63% found this document useful (16 votes)

6K views45 pagesEnergy Balance in Chemical Processing

The document provides information about various components of an energy system including:

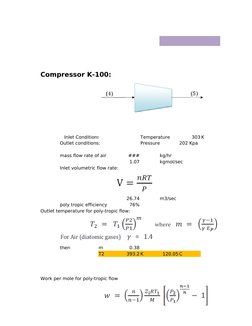

1) A compressor that compresses air from 303K to 393.2K, requiring 97.45KW of power.

2) An air preheater that heats inlet air from 120.05C to 380C, taking ### KJ/hr from the heat.

3) A benzene preheater that heats benzene from 30C to 110C, taking ### KJ/hr of heat.

Uploaded by

usman0553Copyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

63% found this document useful (16 votes)

6K views45 pagesEnergy Balance in Chemical Processing

The document provides information about various components of an energy system including:

1) A compressor that compresses air from 303K to 393.2K, requiring 97.45KW of power.

2) An air preheater that heats inlet air from 120.05C to 380C, taking ### KJ/hr from the heat.

3) A benzene preheater that heats benzene from 30C to 110C, taking ### KJ/hr of heat.

Uploaded by

usman0553Copyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd