Professional Documents

Culture Documents

200101463

Uploaded by

Ben GeorgeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

200101463

Uploaded by

Ben GeorgeCopyright:

Available Formats

INTRODUCTION TO COMPUTER NUMERICAL CONTROL (CNC)

FOURTH EDITION

James Y.Valentino Joseph Goldenberg

PEARSON

Prentice Hall

Upper Saddle River, New Jersey Columbus, Ohio

CONTENTS

CHAPTER I

Introduction to Computer Numerical Control Manufacturing I I

I I Chapter Objectives 1 2 Introduction I

1 3 Numerical Control Definition, Its Concepts and Advantages 1-5 Advantages of CNC Compared with NC 1-7 Financial Rewards of CNC Investment 1-9 Other Types of CNC Equipment I 10 CNC Input and Storage Media I-11 Chapter Summary Review Exercises II 8 8 5 6 4

1-4 Definition of Computer Numerical Control and Its Components 1 6 Special Requirements for Utilizing CNC 4 1 8 CNC Machining Centers and Turning Centers

CHAPTER 1

Modern Machine Tool Controls 13 13 16 19

13

2-1 Chapter Objectives 2-2 Introduction 13

2-3 Different Types of System Control

24 Loop Systems f o r Controlling Tool Movement 2-6 CNC Machine Axes of Motion 2-7 Types ofTool Positioning Modes 29 Chapter Summary Review Exercises 25 20 24 25

25 Establishing Locations via Cartesian Coordinates

2-8 Units Used for Positioning Coordinates

CHAPTER 3

Too/ing for Hole and Milling Operations 32 32

32

3-1 Chapter Objectives 32 Introduction 32

3-3 Tooling for Drilling Operations

XI

xii 3 4 Carbide Insert Technology 37 38 44 41

Contents

3 5 Tooling for Hole Operations That Follow Drilling 3-6 Tool Speeds and Feeds for Hole Operations 3-8 Coated Tooling 48 49 51 37 Tooling for Profile Milling and Facing Operations 3-9 Tool Speeds and Feeds for Milling Operations 3-10 Feed Directions for Milling Operations 3-11 Cutting Fluids for CNC Operations 3-12 Chapter Summary Review Exercises 54 52

CHAPTER 4

Exploring Features of CNC Machining Centers

56 56 60 64 62

56

4-1 Chapter Objectives 4-2 Introduction 56

4-3 Background on CNC Machining Centers 4-5 Methods of Securing Tools in Tool Holders 4-7 Automatic Tool Changer Systems 4-8 Pallet Loading Systems 410 Chapter Summary Review Exercises 77 67 65

44 Tooling Systems Used with Automatic Tool Changers

46 Methods of Securing Tooling Systems to the CNC Spindle

4-9 Features of the Machine Control Unit (MCU) Machining Centers

70

CHAPTERS

Review of Basic Blueprint Reading for CNC Programmers 80

80

5-1 Chapter Objectives 5-2 Introduction 5-3 Sheet Sizes 80 80

5 4 Drawing Formats

81 87 91 93

5 5 Interpreting Lines in Drawings

5-6 Projection Conventions Used in Drawings 5-8 Auxiliary Views 5-9 Sectional Views 93 93 93 115

5-7 Visualizing 3D Objects from 2D Othographic Views

5-10 Reading Dimensions

5-11 Reading Threads and Thread Notes 5-13 Chapter Summary Review Exercises Bibliography 131

5-12 Reading Surface Finish Symbols and Notes

125

Contents

xiii

CHAPTER 6

Review of Basic Material for CNC Programmers 133 133

Specifications

133

6-1 Chapter Objectives 6-2 Introduction 133

6-3 Reading Material Specifications

6-4 Understanding Heat Treatment Notes 65 Interpreting Surface Coating Notes 6-6 Chapter Summary Review Exercises Bibliography 150

141 145

CHAPTER 7

Review of Basic Geometric Dimensioning and Tolerancing for CNC Programmers 151 152 154 159 159 < 166

151

7-1 Chapter Objectives 72 Introduction 151 7-3 GDTTerminology 74 Part Form Controls 7-5 Datums 158 7-6 Part Profile Controls 78 Chapter Summary Review Exercises Bibliography

7-7 Part Location, Orientation, and Runout Controls

CHAPTER 8

Mathematics

for CNC Programming

168

8-1 Chapter Objectives 8-2 Introduction 168

168 168 173

8-3 Determining Sides of Right Triangles 8-4 Useful Angle Concepts 86 Oblique Triangles 175 169 8-5 Determining Angles of Right Triangles

8-7 KwikTrig Trigonometry/Geometry Software 8-8 Installation 176 176 178 8-9 Starting KwikTrig 8-10 Chapter Summary Review Exercises

175

CHAPTER 9

An Overview of CNC Shop Activities 182

182

9-1 Chapter Objectives 9-2 Introduction 182

xiv 9-3 Essential CNC Shop Activities 9-4 Part Drawing Study 182 185 185 186 182

Contents

95 Methodizing o f Operations f o r C N C Machining Centers 9-6 Deciding on a CNC Machine 98 Machining Determination 9-9 Cutting Conditions 194 194 194 193 9-7 Methods of Holding the Part During Machining

9-10 Writing a Programming Manuscript 9-12 Setup Procedure 9-14 Part Production 9-15 Chapter Summary Review Exercises 195

9-11 Inputting Programs to the Machine Control Unit 9-13 Debugging and Verifying the Program 201 201 200

C H A P T E R 10

Word Address Programming 203 203 204 205 206

203

10-1 Chapter Objectives 10-2 Introduction 203

10-3 Programming Language Format

10-4 Programming Language Terminology 10-5 Arrangement of Addresses in a Block 10-7 Preparatory Functions (G Codes) 10-9 Feed Rate (F Code) 210 210

10-6 Program and Sequence Numbers (O, N Codes) 207 209 10-8 Dimension Words ( X . Y . Z . . . Codes) 10-10 Spindle Speed (S Code)

10-11 Miscellaneous Machine Functions (M Codes) 10-12 Automatic Tool Changing (M6 Code) 10-14 Comments 212 213 211

211 212

10-13 Tool Length Offset and Cutter Radius Compensation (H, D Codes) 10-15 Chapter Summary Review Exercises

CHAPTER I I

Running the Mill Simulator

214 214 215 219 221

214

11-I Chapter Objectives 11-2 Introduction 214

11-3 Predator Simulation Software 114 System Requirements 11-6 Installation 215 215

11-5 Conventions Used in This Chapter

117 Running a Mill Simulation Job Stored on CD

11-8 Using the Virtual CNC to Inspect the Machined Part

Contents

xv

CHAPTER 12

Programming Hole Operations 226

226

12-1 Chapter Objectives

122 Introduction 226

12-3 Fixed or Canned Cycles 226 12-4 Hole Operation Commands 228 12-5 Writing a Hole Operation Program 233 12-6 Chapter Summary 240 Review Exercises

CHAPTER I 3 13-1 1 3 2 13-3 13-4 13-5 13-6

Programming Linear Profiles

247

Chapter Objectives 247 Introduction 247 Linear Interpolation Commands 247 Writing a Linear Profiling Program 247 Determining Cutter Offsets for Inclined Line Profiles 253 Chapter Summary 268 Review Exercises

CHAPTER 14

Programming Circular Profiles 275

275

275 '

14-1 Chapter Objectives 14-2 Introduction 275

143 Specifying the Plane f o r Circular A r c Interpolation 144 Circular Interpolation Commands 275

14-5 Circular Interpolation via Direct Radius Specification 281 14-6 Profiling at Constant Feed Rate 283 14-7 Determining Cutter Offsets for Line-Arc Profiles 284 14-8 Chapter Summary 297 Review Exercises

CHAPTER I 5 15-1 15-2 15-3 1 5 4 15-5 15-6 15-7 15-8 15-9

Programming with Cutter Diameter Compensation

308

Chapter Objectives 308 Introduction 308 Cutter Diameter Compensation 308 Advantages of Using Cutter Diameter Compensation 310 Some Restrictions with Cutter Diameter Compensation 310 Cutter Diameter Compensation Commands 312 Cutter Diameter Compensation with Z-Axis Movement 319 Cutter Diameter Compensation Interruptions 320 Chapter Summary 327 Review Exercises

xvi

Contents

CHAPTER 16

Programming with Subprograms 333 333

333

16-1 Chapter Objectives 16-2 Introduction 333 16-3 Subprogram Concept

164 Fanuc Commands for Calling a Subprogram and Returning to the Main Program 334 16-5 Additional Subprogram Control Features 166 General Rules for Subprogramming 338 16-7 Chapter Summary Review Exercises 355 337

CHAPTER 17

Introduction to the CNC Lathe 362

362

17-1 Chapter Objectives 17-2 Introduction 362

17-3 Backround on the CNC Lathe 362 17-4 C N C Lathe Axes of Motion 17-6 Basic Lathe Operations 374 377 381 383 367 367 17-5 Features of the Machine Control Unit (MCU) Lathes 17-7 Tooling for CNC Lathe Operations

17-8 Tool Speeds, Feeds, and Depth of Cut for Lathe Operations 17-9 Feed Directions and Rake Angles for Lathe Operations 17-10 Chapter Summary Review Exercises 385

CHAPTER 18

Running the Lathe Simulator 388

388

18-1 Chapter Objectives 18-2 Introduction 388

18-3 Running a Lathe Simulation Job Stored on CD 388 18-4 Using the Virtual C N C to Inspect the Machined Part 393

CHAPTER 19

Fundamental Concepts of CNC Lathe Programming 395

395

19-1 Chapter Objectives 19-2 Introduction 395

19-3 Establishing Locations via Cartesian Coordinates (CNC Lathes) 397 19-4 Types of Tool Positioning Modes (CNC Lathes) 397

Contents 19-5 Reference Point, Machine Origin, and Program Origin (FANUC Controllers) 398 19-6 Methodizing of Operations for CNC Lathes 19-7 Setup Procedures for CNC Lathes 402 408 409 400

xvii

198 Important Preparatory Functions (G Codes) for Lathes 199 Important Miscellaneous Functions (M Codes) for Lathes 19-10 Setting the Machining Origin 19-11 Feed Rate (F Code) 411 412 19-12 Spindle Speed (S Code) 409

19-13 Spindle Speed with Constant Surface Speed Control

412

19-14 Spindle Speed with Clamp Speed and Constant Surface Speed Controls 413 19-15 Automatic Tool Changing 19-16 Tool Edge Programming 414 415 415 416

19-17 Tool Nose Radius Compensation Programming 19-18 Setting Up Tool Nose Radius Compensation 19-19 Some Restrictions with Tool Nose Radius Compensation 418 19-20 Tool Nose Radius Compensation Commands 19-21 Linear Interpolation Commands (CNC Lathes) 19-22 Circular Interpolation Commands (CNC Lathes) 19-23 Grooving Commands 19-25 Chapter Summary Review Exercises 429 431 19-24 Return to Reference Point Command 432

418 421 423

CHAPTER 20

Techniques and Fixed Cycles for CNC Lathe Programming 440 440 448 449 449 456 469 463

440

20-1 Chapter Objectives 20-2 Introduction 440

20-3 Turning and Boring Cycle: G90 20-4 Facing Cycle: G94 446

20-5 Multiple Repetitive Cycles: G70 to G75 207 Finish Turning and Boring Cycle: G70 20-9 Peck Cutoff and Grooving Cycle: G75 20-11 Single-Pass Threading Cycle: G32 20-12 Multiple-Pass Threading Cycle: G92 20-14 Chapter Summary Review Exercises 478 469 473

20-6 Stock Removal in Turning and Boring Cycle: G71 20-8 Peck Drilling and Face Grooving Cycle: G74

20-10 Thread Cutting on CNC Lathes and Turning Centers

20-13 Multiple Repetitive Threading Cycle: G76

475

xviii

Contents

C H A P T E R 21

Modern Computer-Aided Part Programming 489 489 490 490

489

21-1 Chapter Objectives 21-2 Introduction 489

21-3 Modern Developments in the Process of CNC Programming 215 An Introduction to Computer-Aided Programming Languages 21-6 Basic Elements of the APT Programming Language 21-7 An Introduction to CAD/CAM Technology 21-8 The Elements Comprising CAD 21-9 The Elements Comprising CAM 21-11 Chapter Summary Review Exercises 515 493 497 493 491

214 Using an Off-Line Computer to Write and Store Part Programs

21-10 Creating a Complete Part Program Using Mastercam CNC Software

499

Appendix A Important Safety Precautions 5/7

517

Appendix B Summary of G Codes for Milling Operations (FANUC Controllers) Summary of G Codes for Turning Operations (FANUC Controllers) Summary of M Codes for Milling and Turning Operations (FANUC Controllers) 522 Summary of Auxiliary Functions (FANUC Controllers) 523 519 521

519

Appendix C Recommended Speeds and Feeds for Drilling Recommended Speeds and Feeds for Milling Recommended Speeds and Feeds for Turning 526 527 528

526

Appendix O Summary of Important Machining Formulas 530

530

Appendix E Tables of Important GDT Symbols 532

532

Appendix F Identification System for OD and ID Tools 534

534

Contents

xix

Appendix G Writing and Verifying Mill Part Programs via Predator Simulations Software

537 537

Appendix H Writing and Verifying Turn Part Programs via Predator Simulation Software 552

552

Glossary 568

Index 575

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Photoelasticity ManualDocument31 pagesPhotoelasticity ManualhimanshusekharpandaNo ratings yet

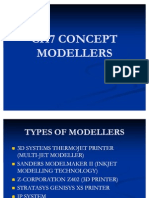

- Concept ModellersDocument39 pagesConcept ModellersParth Modi83% (6)

- Reliability IssuesDocument33 pagesReliability IssuesSunny MoreNo ratings yet

- Reliability IssuesDocument33 pagesReliability IssuesSunny MoreNo ratings yet

- FailsafeDocument4 pagesFailsafearkan1976No ratings yet

- Bridge CircuitsDocument15 pagesBridge CircuitsBen GeorgeNo ratings yet

- CNC 3Document2 pagesCNC 3Ahmed EltaybNo ratings yet

- Computational Fluid Dynamics (CFD) Applications in Vehicle Exhaust SystemDocument2 pagesComputational Fluid Dynamics (CFD) Applications in Vehicle Exhaust SystemBen GeorgeNo ratings yet

- Fundamentals of RoboticsDocument19 pagesFundamentals of RoboticsdharshanirymondNo ratings yet

- CNC Machine Tools and Control Systems GuideDocument39 pagesCNC Machine Tools and Control Systems Guidep_a_jeevaNo ratings yet

- Griffith Theory of Fracture MechanicsDocument15 pagesGriffith Theory of Fracture MechanicshrsreenathNo ratings yet

- Path Independent J Integral: (Rice J.R., 1968, J. Applied Mechanics, 379-386)Document10 pagesPath Independent J Integral: (Rice J.R., 1968, J. Applied Mechanics, 379-386)Ben GeorgeNo ratings yet

- FailsafeDocument4 pagesFailsafearkan1976No ratings yet

- Solid Ground CuringDocument11 pagesSolid Ground CuringParth Modi100% (4)

- Yong DissertationDocument397 pagesYong DissertationBen GeorgeNo ratings yet

- Fundamentals of RoboticsDocument19 pagesFundamentals of RoboticsdharshanirymondNo ratings yet

- Path Independent J Integral: (Rice J.R., 1968, J. Applied Mechanics, 379-386)Document10 pagesPath Independent J Integral: (Rice J.R., 1968, J. Applied Mechanics, 379-386)Ben GeorgeNo ratings yet

- Ilot - Edu.pl Kones 2011-2-2011 2011 Chuchnowski Tokarczyk Method For ModellingDocument8 pagesIlot - Edu.pl Kones 2011-2-2011 2011 Chuchnowski Tokarczyk Method For ModellingBen GeorgeNo ratings yet

- Kelly 110701Document6 pagesKelly 110701Ben GeorgeNo ratings yet

- Ch4 Fused Deposition Modelling SystemsDocument14 pagesCh4 Fused Deposition Modelling SystemsBen GeorgeNo ratings yet

- ICON OF SUSTAINABLE MANUFACTURINGDocument13 pagesICON OF SUSTAINABLE MANUFACTURINGBen GeorgeNo ratings yet

- CNC MachiningDocument19 pagesCNC MachiningAhmad SaepuddinNo ratings yet

- Hy Wire Project ReportDocument24 pagesHy Wire Project ReportBen GeorgeNo ratings yet

- Post Graduate Engineering Project on Creating Plummer Block by FDMDocument1 pagePost Graduate Engineering Project on Creating Plummer Block by FDMBen GeorgeNo ratings yet

- CH6 Laminated Object ManufacturingDocument10 pagesCH6 Laminated Object ManufacturingParth Modi100% (2)

- LohLydia GreenBuildings (Paper)Document10 pagesLohLydia GreenBuildings (Paper)Ben GeorgeNo ratings yet

- Methods For Calculating IlluminationDocument27 pagesMethods For Calculating Illuminationreca4520100% (1)

- Siemens PLM SoftwareDocument8 pagesSiemens PLM SoftwareBen GeorgeNo ratings yet

- PLCMDocument13 pagesPLCMBen GeorgeNo ratings yet