Professional Documents

Culture Documents

10796524

10796524

Uploaded by

jeffturboCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10796524

10796524

Uploaded by

jeffturboCopyright:

Available Formats

CBA-Series Scotch-Yoke Pneumatic Actuators

Compact, Lightweight and Economical

I I I

PED 97/23/EC Compliant Xylan Coated Cylinder Water Ingress Protected IP66 and IP67M Low Maintenance Economical Jackscrew Option Five-Year Warranty Dual Mounting Interface Suitable for SIL 2 or SIL 3 Bi-directional Travel Adjustment

10 12 6

I I I I I I I

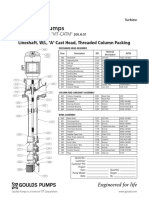

CBA-SERIES PNEUMATIC DESIGN AND CONSTRUCTION

Mechanical Components

The Bettis CBA-Series pneumatic actuators are compact, lightweight and ideally suited for automating ball, butterfly and non-lubricated plug valves, or any quarter-turn (90 degree) rotating mechanism. These economical, low maintenance actuators provide a reliable means of automating your valve. Available with optional features and controls to meet your most demanding automation needs. The CBA-Series, available in double-acting and spring-return models, are independently certified to BS 5490: 1977 - IP66 and IP67M for water ingress protection. temperature requirements exceed these limits. Operating pressures for the CBA-Series range from 40 to 150 PSIG (3 to 10 BAR).

Design Features

Water Ingress Protection The CBAs meet both IP66 and IP67M specifications for submergence and severe high pressure water deluge test, offering superior water ingress protection and corrosion resistance. The actuator has no gaskets and is totally o-ring sealed. 1) New, Outer Lip-Type Torque Shaft Seals restrict external contaminants, providing a high level of corrosion and water-resistance. 2) New O-Ring Sealed Cylinders essentially eliminate the possibility of any cylinder leakage throughout the full range of operating and climatic conditions. 3) Standard Accessory Mounting Pad The new accessory mounting pad is standard and identical on all CBA and CBA-300 Series models, allowing the panel mounting of controls. 4) Dual Valve Mounting Interface allows the flexibility to change the actuator fail mode, without disassembly, by simply inverting the actuator. They may be installed in any position; parallel or at right angles to the flow line, in the vertical or the horizontal plane.

Operating Ranges

Double-acting CBA-Series actuators are available with guaranteed minimum torque outputs to 11,515 lb-in (1,301 Nm). The CBA-Series spring-return models require pressure in only one direction of travel and are suitable for fail clockwise or counterclockwise applications without modification. These models produce guaranteed spring ending torques to 4,269 lb-in (482 Nm). Standard construction CBA-Series actuators are designed for operating temperatures of -20F to +200F (-29C to +93C). High temperature trim allows continuous operation from 0F to +350F (-18C to +177C). Additionally, special non-PED low temperature trim allows operation to -40F (-40C). Consult factory when

5 8

3 1 9 13

Model M3 Jackscrew shown (M3HW with optional handwheel not pictured).

7) New Piston Heel and Yoke Pin Bearings The CBA features PTFE/bronze bearings 11 on the actuators piston heel and yoke pin. These bearings help to assure smooth and consistent torque output, while enhancing total cycle life. 8) Ductile Iron Housing CBA actuator housings are made of pressure vessel quality ductile iron which is approved for use by ASME and the Pressure Equipment Directive (PED 97/23/EC). All housings have been optimized by finite element analysis and are designed for light weight while retaining maximum strength, ductility and corrosion resistance.

5) Jackscrew Option A blowout-proof economical jackscrew manual override is available as an option to the CBA models (see inset above). The jackscrew also acts as a stop adjustment screw. This feature has several advantages:

I

9) The Scotch-Yoke Mechanism transforms linear movement of the piston into a 90 degree rotation, providing optimum torque curves, ideal for most quarter-turn valve applications. 10) Center Bar, made of improved high strength alloy steel, guides the piston throughout its full stroke, preventing metal to metal contact with the cylinder bore. 11) Bi-directional Travel Stops are an integral part of the actuator allowing 80 to 100 total travel adjustment. Extended travel stops are optional. This feature provides an unmatched travel range to assist in prolonging valve seat integrity. 12) Springs High-strength, high-performance alloy carbon steel springs are protected by Tactyl 50, a pliable self-healing coating. Bettis takes and additional step and shot peens the springs, helping to extend the actuators spring cycle life. 13) Yoke Arm Bearing Washer Acetal bearings positively prevent metal-to-metal contact, helping to assure smooth and consistent torque output.

Produces full rated torque output in the event of air supply loss. During normal power operation, the manual override has no affect on actuator torque output or operating speed. Double-acting actuator models are available with one or two jackscrews.

6) XylanTM Cylinder Coating, the standard internal coating on all CBA-Series actuators. This fluoropolymer coating is highly resistant to abrasion, thermal shock and provides excellent lubricity and low friction properties. Corrosive salts and other chemicals normally found in the atmosphere or instrument air supply system will not adversely affect its performance. XylanTM bonds to the chemically prepared surface of the steel cylinder so effectively that, unlike other coatings, cracking and flaking are virtually eliminated.

SIZING AND SELECTION

General Definitions

To clarify and standardize terminology, Bettis offers the following definitions for terms commonly used. Please become familiar with and use the following standard definitions when referring to Bettis quarter-turn actuators. Quarter-turn: A device which rotates a minimum of 90 degrees. All Bettis quarter-turn actuators will rotate more than 90 degrees. Position: That degree of rotation describing an actuators current location. The mid position of a quarter-turn actuator is generally at forty-five (45) degrees. CW: Clockwise rotation. CCW: Counterclockwise rotation. Stroke: A continuous, ninety (90) degree rotation of a quarter-turn actuator. Bettis spring-return actuators have two (2) different strokes, a pressure stroke and a spring stroke. Bettis doubleacting actuators have two (2) pressure strokes. Note that rack and pinon actuators have common torque valves for both pressure strokes, while scotch yoke actuators have different torque values depending on which side of the piston is doing the work. Cycle: The collective reference to two (2) strokes, one (1) for clockwise (CW) rotation and one (1) for counterclockwise (CCW) rotation. Bettis actuators must rotate through two (2) stroke to complete one (1) cycle. Safety Factor: Represents a protective component (an adjustment to torque requirement) sometimes added to a valves required torque value. Often used when the user/specifier is not certain of the valves torque requirements, or because of other application concerns.

Actuator Selection Procedures

A) Determine the type of Bettis actuator required: double-acting or spring-return. B) Determine the power supply media: pneumatic or hydraulic, and the minimum/maximum supply pressure(s) at the actuator. C) Using this information, select the applicable torque rating table and see the appropriate following examples.

Scotch-Yoke, Double-Acting Actuators (example assumes CW to close)

Note: The valves torque requirements must be exceeded by the actuators torque output at all corresponding positions and directions of rotation. Bettis has included Start, Minimum, and End pressure torque outputs for your use. A) Using your minimum operating pressure, select an operating pressure column from the Pressure Torque Rating Section of less than or equal pressure. Move down the column until both starting and minimum output torques are found which exceed the valves maximum and minimum torque requirements. Determine the Bettis model number at the left, under the model number column. B) Once a Bettis actuator model has been selected, use the performance data tables to ensure your maximum supply pressure does not exceed the maximum operating pressure (M.O.P.) for your Bettis actuator. If the actuator selected is not rated for your maximum supply pressure, either the maximum supply pressure must be reduced or an actuator rated for a higher M.O.P. must be selected.

Sizing Bettis Actuators

The following information is generally the minimum required for sizing Bettis quarter-turn pneumatic and hydraulic actuators for specific valve requirements. A) An accurate maximum torque requirement must be obtained before actuator sizing begins. Normal maximum stem torque for a properly applied and maintained valve is usually defined as: The maximum starting torque required to rotate the valve element (ball, disc, plug, etc.) from a fully closed position (unsealing), against the maximum normal valve rated different pressures. Most valve manufacturers make adjustments in the form of torque amendments under various operating conditions. Application operating conditions such as temperature extremes, actual differential pressure, unusual loading, high flow rates, operating speeds, etc. are some of the most common causes for adjustments. Bettis recommends that the valve manufacturer supply the maximum required torque value(s) (including any adjustments or suggested safety factors). Additionally, the valve manufacturer must identify at which position(s) and direction(s) of rotation (CCW or CW) these maximum requirements occur. B) Bettis actuators include stops which will resist the maximum rated torque output of the actuator. The possibility exists, that should the valve become immobilized during rotation, the actuator could exceed the maximum allowable valve input torque rating. If this possibility is a concern, your application needs further review. Once the maximum torque requirements, its position, and direction of rotation are identified, the appropriate Bettis actuator can be selected from torque output charts on pages 47. 4

Scotch-Yoke, Spring-Return, Fail CLOCKWISE Actuators (example assumes CW to close)

Note: The valves maximum torque requirements must be exceeded by the actuators torque output at all corresponding positions and directions of rotation. Bettis has included Start, Minimum, and End Spring Torque outputs, as well as Start, Minimum and End Pressure Torque Outputs for your use. The minimum torque outputs listed on the Spring-Return torque charts are the lowest value of torque output available at any position, during either stroke (pressure or spring). A) Select from the Spring Torque column a Spring Ending torque output which exceeds that of the valves maximum seating requirement. B) Proceed to the right using your minimum operating pressure and select an operating pressure column from the Pressure Torque Rating Section of less than or equal pressure. The Pressure Start torque output must exceed the valves torque requirement at this position (unseating). The Pressure End torque output must exceed the valves torque requirement at this position (full flow) and direction of rotation (CCW). C) Once a Bettis actuator model has been selected, use the performance data tables to ensure your maximum supply pressure does not exceed the maximum operating pressure (M.O.P.) for your Bettis actuator. If the actuator selected is not rated for your maximum supply pressure, either the maximum supply pressure must be reduced or an actuator rated for a higher M.O.P. must be selected. Contact your local Authorized Bettis distributor or a Bettis manufacturing facility if you require assistance.

Performance Data CBA-Series (Pneumatic) Imperial & metric

Double-Acting Actuators

CBA-Series

Volumes Actuator Model Outboard Cu. Inches CBA 315 CBA 420 CBA 520 CBA 525 CBA 725 24 53 83 105 208 Cubic CM 393.3 868.5 1360.1 1720.6 3408.5 Inboard (Housing) Cu. Inches 54 115 148 207 327 Cubic CM 885.0 1884.5 2425.3 3392.1 5358.6 Maximum Operating Pressure (MOP)* PSIG 120 120 70 120 80 Bar 8.3 8.3 4.8 8.3 5.5 Maximum Allowable Working Pressure (MAWP)** PSIG 200 200 160 200 160 Bar 13.8 13.8 11.0 13.8 11.0 Approximate Weight of Actuator (MAWP)** Lbs. 20 22 28 44 68 KG 9.1 10.0 12.7 20.0 31.0

Spring-Return Actuators

CBA-Series

Actuator Model Volume Cu. Inches N CBA 315- SR40 SR60 SR80 SR100 N CBA 415- SR40 SR60 SR80 SR100 N CBA 420- SR40 SR60 SR80 SR100 N CBA 520- SR40 SR60 SR80 SR100 N CBA 525- SR40 SR60 SR80 SR100 N CBA 725- SR40 SR60 SR80 SR100 54 54 54 54 75 75 75 75 115 115 115 115 148 148 148 148 207 207 207 207 327 327 327 327 Cubic CM 885 885 885 885 1229 1229 1229 1229 1884.5 1884.5 1884.5 1884.5 2425.3 2425.3 2425.3 2425.3 3392 3392 3392 3392 5358.6 5358.6 5358.6 5358.6 Maximum Operating Pressure (MOP)* PSIG 155 152 150 164 100 112 117 114 157 156 161 166 110 116 120 132 146 151 159 163 102 115 124 124 Bar 10.7 10.5 10.3 11.3 6.9 7.7 8.1 7.9 10.8 10.8 11.0 11.4 7.6 8.0 8.3 9.1 10.1 10.4 11.0 11.2 7.0 8.0 8.6 8.6 Maximum Allowable Working Pressure (MAWP)** PSIG 200 200 200 200 160 160 160 160 200 200 200 200 160 160 160 160 200 200 200 200 160 160 160 160 Bar 13.8 13.8 13.8 13.8 11.0 11.0 11.0 11.0 13.8 13.8 13.8 13.8 11.0 11.0 11.0 11.0 13.8 13.8 13.8 13.8 11.0 11.0 11.0 11.0 Approximate Weight of Actuator Lbs. 22 23 26 25 27 29 30 31 37 39 40 41 45 48 49 53 62 65 65 67 97 98 104 107 KG 10.0 10.4 11.8 11.4 12.7 14.1 14.1 14.1 16.8 17.7 18.1 18.6 20.4 21.8 22.2 24.0 28.1 29.5 29.5 30.4 44.0 44.5 47.2 48.5

Notes:

N L * ** CBA-SRXXM mechanical handwheel overrides are available on these models. The override adds approximately 2 lbs. (.8 kg) to the weight of the standard CBA model. Maximum volume including cavity required for calculating consumption per stroke. Maximum Operating Pressure (MOP) is the pressure required to produce the maximum rated torque of the actuator. Maximum Allowable Working Pressure (MAWP) is the maximum static pressure that may be applied to a fully stroked actuator against the travel stops. Standard installation produces clockwise rotation when the outboard side of piston is pressurized. Standard installation produces counterclockwise rotation when the inboard side of piston is pressurized. Note: Actuator may be installed opposite of that shown above.

Torque Ratings CBA-Series (Pneumatic) Imperial

All Published Torques are Typical Minimum Values.

Double-Acting Actuators

CBA-Series

Actuator Model CBA 315 CBA 420 CBA 520 CBA 525 CBA 725 See Bettis Definitions Start/End Minimum Start/End Minimum Start/End Minimum Start/End Minimum Start/End Minimum 40 678 404 1536 871 2133 1302 2944 1720 5757 3434 50 848 505 1921 1089 2666 1628 3680 2150 7197 4292 Operating Pressure (PSIG) 60 70 80 90 Pressure Torque Output Start/Min./End (lb-in) 1017 606 2305 1307 3200 1954 4416 2580 8636 5151 1187 707 2689 1525 3733 2279 5152 3009 10075 6009 1356 808 3073 1743 1526 910 3457 1961 100 1695 1011 3841 2179 120 2034 1213 4609 2614

5888 3439 11515 6868

6624 3869

7361 4299

8833 5159

Notes:

Start: (starting) That torque output position at which an actuator produces its greatest torque output. The starting torque outputs listed in Bettis scotch-yoke torque output charts are the lesser of the two (2) pressure strokes, when there is a difference (different areas). Minimum: (min.) That torque output, at an intermediate position, at which an actuator produces its lowest torque output. The minimum torque outputs shown on Bettis pressure torque output charts are the lowest torque values produced during the pressure stroke(s). For double-acting actuators, this is also the mid position. End: (ending) That torque output position at which an actuator has reached the limit of a pressure stroke. For double-acting actuators the end torque output is equal to the start torque output.

Spring-Return Actuators

CBA-Series

Actuator Model CBA315 SR40 Spring Torque Start/Min./End (lb-in) Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End 350 151 202 598 238 305 757 306 402 1069 405 494 682 284 365 1076 431 577 1345 576 711 1659 673 756 40 375 158 216 50 531 247 377 438 153 172 Operating Pressure (PSIG) 60 70 80 90 Pressure Torque Output Start/Min./End (lb-in) 688 336 538 608 249 342 844 424 698 778 343 512 698 237 312 1000 512 859 948 436 681 884 328 498 1157 600 1020 1117 530 851 1069 418 683 876 331 421 2139 1105 1955 1811 934 1516 1648 772 1113 1701 542 564 100 1313 688 1181 1287 623 1021 1254 509 869 1053 428 600 2429 1268 2269 2088 1099 1822 1933 942 1414 2007 719 861 120 1626 864 1502 1627 808 1360 1625 689 1239 1406 621 957 150 2095 1128 1985 2136 1085 1870 2181 958 1795 1935 906 1493

CBA315 SR60

CBA315 SR80

CBA315 SR100

CBA415 SR40

692 285 387

CBA415 SR60

981 451 701 701 264 294

1271 614 1014 979 435 600

CBA415 SR80

1560 778 1328 1256 603 905 1077 428 510

1850 941 1641 1533 770 1211 1362 602 811

CBA415 SR100

Torque Ratings CBA-Series (Pneumatic) Imperial

All Published Torques are Typical Minimum Values.

Spring-Return Actuators

CBA-Series (continued)

Actuator Model CBA420 SR40 Spring Torque Start/Min./End (lb-in) Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End 591 301 479 1320 481 691 1661 655 901 2230 836 1119 1004 445 562 1719 747 966 2575 1019 1243 3880 1361 1715 1652 608 949 2527 983 1372 3038 1293 1680 4620 1676 2234 3148 1283 1641 5249 2106 2762 7370 2830 3330 9482 3260 4269 40 844 317 391 50 1173 500 709 Operating Pressure (PSIG) 60 70 80 90 Pressure Torque Output Start/Min./End (lb-in) 1501 680 1028 1333 480 562 1829 859 1346 1685 670 871 1468 481 502 2157 1037 1665 2037 860 1179 1825 690 844 2485 1215 1983 2390 1048 1488 2182 891 1187 1958 643 674 3783 1867 3568 3424 1685 2821 3183 1424 2095 2535 855 913 5074 2402 4401 4651 2198 3534 4133 1750 2589 3673 1369 1696 10484 4984 9648 8867 4511 7444 7726 3706 5444 7374 2478 2748 100 2813 1393 2302 2742 1235 1797 2539 1088 1529 2320 857 1021 4278 2137 4146 3934 1980 3399 3708 1734 2696 3067 1171 1491 5765 2752 5092 5351 2582 4244 4833 2138 3318 4392 1777 2454 11910 5716 11189 10217 5313 8984 9057 4541 7003 8781 3279 4250 120 3470 1748 2939 3446 1607 2415 3253 1480 2215 3044 1264 1716 150 4454 2282 3894 4503 2166 3341 4325 2068 3243 4130 1859 2758

CBA420 SR60

CBA420 SR80

CBA420 SR100

CBA520 SR40

1311 503 677

CBA520 SR60

1805 782 1255 1385 484 509

2300 1056 1834 1895 794 1087

CBA520 SR80

2794 1326 2412 2405 1095 1665 2133 790 893

3289 1596 2990 2914 1390 2243 2658 1111 1494

CBA520 SR100

CBA525 SR40

1619 638 946

CBA525 SR60

2310 993 1637 1849 632 694

3001 1345 2328 2549 1035 1404

CBA525 SR80

3692 1698 3019 3250 1425 2114 2732 966 1130

4383 2050 3710 3950 1814 2824 3432 1363 1859

CBA525 SR100

4757 2347 3898 4132 1773 2647 7147 3452 6474 6752 3348 5665 6234 2900 4777 5832 2581 3970

8854 4499 7795 8336 4042 6965 7991 3770 6245

CBA725 SR40

3354 1306 1948

CBA725 SR60

4780 2048 3488 3467 1234 1284

6206 2788 5028 4817 2080 2824

CBA725 SR80

7632 3520 6568 6167 2897 4364 5064 2018 2326

9058 4252 8108 7517 3709 5904 6395 2872 3885

CBA725 SR100

11719 6189 10122 11595 4828 7254

Notes: Spring-return, quarter-turn actuators use pressure and springs(s) to produce torque.

Start: (starting) That torque output position at which a spring-return actuator produces its greatest torque output during a spring stroke. The starting torque output listed in Bettis spring-return torque output charts is that torque output position, where the spring is fully compressed, and capable of transferring its maximum force. Minimum: (min.) That torque output, at an intermediate position, at which an actuator produces its lowest torque output. The minimum torque outputs listed on the Bettis spring torque output charts are the lowest value of torque output produced at any position, during either stroke (pressure or spring). End: (ending) That torque output position, at which an actuator has reached the limit of the spring stroke. The spring ending torque output values listed on Bettis spring-return torque output charts is the torque output value where the spring is fully extended and is transferring its lowest force value.

Torque Ratings CBA-Series (Pneumatic) metric

All Published Torques are Typical Minimum Values.

Double-Acting Actuators

CBA-Series

Actuator Model CBA315 CBA420 CBA520 CBA525 CBA725 See Bettis Definitions Start/End Minimum Start/End Minimum Start/End Minimum Start/End Minimum Start/End Minimum 3 83 50 189 107 262 160 362 211 708 422 3.5 97 58 220 125 306 187 422 247 826 492 Operating Pressure (Bar) 4 5 5.5 6 Pressure Torque Output Start/Min./End (Nm) 111 66 252 143 350 213 482 282 944 563 139 83 315 179 437 267 603 352 1179 703 153 91 346 196 167 99 378 214 7 194 116 441 250 8 222 133 504 286

663 387 1297 774

724 423

844 493

965 564

Notes:

Start: (starting) That torque output position at which an actuator produces its greatest torque output. The starting torque outputs listed in Bettis scotch-yoke torque output charts are the lesser of the two (2) pressure strokes, when there is a difference (different areas). Minimum: (min.) That torque output, at an intermediate position, at which an actuator produces its lowest torque output. The minimum torque outputs shown on Bettis pressure torque output charts are the lowest torque values produced during the pressure stroke(s). For double-acting actuators, this is also the mid position. End: (ending) That torque output position at which an actuator has reached the limit of a pressure stroke. For double-acting actuators the end torque output is equal to the start torque output.

Spring-Return Actuators

CBA-Series

Actuator Model CBA315-SR40 Spring Torque Start/Min/End (Nm) Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End 39 17 23 68 27 34 86 35 45 121 46 56 77 32 41 122 49 65 152 65 80 187 76 85 Operating Pressure (Bar) 3 49 21 31 3.5 61 29 44 51 18 21 4 5 5.5 6 7 Pressure Torque Output Start/Min./End (Nm) 74 100 113 125 151 36 51 58 65 79 57 84 97 110 136 65 93 107 121 148 26 41 49 57 72 35 63 76 90 118 84 99 115 145 29 37 44 59 41 56 71 101 93 122 34 50 42 71 137 185 208 232 279 66 93 106 119 146 108 159 185 210 262 104 150 173 195 241 45 73 87 100 127 61 111 136 161 211 130 153 176 223 53 68 82 109 66 91 116 165 182 232 54 84 54 102 8 177 94 162 176 87 146 175 74 132 151 66 100 9 202 108 189 204 102 174 206 89 162 180 81 129 10 228 123 215 232 117 202 236 103 192 209 97 159 11

CBA315-SR60

CBA315-SR80

CBA315-SR100

238 113 188

CBA415-SR40

90 39 56

CBA415-SR60

113 52 82 82 31 36

CBA415-SR80

270 137 214

CBA415-SR100

Torque Ratings CBA-Series (Pneumatic) metric

All Published Torques are Typical Minimum Values.

Spring-Return Actuators

CBA-Series (continued)

Actuator Model CBA420-SR40 Spring Torque Start/Min/End (Nm) Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End Start Min. End 67 34 54 149 54 78 188 74 102 252 94 126 113 50 64 194 84 109 291 115 140 438 154 194 187 69 107 286 111 155 343 146 190 522 189 252 356 145 185 593 238 312 833 320 376 1071 368 482 Operating Pressure (Bar) 3 108 43 57 3.5 135 58 83 4 5 5.5 6 7 Pressure Torque Output Start/Min./End (Nm) 162 216 243 270 324 73 102 117 131 160 109 161 187 213 266 143 200 229 258 316 50 81 97 112 143 56 107 132 158 208 176 205 235 293 61 77 94 126 66 94 123 179 209 268 64 100 64 121 249 330 370 411 492 113 158 180 202 246 194 289 336 384 478 203 286 328 370 453 83 132 156 180 229 110 205 252 299 394 256 299 342 428 98 125 150 201 118 167 216 315 268 356 84 138 84 178 324 437 493 550 663 144 202 231 260 317 248 361 417 474 587 272 387 445 502 617 108 172 204 235 298 143 259 317 375 492 329 386 443 558 121 153 185 248 148 208 268 387 391 509 141 208 166 290 669 903 1020 1137 1370 297 419 479 539 658 534 786 912 1038 1291 514 735 846 956 1178 217 351 417 483 614 284 537 663 789 1042 610 719 828 1046 253 322 391 527 307 435 563 818 786 1016 251 384 260 506 8 377 190 318 374 173 259 352 158 235 328 134 178 9 431 219 370 431 204 310 410 191 291 387 166 235 10 485 248 422 489 234 360 469 223 347 446 199 292 11

CBA420-SR60

CBA420-SR80

CBA420-SR100

527 255 403 506 232 349

CBA520-SR40

168 68 99

CBA520-SR60

208 91 147 161 58 62

CBA520-SR80

CBA520-SR100

CBA525-SR40

210 86 134

CBA525-SR60

267 115 191 215 75 85

CBA525-SR80

CBA525-SR100

537 277 489 514 251 413 443 187 273 776 374 700 732 361 608 673 311 507 627 274 415

530 236 368 890 432 814 846 424 725 788 373 627 745 339 539

1003 489 927 961 487 841 903 435 746 862 404 663

1017 498 866 980 469 787

CBA725-SR40

436 175 281

CBA725-SR60

552 236 407 403 147 158

CBA725-SR80

CBA725-SR100

1399 745 1294 1264 662 1074 1247 511 752

Notes: Spring-return, quarter-turn actuators use pressure and springs(s) to produce torque.

Start: (starting) That torque output position at which a spring-return actuator produces its greatest torque output during a spring stroke. The starting torque output listed in Bettis spring-return torque output charts is that torque output position, where the spring is fully compressed, and capable of transferring its maximum force. Minimum: (min.) That torque output, at an intermediate position, at which an actuator produces its lowest torque output. The minimum torque outputs listed on the Bettis spring torque output charts are the lowest value of torque output produced at any position, during either stroke (pressure or spring). End: (ending) That torque output position, at which an actuator has reached the limit of the spring stroke. The spring ending torque output values listed on Bettis spring-return torque output charts is the torque output value where the spring is fully extended and is transferring its lowest force value.

Dimensions CBA-Series (Pneumatic) Imperial

Double-Acting Actuators CBAXXX

Actuator Model CBA315 CBA420 CBA520 CBA525 CBA725

A 14.16 16.43 16.46 19.22 19.44

B 7.38 8.57 8.63 9.88 10.24

C 3.25 4.25 5.38 5.38 7.50

D 1.09 1.38 1.38 1.69 1.69

E 1.88 2.13 2.07 2.56 2.53

F 3.46 4.37 4.37 5.00 5.00

G 0.94 1.10 1.10 1.25 1.25

H .94 1.10 1.10 1.25 1.25

J/K 1/4 NPT 3/8 NPT 3/8 NPT 3/8 NPT 3/8 NPT

L .313-18 UNC .375-16 UNC .375-16 UNC .500-13 UNC .500-13 UNC

M .38 .50 .50 .50 .50

N 2.250 3.000 3.000 3.500 3.500

Actuator Model CBA315 CBA420

P .313-18 UNC .375-16 UNC

Q 1.125 1.500 1.500 1.750 1.750

R 2.91 3.35 3.35 4.38 4.38

S 5.81 6.69 6.69 8.75 8.75

T .75 .75 .75 1.12 1.12

U 2.22 2.81 2.81 3.50 3.50

V 5.18 6.25 6.25 7.58 7.58

CBA520 .375-16 UNC CBA525 .500-13 UNC CBA725 .500-13 UNC

W .614 .620 .864 .870 .864 .870 1.115 1.121 1.115 1.121

X 1.03 1.03 1.03 1.50 1.50

Y 3.75 4.63 4.63 5.75 5.75

Z 1.09 1.38 1.38 1.69 1.69

AA 0.873 0.875 1.123 1.125 1.121 1.125 1.498 1.500 1.498 1.500

Note: Not Certified dimensional drawings. Such drawings available on request. Contact factory with correct model designation and serial number. All dimensions are expressed in inches.

10

Dimensions CBA-Series (Pneumatic) metric

Double-Acting Actuators CBAXXX

Actuator Model CBA315 CBA420 CBA520 CBA525 CBA725

A 359.8 417.3 418.1 488.1 492.7

B 187.5 217.6 219.2 250.9 260.1

C 82.6 108.0 136.7 136.7 190.5

D 27.8 34.9 34.9 42.9 42.9

E 47.8 54.1 53.5 65.0 64.2

F 87.8 111.0 111.0 127.0 127.0

G 23.8 27.9 27.9 31.8 31.8

H 23.9 27.9 27.9 28.4 28.4

J/K 1/4 NPT 3/8 NPT 3/8 NPT 3/8 NPT 3/8 NPT

L .313-18 UNC .375-16 UNC .375-16 UNC .500-13 UNC .500-13 UNC

M 9.7 12.7 12.7 12.7 12.7

N 57.2 76.2 76.2 88.9 88.9

Actuator Model CBA315 CBA420

P .313-18 UNC .375-16 UNC

Q 28.6 38.1 38.1 44.5 44.5

R 73.8 85.1 85.1 111.1 111.1

S 147.6 169.9 169.9 222.3 222.3

T 19.1 19.1 19.1 28.4 28.4

U 56.4 71.3 71.3 88.9 88.9

V 131.5 158.9 158.9 192.6 192.6

CBA520 .375-16 UNC CBA525 .500-13 UNC CBA725 .500-13 UNC Note: Not Certied dimensional drawings. Such drawings available on request. Contact factory with correct model designation and serial number.

W 15.6 15.73 22.09 21.09 22.09 21.09 28.33 24.47 28.32 28.48

X 26.2 26.2 26.2 38.1 38.1

Y 95.3 117.5 117.5 146.1 146.1

Z 27.8 35.1 35.1 42.9 42.9

AA 22.15 22.25 28.5 28.6 28.5 28.6 38.02 38.12 38.02 38.12

All dimensions are expressed in millimeters.

11

Dimensions CBA-Series (Pneumatic) Imperial

Spring Return Actuators CBA XXX-SRX

Actuator Model CBA315-SRX CBA415-SRX CBA420-SRX CBA520-SRX CBA525-SRX CBA725-SRX Actuator Model CBA315-SRX CBA415-SRX CBA420-SRX CBA520-SRX CBA525-SRX CBA725-SRX

A 20.13 20.20 24.54 24.88 28.21 28.09

B 13.66 13.71 17.07 17.44 18.01 18.37

C 3.25 4.25 4.25 5.38 5.38 7.50

D 1.09 1.09 1.38 1.38 1.69 1.69

E 1.88 1.88 2.13 2.07 2.56 2.53

F 3.46 3.46 4.37 4.37 5.00 5.00

G 0.94 0.94 1.10 1.10 1.25 1.25

H .94 .94 1.10 1.10 1.25 1.25

J/K 1/4 NPT 1/4 NPT 3/8 NPT 3/8 NPT 3/8 NPT 3/8 NPT

L .313-18 UNC .313-18 UNC .375-16 UNC .375-16 UNC .500-13 UNC .500-13 UNC

M .38 .38 .50 .50 .50 .50

N 2.250 2.250 3.000 3.000 3.500 3.500

P .31318 UNC .313 -18 UNC .375 -16 UNC .375 -16 UNC .500 -13 UNC .500 -13 UNC

Q 1.125 1.125 1.500 1.500 1.750 1.750

R 2.91 2.91 3.35 3.35 3.50 3.50

S 5.81 5.81 6.69 6.69 8.75 8.75

T .75 .75 .75 .75 1.12 1.12

U 2.22 2.22 2.81 2.81 3.50 3.50

V 5.18 5.18 6.25 6.25 7.58 7.58

W .614 .620 .614 .620 .864 .870 .864 .870 1.115 1.121 1.115 1.121

X 1.03 1.03 1.03 1.03 1.50 1.50

Y 3.75 3.75 4.63 4.63 5.75 5.75

Z 1.09 1.09 1.38 1.38 1.69 1.69

AA 0.873 0.875 0.871 0.875 1.123 1.125 1.121 1.125 1.498 1.500 1.498 1.500

Note: Not Certified dimensional drawings. Such drawings available on request. Contact factory with correct model designation and serial number. All dimensions are expressed in inches.

12

Dimensions CBA-Series (Pneumatic) metric

Spring Return Actuators CBA XXX-SRX

Actuator Model CBA315-SRX CBA415-SRX CBA420-SRX CBA520-SRX CBA525-SRX CBA725-SRX Actuator Model CBA315-SRX CBA415-SRX CBA420-SRX CBA520-SRX CBA525-SRX CBA725-SRX

A 511.2 513.3 623.3 631.9 716.6 713.6

B 347.0 348.2 433.5 442.9 457.4 466.7

C 82.6 108.0 108.0 136.7 136.7 190.5

D 27.8 27.8 34.9 34.9 42.9 42.9

E 47.8 47.8 54.1 52.2 65.0 64.2

F 87.8 87.8 111.0 111.0 127.0 127.0

G 23.8 23.9 27.9 27.9 31.8 31.8

H 23.9 23.9 27.9 27.9 28.4 28.4

J/K 1/4 NPT 1/4 NPT 3/8 NPT 3/8 NPT 3/8 NPT 3/8 NPT

L .313-18 ULC .313-18 ULC .375-16 UNC .375-16 UNC .500-13 UNC .500-13 UNC

M 9.7 9.7 12.7 12.7 12.7 12.7

N 57.2 57.2 76.2 76.2 88.9 88.9

P .31318 UNC .313 -18 UNC .375 -16 UNC .375 -16 UNC .500 -13 UNC .500 -13 UNC

Q 28.6 28.6 38.1 38.1 44.5 44.5

R 73.8 73.8 85.1 85.1 111.1 111.1

S 147.6 147.6 169.9 169.9 222.3 222.3

T 19.1 19.1 19.1 19.1 28.4 28.4

U 56.4 56.4 71.3 71.3 88.9 88.9

V 131.5 131.5 158.9 158.9 192.6 192.6

W 15.6 15.73 15.59 15.75 22.09 21.09 22.09 21.09 28.33 24.47 28.32 28.48

X 26.2 26.2 26.2 26.2 38.1 38.1

Y 95.3 95.3 117.5 117.5 146.1 146.1

Z 27.8 27.8 35.1 35.1 42.9 42.9

AA 22.15 22.25 22.12 22.22 28.5 28.6 28.5 28.6 38.02 38.12 38.02 38.12

Note: Not Certied dimensional drawings. Such drawings available on request. Contact factory with correct model designation and serial number. All dimensions are expressed in millimeters.

13

Dimensions CBA-Series (Pneumatic) in/mm

Double-Acting Actuators CBA XXX-M3HW

M3HW Override

Actuator Model CBA315-M3HW CBA420-M3HW CBA520-M3HW CBA525-M3HW CBA725-M3HW in mm in mm in mm in mm in mm

A 25.23 640.8 30.58 776.8 30.58 776.8 36.52 927.5 36.65 930.8

B 13.01 365.0 15.82 401.8 15.85 402.5 18.92 480.5 19.08 484.6

C 3.25 82.6 4.25 108.0 5.25 133.4 5.25 133.4 7.50 190.5

D 6.00 152.4 8.00 203.2 8.00 203.2 10.00 254.0 10.00 254.0

E 1/4 NPT 3/8 NPT 3/8 NPT 3/8 NPT 3/8 NPT

F 1/4 NPT 3/8 NPT 3/8 NPT 3/8 NPT 3/8 NPT

G 1.88 47.6 2.13 54.0 2.09 53.2 2.56 65.0 2.53 64.2

H 24.21 614.9 29.12 739.6 29.06 738.0 34.17 867.9 34.17 867.9

J 14.37 365.0 17.37 441.1 17.37 441.1 20.31 515.8 20.31 515.8

K 3.47 88.2 4.38 111.1 4.38 111.1 5.00 127.0 5.00 127.0

Spring Return Actuators CBA XXX-SRX-M3

Note: Not Certified dimensional drawings. Such drawings available on request. Contact factory with correct model designation and serial number. All dimensions are expressed in inches. Actuator Model CBA315-SR-M3HW CBA415-SR-M3HW CBA420-SR-M3HW CBA520-SR-M3HW CBA525-SR-M3HW CBA725-SR-M3HW in mm in mm in mm in mm in mm in mm

A 26.66 677.1 26.74 679.1 32.13 816.2 32.16 816.8 36.93 937.9 36.98 939.2

B 14.43 366.5 14.51 368.6 17.37 441.3 17.43 442.7 19.33 491.0 19.41 493.1

C 3.25 82.6 4.25 108.0 4.25 108.0 5.38 136.7 5.38 136.7 7.50 190.5

D 6.00 152.4 6.00 152.4 8.00 203.2 8.00 203.2 10.00 254.0 10.00 254.0

E 1/4 NPT 1/4 NPT 3/8 NPT 3/8 NPT 3/8 NPT 3/8 NPT

F 9.84 249.9 9.84 249.9 11.69 297.0 11.69 297.0 13.86 351.9 13.86 352.1

G 1.88 47.6 1.88 47.6 2.13 54.0 2.09 53.2 2.56 65.0 2.53 64.2

H 3.47 88.2 3.47 88.2 4.38 111.1 4.38 111.1 5.00 127.0 5.00 127.0

14

Options

SIL-PAC

The unique SIL-PAC solution provides a complete hardware and Bettis-supplied documentation package, embracing IEC, ISA and OSHA standards, for use in a SIL application. The CBA-Series actuators have a Failure Modes and Effects Diagnostics Analysis (FMEDA) report performed by Exida.com for SIL suitability. They can be combined with other components such as solenoid valves, switches and regulators. When Fishers TV-certified FIELDVUE DVC controller is added, SIL-PAC is capable of partial stroke testing PLUS providing continuous monitoring of supply pressure, valve position and pressure values to the actuator to verify its proper working condition. The SIL-PAC package can then be mounted on the appropriate quarter-turn valve as a final control solution suitable for SIL1, 2 or 3 applications.

Bettis Automated Packages

Bettis offers complete packages as a solution for final valve control. Bettis has the capability to combine the CBA actuator, necessary controls and selected valve into a single system perfect for large international projects. With this capability, Bettis can integrate its products with the complete offering of control options, including world-class PlantWeb digital plant architecture and the entire range of Emerson automation solutions.

BettiSystemsTM

Bettis has pre-engineered and documented a series of commonly required control systems. These approved systems utilize standard components, reduce lead times, and simplify purchasing, installation and start-up. Please consult the factory for additional information.

M3/M3HW

This blowout-proof Jackscrew manual override is a mechanical advantage device threaded through a special adapter or the end cap of the CBA-Series cylinder to exert linear thrust on the actuators piston rod. The Jackscrew override is available for all CBA models, with (HW) or without handwheel. It provides fully-rated torque output if air supply is lost.

BettiStopTM Partial Stroke Test Device

This external-mount device is sandwiched between the CBA-Series actuator and the valve. It is ideal for periodic testing of Emergency Shutdown valves (ESD) while remaining in service and is used for other safety process flow applications. It is particularly useful where compliance with ANSI/ISA S84.01, OSHA CFR 1910.119 and IEC 61508/61511 are applicable. The BettiStop can test a valve automation package by mechanically limiting valve stem rotation, clockwise or counter-clockwise, to 20 degrees as standard or 15 degrees optionally. When disengaged, the BettiStop does not interfere with the actuated valve. Consult factory for additional information.

15

ORDERING / MODEL DESIGNATION

Spring-Return Example

CBA 4 20 SR80-M3-CW

Fail CW or CCW Jackscrew Override Spring-Return (80 PSIG nominal) Nominal Moment Arm (e.g. 2.0 In.) Nominal Cylinder Size (4.0 In.) Center Bar

OPTIONAL FEATURES

Fail-Safe Operation

Each Bettis CBA actuator is capable of compressed gas (air) or a mechanical spring.

Double-Acting Example

CBA 3 15

Nominal Moment Arm (e.g. 1.5 In.) fail-safe operation using either stored Nominal Cylinder Size (3.0 In.) Center Bar

Trims

Trim options for CBA-Series actuators include seals for high and low temperature applications and no copper or yellow metals. The N-Series actuator is designed to resist affects of environmental conditions and seismic loading design criteria imposed by the Nuclear Power Industry. Consult Bettis for more information on these and other specific trims.

Contact Us: Emerson Process Management, Valve Automation facilities at your nearest location:

North & South America 18703 GH Circle PO Box 508 Waller, Texas 77484 USA T +1 281 727 5300 F +1 281 727 5353 2500 Park Avenue West Mansfield, Ohio 44906 USA T +1 419 529 4311 F +1 419 529 3688 9009 King Palm Drive Tampa , Florida 33619 USA T +1 813 630 2255 F +1 813 630 9449 4112-91A Street Edmonton, Alberta T6E5V2 Canada T +1 780 450 3600 F +1 780 450 1400 Av. Hollingsworth,325 Iporanga Sorocaba, SP 18087-105 Brazil T +55 15 3238 3788 F +55 15 3228 3300 Europe Asveldweg 11 7556 BT Hengelo(O) The Netherlands T +31 74 256 1010 F +31 74 291 0938 Siemensring 112 D-47877 Willich Germany T +49 2154 499 660 F +49 2154 499 6613 25, Rue de Villeneuve Silic BP 40434 94583 RUNGIS, France T +33 1 49 79 73 00 F +33 1 49 79 73 99 6 Bracken Hill South West Industrial Estate Peterlee, Co Durham SR82LS, United Kingdom T +44 191 518 0020 F +44 191 518 0032 3 Furze Court 114 Wickham Road Fareham, Hampshire PO167SH ,United Kingdom T +44 132 984 8900 F +44 132 984 8901 Middle East & Africa 2 Monteer Road, Isando Kempton Park, 1600 South Africa T +27 11 974 3336 F +27 11 974 7005 PO Box 17033 Jebel Ali Free Zone Dubai, United Arab Emirates T +971 4883 5235 F +971 4883 5312 Asia Pacific 9 Gul Road #01-02 Singapore 629361 T +65 6501 4600 F +65 6268 0028 9/F Gateway Building No.10 Ya Bao Road Chaoyang District Beijing, P.R. China T +86 10 5821 1188 F +86 10 5821 1100 No 15 Xing Wang Road Wuqing Development Area Tianjin 301700 P.R. China T +86 22 8212 3300 F +86 22 8212 3308 Lot 13111, Mukim Labu, Kawasan Perindustrian Nilai 71807 Nilai, Negeri Sembilan Malaysia T +60 6 799 2323 F +60 6 799 9942 471 Mountain Highway Bayswater, Victoria 3153 Australia T +61 3 9721 0200 F +61 3 9720 0588 301, Solitaire Corporate Park 151, M.V. Road, Andheri(E) Mumbai-400093, Maharashtra, India T +91 22 6694 2711 F +91 22 2825 3394 NOF Shinagawa Konan Building 1-2-5, Higashi-shinagawa Shinagawa-Ku, Tokyo 140-0002 Japan T +81 3 5769 6873 F +81 3 5769 6902

2008 Emerson Process Management. All rights reserved. The Emerson logo is a trademark and service mark of Emerson Electric Co. Brand mark listing are marks of one of the Emerson Process Management family of companies. All other marks are property of their respective owners. The contents of this publication are presented for information purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and conditions, which are available on request. We reserve the right to modify or improve the designs or specifications of our products at any time without notice. The color orange, U.S. Reg. No. 2,739,393, is a registered trademark of the Bettis Corporation.

www.Bettis.com

Bettis Brochure # 20.00-6 REV: 6-08 5M/6-08

You might also like

- Hoc3 CatalogoDocument12 pagesHoc3 CatalogoChristianReinoso0% (1)

- Cambridge Lower Secondary Checkpoint: Science 1113/02Document18 pagesCambridge Lower Secondary Checkpoint: Science 1113/02F1yguy480% (10)

- KCDocument3 pagesKCSandheepKumarNo ratings yet

- 04 Samss 042Document6 pages04 Samss 042ShojikuriakoseTNo ratings yet

- Crosby-Pentair JOS-E Series DatasheetDocument14 pagesCrosby-Pentair JOS-E Series Datasheetjromero_rpg100% (1)

- CH 08Document10 pagesCH 08chaitanyacheggNo ratings yet

- Bettis CBB SerieDocument6 pagesBettis CBB SerieCarlos GonzalezNo ratings yet

- Bettis Valve Actuator GuideDocument12 pagesBettis Valve Actuator Guideprufino2No ratings yet

- Specification For GasketsDocument8 pagesSpecification For GasketsMehdi NouriNo ratings yet

- Pneumatic Actuated Ball Valve PE4320Document2 pagesPneumatic Actuated Ball Valve PE4320Fa ChNo ratings yet

- 04-SAMSS-053 - Nov. 28, 2013Document8 pages04-SAMSS-053 - Nov. 28, 2013LainhatanhNo ratings yet

- Bidirectional Sealing Ball Valves in Power ApplicationsDocument3 pagesBidirectional Sealing Ball Valves in Power Applicationsxisefengchuang100% (1)

- Choke Specification - CCIDocument4 pagesChoke Specification - CCIAakashRanjanNo ratings yet

- Hydraulics CurriculumDocument8 pagesHydraulics CurriculumChris ChrisNo ratings yet

- 3 - Rite Manual de Instalacion y MantenimientoDocument18 pages3 - Rite Manual de Instalacion y MantenimientoRoman Arango Herrera0% (1)

- Project ReportDocument36 pagesProject Reportvishi89No ratings yet

- Flowtop-726 & 738 & 740Document32 pagesFlowtop-726 & 738 & 740sonalpanchal7No ratings yet

- Operating Manual: Eagleburgmann Mechanical Seal (M.S.)Document24 pagesOperating Manual: Eagleburgmann Mechanical Seal (M.S.)Morteza ShakerienNo ratings yet

- API 6A and 6D Ball ValvesDocument27 pagesAPI 6A and 6D Ball ValveszayerirezaNo ratings yet

- WKM DynaSeal 370D4 PDFDocument40 pagesWKM DynaSeal 370D4 PDFAlfredo MedinaNo ratings yet

- ValveDocument127 pagesValveAgung SubektiNo ratings yet

- SC/V - Valve Actuator Spring Return: Instruction Manual 5018Document49 pagesSC/V - Valve Actuator Spring Return: Instruction Manual 5018kaicyemNo ratings yet

- EFCO Valve Repair ProductsDocument20 pagesEFCO Valve Repair Productsjay_rajeshirkeNo ratings yet

- MIL 41000 New - Heavy Duty Cage Guided Control ValvesDocument36 pagesMIL 41000 New - Heavy Duty Cage Guided Control ValvesGovarthanan GopalanNo ratings yet

- Gland Packing InstallationDocument2 pagesGland Packing InstallationPramod Kumar GiriNo ratings yet

- Iso 10100Document16 pagesIso 10100Fabio StuiNo ratings yet

- Surge Relief Valve Definition Function Types Sizing SelectionDocument6 pagesSurge Relief Valve Definition Function Types Sizing Selectionkamala 123100% (1)

- Sundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementDocument1 pageSundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementmohammadNo ratings yet

- M7..dw.. en PDFDocument25 pagesM7..dw.. en PDFkiranNo ratings yet

- Sample Pump Rebuild Report - 0Document21 pagesSample Pump Rebuild Report - 0Trịnh Đức Hạnh100% (1)

- 28.GOMA Pump T-8000 CatalougeDocument2 pages28.GOMA Pump T-8000 Catalougeramesh babuNo ratings yet

- IP Pump DataSheet CNLBDocument2 pagesIP Pump DataSheet CNLBVikk Suriya100% (1)

- WKM Pow R Seal Gate Valves BrochureDocument28 pagesWKM Pow R Seal Gate Valves BrochureKhai Huynh100% (1)

- Catálogo HP Hoses - enDocument28 pagesCatálogo HP Hoses - enJavier Alfonso FernandezNo ratings yet

- Valvulas de SeguridadDocument4 pagesValvulas de Seguridadleonardo_cortes_90No ratings yet

- MOGAS Refinery Valve SolutionDocument28 pagesMOGAS Refinery Valve SolutionFaizal AbdullahNo ratings yet

- Grove g4n Gate Valve BrochureDocument24 pagesGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- ITT Gould PumpsDocument2 pagesITT Gould PumpsBilly ZununNo ratings yet

- DBBV-O & M ManualDocument36 pagesDBBV-O & M ManualMuneeshNo ratings yet

- CPKDocument2 pagesCPKMayank PatelNo ratings yet

- Tightening Torques Lubricants Tools: AB 0100 EN Servicing SAMSON ProductsDocument174 pagesTightening Torques Lubricants Tools: AB 0100 EN Servicing SAMSON ProductsGordinhorsNo ratings yet

- Bifold UpdatedDocument8 pagesBifold UpdatedGopinath GunasekaranNo ratings yet

- Perar Compact Ball ValvesDocument16 pagesPerar Compact Ball ValvesUday GokhaleNo ratings yet

- BFP ARC Valve FunctionDocument6 pagesBFP ARC Valve FunctionVenkat ShanNo ratings yet

- Chapter C14: Hydrodynamic PV LimitDocument7 pagesChapter C14: Hydrodynamic PV LimitkiranNo ratings yet

- Triple-Offset Butterflyvalves PDFDocument8 pagesTriple-Offset Butterflyvalves PDFDiwakar NigamNo ratings yet

- Asme Section II A Sa-192 Sa-192mDocument4 pagesAsme Section II A Sa-192 Sa-192mAnonymous GhPzn1xNo ratings yet

- Avk Saudi National Price ListDocument46 pagesAvk Saudi National Price Listjanpaul2481No ratings yet

- NAHAD Hydraulic Hose Assembly GuidelinesDocument65 pagesNAHAD Hydraulic Hose Assembly GuidelinesLuhur BudiNo ratings yet

- As 3791-1991 Hydraulic HoseDocument7 pagesAs 3791-1991 Hydraulic HoseSAI Global - APAC0% (1)

- Robert Cort Brochure Oct12Document8 pagesRobert Cort Brochure Oct12vishnuNo ratings yet

- kfp3 Ball ValvesDocument20 pageskfp3 Ball ValvesKristy DavisNo ratings yet

- Brochure 1Document20 pagesBrochure 1련서긔No ratings yet

- Corken Compresores Amoniaco PDFDocument100 pagesCorken Compresores Amoniaco PDFNicolas BurgosNo ratings yet

- Maverick Valves CatalogueDocument84 pagesMaverick Valves Cataloguer4mms3sNo ratings yet

- MegaCPK Curvas 50 HZDocument142 pagesMegaCPK Curvas 50 HZFlores AlbertoNo ratings yet

- Mud Gate ValveDocument16 pagesMud Gate ValvesudhisnairNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- CBA-Series Scotch-Yoke Pneumatic ActuatorsDocument4 pagesCBA-Series Scotch-Yoke Pneumatic Actuatorsprihartono_diasNo ratings yet

- Bettis CBB 1Document5 pagesBettis CBB 1Avura EdorNo ratings yet

- Valve Automation Brochure USDocument8 pagesValve Automation Brochure USprufino2No ratings yet

- A How To Guide For Adsorber Design 1Document27 pagesA How To Guide For Adsorber Design 1jesiNo ratings yet

- Beginners Guide To Fired Heaters (Rev00) PDFDocument11 pagesBeginners Guide To Fired Heaters (Rev00) PDFkutts76No ratings yet

- Deformation and Deformation RateDocument25 pagesDeformation and Deformation Ratekutts76No ratings yet

- Content: 1 Introduction. Rheology: Subject and Language 1 2 Stresses 9Document4 pagesContent: 1 Introduction. Rheology: Subject and Language 1 2 Stresses 9kutts76No ratings yet

- BAP Choke CatalogDocument26 pagesBAP Choke Catalogkutts76No ratings yet

- 5990 8243ENGasCleanFiltersDocument8 pages5990 8243ENGasCleanFilterskutts76No ratings yet

- Performance Characteristics of Axial FansDocument4 pagesPerformance Characteristics of Axial Fanskutts76No ratings yet

- + Text Only Site + Non-Flash Version + Contact GlennDocument3 pages+ Text Only Site + Non-Flash Version + Contact Glennkutts76No ratings yet

- Offshore CablesDocument96 pagesOffshore Cableskutts76No ratings yet

- Products: Elect. & Inst.: Page 1 of 5Document5 pagesProducts: Elect. & Inst.: Page 1 of 5kutts76No ratings yet

- N2 Generators BulletinDocument8 pagesN2 Generators Bulletinkutts76No ratings yet

- Kinetics OverviewDocument128 pagesKinetics OverviewDr. Srinivas MandavaNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Waterpollution 150120063202 Conversion Gate02Document64 pagesWaterpollution 150120063202 Conversion Gate02JM MagayanesNo ratings yet

- Tab 04-Setting ToolsDocument20 pagesTab 04-Setting ToolsRizwan Farid100% (1)

- Bs-Vi Fuel Quality Upgradation Project: Pre Feasibility ReportDocument41 pagesBs-Vi Fuel Quality Upgradation Project: Pre Feasibility Reportrajeev kumarNo ratings yet

- Stoichiometry - Mole To MoleDocument14 pagesStoichiometry - Mole To MoleClaudia JaukinNo ratings yet

- BCHM 201 Amino AcidDocument28 pagesBCHM 201 Amino AcidHabila OniNo ratings yet

- Cera System Catalogue 2011Document36 pagesCera System Catalogue 2011prihartono_diasNo ratings yet

- Cs 9003Document22 pagesCs 9003ibrahime mohammed100% (1)

- Be It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledDocument7 pagesBe It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledArJanNo ratings yet

- Flare Gas ST100 Series Guide Rev - PDFDocument6 pagesFlare Gas ST100 Series Guide Rev - PDFMatthew FreemanNo ratings yet

- Astm e 1019 - 03 Leco CS NoDocument21 pagesAstm e 1019 - 03 Leco CS NoPYDNo ratings yet

- Physci Q1 M3Document74 pagesPhysci Q1 M3Julie Anne Portal - OdascoNo ratings yet

- DCW Annual Reprot 2020-21Document170 pagesDCW Annual Reprot 2020-21Gourav MalpaniNo ratings yet

- A ReviewDocument17 pagesA ReviewkanomasiNo ratings yet

- Daily InventoryDocument3 pagesDaily InventoryGrace SevillaNo ratings yet

- Industrial Wastewater Treatment by AS PDFDocument404 pagesIndustrial Wastewater Treatment by AS PDFGustavo Mayen100% (2)

- Hydraulic Tubing PunchDocument19 pagesHydraulic Tubing Punchu2006262918No ratings yet

- Vapour Phase Grown Carbon FibreDocument3 pagesVapour Phase Grown Carbon FibreJOGHEE MANIVANNANNo ratings yet

- AMYE Heat Stake Technical Document 03-2016 PDFDocument10 pagesAMYE Heat Stake Technical Document 03-2016 PDFraj_375637980No ratings yet

- Flexicom: Installation and ServicingDocument64 pagesFlexicom: Installation and ServicingDave AllenNo ratings yet

- Nanotecnology Review PDFDocument16 pagesNanotecnology Review PDFCamille Nunes LeiteNo ratings yet

- Fatigue in Steel StructuresDocument7 pagesFatigue in Steel StructuresWahid OmarNo ratings yet

- CHAPTER 3 Fuels and CombustionDocument62 pagesCHAPTER 3 Fuels and CombustionRushabh Patel100% (1)

- OwnersManChemstar 1400N 1402N 1376N 1374NDocument36 pagesOwnersManChemstar 1400N 1402N 1376N 1374NvankarpNo ratings yet

- Cerebral EdemaDocument15 pagesCerebral EdemaMae FlagerNo ratings yet

- Castors and WheelsDocument29 pagesCastors and WheelsJohan ConradieNo ratings yet

- Encyclopedia How Things Are Made Volume FiveDocument370 pagesEncyclopedia How Things Are Made Volume Fivei_b_2hot4u185No ratings yet