Professional Documents

Culture Documents

100-RG-ENG-00000-900006-EOR - Spring 2010

Uploaded by

thamestunnelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

100-RG-ENG-00000-900006-EOR - Spring 2010

Uploaded by

thamestunnelCopyright:

Available Formats

Spring 2010

Engineering Options Report

Please note: Further details are provided in the Final Report on Site Selection Process (doc ref: 7.05) that can be found on the Thames Tideway Tunnel section of the Planning Inspectorates web site.

100-RG-ENG-00000-900006 | Spring 2010

Engineering Options Report

THAMES TUNNEL

ENGINEERING OPTIONS REPORT

LIST OF CONTENTS

Page Number 1 2 EXECUTIVE SUMMARY INTRODUCTION 2.1 2.2 2.3 3 3.1 3.2 3.3 3.4 3.5 3.6 4 4.1 4.2 4.3 4.4 5 Purpose of report Background to project Engineering design development 1 2 2 3 3 4 4 4 4 11 14 23 27 27 27 43 49 55

SYSTEM DESIGN AND ENGINEERING REQUIREMENTS System design and engineering assumptions Health and safety considerations System requirements Engineering geology Tunnel engineering and construction requirements CSO engineering and construction requirements

ENGINEERING DEVELOPMENT AND COMPARISON OF OPTIONS Introduction Main tunnel engineering options preparation Main tunnel engineering options assessment CSO engineering options

CONCLUSIONS AND RECOMMENDATIONS

APPENDICES The following appendices can be found in the accompanying document Engineering Options Report Appendices (100-RG-ENG-00000-000009): APPENDIX A ASSUMPTIONS REGISTER APPENDIX B DRAWINGS APPENDIX C TIME CHAINAGE APPENDIX D GEOLOGY

LIST OF FIGURES Page Number Figure 3.1 General layout of the three Thames Tunnel routes being considered ............................ 8 Figure 3.2 Thames Tunnel CSO connection main system elements............................................. 9 Figure 4.1 Main tunnel shaft zones ................................................................................................. 29 Figure 4.2 Key for matrix of possible drives .................................................................................... 33 Figure 4.3 Main tunnel shaft site types ........................................................................................... 37 Figure 4.4 Drive option example ..................................................................................................... 38 Figure 4.5 Type A CSO connection ................................................................................................ 49 Figure 4.6 Type B CSO connection ................................................................................................ 50 Figure 4.7 Type C CSO connection ................................................................................................ 51 Figure 4.8 Type D CSO connection ................................................................................................ 52 Figure 4.9 Type E CSO connection ................................................................................................ 53

LIST OF TABLES Page Number Table 3.1 Details of combined sewer outfall ..................................................................................... 5 Table 3.2 Geology of London Basin ................................................................................................ 12 Table 3.3 Chalk aquifer groundwater levels 2008 and imposed pressure at tunnel invert (east of Shad) ................................................................................................................................................ 14 Table 4.1 Grouping of main tunnel drive sites ................................................................................ 29 Table 4.2 Western End drive options consideration of practical drive lengths ............................ 33 Table 4.3 Eastern end River Thames route drive options consideration of practical lengths...... 34 Table 4.4 Eastern end Rotherhithe route drive options .................................................................. 35 Table 4.5 Eastern end Abbey Mills (via S8) drive options .............................................................. 36 Table 4.6 Eastern end Abbey Mills route (via S7) drive options ..................................................... 36 Table 4.7 Initial provisional main tunnel drive options matrix.......................................................... 39 Table 4.8 Finalised main tunnel drive options matrix ...................................................................... 41 Table 4.9 Thames Tunnel summary of drive options ...................................................................... 42 Table 4.10 Programme assumptions for comparison of options .................................................... 43 Table 4.11 Summary of construction duration differences for main tunnel drive options ............... 47 Table 4.12 Summary of cost differences for main tunnel drive options .......................................... 48

LIST OF ABBREVIATIONS AOD ATD CSO Defra EA EU EPB GWT LL1 m/s m /s NESR OD Ofwat

3

above Ordnance Datum above tunnel datum combined sewer overflow Department of Environment Food and Rural Affairs Environment Agency European Union earth pressure balance ground water table Low Level Sewer No 1 metres per second cubic metres per second North East Storm Relief Ordnance Datum (mean sea level at Newlyn in Cornwall) Water Services Regulatory Authority

PLA PS SMP SR STW TBM

Port of London Authority pumping station System Master Plan storm relief sewage treatment works tunnel boring machine

GLOSSARY Term Tunnel boring machine (TBM) Drive or Drive Option Slurry Description A machine used to excavate tunnels with a circular cross section through a variety of ground conditions. A possible tunnelling option for driving a tunnel from one location to another with a TBM. A mixture of bentonite and water to form a dense liquid capable of supporting open excavations such as bored piles and diaphragm walls. Also used in TBMs to support the face and transport the excavated material through a pumped system. One of three overall main tunnel routes considered. The River Thames route terminates at Beckton STW and predominantly follows the River Thames, except for crossing the Greenwich Peninsula. This route is closest to the Option 1c tunnel route presented in the December 2006 Tackling Londons Sewer Overflows reports. This route has also previously been referred to as the baseline option and Option 1c-1. Drive option identifiers associated with this route are generally prefixed with a B. This main tunnel route is the same as the River Thames route, except that it cuts across the Rotherhithe Peninsula. This route has also previously been referred to as Alternative 1 and Option 1c-2. Drive option identifiers associated with this route are generally prefixed with A1. This main tunnel route terminates at Abbey Mills, using the Lee Tunnel to convey flows to Beckton STW. This route has also previously been referred to as Alternative 2 and Option 1d. Drive option identifiers associated with this route are generally prefixed with A2.

River Thames route

Rotherhithe route

Abbey Mills route

1 Executive Summary

1 1.1.1

EXECUTIVE SUMMARY This report has been prepared for Thames Water as part of the process to support the creation of the preferred list of shaft sites and preferred scheme. It is specific to the Thames Tunnel Project, but takes cognisance of the Lee Tunnel Project. The need for this report and the process that it is part of is outlined in the Site Selection Methodology Paper, document reference 100-RG-PNC-00000-000025. It is intended that this report is read as a technical document and, as such, the content has been kept brief with the understanding that the reader has technical familiarity with the subject matter. The report begins by defining the overall engineering requirements that are to be considered as part of the development of engineering options. These are largely summarised without providing any in-depth justification; the main aim of the report being the identification of main tunnel drive options. Three main tunnel routes between west London and Beckton Sewage Treatment Works (STW) are identified as part of the design development and it is these that are taken forward separately for evaluation. The second part of the report presents a methodology for determining possible options to deliver a scheme for the three main tunnel routes. This is based on engineering requirements and the list of shortlisted shaft sites provided by the site selection process, which identifies sites potentially suitable for use as either main tunnel drive or intermediate/reception shaft sites to facilitate the construction of the main tunnel and its subsequent operation. Drive options for the connection tunnels in association with the shortlisted CSO sites are not considered in this report as they are dependent upon the selection of the main tunnel route and shaft sites. To build the scheme, it is necessary to drive a tunnel or series of tunnels connecting a number of shaft sites. Possible permutations of tunnel drive scenarios (drive options) for the three tunnel routes and presented sites are established in a systematic manner to permit evaluation. The relative desirability of the feasible drive options for the three routes are then examined in terms of engineering factors, which are separated into engineering risk, programme and cost. These and the other discipline factors, such as planning, environment, community and property, will ultimately be used in conjunction with the site suitability reports to determine preferred sites and the preferred scheme, although this will be addressed in subsequent workshops and presented in the Preferred Scheme Report. It is also noted that the relative merits in system performance of the three main tunnel routes are not discussed or considered within this report as these will be addressed separately by the project team. This report shows that appropriate engineering options are available to drive the main tunnel for each of the three main tunnel routes. These are presented as a schedule of feasible main tunnel drive options to be taken forward to the next stage of the site selection methodology, and therefore the Preferred Scheme Report. Finally, engineering factors that will be used to provide content for consultations and for determining the preferred sites and associated drive options for the three main tunnel routes are also presented. These are the factors that will be used in the Preferred Scheme Report to examine the advantages and disadvantages, including engineering risk, programme and cost.

1.1.2

1.1.3

1.1.4

1.1.5

1.1.6

1.1.7

1.1.8

1.1.9

Page 1

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

2 Introduction

2 2.1 2.1.1

INTRODUCTION Purpose of report The Engineering Options Report has been prepared as part of the process for the creation of the preferred list of shaft sites and preferred scheme as set out in the Thames Tunnel Projects Site Selection Methodology Paper1. The Site Selection Methodology Paper states that the Engineering Options Report will consider: how sites work in combination, and options for the main tunnel alignment and combined sewer overflow (CSO) connections2 how options for tunnel alignment and CSO connection points will be refined, having regard to the availability of and spacing of suitable shaft sites, as well as to the potential for combined use of sites. Cost considerations associated with engineering options, transport and energy will be reported, balanced and taken into account.3

2.1.2

This report identifies and refines possible main tunnel alignment options, giving consideration to the overall location and grouping of the shaft sites that have been shortlisted for site suitability assessment. Drive and alignment options for the CSO connection tunnels are not included in this report as they depend on the selection of the main tunnel shaft sites, but they will be presented in the Preferred Scheme Report. The establishment of preferred sites, and hence preferred scheme, will follow on from this report. The findings of this Engineering Options Report will help inform the preferred scheme selection process. The Engineering Options Report is divided into two parts: Part 1: System design and engineering requirements

2.1.3

2.1.4

This part sets out at high level the system, geological, tunnelling and CSO engineering requirements to be considered as part of the development of engineering options, and subsequent selection of both a preferred scheme and an associated preferred list of shaft sites. As such, this will largely state and summarise requirements without providing an in-depth justification for the system and engineering requirements. Part 2: Engineering review and comparison of tunnel options

2.1.5

This part summarises the tunnel options considered and the analysis and refinement of these options. Included in the analysis is consideration of the relationship of the tunnel options to the available groups of shortlisted shaft sites. The report only considers the development of options from an engineering perspective. The considerations dealt with as part of the site suitability reports for each site have not been referred to in the preparation of this Engineering Options Report. In considering main tunnel routes, drive options and shaft sites, this report does not identify preferred tunnel routes, alignments, preferred shaft sites, connection tunnel routes or CSO sites. The selection of the preferred main tunnel route, alignments, connection tunnel alignments, preferred CSO sites and preferred shaft sites are to be assessed at later stages in the process (selection of the preferred sites and preferred scheme). These stages will be carried out by a broader multidisciplinary team and reported in the Preferred Scheme Report. The considerations in this Engineering Options Report, along with site suitability reports, will feed into and inform these stages.

2.1.6

2.1.7

Site Selection Methodology Paper, document reference 100-RG-PNC-00000-000025 AA, Thames Tunnel, (21 May 2009) 2 Site Selection Methodology Paper, Section 2.3.27, fourth bullet 3 Site Selection Methodology Paper, Section 2.3.32

Page 2

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

2 Introduction

2.2 2.2.1

Background to project The Thames Tunnel Project is required to intercept flows from CSOs along the River Thames between west London and the Beckton STW in east London. It is needed for compliance with Directive 91/271/EEC on Urban Waste Water Treatment and the avoidance of European Union (EU) fines. The project will benefit London as a whole, and those living, working in and visiting London, by providing a cleaner River Thames. The Site Selection Methodology Paper provides further detail on the background to the project. The Minister of State for Climate Change and the Environment issued a Ministerial statement in March 2007 with reference to sewer overflows to the River Thames. This was followed by a letter from the Minister, Ian Pearson MP, to Thames Water in April 2007, indicating that on the basis of the information supplied, it is the Ministers view that an Option 1 type approach is needed. Various options were presented in the December 2006 reports, Tackling Londons Sewer Overflows, Thames Tideway Tunnel and Treatment Option Development, and were also discussed in Defras report, Regulatory Impact Assessment sewage collection and treatment for London (March 2007). The Option 1c solution, presented in the above referenced documents, consists of a full-length tunnel along the River Thames to intercept, store and convey to treatment the discharges from 36 Category 1 and 2 CSOs. The Thames Tunnel Project controls flows from 34 of the 36 CSOs, while the CSO (Abbey Mills) is controlled by the Lee Tunnel Project, and the CSO (Wick Lane) by a standalone project. It is noted that a further 21 Category 3 and 4 CSO are not to be controlled. Engineering design development Following the Ministers letter indicating the need for an Option 1 type approach, there has been ongoing development of the main tunnel based on the Option 1c solution. The Lee Tunnel has also been consented and the contract for its construction awarded. The Thames Tunnel Projects site selection process4 recognises that the engineering design will need to proceed in parallel with the site selection process, and that there is an iterative relationship between the two. Design development activities have included: engineering designs and studies of various components of the scheme, and identification of possible high-level main tunnel routes system master planning to define the sewage system operation changes and facilities needed to control and limit overflows from the scheme construction, transportation and river navigational logistics studies field investigations, including ground investigations and surveys.

2.2.2

2.2.3

2.2.4 2.3 2.3.1

2.3.2

2.3.3

2.3.4

This Engineering Options Report draws on the relevant aspects of these studies and investigations, as well as the results from the site selection shortlisting process.

Site Selection Methodology Paper, Section 1.7.5

Page 3

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

3 3.1 3.1.1

SYSTEM DESIGN AND ENGINEERING REQUIREMENTS System design and engineering assumptions The assumptions made for the preparation of this report are identified and listed in an assumptions register in Appendix A (which can be found in the accompanying document, Engineering Options Report Appendices, reference 100-RG-ENG-00000-000009). These assumptions and further requirements are discussed in the following sections. Health and safety considerations Through risk assessment and management, the Thames Tunnel Project is working in accordance with industry codes and project standards, with the aim to achieve world-class health and safety objectives. The project has a plan and policies in place to ensure compliance with the Construction (Design & Management) Regulations 2007. System requirements Performance objective

3.2 3.2.1

3.3

3.3.1

The need for the project is described in the Site Selection, Background Technical Paper (Ref 100-RG-PNC-00000-000027). Basis for the design and system development General design requirements

3.3.2

The Site Selection, Background Technical Paper states that the main features of the Thames Tunnel Project were proposed to be: the control of 34 combined sewer overflows within the tidal River Thames the capacity to store the intercepted stormwater flows in a main tunnel the ability to pump-out the tunnel to treatment.

3.3.3

The design development activities have progressed and, at the time of this report, the engineering requirements to be taken forward in assessing engineering tunnel route and alignment options are summarised and briefly discussed in the following sections. These details are the subject of ongoing work. However, for the basis of this report, it is noted that the implications of any possible changes would need to be further assessed and reviewed. To achieve the design performance and functionality requirements, the main tunnel is required to be a 7.2m internal diameter tunnel. This has been assessed to provide a system with acceptable capacity to meet the requirements of the project. This section of the report focuses on system requirements relevant to the selection of sites and tunnel engineering alignments. Developments in design requirements

3.3.4

3.3.5

3.3.6

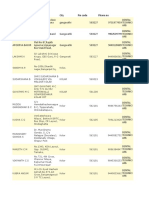

Developments in the design have updated the scheme requirements such that 21 or 22 CSOs are now required to be directly intercepted, depending on the main tunnel route, while the remaining CSOs are to be controlled by other measures. These measures include three interceptions to the existing northern Low Level Sewer No 1 (LL1). Table 3.1 lists the controls needed for all 34 CSOs, as well as indicating the 21 or 22 CSOs requiring interception, and three additional interceptions to the existing LL1.

3.3.7

Page 4

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

Table 3.1 Details of combined sewer outfall

Combined sewer overflow CS01X Acton Storm Relief (SR) CS02X Stamford Brook SR CS03X North West SR CS04X Hammersmith PS and CS04B LL1 Brook Green CS05X West Putney SR CS06X Putney Bridge CS07A Frogmore SR Bell Lane Creek and CS07B Frogmore SR Buckhold Rd CS08A Jews Row Wandle Valley SR and CS08B Jews Row Falconbrook SR CS09X Falconbrook PS CS10X Lots Road PS CS11X Church Street CS12X Queen Street CS13B Smith Street SR and CS13A Smith Street Main Line CS14X Ranelagh CS15X Western PS and CS15B Western PS upstream CS16X Heathwall PS CS17X South West SR CS18X Kings Scholars Pond SR CS19X Clapham SR CS20X Brixton SR CS21X Grosvenor Ditch CS22X Regent Street CS23X Northumberland Street CS24X Savoy Street CS25X Norfolk Street CS26X Essex Street CS27X Fleet Main CS28X Shad Thames PS CS29X North East SR CS30X Holloway SR CS31X Earl PS CS32X Deptford SR CS33X Greenwich PS CS34X Charlton SR Flow interception CSO flow is to be intercepted No modifications required No modifications required CSO flow is to be intercepted CSO flow is to be intercepted CSO flow is to be intercepted CSO flow is to be intercepted CSO flow is to be intercepted CSO flow is to be intercepted CSO flow is to be intercepted Indirect by action at Ranelagh/Western pumping station Indirect by action at Ranelagh/Western pumping station Indirect by action at Ranelagh/Western pumping station CSO flow and LL1 is to be intercepted Control modifications at Western pumping station CSO flow is to be intercepted CSO flow is to be intercepted Indirect by action at Ranelagh/Western pumping station CSO flow is to be intercepted CSO flow is to be intercepted Indirect by action at Ranelagh/Western pumping station Indirect by action at Northumberland Street CSO flow and LL1 is to be intercepted Indirect by action at Northumberland St/Fleet Main Indirect by action at Northumberland St/Fleet Main Indirect by action at Northumberland St/Fleet Main CSO flow and LL1 is to be intercepted CSO flow is to be intercepted CSO flow is to be intercepted CSO flow is to be intercepted CSO flow is to be intercepted CSO flow is to be intercepted CSO flow is to be intercepted CSO flow to be intercepted*/ indirect by action at Greenwich pumping station**

* Applicable to the River Thames and Rotherhithe routes ** Applicable to the Abbey Mills route

Page 5

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

3.3.8

Further elements that the scheme should provide as a minimum are listed below: The westerly start point of the scheme should connect to the Acton Storm Relief (SR) CSO. To meet hydraulic capacity and transient (temporary surge flow) requirements, the main tunnel (7.2m diameter) should extend to Hammersmith Pumping Station (PS) in the west. The easterly end point of the tunnel is to connect to the Lee Tunnel. This can be achieved at either Abbey Mills PSs or at Beckton STW. The provision of three connections to the LL1 along the Chelsea and Victoria embankments, where the high flows can be intercepted at new relief weirs. These flows will be diverted to the main tunnel and the operating philosophy of the Western PS will be amended. These measures enable discharges at some other CSOs to be controlled without the need for direct interception. Relieving controlling flows at LL1, as well as the discharging sewers at the CSO sites required for Ranelagh, Regent Street and Fleet Main CSOs, gives sufficient control to reduce local CSO spills so that direct interception is no longer required on the Northumberland Street, Church Street, Smith Street, Kings Scholars Pond, Grosvenor Ditch, Savoy Street, Norfolk Street and Essex Street sewers. These benefits rely upon the sites for the interception chambers being at locations that allow the full design functionality to be achieved. A system that ensures the health and safety of operatives, public and other third parties. This includes providing, during both the construction and operational phases, a hydraulically safe and robust system without the risk of flooding or adverse transient conditions; secure and resilient facilities, appropriate levels of ventilation and air treatment, and safe methods and facilities for access and egress into and from the main and connection tunnels.

3.3.9

At the time of writing, the system operational philosophy is under development. However, at a high level, the operational philosophy will be common to all options. Details of the proposed operation will be developed separately and presented in separate system engineering reports. Main tunnel routes

3.3.10 Design development has identified three tunnel routes: The River Thames route, Rotherhithe route and Abbey Mills route. 3.3.11 The River Thames route largely follows the route of the Thames, while the two other routes provide respectively an alignment that cuts across the Rotherhithe Peninsula and a route that connects to the Lee Tunnel at Abbey Mills. The latter has become feasible due to an increase in depth of the Lee Tunnel at the Abbey Mills PSs shaft end to avoid difficult geological conditions. This enables a continuous gradient with the Thames Tunnel Projects main tunnel, satisfying the design constraints for the overall vertical alignment and system hydraulic requirements. 3.3.12 These three routes are displayed in Figure 3.1 and described as follows. River Thames route (connection to Lee Tunnel at Beckton STW) 3.3.13 This route is closest to the route in Option 1c, shown in Defras report dated March 2007 entitled Regulatory Impact Assessment sewage collection and treatment for London, but takes account of over two years of additional development work, including the items stated in the General design requirements section above.

Page 6

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

Rotherhithe route 1 (across Rotherhithe Peninsula connection to Lee Tunnel at Beckton STW) 3.3.14 This is a variation to the River Thames route that cuts across the Rotherhithe Peninsula, reducing the River Thames route main tunnel length by 1.8km by not following a major bend in the river. A longer connection tunnel conveys flow from the North East Storm Relief (NESR) to the main tunnel, and a shorter connection tunnel is needed from Greenwich PS. This route is otherwise the same as the River Thames route, by intercepting the Acton Storm Relief (SR) Sewer at its upstream end by connection tunnel to the main tunnel, and connecting to the overflow shaft at Beckton STW at its downstream end. Abbey Mills route (connection to Lee Tunnel at Abbey Mills PSs) 3.3.15 This is different from the River Thames route because it connects the main tunnel to the head of the Lee Tunnel at Abbey Mills. The main tunnel length would reduce by approximately 9km. The upstream tunnel system would stay the same as the River Thames route over the length from the interception of Acton SR to Rotherhithe, but the route then veers northeast to Abbey Mills. A potential route/corridor for this length of tunnel could follow the Limehouse Cut Canal. CSOs to be intercepted downstream of Rotherhithe would connect back to the main tunnel by connection tunnel, except Charlton SR, where alternative methods of control can be implemented.

Page 7

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

Figure 3.1 General layout of the three Thames Tunnel routes being considered

Page 8

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

Control and interception of CSO flows 3.3.16 The CSOs to be controlled and intercepted are outlined in the previous section and listed in the assumption register provided in Appendix A. The register also indicates the minimum diameter of the connection tunnels and drop shaft sizes for hydraulic purposes. 3.3.17 The interception of CSO flows and connection to the main tunnel typically comprises four major elements: A CSO interception chamber, connection culvert, drop shaft and connection tunnel, as shown in Figure 3.2 below. A description of the construction elements is provided in the Site Selection, Background Technical Paper and these are discussed further in CSO interception design and construction in Section 3.6. Figure 3.2 Thames Tunnel CSO connection main system elements

EXISTING OUTFALL

RIVER

Indicative of site clearance and enabling works

BECKTON STW Inlet PS Inlet works

CSO INTERCEPTION CHAMBER Where CSO comprises a PS the location of the interception may be up or downstream of the CSO PS

CONNECTION CULVERT Open-cut or Tunnelled/Jacked 2 nr Flat gate chambers not shown and would naturally form part of the Interception chamber and Drop Shaft

DROP SHAFT

CONNECTIO TUNNEL

MAIN TUNNEL Drive Shafts (not shown) provide principal operational inspection access

Tunnel hydraulic requirements 3.3.18 The tunnel system is to store and convey flow, with the purpose of reducing CSO discharge. 3.3.19 The internal tunnel diameter has been taken at 7.2m, which is compatible with the Lee Tunnel. 3.3.20 The conveyance of flow is dependent upon the hydraulic grade line (rather than physical tunnel gradient). To permit the hydraulic grade line (and therefore flow) to be contained within the system, the general top-of-structure level at the shafts could be as high as 107.0mATD5. The interception chambers will not generally be subject to these higher levels, due to the protection afforded by a range of flap valves (that prevent flow reversing). 3.3.21 The tunnel system has to be self-cleansing. This can be achieved by either the flow regime (physical gradient) or the provision of flushing water.

This report reflects the information available at the time of writing, when it was anticipated that the elevation of top structures at both CSO and shafts sites would be finished at 107mATD. Subsequent to the preparation of this report, this was changed to 104.5mATD, and this updated information has been used at later stages, such as the Preferred Scheme Report.

Page 9

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

3.3.22 A gradient in excess of approximately one in 850 has been found to generate selfcleansing conditions with velocities exceeding 1m/s during event cycles. Based upon international experience, the self-cleansing velocity above this is sufficient to move detritus without further flushing requirements. 3.3.23 The gradient of the connection tunnels is generally in the range of one in 200 to one in 500 in order to achieve flow capacities and maximum peak velocities. The minimum diameter for these tunnels is to be 2m, to reflect the practicality of access for inspection by operatives and to limit peak velocities. 3.3.24 Large tunnel systems are potentially prone to hydraulic pressure effects, due to the generation of transient (temporary surge flow) conditions. Control features therefore need to be incorporated into the tunnel design and mode of operation. These include: the main tunnel diameter of 7.2m should extend to the Hammersmith PS to avoid over-pressurisation provision of overflows6 to the river at main tunnel shafts balancing the flows that are allowed to enter the tunnels with the volumetric capacity of the tunnels after allowing for rates of build up and evacuation of fluids and gases.

System functional and operational requirements Operation and related safety requirements 3.3.25 In order to ensure safe operations, access, inspection and maintenance of the tunnel, design development has defined the following assumptions and features: The main tunnel and connection tunnels are to be maintenance free, such that tunnel entry for inspection and maintenance is only planned to take place approximately every ten years. The ten-year inspection will be a major undertaking in its own right, which will involve elements of design and fabrication to permit entry. The system controlling tunnel filling is to be passive6 where possible to reduce the need for maintenance/access and operational complexity. Main tunnel drive shafts will be the designated access points to the tunnel system. The spacing of the main tunnel drive shafts is controlled by the requirements for maintenance access on the basis that the construction access demands are less onerous, in view of what can be achieved with modern tunnelling techniques. The spacing between permanent access points shall not exceed 9km, and shall be reduced to 5km or less where practicable. However, where main tunnel intermediate shaft access is available, this can be incorporated to improve the overall access conditions and regime. The main tunnel drive shafts shall be provided with large access openings to permit inspection plant to be lowered into the tunnel. CSO and shaft sites are to be selected to ensure space for two cranes to service the shafts. The provision of permanent ventilation and monitoring of the exhaust air quality along with air treatment facilities (odour control). The provision of control gates to isolate the tunnel system and prevent flow from entering. These gates will be controlled from a central control room to permit overview of the system from a single point.

6 This report reflects the information available at the time of writing, when it was anticipated that inflow would be passively controlled and overflows to the river would be required at main tunnel shafts. Subsequent to the preparation of this report, it was considered that overflows would not be required at all main tunnel shafts.

Page 10

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

Integrating the operating regime for the tunnel with the operating regimes at pumping stations, particularly Abbey Mills and Greenwich, along with Beckton STW and Crossness STW. Due to the presence of pressure/pneumatic transients and the conveyance of foul water, access ancillaries (eg, platforms, steps) shall not be provided as part of the permanent works.

3.3.26 When considering the main tunnel shaft spacing for the completed system, and based upon the experience from other major CSO systems, it is assumed maintenance and inspection teams will travel through the main tunnel by inspection vehicle. This reduces the transit time and permits a wider range of equipment to be carried with relative ease. Vehicular access is practicable for this system, given the main tunnel diameter and that the system will be dry when inspection is undertaken. 3.3.27 Access to the connection tunnels will also be required during inspection. Connection tunnel length is highly variable and site-dependent, ranging from 100m to 2,000m in length. Diameters are in the range of 2m to 5m. Provision for emergency egress will be made at the drop shafts, by the provision of suitable access openings and space for cranes to operate a man-rider. 3.4 Engineering geology Route geology 3.4.1 The route geology has been established using the British Geological Survey (BGS) Lithoframe50 Model, from which geological long sections have been prepared. This is considered to be adequate for this report. Additionally, preliminary information from ongoing ground investigations has been taken into account for this report7. Geological long sections, derived from the model, are provided for the three main tunnel routes in Appendix D. The basic geological horizons presented in the London Basin are given in Table 3.2.

3.4.2 3.4.3

This report reflects the information available at the time of writing. Subsequently, additional information and interpretation of conditions have been available. This updated information has been used at later stages, such as the Preferred Scheme Report.

Page 11

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

Table 3.2 Geology of London Basin Era Recent Group Formation Alluvium Floodplain Terrace Kempton Park Terrace Tertiary Thames London Clay Brief description of formation

Soft clays, silts, sands and gravels. May contain peat. Medium to dense sand and flint and chert gravel occasional cobbles and boulders.

Approximate range of thickness (m) 0- 5

0 - 10 >100

Very stiff, fissured silty clay.

Swanscombe member:

Sandy clay to clayey sand (< 2m) with some fine to medium black rounded gravel.

Blackheath member: Harwich

Dense to very dense flint gravel (with occasional cobbles) in silty or clayey, glauconitic, fine to medium sand matrix.

0 - 10

Oldhaven member:

Very dense clayey sand with gravel and shells - often cemented as limestone.

Lambeth Group

Woolwich Reading Upnor

Highly variable material consisting of gravel, sand, clay, silt, limestone, lignite and calcrete. Gravel, glauconitic and organic sand, silt and clay. Very dense silty to very silty sand. The lowest 0.5m consists of a conglomerate of flint pebbles. Homogeneous chalk with flint bands (>100mm thick). Heterogeneous nodular chalk with flint bands and marl seams.

10 20 57 10 15 circa 40 circa 50

Thanet Sands Formation (incl Bullhead Bed at base 0.5m) Cretaceous Chalk Seaford* Lewes*

Notes: * Limited to those formations of the White Chalk subgroup expected within the Thames Tunnel Project. (Upper and Middle Chalk are now known collectively as White Chalk.)

3.4.4

The distribution of strata along the route is largely controlled by the London Basin Syncline, which plunges gently eastwards. Thus, beneath a cover of made ground and recent deposits, the succession of tertiary deposits is gradually exposed west to east along the river until the Chalk occurs at outcrop around Greenwich. The anticipated geology at the proposed main tunnel invert is as follows: London Clay Formation Hammersmith PS/Acton SR to just west of Wandsworth Bridge (Harwich at the base approximately between Wandsworth Bridge and Vauxhall Bridge) Lambeth Group just east of Wandsworth Bridge to Blackfriars Bridge Thanet Sand Formation Blackfriars Bridge to just west of Tower Bridge White Chalk subgroup all routes downstream from just east of Tower Bridge.

3.4.5

3.4.6

Faulting at London Bridge is expected to repeat the sequence, and mixed face conditions in the Lambeth Group and Thanet Sand Formation are expected from Blackfriars Bridge through to Tower Bridge, with only a short section wholly in Thanet Sand Formation, close to Tower Bridge.

Page 12

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

3.4.7

Various structural geological models provide different interpretations of the structural setting across the London Basin, but they all generally indicate regular faulted block topography in the Chalk and NW by SE trending faults cutting the basic east-west main synclinal form. The dominant structural geological features are: the Greenwich Fault down throw 20m to 30m to the northwest in a series of stepped faults. The fault runs generally parallel with the main syncline, SW to NE from Greenwich to Beckton, crossing the River Thames downstream of the Thames Barrier. the Greenwich Anticline sitting to the south of the Greenwich Fault and on a similar trend lifts Chalk to surface outcrop over the eastern section of the routes the London Bridge Fault down throw 10m to the east.

3.4.8

3.4.9

Other structural features include the North Greenwich Syncline, Millwall Anticline and Beckton Anticline, all of which have a NE SW trend, contrary to main basin axis.

3.4.10 Scour hollows are located on previous drainage channels formed by the River Thames and are often found at the confluence with the existing tributaries, eg, at the Fleet, Lee and Wandle. The features usually contain a variety of granular deposits and/or disturbed natural materials and are localised and steep-sided. 3.4.11 The scour hollow in the vicinity of the Blackwall Tunnel is the only scour hollow known to penetrate into the Chalk; elsewhere, the hollows only affect the tertiary deposits and, more particularly, the London Clay. Basal depths are normally 5m to 20m below ground level, exceptionally 33m at Battersea Power Station and 60m at Blackwall Tunnel. 3.4.12 Of the known scour hollows, only the hollow at Hungerford Bridge is close to the Thames Tunnel alignments. This feature attains a base level of 73mATD in London Clay near the south bank, equivalent to only 10m above the tunnel crown. Tunnel alignment should therefore preferably follow a route close to the north bank. Such features may, however, have implications for the shallower connection tunnels in other locations. 3.4.13 Known scour hollow locations affect the following potential shaft and CSO sites: S68WH (Battersea Power Station base 72mATD) S87WH (Heathwall base 82mATD) C23XA (Regents base 90mATD) C27XA (Fleet base 90mATD).

3.4.14 The likely presence of flints within the Chalk may cause excessive wear to the tunnel boring machine (TBM), causing frequent interventions for inspection and maintenance, so an important part of the current ground investigations comprises the investigation of the Chalk structure, Chalk permeability and characteristics of any flint band features. 3.4.15 A number of flint bands are present within the Chalk. However, within the Seaford Chalk, the two principal and well defined flint bands are the Bedwells Columnar and Seven Sisters. The Bedwells typically comprise a discontinuous layer of very large irregular flints up to approximately 500mm high by 300mm in diameter, and the Seven Sisters is a continuous band, with flints between 100mm and 150mm thick. Both bands represent a significant challenge to tunnelling that will need to be assessed when comparing route and alignment options. Hydrogeology 3.4.16 The major aquifer of the London Basin lies in the Chalk, the aquifer being wholly unconfined to the east but confined to the west below the tertiary strata and the London Clay Formation in particular. The Chalk aquifer is generally in hydraulic continuity with the overlying Thanet Sand Formation and sometimes also the granular strata of the Lambeth Group, particularly any local sand channels and the Upnor Formation. The EA refers to this combined aquifer as the Chalk-Basal Sands aquifer.

Page 13

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

3.4.17 Local aquicludes can exist in the overlying Lambeth Group, leading to perched water tables. Historical records of engineering schemes have described these perched features to retain hydrostatic pressures of up to 40m, which may result in high inflows at tunnel levels and particularly in shafts during construction. 3.4.18 The Harwich Formation (Blackheath Member) is also known to contain high groundwater levels in places, which cause problems during tunnel construction. 3.4.19 A minor regional aquifer lies within the floodplain and river terrace deposits and because of the connection to the Thames, this aquifer is generally tidal, with an average level of 100mATD (0mAOD) +/- 2.5m. 3.4.20 Regional monitoring of the Chalk aquifer is reported by the EA and specific monitoring data is available over the years 2000 to 2008. These indicate a depressed groundwater table in central London at 60mATD, with water levels close to Blackfriars Bridge at 62mATD (refer to the groundwater level contour plan of the London Basin in Appendix D). However, the latest ground investigations are showing groundwater levels in the Chalk from Rotherhithe to Charlton 10m higher than the reported EA levels. 3.4.21 Groundwater pressure in the Chalk will have an important bearing on tunnelling. Table 3.3 shows the 2008 levels in the Chalk aquifer eastwards from Tower Bridge, using the data obtained from the EA. Table 3.3 Chalk aquifer groundwater levels 2008 and imposed pressure at tunnel invert (east of Shad) Tunnel section Approx tunnel invert mATD Approx GWT level 2008 mATD Approx GWT pressure bar Tower Bridge 50 NESR 45 Greenwich 46 Charlton 40 Abbey Mills 40 Beckton 32

72

78

91/100*

100

92m

100

2.5

3.5

4.5/5.5*

6.0

4.0

7.0

* Highest levels indicated in Lee Tunnel and Thames Tunnel Project monitoring holes

3.4.22 Short-term effects of pumping can still have a demonstrable impact on the regional contours. For example, levels decreased significantly due to abstractions in supply wells at Battersea/Brixton commencing in 2002, the water level being drawn down some 18m local to the wells, by 10m in central London near Fleet and by approximately 6m respectively in the vicinity of Tower Bridge and the Battersea Power Station area. 3.4.23 The EA reports that the groundwater feeding the Chalk aquifer from the southeast interacts with the River Thames from Greenwich to Woolwich as it flows northwest to Stratford, then west to central London. In the Greenwich to Woolwich area, there is potential for/evidence of saline intrusion within the aquifer. 3.5 Tunnel engineering and construction requirements Risk management considerations 3.5.1 The British Tunnelling Societys and the Association of British Insurers Joint Code of Practice for Risk Management of Tunnel Works in the UK recommendations should be adopted for all significant tunnelling projects in the UK, including the Thames Tunnel. The objective of the code is to promote and secure best practice for the minimisation and management of risks associated with tunnelling works and to set out best practices that should be adopted. At the core of the code is an obligation that owners, designers and contractors should have processes in place to identify and manage risks throughout the life of the project. Page 14

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

3.5.2

The project has a risk management plan and procedures in place to manage and control risks and comply with the requirements of the Joint Code of Practice for Risk Management of Tunnel Works in the UK. Refer also to Health and safety engineering risk considerations in Section 4. General tunnel considerations Tunnel diameters

3.5.3

Tunnels should be sized to suit the hydraulic performance of the system and the storage capacity requirement. This indicates that the main tunnel between its upper western end near Hammersmith PS and Beckton STW needs to be a minimum 7.2m internal diameter throughout its length. Connection tunnels will connect CSOs to the main tunnel via drop shafts. These tunnels should be sized to carry the design flows from the CSOs at gradients to limit maximum flow velocities to 3.5m/s, but not exceeding a maximum gradient of 1:200. The size of the connection tunnels will vary, depending on the flow, from 2m to 5m internal diameter. The minimum tunnel size for safe man access is assumed to be 2m internal diameter. Vertical tunnel alignments

3.5.4

3.5.5

The vertical alignment of the main tunnel should follow an approximate gradient of about one in 850. The overriding criteria controlling the gradient that can be achieved are the hydraulic functional performance, the constraints imposed by existing and proposed third-party infrastructure and the tunnel tie-in connection level at either Beckton STW or Abbey Mills PSs. The main third-party constraints are the Thames Water Lee Valley Water Tunnel near Hammersmith Bridge, and the proposed National Grid Wimbledon to Kensal Green tunnel. The vertical distance separating the Lee Valley Water Tunnel and the main tunnel crossing above would be about 5m. Other existing deep level service tunnels, including National Grids Beverley Brook tunnel and a number of BT Openreach tunnels also present constraints on the alignment. In addition to these, the planned National Grid Wimbledon to Kensal Green tunnel is also noted as requiring co-ordination to ensure that possible interference between these future projects is minimised. The distance between the tunnel and other existing third-party underground tunnels is less critical to the vertical tunnel alignment. The potential connection tunnel connecting Deptford SR and Greenwich PS CSOs to the main tunnel would be restricted vertically by the Jubilee underground line that crosses the Rotherhithe Peninsula. Horizontal tunnel alignments

3.5.6

3.5.7

3.5.8 3.5.9

There are three routes for the main tunnel between west London Hammersmith PS and Beckton STW or Abbey Mills PSs, described in Section 3.3 of this report. These alignment options generally follow the line of the River Thames, particularly to the west of Tower Bridge. There are numerous second order alignment options that are identified and compared in Section 4 of this report. These must all satisfy the hydraulic flow regime requirements.

3.5.10 The minimum horizontal radius for the main tunnel is taken to be 600m for practicable construction purposes. Smaller diameter, segmental lined, connection tunnels are taken to be typically of a minimum radius of 300m, although techniques can be employed to achieve lower radii. 3.5.11 In order to minimise the effect of tunnelling on third-party infrastructure, the tunnel should, so far as practicable: pass under the centre of the mid-deck span of bridges

Page 15

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

avoid interfaces with sensitive existing structures, such as the original Thames Tunnel (Brunels Thames Tunnel, now carrying the East London underground line) and the Rotherhithe road tunnel avoid passing beneath high-rise buildings on deep piles.

3.5.12 The alignment of CSO connection tunnels will generally be based upon the location of the main tunnel and its shafts, along with hydraulic considerations. Tunnel lining 3.5.13 The primary lining for the main tunnel is assumed to comprise a reinforced concrete, tapered, segmental lining ring, approximately 350mm thick and 7.8m internal diameter. This assumes a 300mm thick concrete secondary lining8 to provide the required finished tunnel of 7.2m internal diameter. The connection tunnels are also assumed to have a secondary lining for the purposes of this report. Shaft sizes 3.5.14 The main tunnel drive shafts are anticipated to be 25m internal diameter, with depths ranging from 40m in west London to 65m or 75m in east London, depending on the main tunnel route. Shafts of 25m are considered to be the minimum size required to both ensure that a TBM can be launched and that all equipment required for safe construction of the tunnel can be accommodated. 3.5.15 The intermediate shafts and reception shafts for the main tunnel are assumed to have an internal diameter of between 20m and 25m. 3.5.16 The internal diameter of CSO shafts range from 6m to 20m to suit the hydraulic requirements, although at some locations, it may be advantageous to incorporate the CSO connection culvert directly into a main tunnel shaft. Location of main tunnel shafts 3.5.17 The preferred location of main tunnel shafts for construction from solely an engineering viewpoint is influenced by the tunnel drive options and other considerations described in Section 4 of this report. In addition, consideration has been given to the following functional requirements: Every ten years, the tunnels will be inspected for operational and maintenance purposes. Access to the main tunnel will be via main tunnel shafts. A safe methodology, including equipment, will be developed to reduce, where possible, the need for additional intermediate shafts, simply to provide access between drive shafts. This is the basis of inspection and maintenance access for other large CSO schemes in the world. The main tunnel shafts will incorporate weirs9 to allow spills into the River Thames during full tunnel conditions. As a minimum, there would be an overflow weir at Beckton STW and two between Shad and the Charlton/Woolwich areas, and at least two upstream of Wandsworth. This would need to be subject to further hydraulic modelling.

The decision about whether secondary lining is required has not be made at the time of writing this report, but this report has been based on the assumption that it is required, as that represents the worst case for programme considerations. 9 This report reflects the information available at the time of writing, when it was anticipated that overflows to the river would be required at main tunnel shafts. Subsequent to the preparation of this report, it was considered that overflows would not be required at all main tunnel shafts.

Page 16

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

Tunnelling and shaft construction methods Tunnelling construction methods 3.5.18 The main tunnel has been assumed to have an external excavated diameter of 8.8m to provide for a 7.2m internal diameter after allowing for the primary lining, secondary lining10 and annulus grout thicknesses. 3.5.19 In order to achieve a completion date in 2020, several TBMs will be required. In addition to this, managing construction risk and the suitability of TBM types for the varying ground conditions along the route will also affect the determination of the number of TBMs to be used. 3.5.20 The geology and hydrogeology along each tunnel alignment will influence the selection of the TBM type. Full face TBMs will be required to support the ground during tunnelling to prevent excessive water inflows and excess excavation, and therefore minimise scope for ground settlement. 3.5.21 The types of full face TBMs can be either earth pressure balance (EPB) or slurry/mixshield. However, convertible TBMs, which have been used in the past, can operate as either an EPB or slurry machine but result in additional plant, equipment and impact to programme, to allow for changes to the operational method. For the purpose of this report, it has been assumed that specific machines will be tailored to the ground conditions. These would typically be EPB type TBMs for the main tunnel drives through the Lambeth Group west of the Shad PS area and also the London Clay, and slurry type TBMs for the eastern drives through the Chalk. Shafts construction methods 3.5.22 The geology, hydrogeology, depth and size of shaft will influence the method of shaft construction. Various methods of construction can be used, such as: segmental lined caisson or underpinned construction sprayed concrete lined reinforced concrete sunk caisson secant piled wall diaphragm wall.

3.5.23 The construction of shafts in the London Clay is likely to be by conventional methods, with segmental lining, sunk either as a caisson or underpinned. Sprayed concrete linings are also possible. 3.5.24 Where the shafts are very deep, constructed through mixed ground conditions and under high groundwater pressures, diaphragm wall type construction is the most likely method of construction. In general, the diaphragm wall type of construction requires a larger working area than other methods of shaft construction. A diaphragm wall shaft is a reinforced concrete lined shaft, comprising individually installed, abutting vertical concrete wall panels, constructed in the ground using specialist plant, prior to the excavation of the ground within the centre of the shaft. Ground treatment and control of groundwater 3.5.25 For all methods of shaft construction, the control of groundwater will be required to enable both safe excavation and sinking of the shaft and base slab construction.

10 The decision about whether secondary lining is required has not been made at the time of writing this report, but this report has been based on the assumption that it is required, as that represents the worst case for programme considerations.

Page 17

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

3.5.26 In some locations, ground treatment may be required to improve the natural state of the ground in advance of shaft construction or tunnelling. The term ground treatment covers a variety of techniques to strengthen or stabilise the ground: Injection of chemical or cementitious grouts to form blocks that can be excavated without collapse. The method used will be dependent on the ground encountered. Ground freezing, where injection pipes circulate brine or liquid nitrogen to freeze the groundwater and produce a stable block that can be excavated. Ground freezing is costly and takes a long time to implement. Compressed air, where a section of tunnel at the face has the air pressure increased, using air locks and compressors. The air pressure is increased to resist the inflow of groundwater. This technique has several health and safety implications and, with the 8.8m high face of the main tunnel, is unlikely to be completely successful. Dewatering to control the inflow of water into shafts and tunnel excavations, thus ensuring excavation stability. This can take the form of either regional (widespread) or localised dewatering methods, depending on the purpose and the extent of pressure reduction required. These methods will include deep borehole wells or localised drains, well points and injector wells.

Main tunnel shaft site requirements Main tunnel shaft sites 3.5.27 Three types of shaft site may be needed to construct the main tunnel: drive shafts, reception shafts and intermediate shafts. 3.5.28 The main tunnel will be driven from main drive shafts, which will be equipped to enable the efficient operation of the tunnelling excavation and construction. 3.5.29 Reception shafts will be used to remove the TBM from the tunnel at the end of a drive. Given a sufficient size of site, a shaft could be used for both drive and reception purposes. 3.5.30 Intermediate shafts can be used to gain access to the main tunnel bore during construction, either to inspect and/or maintain the TBM or to provide access for secondary lining construction (should a secondary lining be required). Location of sites 3.5.31 The required number and distribution of sites for tunnel construction will be informed by the following key considerations: The Thames Tunnel Project is to be operational by 2020. The TBM types must be appropriate to the geological conditions expected. The risk of TBM breakdowns/servicing requirements, and their severity and frequency, increases with the length of the drive. The emergency egress of the construction workforce will become more difficult the longer the length of the drive.

3.5.32 The final decision on the number of TBMs, and hence the number of associated drive shaft sites, will be based on a balance between the type of TBM appropriate to the ground, the available locations of main drive shafts, geology, programme, environment, amenity, health and safety, risk and cost considerations. 3.5.33 Construction of CSO connection tunnels will, where possible, be constructed from main shaft sites to reduce the space required for CSO sites. Where CSO connection tunnels are driven from main tunnel shaft sites, the CSO drop shafts would comprise smaller reception shaft sites. Excavated material from the CSO connection tunnel could also be handled at the main tunnel shaft sites.

Page 18

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

Main tunnel drive shaft site requirements 3.5.34 The main tunnel drive shaft sites must provide for the following core and ancillary construction activities for construction of the shaft and main tunnel: Construction of 25m diameter shaft Delivery of construction materials for shaft and tunnelling materials Storage, treatment and removal of excavated material arising from the shaft excavation and tunnel excavation Material stockyard for tunnel segments and accessories, including loading/unloading areas Craneage and transfer of materials within the worksite and into and out of the tunnel shaft access Grout batching plant River access comprising jetty/wharf facilities for loading/unloading materials for marine transport Workshops to maintain all the mechanical and electrical plant, and large stores for spare parts; stockyard for rails, pipes, grease, foam, cable drums, and temporary works items Power supply installations with possible need for substation Construction offices, welfare facilities and medical facilities Parking for construction traffic Incoming and outgoing goods and material marshalling area Possible logistics hub area to service satellite sites.

3.5.35 In order to provide space for both core and ancillary activities, it is anticipated that main tunnel drive shaft sites from which slurry TBMs will be driven will need to be approximately 20,000m2, whereas sites hosting an EPB TBM will need approximately 18,000m2, in line with the material handling requirements. The above areas do not allow for a logistics hub. 3.5.36 The construction activities that follow tunnel excavation are less onerous with respect to site spatial requirements. These will include tunnel secondary lining (if required), shaft lining, buildings and surface works, and mechanical and electrical fit-out works. Main tunnel reception shaft sites and intermediate shaft site requirements 3.5.37 Main tunnel reception shaft sites and intermediate shaft sites are not intended to be used for driving the main tunnel. Apart from providing access and egress points to the tunnel, the core activities to be undertaken from these shafts will be restricted to the construction of the shaft itself, removal (at reception shaft sites) or access to (at intermediate shaft sites) the TBMs, secondary lining (if required) and mechanical and electrical fit-out activities. 3.5.38 It is estimated that the areas required for both reception or intermediate shaft sites will range from 5,000m2 for sites with shafts constructed into the London Clay to 7,500m2, if deep diaphragm walling is proposed for shaft construction into Chalk. Construction logistics 3.5.39 For the purposes of this Engineering Options Report, the following logistical needs have been considered: The ability to provide efficient site layouts Logistics hubs Critical services: Power and water Page 19

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

Transport of materials and equipment Main tunnel segment fabrication and supply.

Site layouts for logistics 3.5.40 The layouts of individual sites for the logistics purposes will depend upon the specific site use and local constraints. The Site Selection Background Technical Paper indicates typical layouts for the different types of sites. Logistics hubs 3.5.41 The supply and servicing of the smaller CSO sites could be carried out as satellites to the main tunnel drive shaft sites. These drive shaft sites may therefore require an allowance for a logistics hub area for facilities to service the satellite sites. Critical services: Power and water 3.5.42 The temporary power supply requirements for construction sites typically varies from 0.5MVA to 2MVA for the smaller CSO sites, and up to 11MVA to 14MVA for the large main drive shaft sites serving a single TBM. 3.5.43 The number and potential spread of sites for main tunnel drives is such that for the majority of areas, it is likely that insufficient capacity exists, or will be available from EDF Energy at the time construction commences. Therefore, power supply improvement works would be required. 3.5.44 Discussions with EDF Energy have established that it would be prudent to plan for the early procurement of power supplies for the main drive sites. It is likely that power supply improvement works would be required because it is considered that there will be insufficient capacity to accommodate this projects requirements. Drive shaft sites should therefore be planned to accommodate new substation installations, for which an area of at least 60m x 20m is required. Transport of materials and equipment 3.5.45 Construction of the shafts and tunnel works would require a wide variety of materials and equipment to be transported to and from the working sites. 3.5.46 Excavated material will need to be taken away from the drive shaft sites and a wide variety of materials would need to be delivered, particularly the concrete segments for the main tunnel lining. Other logistical activities will include workforce arrival/departure, equipment deliveries/return, consumables and, for the drive shaft sites, the delivery of the large TBM components. 3.5.47 Due to the large volume of materials to be transported in and out of the main tunnel drive shaft sites, marine transport is the preferred option in order to minimise disruption to the surrounding communities. However, barge operation will only be practical in the following circumstances: Material can easily be conveyed between worksite and river Barge facilities can be provided within the river (jetty/wharfage) Barge movements can satisfy the logistics supply needs Barge operations do not interfere with navigation or with other river users to an unacceptable degree.

3.5.48 The practicality of rail transportation will depend on both the proximity of the main sites to suitable rail sidings and the local networks capacity for freight movements. 3.5.49 It is expected that some deliveries would be need to be transported by road, even if barge and/or rail transport facilities were available. Any necessary highway routes will need to be

Page 20

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

identified as part of the project development. Major deliveries/removals will be subject to specific movement restrictions and conditions imposed by police and traffic authorities. 3.5.50 For the majority of the CSO sites, it is envisaged that the primary mode of transport will be by road. Main tunnel segment fabrication and supply 3.5.51 The supply of tunnel lining segments to the individual drive shaft site locations will depend upon their final location and the location of the potential fabrication facility or facilities. 3.5.52 It is considered that the supply of these could either be by road or river, while river transport would be preferred where practical and economic. Excavated material handling and disposal Material type and handling 3.5.53 The main excavated material types will be London Clay, Lambeth Group, Thanet Sands Formation and Chalk. The overall route geology dictates where these are encountered. 3.5.54 The type of material and TBM choice will dictate the material handling and treatment requirements; the excavated material consistency will vary from relatively dry London Clay to Chalk slurry. 3.5.55 For the purposes of site planning, an allowance has been made for onsite storage of excavated material equating to five days production. This allows for issues relating to maintenance, plant breakdown and risks to barge operations on the River Thames. Quantities and programme requirements 3.5.56 The total quantity of excavated material for all tunnels and shafts is anticipated to be in the region of 2.5 to 3 million m3 (in situ quantity). This will vary, depending on the tunnel alignment and connections. 3.5.57 The quantity of excavated material arising per drive at main tunnel drive shaft sites will be approximately 300,000m3 to 500,000m3, assuming a tunnel length of between 5km to 8km. 3.5.58 Where two drives are carried out from the same site location, this will increase the capacity required if these are to be carried out simultaneously. 3.5.59 The tunnelling advance rates dictate the requirements for material removal. For the purposes of preliminary planning, a rate of 2,000m3 to 4,000m3 per day from a site is assumed, depending on TBM type and ground conditions. Marine transport 3.5.60 The feasibility and use of marine transport for the removal of excavated material from potential main tunnel drive shaft sites along the river is dependent on location. 3.5.61 Operations in the upper reaches of the River Thames beyond Hammersmith Bridge are considered to be unworkable, due to the restrictions of bridge height, tidal range and width of the navigable channel. These would impose constraints to barges that would reduce substantially the quantity and rate of material that can be removed, making the viability of solely marine transport in these areas unacceptable. 3.5.62 The operations between Putney Bridge and Hammersmith Bridge are considered to be challenging, especially when servicing the peak tunnelling rates. However, sites along this length of the Thames could be accessed and serviced but would require careful planning to mitigate the problems associated with navigational constraints. 3.5.63 Downstream of Putney Bridge, there are fewer navigational constraints and, as such, it is possible to use reduced numbers of larger size barges on the lower reaches of the Thames to the east. Hence, only 350t barges can be used around Putney Bridge, 1,000t

Page 21

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

barges can be used in the vicinity of Battersea Power Station and 1,500t barges can be used from Greenwich to Beckton. In-river facilities 3.5.64 Jetty/wharf structures and their location with respect to the navigational channel, together with associated dredging of the river for access purposes, will be site specific. Each main tunnel drive shaft site not having substantial jetty or deep water wharf facilities is likely to require a bespoke solution with specific consents from the Port of London Authority (PLA) and the EA. 3.5.65 The above issues, with respect to in-river facilities, are more onerous on the upper reaches of the river. Thus, beyond Hammersmith Bridge and to a lesser extent beyond Putney Bridge the scale of facilities for barges is likely to impinge greatly on the existing river and its users, leading to difficulties in obtaining the required consents. 3.5.66 Particular risks to in-river facilities and barge movements relate to other river users and the need to obtain a marine risk assessment for operations. As such, it is noted that in the upper reaches of the river beyond Putney Bridge, the presence of recreational users, such as rowers and small boats, presents a major hazard and risk to be considered when evaluating sites. Disposal of material 3.5.67 The total quantity of excavated material to be disposed of for the Thames Tunnel Project is in the region of 2.5 to 3 million m3 (in situ quantity). The methods of treatment, transport and disposal are dependent upon the nature and consistency of the excavated material and requirements for final disposal. 3.5.68 The overall policy is to favour marine transport of excavated material along the River Thames, where practicable. 3.5.69 The details of potential disposal sites are not discussed or considered in this report. These will be covered by the project Waste Management Strategy, forming part of the future Environmental Impact Assessment. CSO connection to the main tunnel 3.5.70 Where the CSO connection tunnels are directly connected to the main tunnel, it has been assumed that the internal diameter will be no greater than 3m and at an angle of about 70 degrees to the main tunnel, unless there are overriding technical considerations, which mean that this cannot be achieved. The limitation on diameter is due to construction constraints and the need to maintain structural stability of the main tunnel lining. 3.5.71 The CSO connections to the main tunnel are to be grouped into five generic options/types. These are outlined in greater detail in Section 4. Connection with Beckton STW or Lee Tunnel 3.5.72 The main tunnel can either connect with the Lee Tunnel at Beckton STW or Abbey Mills PSs, depending on the main tunnel alignment. The details of these connections are outlined below. Beckton STW connection (for the River Thames and Rotherhithe routes) 3.5.73 For the River Thames and Rotherhithe routes, the main tunnel would connect to the Lee Tunnel at the proposed overflow shaft at Beckton STW. The overflow shaft will be completed as part of the Lee Tunnel prior to the Thames Tunnel Project. The connection will need to provide a smooth hydraulic path for flows in both directions, to allow both tunnels to overflow to the River Thames when required, and for the construction of the connection to minimise the effect on the Lee Tunnel operations.

Page 22

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

3.5.74 It is planned that the Lee Tunnel overflow shaft will make provision for the connection by incorporating a tunnel eye in the shaft wall. The Thames Tunnel Project will include a shaft approximately 30m to one side of the Lee Tunnel overflow shaft, either to launch or receive the main tunnel TBM. The two shafts will be connected by a short 7.2m internal diameter tunnel. Abbey Mills connection (for the Abbey Mills route) 3.5.75 For the Abbey Mills route, the main tunnel will connect to the Lee Tunnel at Abbey Mills. The proposed arrangement is for the main tunnel to connect at or close to the Lee Tunnel Shaft F (proposed Lee Tunnel shaft to be located at Abbey Mills PSs). The connection will need to provide a smooth hydraulic confluence to allow flows in both directions, and for the construction of the connection to minimise the effect on the Lee Tunnel operations. 3.5.76 Two connection arrangements are considered feasible, although other arrangements may be considered as the design develops: The main tunnel connects directly into Shaft F. The Lee Tunnel Shaft F will incorporate a tunnel eye in the shaft wall for the connection. A shaft approximately 50m to one side of the Lee Tunnel Shaft F will be constructed, either to launch or receive the main tunnel TBM. The Lee Tunnel will be enlarged over a short length to form a connection chamber and the Lee Tunnel and the main tunnel will be connected by a short tunnel.

Third-party infrastructure impact 3.5.77 The nature of operations involved in construction of the main tunnel and associated shafts has the potential to cause ground movements that could affect existing third-party infrastructure and buildings. The horizontal and vertical alignment of the main tunnel shaft locations and construction methodologies will be selected so that the impact on third-party infrastructure due to settlement will be avoided or minimised, as far as reasonably practicable. 3.5.78 Searches of historical and other records have revealed wells located within the alignment corridor, some of which are operational abstraction wells. The tunnel alignment will, wherever possible, avoid any adverse affect on these wells. 3.5.79 Searches have revealed, in addition to road and underground rail transport tunnels, a number of existing deep level service tunnels, including National Grids Beverley Brook tunnel and a number of BT Openreach tunnels. In addition to these, the planned National Grid Wimbledon to Kensal Green tunnel is also noted. The alignment of the main tunnel will avoid these assets, with acceptable clearances. 3.6 CSO engineering and construction requirements General considerations 3.6.1 The design requirements for CSOs are outlined in Developments in design requirements in Section 3.3 with a list of the controls required for all 34 CSOs, as well as indicating the 21 or 22 CSOs requiring interception, depending on the route, and three interceptions to the existing LL1. The CSO interceptions identified comprise a combination of direct gravity overflows and pumping stations. In each case, the location of the CSO interception works will be constrained by the layout of the existing sewer system. In general, interception of gravity CSOs will be downstream of the last incoming connection into the overflow before the overflow sewer reaches the river, to ensure that the CSO interception is not bypassed during a storm event. For the interception of flows from pumping stations, there are advantages and disadvantages associated with interception pre- and post-pumping. For example,

3.6.2

3.6.3

3.6.4

Page 23

100-RG-ENG-00000-900006-Engineering-Options-Report.doc

Printed 04/11/2010

3 System Design and Engineering Requirements

intercepting the flows pre-pumping allows direct gravity interception without reliance on the pumps and therefore provides energy savings, whereas post-pumping interception allows the pumps to be used regularly and therefore provides maintenance benefits. In practice, the criterion governing whether pumping station flows are intercepted pre- or post-pumping is likely to be the availability of suitable CSO sites. CSO interception design and construction 3.6.5 The CSO interceptions typically consist of the following elements: 3.6.6 CSO interception chamber CSO connection culvert CSO drop shaft CSO connection tunnel.

Details of each of these elements are outlined below. CSO interception chambers

3.6.7

The CSO interception chamber will typically be a box-shaped structure and will be positioned on the line of the existing sewer pipe. The purpose of this structure is to intercept the CSO flow and direct it into the connection culvert leading to the drop structure. The size of the interception chamber will be determined to suit the existing sewer and to accommodate the maximum flow requirements for interception. This will be done following a combination of theoretical and physical modelling. The depth of the interception chamber will be determined by the depth of the existing sewer and, although relatively shallow, these can be up to approximately 22m deep, depending on the depth of the existing sewer at the location of interception.

3.6.8

3.6.9