

- Top 9 Best Badminton Shoes For Wide Feet 2022Document7 pagesTop 9 Best Badminton Shoes For Wide Feet 2022danishfiverr182No ratings yet

- Product ListDocument7 pagesProduct ListXplore OutdoorGearsNo ratings yet

- Footwear GlossaryoftermsDocument22 pagesFootwear GlossaryoftermschienNo ratings yet

- WINTER CLOTHING CHECKLISTv2Document2 pagesWINTER CLOTHING CHECKLISTv2zineil BlackwoodNo ratings yet

- 10 Best Casual Shoes For MenDocument2 pages10 Best Casual Shoes For MenZainab KhettyNo ratings yet

- Footwear MaterialsDocument6 pagesFootwear MaterialsShima EsmaeiliNo ratings yet

- Stan Lee Didn't Die He Just Went HomeDocument7 pagesStan Lee Didn't Die He Just Went HomeQuantum CrabcakeNo ratings yet

- Your Feet, Work Shoes, ErgonomicsDocument22 pagesYour Feet, Work Shoes, ErgonomicsTrandafir LacramioaraNo ratings yet

- Bahria FOOT ORTHOSISDocument59 pagesBahria FOOT ORTHOSISRomana VayaniNo ratings yet

- Making ShoesDocument12 pagesMaking Shoesranzhao chenNo ratings yet

- Saddle Design, Features and Materials: ShellDocument6 pagesSaddle Design, Features and Materials: ShellAnonymous dJ7nOqZvNo ratings yet

- 2016 Katalog Kurac PalacDocument158 pages2016 Katalog Kurac Palacanon_486275253No ratings yet

- Beige and Brown Beauty Fashion Style Proposal PresentationDocument12 pagesBeige and Brown Beauty Fashion Style Proposal PresentationKashish MishraNo ratings yet

- Studies On The Production of EspadrillesDocument30 pagesStudies On The Production of Espadrillesahmed sakinNo ratings yet

- How To Run a 5K Race: Your Step-By-Step Guide To Running a 5K FasterFrom EverandHow To Run a 5K Race: Your Step-By-Step Guide To Running a 5K FasterRating: 5 out of 5 stars5/5 (1)

- Special Shoeing: Polo Horses, Hunters, Jumpers and Draft Animals - A Historical Article on the Art of the FarrierFrom EverandSpecial Shoeing: Polo Horses, Hunters, Jumpers and Draft Animals - A Historical Article on the Art of the FarrierNo ratings yet