M00 Programmed stop M01 Optional stop

(Siemens) (Siemens) (Siemens)

M02 End of program main program

M03 Workpiece spindle on right-handed rot. (Siemens) M04 Workpiece spindle on left-handed rot. (Siemens) M05 Workpiece spindle stop M07 Coolant grinding on M08 Coolant dressing on M09 Coolant off M10 Release balancing M11 Coolant grinding low pressure on M21 SPC take out from NC M22 LMH_11 probe lifting M24 Extend coolant nozzle M25 Retract coolant nozzle M28 Extend longitudinal meas. head_11 M29 Retract longitudinal meas. head_11 M34 Close workpiece clamping M35 Open work piece clamping M36 Close tail stock M37 OPen tail stock M38 NC-RESET M39 Program interrupt M52 Start first-cut recognition (frame selection through H-word H1-H32) M58 Wait for messure value of rough tool M60 Release loader change of parts M61 Loader start load 1 unfinished part M62 Clamped part is scrap (Siemens)

�M63 Testpat M64 Dressing spindle ganging (speed through H-word)(speed reached trough DPR ) M65 Dressing spindle antirotation (speed through H-word)(speed reached through DPR) ) M66 Dressing spindle off M68 quick start tool change M69 Stop until loading process finished (read in interlock) M80 JOG-ASUP (bevelled axis) M81 Grinding finished, part finished M84 Increment workpiece counter M85 Dressing start EGS M86 Dressing end EGS M88 Automatic door opening M89 Operator's call (yellow signal lamp) M90 Hydraulic unit on (units) M91 Hydraulic unit off (units) M92 External grinding wheel on M93 External grinding wheel off (spindle reset ELS - until standstill)(centrifugal time through H-word) M94 Coolant unit on M95 Coolant unit off M532 DMH 11 in front dynamic (no RII) M533 DMH 11 back dynamic (no RII) M600 Coolant grinding seat on high pressure M610 Coolant grinding seat on low pressure M680 Coolant ASS11 high pressure cleaning on (Time with H word option) M681 Coolant ASS11 high pressure cleaning off M701 Pieceinformation from shuttle rough gripper to loader raw part gripper M702 Pieceinformation from loader raw part gripper to workpiece spindle M703 Pieceinformation from workpiece spindle to loader finished part gripper

�M704 Pieceinformation from loader finish part gripper to shuttle finish gripper M708 Pieceinformation clear loader finish gripper M709 Pieceinformation clear loader raw gripper M710 Errormessage from loader program M714 Checking raw part is in gripper M715 Checking part is in gripper M721 Active working limit area top M722 Active working limit area chuck workpiece spindle M724 Active working limit area calibration piece M725 Active working limit area loading M726 Active working limit area unloading M732 raw gripper loader close M832 raw gripper loader open M734 finish gripper loader close M834 finish gripper loader open M740 blow out workpiece spindle off M840 blow out workpiece spindle on M741 clean air internal loader of M841 clean air internal loader on M752 measure heat LMk11 move out M852 measure heat LMk11 move in M760 shuttle rotation unit raw part gripper to 0 degree M860 shuttle rotation unit raw part gripper to 90 degree M761 shuttle rotation unit finished part gripper to 0 degree M861 shuttle rotation unit finished part gripper to 90 degree M762 shuttle position unit raw part gripper close M862 shuttle position unit raw part gripper open

�M763 shuttle position unit finished part gripper close M863 shuttle position unit finished part gripper open M766 finish piece shuttle gripper close M866 finish piece shuttle gripper open M767 raw piece shuttle gripper close M867 raw piece shuttle gripper open M768 linear unit shuttle into machine M868 linear unit shuttle into extenal loader M772 shuttle movement blocking M872 shuttle movement releas *** NCK INPUTS :******************************************* $A_IN(1)= $A_IN(2)= $A_IN(3)= $A_IN(4)= (ONBOARD) (ONBOARD) (ONBOARD) (ONBOARD)

$A_IN(5)= Endurance run cycle $A_IN(6)= Finish cycle $A_IN(7)= $A_IN(8)= PLOS (Test run_without_wheel) $A_IN(9)= Acoustic noise control-signal limit 1 Unit 1 $A_IN(10)= Acoustic noise control-signal limit 2 Unit 1 $A_IN(11)= Acoustic noise control-signal limit 3 Unit 1 $A_IN(12)= Acoustic noise control-signal limit 4 Unit 1 $A_IN(13)= Acoustic noise control-signal limit 1 Unit 2 $A_IN(10)= Acoustic noise control-signal limit 2 Unit 2 $A_IN(14)= Acoustic noise control-signal limit 3 Unit 2 $A_IN(15)= Acoustic noise control-signal limit 4 Unit 2 $A_IN(17)= (hardware card)

�$A_IN(18)= (hardware card) $A_IN(19)= (hardware card) $A_IN(20)= (hardware card) $A_IN(21)= (hardware card) $A_IN(22)= (hardware card) $A_IN(23)= (hardware card) $A_IN(24)= UCEIN ok $A_IN(27)= Call pause cycle $A_IN[35]= $A_IN[36]= $A_IN[37]= $A_IN[38]= $A_IN[39]= Tow interconnection Unit 1 on/off $A_IN[40]= (hardware card)

*** Analog NCK INPUTS :************************************** $A_INA[1]= $A_INA[2]= $A_INA[3]= $A_INA[4]= $A_INA[5]= $A_INA[6]= $A_INA[7]= $A_INA[8]=

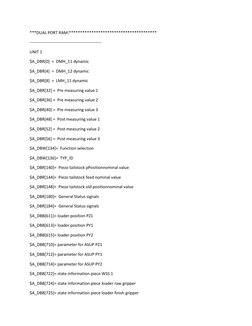

�***DUAL PORT RAM:*************************************** ---------------------------------------------------UNIT 1 $A_DBR[0] = DMH_11 dynamic $A_DBR[4] = DMH_12 dynamic $A_DBR[8] = LMH_11 dynamic $A_DBR[32] = Pre measuring value 1 $A_DBR[36] = Pre measuring value 2 $A_DBR[40] = Pre measuring value 3 $A_DBR[48] = Post measuring value 1 $A_DBR[52] = Post measuring value 2 $A_DBR[56] = Post measuring value 3 $A_DBW[134]= Function selection $A_DBW[136]= TYP_ID $A_DBR[140]= Piezo tailstock pPositionnominal value $A_DBR[144]= Piezo tailstock feed nominal value $A_DBR[148]= Piezo tailstock old positionnominal value $A_DBR[180]= General Status signals $A_DBR[184]= General Status signals $A_DBB[611]= loader position PZ1 $A_DBB[613]= loader position PY1 $A_DBB[615]= loader position PY2 $A_DBB[710]= parameter for ASUP PZ1 $A_DBB[712]= parameter for ASUP PY1 $A_DBB[714]= parameter for ASUP PY2 $A_DBB[722]= state information piece WSS 1 $A_DBB[724]= state information piece loader raw gripper $A_DBB[725]= state information piece loader finish gripper

�$A_DBB[732]= state information loader raw gripper $A_DBB[734]= state information loader finish gripper $A_DBB[740]= state information WSS1 blow out piece $A_DBB[741]= state information loader piece clean air $A_DBB[742]= state information WSS1 $A_DBB[752]= state information LMK1 $A_DBB[760]= state rotation unit raw gripper $A_DBB[761]= state rotation unit finished gripper $A_DBB[762]= state position unit raw gripper $A_DBB[763]= state position unit raw gripper $A_DBB[764]= state information master piece gripper $A_DBB[766]= state information raw piece shuttle gripper $A_DBB[768]= state information finish piece shuttle gripper $A_DBB[770]= state information coolant WSS1

-------------------------------------------------------UNIT 2 $A_DBR[200] = DMH_21 dynamic $A_DBR[208] = LMH_21 dynamic $A_DBR[232] = Pre measuring value 1 $A_DBR[236] = Pre measuring value 2 $A_DBR[248] = Post measuring value 1 $A_DBR[252] = Post measuring value 2 $A_DBW[334] = Function selection $A_DBW[336] = TYP_ID $A_DBR[340] = Piezo tailstock pPositionnominal value $A_DBR[344] = Piezo tailstock feed nominal value

�$A_DBR[348] = Piezo tailstock old positionnominal value $A_DBR[380] = General Status signals $A_DBR[384] = General Status signals

----------------------------- CAMS -----------------------------------------------------

SW_CAM_xxx_TAB_[0] = Cam from Axis X1 for Work piece exchange SW_CAM_xxx_TAB_[1] = Cam from Axis Z1 SW_CAM_xxx_TAB_[2] = Nocken of workpiece spindle SW_CAM_xxx_TAB_[3] = SW_CAM_xxx_TAB_[4] = SW_CAM_xxx_TAB_[5] = SW_CAM_xxx_TAB_[6] = Cam from workpiece spindle in position SW_CAM_xxx_TAB_[7] = PZ1-axis out of collision area x-axis SW_CAM_xxx_TAB_[8] = PZ1-axis in area of chuck workpiece spindle SW_CAM_xxx_TAB_[9] = SW_CAM_xxx_TAB_[10] = SW_CAM_xxx_TAB_[11] = SW_CAM_xxx_TAB_[12] = PZ1-axis in area of calibration piece SW_CAM_xxx_TAB_[13] = PZ1-axis in area of round table SW_CAM_xxx_TAB_[14] = SW_CAM_xxx_TAB_[15] = SW_CAM_xxx_TAB_[16] = loader area PY 1 on top SW_CAM_xxx_TAB_[17] = SW_CAM_xxx_TAB_[18] = loader area PY 2 on top SW_CAM_xxx_TAB_[19] =

![$A_DBB[732]= state information loader raw gripper

$A_DBB[734]= state information loader finish gripper

$A_DBB[](https://screenshots.scribd.com/Scribd/252_100_85/326/177495548/7.jpeg)

![$A_DBR[348] = Piezo tailstock old positionnominal value

$A_DBR[380] = General Status signals

$A_DBR[384] = General Status](https://screenshots.scribd.com/Scribd/252_100_85/326/177495548/8.jpeg)