Professional Documents

Culture Documents

TEMA Shell & Tube Nomenclature

TEMA Shell & Tube Nomenclature

Uploaded by

Ismael ZavalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TEMA Shell & Tube Nomenclature

TEMA Shell & Tube Nomenclature

Uploaded by

Ismael ZavalaCopyright:

Available Formats

TEMA Shell & Tube Nomenclature

API Heat Transfer is a proud member of TEMA - Tubular Exchanger Manufacturers Association. TEMA members set the standards by which virtually all custom shell & tube heat exchangers are specified and built. Basco has been a member since the 1950s, and consequently we have a complete and comprehensive understanding of the engineering, manufacturing and testing requirements to meet this world-recognized standard. While other manufacturers may simply interpret the regulations, API Basco has the requisite member design and fabrication capabilities to lead the industry by helping to shape and define those standards for the long-term benefit of all users.

TEMA BET

Description: Pull through tube bundle studded internal floating head to tubesheet joint multi-pass tubeside or single pass with Slip Tube design channel or bonnet tubeside connection pressure range 75 psi to 300 psi.

Applications: Liquid heaters with low pressure steam on the shell side single and double shell (gas in shell) compressor intercoolers on refinery applications shellside gas or oil coolers

GASKET

FLOATING TUBESHEET GASKET GASKET

STATIONARY TUBESHEET FULL FACE METAL GASKET WITH BOLT HOLES SHELL COVER BONNET ASSEMBLY GASKET

FLOATING HEAD COVER SHELL COVER (Optional)

FLOATING TUBESHEET

FLOATING HEAD COVER FLOATING END DETAIL

Advantages: 1. Relatively large annulus around outer tube limit (O.T.L.) and shell I.D. permits entrance to the tube bundle with little resistance. The results are low entrance-exit velocities and pressure loss. 2. Easily removable tube bundle. 3. Tube bundle expands freely with no special provisions for expansion.

Limitations: 1. No gasket leak detection at floating head and tubesheet. 2. Relatively low thermal efficiency due to large annulus between outer tube limit (O.T.L.) and shell I.D. (results in low shell side heat transfer coefficient). 3. Less tubes for any given shell size compared to other types.

TEMA AES

Description: Removable tube bundle, split clamp-ring floating head multi-pass tubeside or single pass with Slip Tube design floating head bolted to split clamp-ring (requires shell cover larger than shell to accommodate floating head) pressure range 75 psi to 600 psi.

CONFINED GASKETS

Applications: Often used in refineries gas in shell units up to 600 psi high pressure seal oil coolers up to 600 psi API 660 oil coolers

CLAMP RING (SPLIT)

CHANNEL COVER CONFINED GASKET STATIONARY TUBESHEET SHELL FLANGE SHELL COVER ASSEMBLY CONFINED GASKET CONFINED GASKET

CONFINED GASKET FLOATING TUBESHEET FLOATING HEAD COVER ASSEMBLY

SHELL COVER ASSEMBLY SHELL PIPE CLAMP RING (SPLIT) FLOATING TUBESHEET FLOATING HEAD COVER ASSEMBLY CHANNEL ASSEMBLY

FLOATING END DETAIL

Advantages: 1. Higher efficiency compared to Type BET units because of smaller annulus and more tubes per shell size. 2. Tube bundle expands freely with no special provisions for expansion.

Limitations: 1. No gasket leak detection at floating head. 2. Floating head and fixed end connection must be unbolted to remove tube bundle.

TEMA BEP

Description: Removable tube bundle, outside packed floating tubesheet design. Tubesheet assembly may be of fabricated or forged steel to satisfy design pressure requirements tubeside fluid is fully gasketed; shellside packing available in various materials tubeside pressure range to 3000 psi. Max 150 psi shellside.

Applications: Where lethal or explosive gasses are involved Where high pressure is applied only on the tubeside Where gasket malfunction must be detectable.

STATIONARY TUBESHEET

PACKING RINGS

PACKING GLAND

GASKETS

PACKING GLAND GASKET

PACKING RINGS FLOATING TUBESHEET

SHELL ASSEMBLY

GASKETS

FLOATING TUBESHEET ASSEMBLY

Advantages: 1. No packing exposed to tubeside fluid. 2. Compared to BET and BES, outer tube limit (O.T.L.) relatively close to shell I.D. resulting in increased heat transfer efficiency. 3. No possibility of shell and tubeside fluids intermixing through packing or gaskets.

Limitations: 1. One or two pass configurations only. 2. Shellside pressure up to 150 psi because of packing rings at floating tubesheet head. 3. Bundle expands into customers piping.

TEMA BEM

Description: Fixed tubesheet, non-removable bundle tubesheet welded directly to shell single or multi-pass design

TUBESHEET GASKET

Applications: Chemical processes high pressure air and nitrogen chillers (gas in tubes, freon shellside).

TUBESHEET GASKET BONNET ASSEMBLY

BONNET FLANGE SHELL PIPE GASKET

TUBESHEET

ELLIPTICAL HEAD GASKET JOINT DETAIL

Advantages: 1. Economical design. 2. No possibility of contamination compared to designs with floating head gaskets (except in tube failures). 3. High pressure shellside designs more easily accomplished than in floating head types. 4. Extremely efficient shellside heat transfer due to small annulus between outer tube limit (O.T.I.) and shell I.D. 5. Shell design can be modified for large expansion area where partial vaporization of liquid occurs. 6. No gasketed joints on shellside.

Limitations: 1. No provisions for differential expansion of tubes and shell without expansion joint. 2. Shell and tubesheet material must be weldable 3. Tube bundle is not removable for cleaning.

TEMA BEU

Description: U-tube design with pull through, removable or non-removable tube bundle furnished in multi-pass design only pressure range 75 psi to 3000 psi tubeside and 75 psi to 1500 psi shellside.

Applications: Chemical processes tank suction heater liquid heaters vaporizers (where partial vaporization of liquid occurs).

TUBESHEET

CONFINED GASKETS

U TUBES

BONNET ASSEMBLY

BONNET ASSEMBLY CONFINED GASKETS TUBESHEET GASKET DETAIL

SHELL ASSEMBLY TUBESHEET

Advantages: 1. Tubes expand freely without special provisions. 2. Single tubesheet minimizes number of tubeside joints. 3. Economical construction. 4. Highly efficient heat transfer small annulus between outer tube limit (O.T.L.) and shell I.D. 5. Tube bundle easily removable.

Limitations: 1. Outer tube rows must be removed before replacing inner rows. 2. Requires chemical cleaning. 3. May not be advisable for use where tubeside fouling is anticipated.

TEMA AEW

Description: Removable tube bundle, one or two-pass design double packed floating tubesheet with O rings and threaded retainer with telltale holes for leak detection shell sizes from 6" to 42" pressure range 75 psi to 600 psi.

GASKET

Applications: Lube oil coolers water coolers aftercoolers.

jacket

TELLTALE HOLES

ORING RETAINER

GASKET STATIONARY TUBESHEET CHANNEL COVER O RING PACKING FLOATING TUBESHEET

TELLTALE HOLES SHELL FLANGE

ORING RETAINER

SHELL PIPE

CHANNEL

FLOATING TUBESHEET PACKED END DETAIL

O RING PACKING

3. Leaks easily detected mixing or contamination of fluids eliminated. 4. Channel covers and return heads are easily removable for bundle inspection and cleaning. 5. Because of full thickness metal of O ring retainer, possibility of overtightening bolts and resultant O ring damage is eliminated. Limitations: 1. Should not be used for explosive or lethal fluids where packing leak cannot be tolerated. 2. One or two-pass configuration only.

Advantages: 1. Highly efficient heat transfer small annulus between outer tube limit (O.T.L.) and shell I.D. 2. Threaded O ring retainer permits tube inspection and cleaning without releasing shellside pressure.

You might also like

- Oil Storage Tanks Environmental Code of Practice - PN - 1326 - Eng PDFDocument66 pagesOil Storage Tanks Environmental Code of Practice - PN - 1326 - Eng PDFraneensysNo ratings yet

- Discover CanadaDocument68 pagesDiscover CanadaqatharyNo ratings yet

- Plate Type Heat Exchangers: Operation & Maintenance ManualDocument24 pagesPlate Type Heat Exchangers: Operation & Maintenance ManualasjkhjshdjkashdashNo ratings yet

- Check List For Piping Unit Plot PlanDocument5 pagesCheck List For Piping Unit Plot PlanVijay GaikwadNo ratings yet

- Report On Compensation ManagementDocument30 pagesReport On Compensation ManagementBana Zeeshan100% (1)

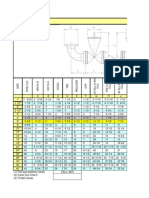

- FITTINGS WEIGHT CHART - XLSX - PDFDocument38 pagesFITTINGS WEIGHT CHART - XLSX - PDFSriram RNo ratings yet

- Steam Systems Design - Pipes and ValvesDocument160 pagesSteam Systems Design - Pipes and Valvesgladiatork00794% (53)

- Specification FOR Reciprocating Compressors: National Iranian South Oil-Fields Company (NISOC)Document27 pagesSpecification FOR Reciprocating Compressors: National Iranian South Oil-Fields Company (NISOC)Mehrshad ShakibNo ratings yet

- Piping ToolsDocument279 pagesPiping ToolsTroy HooperNo ratings yet

- Control of MachinesDocument355 pagesControl of Machineswado11No ratings yet

- Competency MappingDocument32 pagesCompetency MappingShallu AggarwalNo ratings yet

- Rubber BellowDocument20 pagesRubber BellowPrateek100% (1)

- Management of Petroleum Storage Tanks PDFDocument13 pagesManagement of Petroleum Storage Tanks PDFraneensys100% (1)

- Piping MaterialsDocument1 pagePiping Materialslibid_rajNo ratings yet

- Plot Plan PDFDocument1 pagePlot Plan PDFBadredine Farah100% (1)

- Eil Steam Trap StanderedDocument56 pagesEil Steam Trap StanderedVIVEK TIWARINo ratings yet

- Ideas To Achieve Optimal Combination of Axial & Cross FlowDocument28 pagesIdeas To Achieve Optimal Combination of Axial & Cross FlowAmirah SufianNo ratings yet

- Flow Meter Installatioin Guide by ABBDocument1 pageFlow Meter Installatioin Guide by ABBMWBABARNo ratings yet

- Top Entry Ball ValvesDocument8 pagesTop Entry Ball ValvesHuda LANo ratings yet

- Junttan PMx27 DatasheetDocument4 pagesJunttan PMx27 DatasheetIkhsan SetiawanNo ratings yet

- Udhe 2.standardsDocument1 pageUdhe 2.standardsom dhamnikarNo ratings yet

- 6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiDocument15 pages6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiAvinash ShuklaNo ratings yet

- SMPVDocument8 pagesSMPVPrasanta Kumar BeheraNo ratings yet

- 23 22 00 - Steam and Condensate Piping and PumpsDocument6 pages23 22 00 - Steam and Condensate Piping and PumpsDiana SoareNo ratings yet

- OISD Tank Farm Rules The Piping Engineering WorldDocument1 pageOISD Tank Farm Rules The Piping Engineering Worldrenger20150303No ratings yet

- Agitated Thin Film Dryer ClaculationDocument12 pagesAgitated Thin Film Dryer ClaculationakaashNo ratings yet

- Eil Spec Bo16-000-80-44-Ol-S001 Rev ADocument2 pagesEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganNo ratings yet

- Mineral Wool Pipe Insulation DatasheetDocument2 pagesMineral Wool Pipe Insulation DatasheetDenny Akbar Nur Hadyansyah100% (1)

- Final Nozzle Orientation For KodDocument6 pagesFinal Nozzle Orientation For KodSachin5586No ratings yet

- Flowmeter Piping RequirementsDocument4 pagesFlowmeter Piping RequirementsYoke ShuNo ratings yet

- Portfolio Performance EvaluationDocument28 pagesPortfolio Performance Evaluationleolau2015No ratings yet

- 150 # ANSI Piping DataDocument21 pages150 # ANSI Piping DataMekar MeinaNo ratings yet

- Toyo ( ) PDFDocument16 pagesToyo ( ) PDFJolang NusodarpitoNo ratings yet

- 6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferDocument35 pages6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferAthar IqbalNo ratings yet

- EIL Technical Notes For PipesDocument9 pagesEIL Technical Notes For PipesMurli ramchandran100% (1)

- 6-44-0002-Rev 2Document53 pages6-44-0002-Rev 2Vineet Singh100% (2)

- Smart Plant Engineering SchematicsDocument16 pagesSmart Plant Engineering Schematicsraneensys0% (2)

- Fathom 7.0 Modules GuideDocument202 pagesFathom 7.0 Modules Guideraneensys100% (1)

- Dummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMDocument2 pagesDummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMashish shrivastavNo ratings yet

- Hot Tapping Data Sheet-2012 From TDWDocument1 pageHot Tapping Data Sheet-2012 From TDWRachel Flores0% (1)

- Desuperheater Online Program Sizing GuidanceDocument12 pagesDesuperheater Online Program Sizing GuidancebadesharamkNo ratings yet

- Pipe ThicknessDocument1 pagePipe ThicknessalvinchuanNo ratings yet

- Trigonometry - Excel Spreadsheet by WWW - Mathematics.me - UkDocument3 pagesTrigonometry - Excel Spreadsheet by WWW - Mathematics.me - UkrodwellheadNo ratings yet

- API Standard 660: Shell-and-Tube Heat Exchangers For General Refinery ServicesDocument3 pagesAPI Standard 660: Shell-and-Tube Heat Exchangers For General Refinery Servicesrtrajan_mech54080% (1)

- NTPC Project ReportDocument31 pagesNTPC Project ReportDeepak Ranjan ParidaNo ratings yet

- J3X & JF3X PDFDocument2 pagesJ3X & JF3X PDFMukiara LuffyNo ratings yet

- When Is An Expansion Bellows Required in A Heat ExchangerDocument3 pagesWhen Is An Expansion Bellows Required in A Heat ExchangerTiHoRNo ratings yet

- Bleed Rings RTJDocument1 pageBleed Rings RTJAlessandro1975No ratings yet

- 11d Pms Rev00a Ongc 27jul15Document3 pages11d Pms Rev00a Ongc 27jul15abhiNo ratings yet

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Butterfly ValvesDocument6 pagesButterfly ValvestezgidenNo ratings yet

- Diaphragm ValveDocument10 pagesDiaphragm Valveshganesh81No ratings yet

- Product Key Autodesk 2016Document5 pagesProduct Key Autodesk 2016mila beusesNo ratings yet

- 6-79-0013 - r1 Material in Sour ServiceDocument6 pages6-79-0013 - r1 Material in Sour ServiceMurli ramchandran100% (1)

- Fisher 630 Series PDFDocument10 pagesFisher 630 Series PDFClemente Rafael Marval EscalonaNo ratings yet

- Pipe Schedule ChartDocument16 pagesPipe Schedule ChartSamir ChaudharyNo ratings yet

- 7-12-0026 Rev 5Document1 page7-12-0026 Rev 5cynideNo ratings yet

- Induced Vibration HXDocument7 pagesInduced Vibration HXPatricia.PNo ratings yet

- SPR Basic Training ManualDocument140 pagesSPR Basic Training Manualjlvega18No ratings yet

- Datasheet For Steel Grades Special Alloy Gs-25Crmo4Document2 pagesDatasheet For Steel Grades Special Alloy Gs-25Crmo4ssvrNo ratings yet

- Function of Piping Component: Steam Trap and Drain TrapDocument23 pagesFunction of Piping Component: Steam Trap and Drain TrapMallela Sampath KumarNo ratings yet

- 7-12-0014 Rev 5Document1 page7-12-0014 Rev 5cynideNo ratings yet

- Checklist GD BandlockDocument3 pagesChecklist GD BandlockdeogmozyxNo ratings yet

- Analysis of Air Water Cooled Condenser in Vapour Compression System IJERTV10IS050132Document6 pagesAnalysis of Air Water Cooled Condenser in Vapour Compression System IJERTV10IS050132Abdulrahman AlnasharNo ratings yet

- 7-12-0033 Rev 4Document1 page7-12-0033 Rev 4cynideNo ratings yet

- BOQ-ValvesDocument4 pagesBOQ-ValvesGourav SharmaNo ratings yet

- TLV - Manifolds Vapor y Condensado PDFDocument4 pagesTLV - Manifolds Vapor y Condensado PDFsirballesterosNo ratings yet

- 1.8. Difference Between Pipe and Tube: Process Piping Fundamentals, Codes and Standards - Module 1Document5 pages1.8. Difference Between Pipe and Tube: Process Piping Fundamentals, Codes and Standards - Module 1Raakze MoviNo ratings yet

- The Plant Cell Wall: A Topical Study of Architecture, Dynamics, Comparative Chemistry and Technology in a Biological SystemFrom EverandThe Plant Cell Wall: A Topical Study of Architecture, Dynamics, Comparative Chemistry and Technology in a Biological SystemNo ratings yet

- Multi-Outlet Drum Pumps GSEDocument4 pagesMulti-Outlet Drum Pumps GSEtranceinttNo ratings yet

- Tyco ADC NetworkDocument28 pagesTyco ADC NetworkraneensysNo ratings yet

- 422 Model E Alarm Check ValveDocument6 pages422 Model E Alarm Check ValveraneensysNo ratings yet

- Reliability Enfineering - IntroductionDocument29 pagesReliability Enfineering - IntroductionHarshavardhan Raju100% (7)

- Porplastic Race Ep CourtDocument2 pagesPorplastic Race Ep CourtPratista HighlanderNo ratings yet

- Metod Statement of Well Point De-Watering For Cement SiloDocument5 pagesMetod Statement of Well Point De-Watering For Cement SiloSmart ShivaNo ratings yet

- Modern Marvels Fast Food TechDocument2 pagesModern Marvels Fast Food TechadeaversNo ratings yet

- CRT AssignmentDocument21 pagesCRT AssignmentRittika RatawaNo ratings yet

- JHS LCP English Grade 7 10Document25 pagesJHS LCP English Grade 7 10Daryl RiveraNo ratings yet

- Lesson 5 - Value of ResearchDocument10 pagesLesson 5 - Value of ResearchAiko CunananNo ratings yet

- Finepix s8200-s8500 Manual en PDFDocument143 pagesFinepix s8200-s8500 Manual en PDFIonescu Alexandru MihaiNo ratings yet

- Monthly Remittance Form: For Creditable Income Taxes Withheld (Expanded)Document1 pageMonthly Remittance Form: For Creditable Income Taxes Withheld (Expanded)Jonalyn BalerosNo ratings yet

- Blooming Bath OilDocument1 pageBlooming Bath OilBalm OilNo ratings yet

- TIERNO, Michael. Aristotle's Poetics For Screenwriters: Storytelling Secrets From The Greatest Mind in Western CivilizationDocument121 pagesTIERNO, Michael. Aristotle's Poetics For Screenwriters: Storytelling Secrets From The Greatest Mind in Western Civilizationlinharesf147No ratings yet

- Resume - Daniel Liu Aug 2019 3Document1 pageResume - Daniel Liu Aug 2019 3Daniel LiuNo ratings yet

- Retail Buy & Sell: Can't Ind What You're Looking For? Check Online at Freepressseries - Co.ukDocument4 pagesRetail Buy & Sell: Can't Ind What You're Looking For? Check Online at Freepressseries - Co.ukDigital MediaNo ratings yet

- READ A Thon MechanicsDocument6 pagesREAD A Thon MechanicsJohn Michael CariazoNo ratings yet

- As 4962-2005 Electronic Toll Collection - Transaction Specification For Australian Interoperability On The DSDocument7 pagesAs 4962-2005 Electronic Toll Collection - Transaction Specification For Australian Interoperability On The DSSAI Global - APACNo ratings yet

- WSH Alert, 3 February 2023, Pump Attendant Knocked Down by A CarDocument1 pageWSH Alert, 3 February 2023, Pump Attendant Knocked Down by A CarGoodLink EnquiryNo ratings yet

- Compression Labs Incorporated v. Dell, Inc Et Al - Document No. 35Document14 pagesCompression Labs Incorporated v. Dell, Inc Et Al - Document No. 35Justia.comNo ratings yet

- QR5 Draft Annex07aDocument171 pagesQR5 Draft Annex07aShobha KunduNo ratings yet

- Adventist University of The Philippines: Dental ChartDocument6 pagesAdventist University of The Philippines: Dental ChartYossy TjahyonoNo ratings yet

- New Coleccion Harmony DJ AcademyDocument6 pagesNew Coleccion Harmony DJ AcademyvictoredjNo ratings yet

- Service Support Catalog 2020Document178 pagesService Support Catalog 2020Xin GaoNo ratings yet

- LPJ MR AreaDocument11 pagesLPJ MR AreaBagas AudiNo ratings yet

- Guidelines To Avoid ADMsDocument4 pagesGuidelines To Avoid ADMshekoxe6441No ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)prateekNo ratings yet

- HX200 Installation Guide Rev BDocument160 pagesHX200 Installation Guide Rev Bcarliemorsey9No ratings yet

- 1 2 Performing Mensuration and CalculationDocument4 pages1 2 Performing Mensuration and CalculationRonaldo CruzNo ratings yet