Professional Documents

Culture Documents

Nucleation and Growth of Crystals

Nucleation and Growth of Crystals

Uploaded by

charudatt2008Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nucleation and Growth of Crystals

Nucleation and Growth of Crystals

Uploaded by

charudatt2008Copyright:

Available Formats

Nucleation and Growth of

Crystals

Nucleation and Growth Rates

Control R

c

Nucleation, the first step

First process is for microscopic clusters (nuclei)

of atoms or ions to form

Nuclei possess the beginnings of the structure of the

crystal

Only limited diffusion is necessary

Thermodynamic driving force for crystallization must

be present

NUCLEATION

water as example

initiation of freezing

formation of small nuclei -center of

crystals

homogeneous or heterogeneous

homogeneous -water -random

accumulation of water molecules

heterogeneous -small particles present in

the solution act as nuclei

Crystal Growth

water as example

can only occur after nuclei are formed

exceed the crystal size

function of :

rate at which the water molecules reacts

at the crystal surface

diffusion rate of water molecules from the

unfrozen solution to the crystal surface

rate heat is removed

Growth of crystals from nuclei

Growth processes then enlarge existing

nuclei

Smallest nuclei often redissolve

Larger nuclei can get larger

Thermodynamics favors the

formation of larger nuclei

Nucleation and Growth Rates

Poor Glass Formers

T

m

T

Strong overlap of growth

and nucleation rates

Nucleation rate is high

Growth rate is high

Both are high at the same

temperature

Rate

Growth Rate

Nucleation Rate

Nucleation and Growth Rates

Good Glass Formers

T

m

T

No overlap of growth

and nucleation rates

Nucleation rate is small

Growth rate is small

At any one temperature one

of the two is zero

Rate

Growth Rate

Nucleation Rate

Fluid Processing

Molten glass is processed to maximize

clarity or durability.

Pure raw materials are often produced to

exacting sizes through precipitation from

aqueous solutions.

Large single crystals are grown from pure

molten solids for specialty applications.

Liquid

Critical Cooling Rate

Rapidly cooled liquids skip crystallization

and form random amorphous solids.

Calculating this rate involves minimizing

both nucleation and grain growth.

Glass

What This Means

Clear glasses are processed to reduce the

number and size of crystals.

Crystalline ceramics are processed so that

properties are optimized.

Nucleation Rate

Thermodynamic barrier W

*

At r

*

, (cW(r)/ cr)

r=r*

= 0

r

*

= -2o/ AG

cryst

(T)

W(r

*

) W

*

= 16t o

3

/3(AG

cryst

(T))

2

r

W

S

= 4tr

2

o,

o is the surface energy

W

B

= 4/3tr

3

AG

crsyt

(T),

the Gibbs Free-Energy of

Crystallization

W

tot

= W

S

+ W

B

W

*

r

*

+

-

0

Nucleation Rate I(T)

I = nvexp(-N 16t o

3

/3(AG

crsyt

(T))

2

/RT)exp(-AE

D

/RT)

AG

cryst

(T) = AH

cryst

(T

m

)(1 T/T

m

)

AG

cryst

(T)

0

+

-

T

m

Approx. for o:

o ~ 1/3AH

cryst

/N

1/3

V

m

2/3

)

`

|

|

.

|

\

|

A

A

|

|

.

|

\

|

=

RT

E

T

T H

RT V

n I

D

m cryst

m

exp

81

16

exp

2

2

t

v

Liquid is Stable

Crystal is Stable

Growth Rates -

Crystal Growth requires diffusion to the nuclei surface

Crystallization onto the exposed crystal lattice

AG

cryst

AE

D

v

lc

= vexp(-AE

D

/RT)

v

cl

= vexp(-(AE

D

- AG

cryst

) /RT)

v

net

= v

lc

- v

cl

=

vexp(-AE

D

/RT) -

vexp(-(AE

D

- AG

cryst

) /RT)

= a v

net

= a v exp(-AE

D

/RT) x

(1 exp(AG

cryst

) /RT)

Growth Rates -

Diffusion coefficient, D

D = a

2

vexp(-AE

D

/RT) = fRT/3Ntaq(T)

Hence:

= fRT/3Nta

2

q(T)(1 exp(AH

m

/RT(AT/T

m

)

where q(T) = q

0

exp(AE

D

/RT)

Precipitation

The objective of precipitation is to

remove salts, metals, or other

contaminants present in liquid waste

streams. Most often, this deals with the

removal of metals at varying pH levels.

Generally, the size of a precipitated

particle increases if the reaction is

allowed to occur with previously

precipitated particle.

1. Process Description

Precipitation has generally been shown to occur in three

steps: (a) nucleation; (b) crystal growth; and (3)

agglomeration and the ripening of the solids.

(a) Nucleation

:a nucleus is a fine particle on which the spontaneous

formation or precipitation of a solid phase can take place

in a supersaturated solution.

Homogeneous nucleation occurs when the nuclei is

formed from component ions of the precipitate; if

foreign particles are the nuclei, heterogeneous nucleation

occurs.

PRECIPITATION

(b) Crystal growth

: crystals form by the deposition of the precipitate constituent ions onto nuclei.

Crystal growth rate can be expressed as:

where

C* = saturation concentration (mole/L)

C = actual concentration of limiting ion (mole/L)

k = rate constant (L

n

/ time mg)

S = surface area available for precipitation (mg/L of a given particle size)

n = constant

When the diffusion rate of ions to the surface of the crystal controls the crystal

growth rate, the exponent n has a value of unity; when other processes such as the

reaction rate at the crystal surface are rate limiting, n may have a value other than

unity.

dC

dt

kS C C

n

= ( *)

PRECIPITATION

Protein Crystals

day 6 day 10

Day 13

Day 16

(c) Agglomeration and ripening

: conversion of small particles into larger

particles is enhance by agglomeration of

particles to form larger particles, which is the

continual growth until equilibrium is reached.

The changes in crystal structure that take

place over time are often called aging.

A phenomenon called ripening may also take

place whereby the crystal size of the

precipitate increases.

PRECIPITATION

Definition of Ostwald ripening

Many small crystals form in a system

initially but slowly disappear except for

a few that grow larger, at the expense

of the small crystals. The smaller

crystals act as "nutrients" for the

bigger crystals. As the larger crystals

grow, the area around them is depleted

of smaller crystals.

LEEM (Low-energy electron microscopy) images of ripening of

single atomic layer height islands on Si(001) at various times after

the temperature was increased to 670 C: (a) 10 s, (b) 50 s, (c) 400

s, and (d) 1300 s.

Explanation for the occurrence

of Ostwald ripening

This is a spontaneous process that occurs because larger

crystals are more energetically favored than smaller crystals.

(This might be hard to believe seeing as how it seems far more

common to get many small crystals than a few large ones, but

there is a believable explanation.) . While the formation of many

small crystals is kinetically favored, (i.e. they nucleate more

easily) large crystals are thermodynamically favored. Thus,

from a standpoint of kinetics, it is easier to nucleate many

small crystals. However, small crystals have a larger surface

area to volume ratio than large crystals. Molecules on the

surface are energetically less stable than the ones already well

ordered and packed in the interior. (Think of packing your

vacation clothes in a suitcase. Which ones are more energetic?

The ones in the middle or the ones you are packing in on top,

trying to get them to fit?) Large crystals, with their greater

volume to surface area ratio, represent a lower energy state.

Thus, many small crystals will attain a lower energy state if

transformed into large crystals and this is what we see in

Ostwald ripening.

So why doesn't Ostwald ripening

happen all the time? One reason

is that the nucleation of many

small crystals reduces the amount

of supersaturation and thus, the

thermodynamically favored large

crystals never get a chance to

appear.

You might also like

- (BS en 14511-3 - 2013) - Air Conditioners, Liquid Chilling Packages and Heat Pumps With Electrically Driven Compressors For Space Heating and Cooling. Test MethodsDocument60 pages(BS en 14511-3 - 2013) - Air Conditioners, Liquid Chilling Packages and Heat Pumps With Electrically Driven Compressors For Space Heating and Cooling. Test MethodsRinno100% (2)

- Weather - A Golden Science Guide - Paul E. LehrDocument164 pagesWeather - A Golden Science Guide - Paul E. LehrKenneth100% (7)

- CrystallizationDocument14 pagesCrystallizationAbhimanyu AwasthiNo ratings yet

- Lecture 2 - Nucleation and Growth of NanomaterialsDocument17 pagesLecture 2 - Nucleation and Growth of NanomaterialsRachit Goyal100% (1)

- Mass Transfer Operation 1 (2150501) : Crystallization Concept, Techniques and ProcessesDocument18 pagesMass Transfer Operation 1 (2150501) : Crystallization Concept, Techniques and Processesvashu patelNo ratings yet

- ECE-309E Microelectronics: Crystal Growth & Wafer PreparationDocument68 pagesECE-309E Microelectronics: Crystal Growth & Wafer PreparationMona SinghNo ratings yet

- Crystallization PDFDocument7 pagesCrystallization PDFMallick Zeyshan Tariq100% (1)

- Zone MeltingDocument3 pagesZone MeltingpradyumnavaikuntNo ratings yet

- Silicon Solar Cell TechnologiesDocument16 pagesSilicon Solar Cell TechnologiesAnshu Kumar Srivastava100% (2)

- Chapter 2 Crystal GrowthDocument44 pagesChapter 2 Crystal GrowthsunNo ratings yet

- Semiconductor Grade SiliconDocument41 pagesSemiconductor Grade SiliconDimas100% (1)

- Chapter - 2: Introduction To Crystal GrowthDocument26 pagesChapter - 2: Introduction To Crystal GrowthShravan PatelNo ratings yet

- CrystallizationDocument17 pagesCrystallizationAsif MassudNo ratings yet

- CrystallographyDocument11 pagesCrystallographyShailendra AgarwalNo ratings yet

- Fade Margin CalculationDocument9 pagesFade Margin CalculationMohammad Belal HossainNo ratings yet

- No.04-Hydrothermal Synthesis of Nanomaterials-GUODocument22 pagesNo.04-Hydrothermal Synthesis of Nanomaterials-GUOPsyke R. Once50% (4)

- Solar Photovoltaics: by Chirag GoelDocument35 pagesSolar Photovoltaics: by Chirag Goelchirag goelNo ratings yet

- Hydrothermal MethodDocument16 pagesHydrothermal Methodavni vatsNo ratings yet

- Hydrothermal Process Chinmoy 2Document32 pagesHydrothermal Process Chinmoy 2Utpol DoleyNo ratings yet

- Continuous Hydrothermal Synthesis of Inorganic NanoParticles: Applications and Future DirectionsDocument114 pagesContinuous Hydrothermal Synthesis of Inorganic NanoParticles: Applications and Future DirectionsLưu Mạnh QuỳnhNo ratings yet

- Kirkendal Effect Paper PDFDocument4 pagesKirkendal Effect Paper PDFAnonymous DmKpKA6wHNo ratings yet

- Hydrogen Production Using ElectrolysisDocument15 pagesHydrogen Production Using ElectrolysisInda RobayaniNo ratings yet

- Crystal Growth Techniques PDFDocument30 pagesCrystal Growth Techniques PDFanis100% (1)

- CZ and FZ GrowthDocument18 pagesCZ and FZ GrowthSidra IqbalNo ratings yet

- Fluid Mechanics: Dr. Kamel Mohamed GuedriDocument28 pagesFluid Mechanics: Dr. Kamel Mohamed GuedriAd Man GeTigNo ratings yet

- Monocrystalline Silicon PDFDocument5 pagesMonocrystalline Silicon PDFAdamRaczNo ratings yet

- Twinning in CrystalsDocument5 pagesTwinning in CrystalsShoaib Imam NaqviNo ratings yet

- Ece Laws Mnemonics PDFDocument2 pagesEce Laws Mnemonics PDFjonalyn EscosioNo ratings yet

- Float Zone & Bridgman Crystal Growth Techniques: Abu Syed Md. Jannatul Islam Lecturer, Dept. of EEE, KUET, BDDocument27 pagesFloat Zone & Bridgman Crystal Growth Techniques: Abu Syed Md. Jannatul Islam Lecturer, Dept. of EEE, KUET, BDBomkesh SardarNo ratings yet

- Considering The High Impact of Gettering of Silicon On Fabrication of Wafer Designing and Optimize The Designing With New Innovative SolutionsDocument7 pagesConsidering The High Impact of Gettering of Silicon On Fabrication of Wafer Designing and Optimize The Designing With New Innovative SolutionsJournal of ComputingNo ratings yet

- (L17) Twinning F12 PlagioklasDocument30 pages(L17) Twinning F12 PlagioklasRadhitya Adzan HidayahNo ratings yet

- CZTS TaguchiDocument6 pagesCZTS TaguchiYoussef ArbaNo ratings yet

- SedimentationDocument2 pagesSedimentationAngellicaNo ratings yet

- CzochralskiDocument4 pagesCzochralskininnette1No ratings yet

- Constantes CZTS PDFDocument16 pagesConstantes CZTS PDFEdison Fernando RamirezNo ratings yet

- Thin Film Deposition TechniquesDocument20 pagesThin Film Deposition TechniquesShayan Ahmad Khattak, BS Physics Student, UoPNo ratings yet

- Bridgman-Stockbarger TechniqueDocument2 pagesBridgman-Stockbarger TechniqueSuraj SutarNo ratings yet

- The Steady State Approximation Is A Method Used To Estimate The Overall Reaction Rate of A MultiDocument6 pagesThe Steady State Approximation Is A Method Used To Estimate The Overall Reaction Rate of A MultiMubashar ShakeelNo ratings yet

- States of MatterDocument17 pagesStates of MatterPaschal JLLANo ratings yet

- CHE 321 Unit Operation 1 (3 Units) : 1: Drying, Conveying 2: Sedimentation, ClarificationDocument32 pagesCHE 321 Unit Operation 1 (3 Units) : 1: Drying, Conveying 2: Sedimentation, ClarificationGlory UsoroNo ratings yet

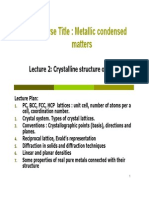

- Lecture 2 - Crystalline Structure of MetalsDocument25 pagesLecture 2 - Crystalline Structure of MetalsAkerkeMami100% (1)

- Eme 1166 Materials Science: DiffusionDocument55 pagesEme 1166 Materials Science: DiffusionJONATHAN RAJ A/L SEMANNo ratings yet

- Chapter 11-Homogeneous ReactionDocument55 pagesChapter 11-Homogeneous ReactionBryan ManaliliNo ratings yet

- Ewald SphereDocument57 pagesEwald SphereMohammad Rameez0% (1)

- Band Theory of SolidsDocument46 pagesBand Theory of SolidsMohammad Gulam AhamadNo ratings yet

- Iso and PolymophismDocument17 pagesIso and PolymophismFozia Shaikh100% (1)

- Hydro Thermal Technology For NanotechnologyDocument50 pagesHydro Thermal Technology For Nanotechnologyhichiku4u0% (1)

- CH 12-Structures and Properties of CeramicsDocument36 pagesCH 12-Structures and Properties of CeramicsVicces P. EstradaNo ratings yet

- Chemical KineticsDocument69 pagesChemical KineticsDaniel YakubovichNo ratings yet

- Silicon Processing: From Quartz To Crystalline Silicon Solar CellsDocument18 pagesSilicon Processing: From Quartz To Crystalline Silicon Solar CellsRavi JaiswalNo ratings yet

- Structure and BondingDocument12 pagesStructure and BondingNisha JodhanNo ratings yet

- Mat Sci Slides 2Document29 pagesMat Sci Slides 2abcdNo ratings yet

- Electrometallurgy PDFDocument34 pagesElectrometallurgy PDFJeremy PutraNo ratings yet

- Dec 1st - 2015 L10c Diffusion Ficks Laws 2Document11 pagesDec 1st - 2015 L10c Diffusion Ficks Laws 2abo1510No ratings yet

- Factors Affecting The Growth ProcessDocument23 pagesFactors Affecting The Growth ProcessBhaagi Sird100% (1)

- Powder Technology Presentation Ali HashemiDocument68 pagesPowder Technology Presentation Ali HashemiahashemicheNo ratings yet

- ELECTROMETALLURGYDocument24 pagesELECTROMETALLURGYfadel sidiqNo ratings yet

- Lecture 2 Si Growth - 2022Document20 pagesLecture 2 Si Growth - 2022DrNasser MorganNo ratings yet

- Climate Change Study GuideDocument107 pagesClimate Change Study GuideDharani Nachiyar100% (1)

- (Mineralogy) Crystal GrowthDocument29 pages(Mineralogy) Crystal GrowthSivaKumarNo ratings yet

- Crystal Growth and Ore Texture SP4Document129 pagesCrystal Growth and Ore Texture SP4dennysikasepNo ratings yet

- Methods of Producing Single Crystal: Author NoteDocument20 pagesMethods of Producing Single Crystal: Author NoteMohit SinhaNo ratings yet

- Hexavalent Chromium in Portland CementDocument5 pagesHexavalent Chromium in Portland Cementyinglv100% (1)

- Accurate Rapid Analysis of Alkali Contents in Portland CementDocument4 pagesAccurate Rapid Analysis of Alkali Contents in Portland CementyinglvNo ratings yet

- The Composition and Crystallography of An Anhydrous Calcium Aluminosulphate Occurring in Expanding Cement PDFDocument5 pagesThe Composition and Crystallography of An Anhydrous Calcium Aluminosulphate Occurring in Expanding Cement PDFyinglvNo ratings yet

- Formation of Ettringite From Monosubstituted Calcium Sulfoaluminate Hydrate and Gypsum PDFDocument6 pagesFormation of Ettringite From Monosubstituted Calcium Sulfoaluminate Hydrate and Gypsum PDFyinglvNo ratings yet

- Opportunities For Use of Bauxite Residue in Special CementsDocument46 pagesOpportunities For Use of Bauxite Residue in Special CementsyinglvNo ratings yet

- Thermodynamic Data of Ye'elimite (C4A3$) For Cement Clinker Equilibrium PDFDocument7 pagesThermodynamic Data of Ye'elimite (C4A3$) For Cement Clinker Equilibrium PDFyinglvNo ratings yet

- Relationship Between Raw Mixture and Mineralogical Composition of Sulphoaluminate Belite Clinkers in The System CaO SiO2 Al2O3 Fe2O3 SO3 PDFDocument6 pagesRelationship Between Raw Mixture and Mineralogical Composition of Sulphoaluminate Belite Clinkers in The System CaO SiO2 Al2O3 Fe2O3 SO3 PDFyinglvNo ratings yet

- Carbon Dioxide Reduction Potential in The Global Cement Industry by 2050 PDFDocument10 pagesCarbon Dioxide Reduction Potential in The Global Cement Industry by 2050 PDFyinglvNo ratings yet

- (9783110461381 - Rietveld Refinement) FrontmatterDocument4 pages(9783110461381 - Rietveld Refinement) FrontmatteryinglvNo ratings yet

- Electron Diffraction PHYWEDocument5 pagesElectron Diffraction PHYWEChakri RangiNo ratings yet

- BurnersDocument2 pagesBurnersArfianti Kurnia Nur FadillaNo ratings yet

- 220-240 ServDocument700 pages220-240 ServRenato SpiropulosNo ratings yet

- Durability and SoundnessDocument9 pagesDurability and SoundnessPhillimon ShabaNo ratings yet

- Wax Deposition and Prediction in Petro 2019 Journal of Petroleum Science andDocument15 pagesWax Deposition and Prediction in Petro 2019 Journal of Petroleum Science andThevaruban RagunathanNo ratings yet

- Expt. 3 Heat Transfer in Agitated VesselDocument7 pagesExpt. 3 Heat Transfer in Agitated VesselPradeep Diwakar67% (3)

- Tds 1000 PPM COADocument1 pageTds 1000 PPM COAtechNo ratings yet

- What Captions Appear On These Labels?Document11 pagesWhat Captions Appear On These Labels?Alaa Al HamedNo ratings yet

- Chapter 12 (Hydro Statics)Document6 pagesChapter 12 (Hydro Statics)Teresa PulgaNo ratings yet

- Volumetric AnalysisDocument13 pagesVolumetric AnalysisJuliusNo ratings yet

- Astm F136-13Document5 pagesAstm F136-13Shani GeanNo ratings yet

- Resistance and Equivalent Length of FittingsDocument8 pagesResistance and Equivalent Length of Fittingsyarzar17No ratings yet

- Clerk 2018 Main P2 PDFDocument40 pagesClerk 2018 Main P2 PDFJust a TrickNo ratings yet

- CGR ReportDocument18 pagesCGR ReportPrashant PoteNo ratings yet

- Production of Lactic Acid From Mango Peel WasteDocument7 pagesProduction of Lactic Acid From Mango Peel WasteFiqa SuccessNo ratings yet

- Astrology and MarriageDocument32 pagesAstrology and MarriageprngalaNo ratings yet

- Fish Cum Pig CultureDocument18 pagesFish Cum Pig CultureMadhuban Bhattacharya50% (2)

- Chiling Injury As An Indicator of Critical Temperature For Cold Storage of Guava Cv. Allahabad SafedaDocument8 pagesChiling Injury As An Indicator of Critical Temperature For Cold Storage of Guava Cv. Allahabad SafedayunitaNo ratings yet

- Tank TOFD-Presentation PDFDocument31 pagesTank TOFD-Presentation PDFJavierfox98100% (2)

- The Effect of Clay Organophilization On Wood Plastic Composite (WPC) Based On Recycled High Density Polyethylene (HDPE) and Coir FiberDocument18 pagesThe Effect of Clay Organophilization On Wood Plastic Composite (WPC) Based On Recycled High Density Polyethylene (HDPE) and Coir FiberEliton Medeiros Candido de MacêdoNo ratings yet

- MitDocument7 pagesMitLam LagNo ratings yet

- Answers: T Est - 7Document10 pagesAnswers: T Est - 7Arunanshu PalNo ratings yet

- Kodak Plus XDocument12 pagesKodak Plus XjtmjtmjtmNo ratings yet

- Overview of Endo Physiology - HandoutDocument19 pagesOverview of Endo Physiology - HandoutVDiesel99No ratings yet

- Data SheetDocument14 pagesData SheetMelchiNo ratings yet

- Dr. Leonardo C. Medina JRDocument23 pagesDr. Leonardo C. Medina JRaaa100% (1)

- Erik Dick-Book Turbomachines PDFDocument16 pagesErik Dick-Book Turbomachines PDFmailsk12367% (3)

- Br. No-201 - Box Culvert 2cells - 5m X 2.5m - R1Document330 pagesBr. No-201 - Box Culvert 2cells - 5m X 2.5m - R1RameshNo ratings yet