Professional Documents

Culture Documents

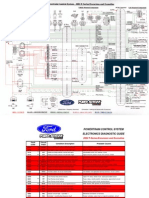

OBDC II Diagnostic Trouble Codes-Detalii

Uploaded by

Aiurel AiureluCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OBDC II Diagnostic Trouble Codes-Detalii

Uploaded by

Aiurel AiureluCopyright:

Available Formats

OBDC II Diagnostic Trouble Codes Diagnostic Trouble Code (DTC) Descriptions DTC - Description Possible Causes Diagnostic Aides

P0102 - Mass Air Flow (MAF) Circuit Low Input The MAF sensor circuit is monitored b the PCM !or low air !low (or "oltage) input through the comprehensi"e component monitor (CCM)# I! during $e %& engine running the air !low (or "oltage) changes below a minimum calibrated limit' the test !ails# MAF sensor disconnected MAF circuit open to PCM (P)* open to MAF sensor P)* +&D open to MAF sensor MAF *T& circuit open to PCM MAF circuit shorted to +&D Inta$e air lea$ (near MAF sensor) A closed throttle indication ,throttle position (TP) sensor s stemDamaged MAF sensor Damaged PCM A MAF ( PID (MAF PID) reading less than .#/0 "olts (*e!er to e1ui"alent grams2second chart in +% to Pinpoint Test DC ) in continuous memor or $e %& and engine running indicates a hard !ault# P0103 - Mass Air Flow (MAF) Circuit 3igh Input The MAF sensor circuit is monitored b the PCM !or high air !low (or "oltage) input through the comprehensi"e component monitor (CCM)# I! during $e %& engine %FF or $e %& engine running the air !low (or "oltage) changes abo"e a ma4imum calibrated limit' the test !ails# MAF sensor screen is bloc$ed MAF circuit shorted to (P)* Damaged MAF sensor Damaged PCM A MAF ( PID (MAF PID) reading less than 5#6 "olts (*e!er to e1ui"alent grams2second chart in +% to Pinpoint Test DC ) in continuous memor or $e %& and engine running indicates a hard !ault# P0106 - 7arometric (7A*%) Pressure 8ensor Circuit Per!ormance 7aro sensor input to the PCM is monitored and is not within the calibrated "alue# 8low responding 7A*% sensor 9lectrical circuit !ailure Damaged 7A*% sensor Damaged PCM (*9F "oltage should be between 5#. and 6#. "olts PID reading is in !re1uenc P0107 - 7A*%2MAP 8ensor Low (oltage Detected 8ensor operating "oltage is less than .#/: "olts ((*9F)' as a result it !ailed below the minimum allowable calibrated

parameter# %pen in the circuit' or short to ground (*9F circuit open' or short to ground Damaged 7A*%2MAP sensor Damaged PCM (*9F should be greater than 5#. "olts PID reading is in !re1uenc 2"olts P0108 - 7A*%2MAP 8ensor 3igh (oltage Detected 8ensor operating "oltage is greater than :#. "olts ((*9F)' as a result it !ailed abo"e ma4imum allowable calibrated parameter# (*9F shorted to ()P* 7A*%2MAP signal shorted to (P)* Damaged 7A*%2MAP sensor Damaged PCM (*9F should be less than 6#. "olts# PID reading is in !re1uenc 2(olts P0109 - 7A*%2MAP 8ensor Circuit Intermittent The sensor signal to the PCM is !ailing intermittentl # Loose electrical connection Damaged 7A*%2MAP sensor Chec$ harness and connection# P0112 - Inta$e Air Temperature (IAT) Circuit Low Input Indicates the sensor signal is less than 8el!-Test minimum# The IAT sensor minimum is .#/ "olts or ;/;<C (/:.<F)# +rounded circuit in harness Damaged sensor Improper harness connection Damaged PCM IAT ( PID reading less than .#/ "olts with $e %& and engine %FF or during an engine operating mode indicates a hard !ault# P0113 - Inta$e Air Temperature (IAT) Circuit 3igh Input Indicates the sensor signal is greater than 8el!-Test ma4imum# The IAT sensor ma4imum is 5#6 "olts or -:.<C (-:=<F)# %pen circuit in harness 8ensor signal short to power Damaged sensor Improper harness connection Damaged PCM IAT ( PID reading greater than 5#6 "olts with $e %& and engine %FF or during an engine operating mode indicates a hard !ault# P0116 - 9ngine Coolant Temperature Circuit *ange2Per!ormance Failure Indicates the engine coolant temperature rationalit test has !ailed# The PCM logic that sets this DTC indicates that engine coolant temperature sensor (9CT or C3T) dri!ted higher than the nominal sensor calibration cur"e and could pre"ent one or more %7D II monitors !rom e4ecuting# The PCM runs this logic a!ter an engine o!! >calibrated soa$ period (t picall 6 hours)# This soa$ period allows the Inta$e Air Temperature (IAT) and engine coolant

temperature (C3Tor 9CT) to stabili?e and not di!!er b more than a calibrated "alue# DTC P.;;6 is set when all o! the !ollowing conditions are met@ 9ngine coolant temperature at engine start e4ceeds IAT at engine start b more than a calibrated "alue' t picall 0.<F (;<C)# 9ngine coolant temperature e4ceeds a calibrated "alue' t picall //:F (;.AC)# The Fuel' 3eated %4 gen 8ensor' Catal st and Mis!ire monitors ha"e not completed# Calibrated timer to set DTC P.;;6 has e4pired# 9ngine Coolant Temperature (9CT) or C linder 3ead Temperature (C3T) sensor Coolant 8 stem Concern 9nsure IAT and engine coolant temperature are similar when engine is cold# Also ensure engine coolant temperature sensor (9CT or C3T) and actual engine operating temperature are the same# P0117 - 9ngine Coolant Temperature (9CT) Circuit Low Input Indicates the sensor signal is less than 8el!-Test minimum# The 9CT sensor minimum is .#/ "olts or ;/;<C (/:.<F)# &ote on some "ehicles that are not e1uipped with an 9CT sensor' C3T can be used and can set this DTC# +rounded circuit in harness Damaged sensor Improper harness connection Damaged PCM 9CT ( PID reading less than .#/ "olts with $e %& and engine %FF or during an engine operating mode indicates a hard !ault# P0118 - 9ngine Coolant Temperature (9CT) Circuit 3igh Input Indicates the sensor signal is greater than 8el!-Test ma4imum# The 9CT sensor ma4imum is 5#6 "olts or -:.<C (-:=<F)# &ote on some "ehicles that are not e1uipped with an 9CT sensor' C3T can be used and can set this DTC# %pen circuit in harness 8ensor signal short to power Damaged PCM Improper harness connection Damaged sensor 9CT ( PID reading greater than 5#6 "olts with $e %& and engine %FF or during an engine operating mode indicates a hard !ault# P0121 - Throttle Position (TP) Circuit Per!ormance Problem The TP sensor circuit is monitored b the PCM !or a non closed throttle position at idle# I! $e %& engine running sel!-test terminates upon placing the transmission range selector in gear (D*I(9 or *9(9*89) or when closing the throttle (idle) a!ter opening it (in PA*B or &9CT*AL) the TP closed throttle position is not attained' the test !ails# 7inding throttle lin$age Damaged throttle bod TP circuit open to PCM Damaged TP sensor 8I+ *T& circuit open to TP sensor Dri"e "ehicle' bring to a stop' turn $e %FF# 8tart "ehicle' run $e %& engine running sel!-test at idle# Access B%9* diagnostic trouble codes on scan tool#

P0122 - Throttle Position (TP) Circuit Low Input The TP sensor circuit is monitored b the PCM !or a low TP rotation angle (or "oltage) input through the comprehensi"e component monitor (CCM)# I! during $e %& engine %FF or $e %& engine running the TP rotation angle (or "oltage) changes below a minimum calibrated limit' the test !ails# TP sensor not seated properl TP circuit open to PCM (*9F open to TP sensor TP circuit short to +&D Damaged TP sensor Damaged PCM A TP PID (TP ( PID) reading less than 0#5/D (.#;A "olt) in $e %& engine %FF' continuous memor or $e %& engine running indicates a hard !ault# P0123 - Throttle Position (TP) Circuit 3igh Input The TP sensor circuit is monitored b the PCM !or a high TP rotation angle (or "oltage) input through the comprehensi"e component monitor (CCM)# I! during $e %& engine %FF or $e %& engine running the TP rotation angle (or "oltage) changes abo"e ma4imum calibrated limit' the test !ails# TP sensor not seated properl TP circuit short to P)* (*9F short to P)* 8I+ *T& circuit open to TP sensor Damaged TP sensor Damaged PCM A TP PID (TP ( PID) reading greater than E0D (5#6: "olts) in $e %& engine %FF' continuous memor or $e %& engine running indicates a hard !ault# P012 - Insu!!icient Coolant Temperature For Closed Loop Fuel Control Indicates the 9CT or C3T sensor has not achie"ed the re1uired temperature le"el to enter closed loop operating conditions within a speci!ied amount o! time a!ter starting engine# Insu!!icient warm up time Low engine coolant le"el Lea$ing or stuc$ open thermostat Mal!unctioning 9CT sensor Mal!unctioning C3T sensor *e!er to Thermostat Monitor in 8ection ;' Description and %peration' !or s stem in!ormation# P0127 - Inta$e Air Temperature Too 3igh Indicates that IAT/ sensor has detected a potential abnormalit in the intercooler s stem# This condition will cause the boost !rom the supercharger to be b passed to a"oid potential engine damage# 7loc$age o! heat e4changers Low !luid le"el Fluid lea$age Intercooler pump or rela !ailure Crossed intercooler coolant lines

Monitor IAT/ PID# T pical IAT/ temperature should be greater than IAT;# *e!er to 8ection 6 @ *e!erence (alues !or ranges# P0131 - 3%/8 8ensor Circuit %ut o! *ange Low (oltage (3%/8-;;) The 3%/8 sensor is monitored !or a negati"e "oltage $nown as characteristic shi!t downward (C8D)# I! the sensor is thought to be switching !rom . "olts to -; "olts during testing' the PCM will use this input and remain in !uel control# Contaminated 3%/8 (water' !uel' etc) Crossed 3%/8 signal2signal return wiring P0133 - 3%/8 8ensor Circuit 8low *esponse (3%/8-;;) The 39+% Monitor chec$s the 3%/8 8ensor !re1uenc and amplitude# I! during testing the !re1uenc and amplitude were to !all below a calibrated limit' the test will !ail# Contaminated 3%/8 sensor# 94haust lea$s# 8horted 2open wiring# Improper !ueling# MAF sensor# Deteriorating 3%/8 sensor# Inlet air lea$s# Access 3%/8 test results !rom the +eneric %7D-II menu to "eri! DTC# P013 - 3%/8 8ensor Circuit Mal!unction (3%/8-;;) During testing the 3%/8 3eaters are chec$ed !or opens2shorts and e4cessi"e current draw# The test !ails when current draw e4ceeds a calibrated limit and2or an open or short is detected# 8hort to (P)* in harness or 3%/8# )ater in harness connector# %pen (P)* circuit# %pen +&D circuit# Low batter "oltage# Corrosion or poor mating terminals and wiring Damaged 3%/8 heater# Damaged PCM# )iring# Damaged 3%/8 heater# Damaged PCM# P0136 - 3%/8 8ensor Circuit Mal!unction (3%/8-;/) The downstream 3%/8 sensor(s) are continuousl chec$ed !or ma4imum and minimum "oltages# The test !ails when the "oltages !ail to meet the calibrated limits# Pinched' shorted' and corroded wiring and pins# Crossed sensor wires# 94haust lea$s# Contaminated or damaged sensor# P01!1 - 3%/8 8ensor Circuit Mal!unction (3%/8-;/:) 8ee DTC P.;0: P01!8 - Fuel Deli"er 9rror At least one ban$ lean at wide open throttle# 8e"erel

restricted !uel !ilter# 8e"erel restricted !uel suppl line# P01 1 - 3%/8 8ensor Circuit %ut o! *ange Low (oltage (3%/8-/;) 8ee DTC P.;0; P01 3 - 3%/8 8ensor Circuit 8low *esponse (3%/8-/;) 8ee DTC P.;00 P01 - 3%/8 8ensor Circuit Mal!unction (3%/8-/;) 8ee DTC P.;0: P01 6 - 3%/8 8ensor Circuit Mal!unction (3%/8-//) 8ee DTC P.;06 P0161 - 3%/8 8ensor Circuit Mal!unction (3%/8-//) 8ee DTC P.;0: P0171 - 8 stem to Lean (7an$ ;) The Adapti"e Fuel 8trateg continuousl monitors !uel deli"er hardware# The test !ails when the adapti"e !uel tables reach a rich calibrated limit# For lean and rich DTCs@ Fuel s stem 94cessi"e !uel pressure# Lea$ing2contaminated !uel inFectors# Lea$ing !uel pressure regulator# Low !uel pressure or running out o! !uel# (apor reco"er s stem# Induction s stem@ Air lea$s a!ter the MAF# (acuum Lea$s# PC( s stem# Improperl seated engine oil dipstic$# 9+* s stem@ Lea$ing gas$et# 8tuc$ 9+* "al"e# Lea$ing diaphragm or 9(*# 7ase 9ngine@ %il o"er!ill# Cam timing# C linder compression# 94haust lea$s be!ore or near the 3%/8s# A 83*TFT-;'/ PID "alue between -/:D to G0:D and a L%&+FT-;'/ PID "alue between -0:D to G0:D is acceptable# *eading be ond these "alues indicate a !ailure# P0172 - 8 stem to *ich (7an$ ;) The Adapti"e Fuel 8trateg continuousl monitors the !uel deli"er hardware# The test !ails when the adapti"e !uel tables reach a lean calibrated limit# 8ee Possible Causes !or DTC P.;A; 8ee Diagnostic Aides !or DTC P.;A; P017! - 8 stem to Lean (7an$ /) The Adapti"e Fuel 8trateg continuousl monitors the !uel deli"er hardware# The test !ails when the adapti"e !uel tables reach a rich calibrated limit# 8ee Possible Causes !or DTC P.;A;# 8ee Diagnostic Aides !or DTC P.;A; P017 - 8 stem to *ich (7an$ /) The Adapti"e Fuel 8trateg continuousl monitors the !uel deli"er hardware# The test !ails when the adapti"e !uel tables reach a lean calibrated

limit# 8ee Possible Causes !or DTC P.;A;# 8ee Diagnostic Aides !or DTC P.;A; P0176 - Fle4ible Fuel (FF) 8ensor Circuit Mal!unction The FF sensor input signal to PCM is continuousl monitored# The test !ails when the signal !alls out o! a ma4imum or minimum calibrated range# %pen or short in FF sensor (P)* circuit %pen in batter ground to FF sensor circuit %pen in FF sensor signal circuit 8hort to ground in FF sensor signal circuit Fuel contamination 8hort to (P)* in FF sensor batter ground circuit 8hort to (P)* in FF sensor signal circuit Fuel separation Damaged FF sensor Damaged PCM A !le4 !uel (FF) PID reading o! . 3? with the $e %& and engine %FF or with engine at idle indicates a hard !ault# P0180 - 9ngine Fuel Temperature 8ensor A Circuit Low Input (9FT) The comprehensi"e component monitor (CCM) monitors the 9FT sensor circuit to the PCM !or low and high "oltage# I! "oltage were to !all below or e4ceed a calibrated limit and amount o! time during testing' the test will !ail# %pen or short in harness# Low ambient temperature operation# Improper harness connection# Damaged 9FT sensor# Damaged PCM# (eri! 9FT-PID "alue to determine open or short# P0181 - 9ngine Fuel Temperature 8ensor A Circuit *ange2 Per!ormance (9FT) The comprehensi"e component monitor (CCM) monitors the 9FT Temperature !or acceptable operating temperature# I! during testing "oltage were to !all below or e4ceed a calibrated limit' a calibrated amount o! time the test will !ail# %pen or short in harness# Low ambient temperature operation# Improper harness connection# Damaged 9FT sensor# Damaged PCM# (eri! 9FT-PID "alue to determine open or short# P0182 - 9ngine Fuel Temperature 8ensor A Circuit Low Input (9FT) The comprehensi"e component monitor (CCM) monitors the 9FT sensor circuit to the PCM !or low "oltage# I! "oltage were to !all below a calibrated limit and amount o! time during testing' the test will !ail# 8hort in harness# (*9F open or shorted# Low ambient temperature operation# Improper harness connection# Damaged 9FT sensor# Damaged PCM#

(eri! 9FT-PID and (*9F "alues to determine open or short# P0183 - 9ngine Fuel Temperature 8ensor A Circuit 3igh Input (9FT) The comprehensi"e component monitor (CCM) monitors the 9FT sensor circuit to the PCM !or high "oltage# I! "oltage were to e4ceed a calibrated limit and a calibrated amount o! time during testing' the test will !ail# %pen or short to P)* in harness# Damaged 9FT sensor# Improper harness connection# Damaged PCM# (eri! 9FT-PID "alue to determine open or short# P0186 - 9ngine Fuel Temperature 8ensor 7 Circuit *ange2Per!ormance (9FT) 8ee DTC P.;=;# P0187 - 9ngine Fuel Temperature 8ensor 7 Circuit Low Input (9FT)# 8ee DTC P.;=/# P0188 - 9ngine Fuel Temperature 8ensor 7 Circuit 3igh Input (9FT) 8ee DTC P.;=0# P0190 - Fuel *ail Pressure 8ensor Circuit Mal!unction (F*P) The comprehensi"e component monitor (CCM) monitors the F*P sensor to the PCM !or (*9F "oltage# The test !ails when the (*9F "oltage !rom the PCM drops to a "oltage less than a minimum calibrated "alue# (*9F open in harness# (*9F open in sensor# (*9F open in PCM# (eri! (*9F "oltage between 5#. and 6#.(# P0191 - Fuel *ail Pressure 8ensor Circuit Per!ormance (F*P) The comprehensi"e component monitor (CCM) monitors the F*P pressure !or acceptable !uel pressure# The test !ails when the !uel pressure !alls below or e4ceeds a minimum2ma4imum calibrated "alue !or a calibrated period o! time# 3igh !uel pressure# Low !uel pressure# Damaged F*P sensor# 94cessi"e resistance in circuit# Low or no !uel# A F*P PID "alue during B%9* o! ;0= $pa (/. psi) and 5;0 $pa (6. psi) !or gasoline or :=6 $pa (=: psi) and A/: $pa (;.: psi) !or natural gas "ehicles (&+) is acceptable# P0192 - Fuel *ail Pressure 8ensor Circuit Low Input (F*P) The comprehensi"e component monitor (CCM) monitors the F*P sensor circuit to the PCM !or low "oltage# I! "oltage were to !all below a calibrated limit and amount o! time during testing' the test will !ail# F*P signal shorted to 8I+ *T& or P)* +&D# F*P signal open (&+ onl ) Low !uel pressure (&+ onl ) Damaged F*P sensor# Damaged PCM# A F*P PID "alue during B%9* or B%9% less than .#0 "olts !or gasoline or .#: "olts !or

natural gas "ehicles (&+) would indicate a hard !ault# P0193 - Fuel *ail Pressure 8ensor Circuit 3igh Input (F*P) The comprehensi"e component monitor (CCM) monitors the F*P sensor circuit to the PCM !or high "oltage# I! "oltage were to !all below a calibrated limit and a calibrated amount o! time during testing' the test will !ail# F*P signal shorted to (*9F or (P)*# F*P signal open (gasoline onl ) Low !uel pressure (&+ onl ) Damaged F*P sensor# Damaged PCM# 3igh !uel pressure (caused b damaged !uel pressure regulator) &+# A F*P PID "alue during B%9* or B%9% less than .#0 "olts !or gasoline or .#: "olts !or natural gas "ehicles (&+) would indicate a hard !ault# P0201 t"roug" P0212 - C linder H; through C linder H;/ InFector Circuits The comprehensi"e component monitor (CCM) monitors the operation o! the !uel inFector dri"ers in the PCM# The test !ails when the !uel inFector does not operate electricall e"en though the harness assembl and !uel inFectors test satis!actoril # Fault !uel inFector dri"er within the PCM# PID Data Monitor I&I;F-I&I;/F !ault !lags J K98# P0217 - 9ngine Coolant %"er-Temperature Condition Indicates an engine o"erheat condition was detected b the c linder head temperature (C3T) sensor# This condition will cause the boost !rom the supercharger to be b passed to a"oid potential engine damage# 9ngine cooling s stem concerns# Low engine coolant le"el# 7ase engine concerns# Monitor C3T PID !or o"erheat condition# T pical C3T temperature should be close to cooling s stem thermostat opening speci!ication# P0230 - Fuel Pump Primar Circuit Mal!unction &%T9@ For natural gas applications' the !ollowing description applies to the !uel shuto!! "al"e (F8() circuit# The PCM monitors the !uel pump (FP) circuit output !rom the PCM# The test !ails i!@ )ith the FP output commanded %& (grounded)' e4cessi"e current draw is detected on the FP circuitL or with the FP output commanded %FF' "oltage is not detected on the FP circuit (the PCM e4pects to detect (P)* "oltage coming through the !uel pump rela coil to the FP circuit)# %pen or shorted !uel pump (FP) circuit %pen (P)* circuit to !uel pump rela Damaged !uel pump rela Damaged PCM )hen the FPF PID reads K98' a !ault is currentl present# An open circuit or short to ground can onl be detected with the !uel pump commanded %FF# A short to power can onl be detected with the !uel pump commanded %&# During B%9% and B%9* sel!-test' the !uel pump output command will be c cled %& and %FF#

P0231 - Fuel Pump 8econdar Circuit Low &%T9@ For natural gas applications' the !ollowing description applies to the !uel shuto!! "al"e monitor (F8(M) and the !uel shuto!! "al"e power (F8( P)*) circuits# The PCM monitors the !uel pump monitor (FPM) circuit# The test !ails i! the PCM commands the !uel pump %& and 7G "oltage is not detected on the FPM circuit# %pen 7G circuit to the !uel pump rela %pen FP P)* circuit between the !uel pump rela and its connection to the FPM circuit Damaged !uel pump rela Damaged PCM (engine will start) For 5#6L Mustang' open FP P)* circuit !rom low speed !uel pump rela ' through resistor to FPM splice (engine will start) For :#5L 8C Lightning' damaged IF8 switch' IF8 switch rela ' or concern with related circuits# During B%9% sel!-test' the PCM will command the !uel pump %& so this test can be per!ormed# P0232 - Fuel Pump 8econdar Circuit 3igh &%T9@ For natural gas applications' the !ollowing description applies to the !uel shuto!! "al"e monitor (F8(M) and the !uel shuto!! "al"e power (F8( P)*) circuits# The PCM monitors the !uel pump monitor (FPM) circuit# This test !ails when the PCM detects "oltage on the FPM circuit while the !uel pump is commanded %FF# The FPM circuit is wired to a pull-up "oltage inside the PCM# The FPM circuit will go high i!' with the $e %& and the !uel pump commanded %FF' the FPM2FP P)* circuit loses its path to ground through the !uel pump# The FPM circuit will also go high i! the FPM2FP P)* circuit is shorted to power# Inertia !uel shuto!! (IF8) switch not reset or electricall open %pen circuit between the !uel pump and the FPM connection to the FP P)* circuit Poor !uel pump ground Fuel pump electricall open Fuel pump secondar circuits short to power Fuel pump rela contacts alwa s closed %pen FPM circuit between PCM and connection to FP P)* circuit Damaged low speed !uel pump rela or concern with related circuits (i! e1uipped)# Damaged PCM Continuous memor P./0/ can be set i! the IF8 switch was tripped' then reset' or i! the !uel pump circuit is acti"ated when the PCM e4pected the circuit to be o!! (i#e# !uel s stem test or prime procedure)# P023! - 8upercharger %"erboost Condition The PCM disables (b passes) the supercharger boost and sets a diagnostic trouble code (DTC) to $eep !rom damaging the powertrain (engine or transmission) during potential harm!ul operating conditions# 7ra$e tor1ue (bra$e on and throttle at wide open) Transmission oil temperature (T%T) e4ceeds calibrated threshold 9ngine o"er temperature Ignition mis!ire e4ceeds calibrated threshold

Bnoc$ sensor (B8) !ailure or $noc$ detected Low speed !uel pump rela not switching Chec$ !or other diagnostic trouble codes accompan ing the P./05 or chec$ appropriate and a"ailable PIDs related to abo"e possible causes# P02!3 - 8upercharger (7oost) 7 pass 8olenoid Circuit Mal!unction The PCM monitors the supercharger (boost) b pass (8C7) solenoid circuit !or an electrical !ailure# The test !ails when the signal mo"es outside the minimum or ma4imum allowable calibrated parameters !or a speci!ied 8C7 solenoid dut c cle (;..D or .D) b PCM command# (P)* circuit open to 8C7 solenoid 8C7 solenoid circuit shorted to P)* +&D or C3A88I8 +&D Damaged 8C7 solenoid 8C7 solenoid circuit open 8C7 solenoid circuit shorted to (P)* Damaged PCM Disconnect 8C7 solenoid# Connect test lamp to 8C7 solenoid harness connector# C cle 8C7 dri"er in PCM b %utput Test Mode# Test lamp c cle on and o!! - 8C7 solenoid is suspect# Test lamp alwa s on - 8C7 signal short in harness or PCM# Test alwa s o!! 8C7 signal or (P)* open in harness or PCM# P0298 - 9ngine %il %"er Temperature Condition Indicates the 9ngine %il Temperature Protection strateg in the PCM has been acti"ated# This will temporaril prohibit high engine speed operation b disabling inFectors' there!ore reducing the ris$ o! engine damage !rom high engine oil temperature# &ote@ %n engines which are e1uipped with an oil temperature sensor' the PCM reads oil temperature to determine i! it is e4cessi"e# )hen an oil temperature sensor is not present' the PCM uses an oil algorithm to in!er actual temperature# 9ngine shutdown strateg !unction is the same on "ehicles with and without oil temperature sensors# (er high engine rpm !or e4tended period o! time# %"er-heating condition# Mal!unction 9%T sensor or circuit ("ehicles w29%T sensor)# 7ase engine concerns# 9ngine operating in high rpm range' due to improper gear selection# Ma cause Lac$2Loss o! Power or 8urge customer concern# P0300 - *andom Mis!ire The random mis!ire DTC indicates multiple c linders are mis!iring or the PCM cannot identi! which c linder is mis!iring# Camsha!t position sensor (CMP) Low !uel@ less than ;2= tan$ 8tuc$ open 9+* "al"e 7loc$ed 9+* passages %ne or more 9+* passages ma be bloc$ed or partiall bloc$ed# I! this is the case the Mis!ire Detection Monitor will indicate the 9+* port to chec$ !or possible bloc$age# P0301 t"roug" P0310 - Mis!ire Detection Monitor The mis!ire detection monitor is designed to monitor engine mis!ire and identi! the speci!ic c linder in which the mis!ire has occurred# Mis!ire is de!ined as lac$ o! combustion in a c linder due to absence o!

spar$' poor !uel metering' poor compression' or an other cause# Ignition s stem Fuel inFectors *unning out o! !uel 9(AP canister purge "al"e Fuel pressure 9"aporati"e emission s stem 7ase engine The MIL will blin$ once per second when a mis!ire is detected se"ere enough to cause catal st damage# I! the MIL is on stead state' due to a mis!ire' this will indicate the threshold !or emissions was e4ceeded and cause the "ehicle to !ail an inspection and maintenance tailpipe test# P0320 - Ignition 9ngine 8peed Input Circuit Mal!unction The ignition engine speed sensor input signal to PCM is continuousl monitored# The test !ails when the signal indicates that two successi"e erratic pro!ile ignition pic$up (PIP) pulses ha"e occurred# Loose wires2connectors# Arcing secondar ignition components (coil' wires and plugs) %n board transmitter (/-wa radio) The DTC indicates that two successi"e erratic PIP pulses occurred# P032 - Bnoc$ 8ensor ; Circuit Mal!unction (7an$ ;) 8ee DTC P.0/6 P0326 - Bnoc$ 8ensor ; Circuit *ange2 Per!ormance (7an$ ;) The $noc$ sensor detects "ibrations upon increase and decrease in engine rpm# The $noc$ sensor generates a "oltage based on this "ibration# 8hould this "oltage go outside a calibrated le"el a DTC will set# Bnoc$ sensor circuit short to +&D Bnoc$ sensor circuit short to P)* Bnoc$ sensor circuit open Damaged $noc$ sensor Damaged PCM A $noc$ sensor "oltage greater than .#:( with the $e %& and engine %FF indicates a hard !ault# P0330 - Bnoc$ 8ensor / Circuit Mal!unction (7an$ /) 8ee DTC P.00; P0331 - Bnoc$ 8ensor / Circuit *ange2per!ormance (7an$ /) The $noc$ sensor detects "ibration upon increase and decrease in engine rpm# The $noc$ sensor generates a "oltage based on this "ibration# 8hould this "oltage go outside a calibrated le"el a DTC will set# Bnoc$ sensor circuit short to +&D Bnoc$ sensor circuit short to P)* Damaged $noc$ sensor Damaged PCM Bnoc$ sensor circuit open A $noc$ sensor "oltage greater than .#:( with the $e %& and engine %FF indicates a hard !ault#

P03!0 - Camsha!t Position (CMP) 8ensor Circuit Mal!unction The test !ails when the PCM can no longer detect the signal !rom the CMP sensor# CMP circuit open CMP circuit short to +&D CMP circuit short to P)* 8I+ *T& open ((* sensor) CMP +&D open (3all e!!ect sensor) CMP misinstalled (3all e!!ect sensor) Damaged CMP sensor shielding Damaged CMP sensor Damaged PCM 3arness routing' harness alterations' improper shielding' or electrical inter!erence !rom other improperl !unctioning s stems ma ha"e intermittent impact on the CMP signal# P03 0 - Ignition Coil (Cndetermined) Primar 2 8econdar Circuit Mal!unction 9ach ignition primar circuit is continuousl monitored# The test !ails when the PCM does not recei"e a "alid IDM pulse signal !rom the ignition module (integrated in PCM)# %pen or short in Ignition 8TA*T2*C& circuit %pen coil dri"er circuit Coil dri"er circuit shorted to ground Damaged coil Damaged PCM Coil dri"er circuit shorted to (P)* P03 1 T"roug" P0360 - Ignition Coil A through I Primar 2 8econdar Circuit Mal!unction 9ach ignition primar circuit is continuousl monitored# The test !ails when the PCM does not recei"e a "alid IDM pulse signal !rom the ignition module (integrated in PCM)# %pen or short in Ignition 8TA*T2*C& circuit %pen coil dri"er circuit in harness Coil dri"er circuit shorted to ground Damaged coil Damaged PCM Coil dri"er circuit shorted to P)* P0!00 9+* Flow Failure (outside the minimum or ma4imum limits) The 99+* s stem is monitored once per dri"e c cle during stead state conditions abo"e 5= mph # The test will !ail when a mal!unction is detected b PCM calculations indicating the 9+* !low is less or greater than e4pected# 99+* "al"e stuc$ open or closed Connector to 99+* not seated 99+* motor windings shorted or open circuited &o power to 99+* 3arness open or shorted to power or ground (acuum signal to MAP restricted or lea$ing MAF sensor signal erroneous Damaged PCM Carbon build up in 99+* "al"e seat area %ne or more sensor not responding or out o! range

All o! the !ollowing sensors input data to the PCM !or proper operation o! the 99+* s stem@ 9CT' CP8' IAT' MAF' TP' MAP# An DTC relating to these sensors must be resol"ed prior to addressing P0!00 code# P0!01 - 9+* Flow Insu!!icient Detected The 9+* s stem is monitored during stead state dri"ing conditions while the 9+* is commanded on# The test !ails when the signal !rom the DPF 9+* sensor indicates that 9+* !low is less than the desired minimum# (acuum suppl 9+* "al"e stuc$ closed 9+* "al"e lea$s "acuum 9+* !low path restricted 9+*(* circuit shorted to P)* (*9F open to D#P#F# 9+* sensor D#P#F# 9+* sensor downstream hose o!! or plugged 9+*(* circuit open to PCM (P)* open to 9+*(* solenoid D#P#F# 9+* sensor hoses both o!! D#P#F# 9+* sensor hoses re"ersed Damaged 9+* ori!ice tube Damaged 9+*(* solenoid Damaged PCM Per!orm B%9* sel!-test and loo$ !or DTC P;5.= as an indication o! a hard !ault# I! P;5.= is not present' loo$ !or contamination' restrictions' lea$s' and intermittents# P0!02 - 9+* Flow 94cessi"e Detected The 9+* s stem is monitored !or undesired 9+* !low during idle# The 9+* monitor loo$s at the DPF 9+* signal at idle and compares it to the stored signal measured during $e %& and engine %FF# The test !ails when the signal at idle is greater than at $e %& engine %FF b a calibrated amount# 9+* "al"e stuc$ open Plugged 9+* "acuum regulator solenoid "ent Plugged 9+* tube 8low responding D#P#F# 9+* sensor Damaged DPF 9+* sensor Improper "acuum hose connection Plugged "acuum hoses 9+*(* circuit shorted to ground Damaged 9+* "acuum regulator solenoid Damaged PCM A DPF9+* PID reading that is greater at idle than during $e %& and engine %FF b .#: "olt or a rough engine idle' ma indicate a hard !ault# P0!03 99+* 9lectric Motor )indings %r Circuits To The PCM 8horted %r %pen The 99+* s stem is continousl monitored to chec$ the 5 99+* motor coils' circuits' and the PCM !or opens' shorts to power and ground# I! a mal!unction is detected the 99+*

s stem will be disabled and additional monitoring will be suspended !or the remainder o! the dri"e until the ne4t dri"e c cle# 99+* motor windings open Connector to 99+* not seated %pen circuit in harness !rom PCM to 99+* %pen circuit in PCM 8hort circuit in 99+* motor 8hort circuit in harness !rom PCM to 99+* 8hort circuit in PCM I! an intermittent condition is suspected the most e!!ecti"e methoid o! wiring !ault isolation is to use the wiggle test methoid while measuring !or shorts and open circuits# P0!11 - 8econdar Air InFection (AI*) s stem upstream !low 8ee DTC P;5;; P0!12 - 8econdar Air InFection 8 stem (AI*) circuit mal!unction The PCM attempts to control when air is inFected in the e4haust# The DTC indicates a 8econdar Air inFection s stem AI* circuit !ault# AI* circuit open AI* b pass solenoid !ault Damaged PCM AI* circuit short to power 8olid state rela !ault Damaged AI* pump The AI* circuit is normall held high through the AI* b pass solenoid and 88* when the output dri"er is o!!# There!ore' a low AI* circuit indicates a dri"er is alwa s on and a high circuit indicates an open in the PCM# P0!20 - Catal st 8 stem 9!!icienc 7elow Threshold (7an$ ;) Indicates 7an$ ; catal st s stem e!!icienc is below the acceptable threshold Cse o! leaded !uel Damaged 3%/8 Mal!unctioning 9CT 3igh !uel pressure Damaged e4haust mani!old Damaged catal tic con"erter %il contamination C linder mis!iring Downstream 3%/8 wires improperl connected Damaged e4haust s stem pipe Damaged mu!!ler2tailpipe assembl *etarded spar$ timing Compare 3%/8 upstream and downstream switch rate and amplitude# Cnder normal closed loop !uel conditions' high e!!icienc catal sts ha"e o4 gen storage which ma$es the switching !re1uenc o! the downstream 3%/8 "er slow and reduces the amplitude o! those switches as compared to the upstream 3%/8# As catal st e!!icienc deteriorates' its abilit to store o4 gen declines and the downstream 3%/8 signal begins to switch more rapidl with increase amplitude' approaching the switching rate and amplitude o! the upstream 3%/8# %nce be ond an acceptable limit the DTC is set#

P0!30 - Catal st 8 stem 9!!icienc 7elow Threshold (7an$ /) Indicates 7an$ / catal st s stem e!!icienc is below the acceptable threshold# Cse o! leaded !uel Damaged 3%/8 Mal!unctioning 9CT 3igh !uel pressure Damaged e4haust mani!old Damaged catal tic con"erter %il contamination C linder mis!iring Downstream 3%/8 wires improperl connected Damaged e4haust s stem pipe Damaged mu!!ler2tailpipe assembl *etarded spar$ timing Compare 3%/8 upstream and downstream switch rate and amplitude# Cnder normal closed loop !uel conditions' high e!!icienc catal sts ha"e o4 gen storage which ma$es the switching !re1uenc o! the downstream 3%/8 "er slow and reduces the amplitude o! those switches as compared to the upstream 3%/8# As catal st e!!icienc deteriorates' its abilit to store o4 gen declines and the downstream 3%/8 signal begins to switch more rapidl with increase amplitude' approaching the switching rate and amplitude o! the upstream 3%/8# %nce be ond an acceptable limit the DTC is set# P0!!2 - 9(AP Control 8 stem Lea$ Detected (8mall Lea$) The PCM monitors the complete 9(AP control s stem !or presence o! a small !uel "apor lea$# The s stem !ailure occurs when a !uel "apor lea$ !rom an opening as small as ;#.;6 mm (.#.5 inch) is detected b the 9(AP running loss monitor test# A!ter-mar$et 9(AP hardware (such as !uel !iller cap) non-con!orming to re1uired speci!ications 8mall holes or cuts in !uel "apor hoses2tubes Canister "ent solenoid sta s partiall open on closed command Damaged' cross-threaded or loosel installed !uel !iller cap Loose !uel "apor hose2tube connections to 9(AP s stem components 9(AP s stem component seals lea$ing (9(AP canister purge "al"e' !uel tan$ pressure sensor' canister "ent solenoid' !uel "apor control "al"e tube assembl or !uel "apor "ent "al"e assembl ) P0!!3 - 9(AP Control 8 stem Canister Purge (al"e Circuit Mal!unction The PCM monitors the 9(AP canister purge "al"e circuit !or an electrical !ailure# The test !ails when the signal mo"es outside the minimum or ma4imum allowable calibrated parameters !or a speci!ied purge dut c cle b PCM command# (P)* circuit open 9(AP canister purge "al"e circuit shorted to +&D Damaged 9(AP canister purge "al"e 9(AP canister purge "al"e circuit open 9(AP canister purge "al"e circuit shorted to (P)* Damaged PCM Monitor 9(APPDC PID and "oltage between 9(AP canister "al"e signal and P)* +&D in output test mode with $e %& engine %FF (or in $e %& engine *C&&I&+ mode)# 9(APPDC PID at .D and "oltage less than ;#. "olts (or 9(APPDC PID at ;..D

and "oltage less than .#: "olts) indicates a hard !ault# P0! 1 - FTP 8ensor Circuit &ois The !uel tan$ pressure changes greater than ;5 inches o! 3 / . in .#;. seconds# Intermittent open or short in the FTP sensor or the FTP sensor signal# Monitor FTP PID and does it change !rom abo"e ;: inches o! 3 / . to below a minus (-) ;: inches o! 3 / . o!ten in ;#. minute# P0! 2 - FTP 8ensor Circuit Low (oltage Detected The PCM monitors the 9(AP control s stem FTP sensor input signal to the PCM# The test !ails when the signal a"erage drops below a minimum allowable calibrated parameter# Contamination internal to FTP sensor connector Damaged PCM FTP circuit shorted to +&D or 8I+ *T& Damaged FTP sensor FTP ( PID reading less than .#// "olt with $e %& and engine %FF or during an engine operating mode indicates a hard !ault# P0! 3 - FTP 8ensor Circuit 3igh (oltage Detected The PCM monitors the 9(AP control s stem FTP sensor input signal to the PCM# The test !ails when the signal a"erage Fumps abo"e a minimum allowable calibrated parameter# FTP circuit open (*9F shorted to (P)* Damaged PCM FTP circuit shorted to (*9F or (P)* 8I+ *T& circuit open Damaged FTP sensor FTP ( PID reading greater than 5#:. "olts with $e %& and engine %FF or during an engine operating mode indicates a hard !ault# P0! - 9(AP Control 8 stem Lea$ Detected (&o Purge Flow or Large Lea$) The PCM monitors the complete 9(AP control s stem !or no purge !low' the presence o! a large !uel "apor lea$ or multiple small !uel "apor lea$s# The s stem !ailure occurs when no purge !low (attributed to !uel "apor bloc$ages or restrictions)' a large !uel "apor lea$ or multiple !uel "apor lea$s are detected b the 9(AP running loss monitor test with the engine running (but not at idle)# A!ter-mar$et 9(AP hardware (such as !uel !iller cap) non-con!orming to re1uired speci!ications Disconnected or crac$ed !uel 9(AP canister tube' 9(AP canister purge outlet tube or 9(AP return tube 9(AP canister purge "al"e stuc$ closed Damaged 9(AP canister Damaged or missing !uel !iller cap Insu!!icient !uel !iller cap installation Loose !uel "apor hose2tube connections to 9(AP s stem components 7loc$ages or restrictions in !uel "apor hoses2tubes (items also listed under disconnections or crac$s) Fuel "apor control "al"e tube assembl or !uel "apor "ent "al"e assembl bloc$ed

Canister "ent (C() solenoid stuc$ open Mechanicall inoperati"e !uel tan$ pressure (FTP) sensor Chec$ !or audible "acuum noise or signi!icant !uel odor in the engine compartment or near the 9(AP canister and !uel tan$# P0! 6 - 9(AP Control 8 stem Lea$ Detected ((er 8mall Lea$) The PCM monitors the complete 9(AP control s stem !or the presence o! a "er small !uel "apor lea$# The s stem !ailure occurs when a !uel "apor lea$ !rom an opening as small as .#:.= mm (.#./. inch) is detected b the 9(AP running loss monitor test# (er small holes or cuts in !uel "apor hoses2tubes# Loose !uel "apor hose2tube connections to 9(AP s stem components# 9(AP s stem component seals lea$ing (re!er to Possible Causes under DTC P.55/)# P0! 7 - 9(AP Control 8 stem Lea$ Detected (Fuel Filler Cap Loose2%!!) A !uel tan$ pressure change greater than a minus (-) A inches o! 3 / . in 0. seconds has occurred a!ter re!uelingL or there is e4cessi"e purge (!uel "apor) !low greater than .#.6 pounds per minute# Fuel !iller cap not installed on re!ueling (storing continuous memor DTC) and >chec$ Fuel Cap> light ma also be illuminated# Fuel !iller cap missing' loose or cross-threaded# Chec$ !or missing !uel !iller cap or integrit o! the cap# I! %B' clear continuous memor DTCs and re-initiate 9(AP 9mission *unning Loss Monitor Dri"e C cle# P0!60 - Fuel Le"el 8ensor Circuit Mal!unction The PCM monitors the !uel le"el input (FLI) circuit !or electrical !ailure# The test !ails when the signal mo"es outside the minimum or ma4imum allowable calibrated parameters !or a speci!ied !uel !ill percentage in the !uel tan$# 9mpt !uel tan$ Fuel pump (FP) module stuc$ open Incorrectl installed !uel gauge Damaged instrument cluster CA89 +&D circuit open FLI shorted to (P)* Damaged PCM %"er!illed !uel tan$ Fuel pump (FP) module stuc$ closed Damaged !uel gauge FLI circuit open FLI circuit shorted to CA89 +&D or P)* +&D C89 +&D shorted to (P)* Monitor FLI PID and FLI ( PID in $e %& engine *C&&I&+# FLI PID at /:D !ill (with non matching !uel gauge) and FLI ( PID less than .#E. "olts ,!or FLI PID at A:D !ill (with non matching !uel gauge) and FLI ( PID greater than /#5: "olts- indicates a hard !ault# P0 00 - (ehicle 8peed 8ensor ((88) Mal!unction Indicates the powertrain control module (PCM) detected an error in the "ehicle speed in!ormation# (ehicle speed data is recei"ed !rom either the "ehicle speed sensor ((88)' trans!er case speed sensor (TC88)'

anti-loc$ bra$e s stem (A78) control module' generic electronic module (+9M)' or central timer module (CTM)# I! the engine rpm is abo"e the tor1ue con"erter stall speed (automatic transmission) and engine load is high' it can be in!erred that the "ehicle must be mo"ing# I! there is insu!!icient "ehicle speed data input' a mal!unction is indicated and a DTC is set# %n most "ehicle applications the mal!unction indicator lamp (MIL) will be triggered when this DTC is set# %pen in (88G2(88- harness circuit# %pen in TC88 signal or TC88 signal return harness circuit# 8hort to +&D in (88 harness circuit# 8hort to +&D in TC88 harness circuit# 8hort to P)* in (88 harness circuit# 8hort to P)* in TC88 harness circuit# %pen or short in the "ehicle speed circuit(s) ((8C) between the PCM and appropriate control module# Damaged (88 or TC88# Damaged wheel speed sensors# Damaged wheel speed sensor harness circuits# Damage in module(s) connected to (8C2(88 circuit# Damage dri"e mechanism !or (88 or TC88# Monitor (88 PID while dri"ing "ehicle# This DTC is set when the PCM detects a sudden loss o! "ehicle speed signal o"er a period o! time# I! "ehicle speed data is lost' chec$ the source o! where the "ehicle speed input originates !rom@ (88' TC88' A78' +9M or CTM# &ote@ %n some M8%F applications' (88 and TC88 PID can be monitor# 3owe"er i! no TC88 PID is a"ailable and (88 PID is ?ero' TC88 circuitr !re1uenc must be chec$ed !or loss o! sensor signal# I! another "ehicle electronic module has generated the P.:.. and the "ehicle does not recei"e its "ehicle speed input !rom one o! the abo"e mention sources ((88' TC88' A78' +9M or CTM)# Chec$ the PCM !or %utput 8ha!t 8peed 8ensor (%88) DTCs# %n %88 applications the PCM uses the %88 to calculated the "ehicle speed# I! no %88 DTCs are !ound chec$ !or correct PCM con!iguration# Chec$ PCM con!iguration !or correct tire si?e and a4le ratio# P0 01 - (ehicle 8peed 8ensor ((88) *ange2 Per!ormance Indicates the powertrain control module (PCM) detected an error in the "ehicle speed in!ormation# This DTC is set the same wa as P.:..' howe"er the mal!unction indicator lamp (MIL) is not triggered# *e!er to possible causes !or P.:..# *e!er to diagnostic aids !or P.:..# P0 03 - (ehicle 8peed 8ensor ((88) Intermittent Indicates poor or nois (88 per!ormance# (ehicle speed data is recei"ed !rom either the "ehicle speed sensor ((88)' trans!er case speed sensor (TC88)' anti-loc$ bra$e s stem (A78) control module' generic electronic module (+9M)' or central timer module (CTM)# &ois (882TC88 input signal !rom *adio Fre1uenc Inter!erence2 9lectro-Magnetic Inter!erence (*FI29MI) e4ternal sources such as ignition components or charging circuit# Damaged (88 or dri"en gears# Damaged TC88# Damaged wiring harness or connectors# Mal!unction in module(s) or circuit connected to (882TC88 circuit#

A!ter mar$et add-on# Monitor (88 PID while dri"ing "ehicle' chec$ !or intermittent "ehicle speed indication# (eri! ignition and charging s stem are !unctioning correctl # P0 0 - Idle Air Control 8 stem Mal!unction The PCM attempts to control engine speed during B%9* sel!-test# The test !ails when the desired rpm could not be reached or controlled during the sel!-test# IAC circuit open (P)* to IAC solenoid open IAC circuit shorted to P)* Air inlet is plugged Damaged IAC "al"e Damaged PCM The IAC solenoid resistance is !rom 6 to ;0 ohms# P0 2 - Power 8teering Pressure (P8P) 8ensor Circuit Mal!unction The P8P sensor input signal to the PCM is continuousl monitored#The test !ails when the signal is open or shorted to ground# P8P sensor damaged 8I+ *T& circuit open or shorted (*9F circuit open or shorted P8P sensor signal circuit open or shorted Damaged PCM The DTC indicates the P8P sensor circuit is open or shorted to ground# P0 3 - Power 8teering Pressure (P8P) 8ensor Circuit Mal!unction The P8P sensor input signal to PCM is continuousl monitored# The test !ails when the signal is shorted to power# P8P sensor damaged 8I+ *T& circuit shorted to power (*9F circuit shorted to power P8P sensor signal circuit shorted to power Damaged PCM The code indicates the P8P sensor circuit is shorted to power# P0602 - Control Module Programming 9rror This Diagnostic Trouble Code (DTC) indicates programming error within (ehicle ID bloc$ ((ID)# (ID data corrupted b the scan tool during (ID reprogramming Csing the scan tool' reprogram the (ID bloc$# I! PCM does not allow reprogramming o! the (ID bloc$' re!lashing PCM will be re1uired# P0603 - Powertrain Control Module BAM Test 9rror Indicates the PCM has e4perienced an internal memor !ault# 3owe"er there are e4ternal items that can cause this DTC# *eprogramming 7atter terminal corrosion BAP)* to PCM interrupt2open Loose batter connection Damaged PCM I! BAP)* is interrupted to the PCM because o! a batter or PCM disconnect' DTC can

be generated on the !irst power-up# P060 - PCM read onl memor (*%M) error Indicates the PCM *%M has been corupted# An attempt was made to change the calibration# Module programming error# Damaged PCM *eprogram or update calibration# *eprogram (ID bloc$ (use as built data)# Chec$ !or other DTCMs or dri"e s mptoms !or !urther action# P0703 - 7ra$e 8witch Circuit Input Mal!unction Indicates PCM did not recei"e a bra$e pedal position (7PP) input# %pen or short in 7PP circuit %pen or short in stoplamp circuits Damaged PCM Mal!unction in module(s) connected to 7PP circuit# (*ear 9lectronic Module ,*9M)indstar and L862L8= or Lighting Control Module (LCM) Continental and Town Car# Damaged bra$e switch MisadFusted bra$e switch Chec$ !or proper !unction o! stoplamps# Follow correct 8el!-Test procedures' re!er to 8ection / o! Nuic$ Test# P070! - Clutch Pedal Position 8witch Mal!unction )hen the clutch pedal is depressed the "oltage goes to low# I! the PCM does not see this change !rom high to low the DTC is set# CPP circuit short to P)* Damaged CPP switch CPP circuit open in the 8I+*T& Damaged PCM )hen depressing the CPP switch the "oltage should c cle !rom :#.( down# P0720 - Insu!!icient input !rom %utput 8ha!t 8peed sensor The output sha!t speed sensor inputs a signal to the PCM' based on the speed o! the output sha!t o! the transmission# The PCM compares this signal with the signal o! the (88 or TC88 and determines correct tire si?e and a4le gear ratio# %88 sensor circuit short to +&D %88 sensor circuit short to P)* %88 sensor circuit open Damaged %88 sensor Damaged PCM (eri! sensor signal output "aries with "ehicle speed# P0721 - &oise inter!erence on %utput 8ha!t 8peed sensor signal The output sha!t speed sensor signal is "er sensiti"e to noise# This noise distorts the input to the PCM# )iring misrouted A!ter mar$et add-on )iring damaged )iring insulation wear Chec$ routing o! harness#

Chec$ wiring and connector !or damage# P0722 - &o signal !rom %utput 8ha!t 8peed sensor The output sha!t speed sensor !ailed to pro"ide a signal to the PCM upon initial mo"ement o! "ehicle# Damaged %88 connector Damaged %88 sensor' or not installed properl 3arness intermittentl shorted or open P0723 - %utput 8ha!t 8peed sensor circuit intermittent !ailure The output sha!t speed sensor signal to the PCM is irregular or interrupted# 3arness connector not properl seated 3arness intermittentl shorted' or open 3arness connector damaged %88 sensor damaged' or not installed properl (eri! harness and connector integrit (eri! %88 sensor proper installation P0812 - *e"erse 8witch (*8) input circuit mal!unction The DTC indicates that the "oltage is high when it should be low# Transmission shi!t not indicating neutral while in B%9% 8el!-Test *8 circuit short to P)* Damaged re"erse switch *8 circuit open or short to 8I+*T& Damaged PCM Chec$ *8 PID while e4ercising shi!t le"er in and out o! re"erse# P1000 - Monitor Testing &ot Complete The on board diagnostic II (%7D II) monitors are per!ormed during the %7D II Dri"e C cle# The DTC will be stored in continuous memor i! an o! the %7D II monitors do not complete# (ehicle is new !rom the !actor 7atter or PCM had recentl been disconnected An %7D II monitor !ailure had occurred be!ore completion o! an %7D II dri"e c cle PCM DTCs ha"e recentl been cleared with a scan tool PT% circuit is shorted to (P)* or 7G or PT% is on during testing The DTC does not need to be cleared !rom the PCM e4cept to pass an inspection2maintenance test# P1001 - B%9* &ot Able To Complete' B%9* Aborted This &on-MIL (Mal!unction Indicator Lamp) code will be set when Be %n 9ngine *unning (B%9*) 8el!-Test does not complete in the time intended# Incorrect 8el!-Test Procedure# Cne4pected response !rom 8el!-Test monitors# rpm out o! speci!ication# *erun 8el!-Test !ollowing NT; in 8ection 0 ' 8 mptom Charts' 8T9P ;@ PCM Nuic$ Test# P1100 - Mass Air Flow (MAF) 8ensor Intermittent The MAF sensor circuit is monitored b the PCM !or sudden "oltage (or air !low) input change through the comprehensi"e

component monitor (CCM)# I! during the last 5. warm-up c cles in $e %& engine running the PCM detects a "oltage (or air !low) change be ond the minimum or ma4imum calibrated limit' a continuous memor diagnostic trouble code (DTC) is stored# Poor continuit through the MAF sensor connectors Poor continuit through the MAF sensor harness Intermittent open or short inside the MAF sensor# )hile accessing the MAF ( PID on the scan tool' lightl tap on the MAF sensor or wiggle the MAF sensor connector and harness# I! the MAF ( PID suddenl changes below .#/0 "olt or abo"e 5#6. "olts' an intermittent !ault is indicated# P1101 - Mass Air Flow (MAF) 8ensor %ut o! 8el!-Test *ange The MAF sensor circuit is monitored b the PCM !or an out o! range air !low (or "oltage) input# I! during $e %& engine %FF the air !low "oltage signal is greater than .#/A "olts the test !ails# Li$ewise' i! during $e %& engine running' an air !low "oltage signal is not within .#56 "olt to /#55 "olts' the test !ails# For "oltage to air !low gm2sec con"ersion' +% to Pinpoint Test DC and re!er to (oltage To Mass Air Flow Con"ersion Table# Low batter charge MAF sensor partiall connected MAF sensor contamination P)* +&D open to MAF sensor MAF *T& circuit open to PCM Damaged MAF sensor Damaged PCM A MAF ( PID reading greater than .#/A "olts (B%9%) or a MAF ( PID reading outside the .#56 "olt to /#55 "olts range (B%9*) indicates a hard !ault# P1112 - Inta$e Air Temperature (IAT) 8ensor Intermittent Indicates IAT sensor signal was intermittent during the comprehensi"e component monitor# Damaged harness Damaged sensor Damaged harness connector Damaged PCM Monitor IAT on scan tool' loo$ !or sudden changes in reading when harness is wiggled or sensor is tapped# P111! - Inta$e Air Temperature / Circuit Low Input Indicates the sensor signal is less than 8el!-Test minimum# The IAT/ sensor minimum is .#/ "olts# +rounded circuit in harness Improper harness connection Damaged sensor Damaged PCM Monitor IAT/ PID# T pical IAT/ temperature should be greater than IAT;# *e!er to 8ection 6 @ *e!erence (alues !or ranges# P111 - Inta$e Air Temperature / Circuit 3igh Input Indicates the sensor signal is greater than 8el!-Test ma4imum# The IAT/ sensor ma4imum is 5#6 "olts# %pen circuit in harness 8ensor signal short to power

Improper harness connection Damaged sensor Damaged PCM Monitor IAT/ PID# T pical IAT/ temperature should be greater than IAT;# *e!er to 8ection 6 @ *e!erence (alues !or ranges# P1116 - 9ngine Coolant Temperature (9CT) 8ensor %ut o! 8el!-Test *ange Indicates the 9CT sensor is out o! 8el!-Test range# Correct range is .#0 to 0#A "olts# %"erheating condition Mal!unctioning thermostat Damaged 9CT sensor Low engine coolant Damaged harness connector Damaged PCM 9ngine coolant temperature must be greater than ;.<C (:.<F) to pass the B%9% 8el!Test and greater than =/<C (;=.<F) to pass the B%9* 8el!-Test# P1117 - 9ngine Coolant Temperature (9CT) 8ensor Intermittent Indicates 9CT circuit became intermittentl open or shorted while engine was running# Damaged harness Damaged sensor Damaged PCM Damaged harness connector Low engine coolant Monitor 9CT on scan tool' loo$ !or sudden changes in reading when harness is wiggled or sensor is tapped# P1120 - Throttle Position (TP) 8ensor %ut o! *ange Low (*ATC3 too Low) The TP sensor circuit is monitored b the PCM !or a low TP rotation angle (or "oltage) input below the closed throttle position through the comprehensi"e component monitor (CCM)# I! during $e %& engine %FF or $e %& engine running the TP rotation angle (or "oltage) remains within the calibrated sel!-test range but !alls between 0#5/ and E#=:D (.#;A and .#5E "olt)' the test !ails# TP circuit with !ra ed wires Corrosion on TP circuit connectors (*9F open to TP sensor (*9F short to 8I+ *T& TP sensor loose pins A TP PID (TP ( PID) between 0#5/ and E#=:D (.#;A and .#5E "olt) in $e %& engine %FF' continuous memor or $e %& engine running indicates a hard !ault# P1121 - Throttle Position (TP) 8ensor Inconsistent with MAF 8ensor The PCM monitors a "ehicle operation rationalit chec$ b comparing sensed throttle position to mass air !low readings# I! during $e %& engine running sel!-test the comparison o! the TP sensor and MAF sensor readings are not consistent with calibrated load "alues' the test !ails and a diagnostic trouble code is stored in continuous memor # Air lea$ between MAF sensor and throttle bod TP sensor not seated properl

Damaged TP sensor Damaged MAF sensor Dri"e "ehicle and e4ercise throttle and TP sensor in all gears# A TP PID (TP ( PID) less than 5#=/ D (.#/5 "olt) with a L%AD PID greater than ::D or a TP ( PID greater than 5E#.:D (/#55 "olts) with a L%AD PID less than 0.D indicates a hard !ault# P112! - Throttle Position (TP) 8ensor %ut o! 8el!-Test *ange The TP sensor circuit is monitored b the PCM !or an out o! range TP rotation angle (or "oltage) input# I! during $e %& engine %FF or $e %& engine running the TP rotation angle (or "oltage) reading is less than ;0#/AD (.#66 "olt) or greater than /0#:/D (;#;A "olts)' the test !ails# 7inding or bent throttle lin$age TP sensor not seated properl Throttle plate below closed throttle position Throttle plate2screw misadFusted Damaged TP sensor Damaged PCM A TP PID (TP ( PID) reading not between ;0#/A and /0#:/D (.#66 and ;#;A "olts) in $e %& engine %FF or $e %& engine running indicates a hard !ault# P112 - Throttle Position (TP) 8ensor Intermittent The TP sensor circuit is monitored b the PCM !or sudden TP rotation angle (or "oltage) input change through the comprehensi"e component monitor (CCM)# I! during the last =. warm-up c cles in $e %& engine running the PCM detects a TP rotation angle (or "oltage) changes be ond the minimum or ma4imum calibrated limit' a continuous diagnostic trouble code (DTC) is stored# Poor continuit through the TP sensor connectors Poor continuit through the TP harness Intermittent open or short inside the TP sensor )hile accessing the TP ( PID on the scan tool' lightl tap on the TP sensor or wiggle the TP sensor connector and harness# I! the TP ( PID suddenl changes below .#5E "olt or abo"e 5#6: "olts' an intermittent !ault is indicated# P1127 - 94haust &ot )arm 9nough' Downstream 8ensor &ot Tested The 39+% monitor uses an e4haust temperature model to determine when the 3%/8 heaters are c cled %&# The test !ails when the in!erred e4haust temperature is below a minimum calibrated "alue# 9ngine not operating long enough prior to per!orming B%9* sel!-test# 94haust s stem too cool# Monitor 3%/8 3eater PIDs to determine their %&2%FF state# DTC P;;/A will be present i! the e4haust is not hot# P1128 - Cpstream %4 gen 8ensors 8wapped !rom 7an$ to 7an$ (3%/8-;;-/;) The 39+% monitor chec$s and determines i! the 3%/8 signal response !or a !uel shi!t corresponds to the correct engine ban$# The test !ails when a response !rom the 3%/8(s) being tested is not indicated# Crossed 3%/8 harness connectors (upstream)# Crossed 3%/8 wiring at the harness connectors (upstream)# Crossed 3%/8 wiring at the ;.5-pin harness connectors (upstream)#

P1129 - Downstream %4 gen 8ensors 8wapped !rom 7an$ to 7an$ (3%/8-;/-//) The 39+% monitor chec$s and determines i! the 3%/8 signal response !or a !uel shi!t corresponds to the correct engine ban$# The test !ails when a response !rom the 3%/8(s) being tested is not indicated# Crossed 3%/8 harness connectors (downstream)# Crossed 3%/8 wiring at the harness connectors (downstream)# Crossed 3%/8 wiring at the ;.5-pin harness connectors (downstream)# P1130 - Lac$ o! 3%/8-;; 8witch' Fuel Trim at Limit The 39+% 8ensor is monitored !or switching# The test !ails when the 3%/8 !ails to switch due to circuit or !uel at or e4ceeding a calibrated limit# 9lectrical@ 8hort to (P)* in harness or 3%/8 )ater in harness connector %pen28horted 3%/8 circuit Corrosion or poor mating terminals and wiring Damaged 3%/8 Damaged PCM Fuel 8 stem@ 94cessi"e !uel pressure Lea$ing2contaminated !uel inFectors Lea$ing !uel pressure regulator Low !uel pressure or running out o! !uel (apor reco"er s stem Induction 8 stem@ Air lea$s a!ter the MAF (acuum Lea$s PC( s stem Improperl seated engine oil dipstic$ 9+* 8 stem@ Lea$ing gas$et 8tuc$ 9+* "al"e Lea$ing diaphragm or 9(* 7ase 9ngine@ %il o"er!ill Cam timing C linder compression 94haust lea$s be!ore or near the 3%/8(s) A !uel control 3%/8 PID switching across .#5: "olt !rom .#/ to .#E "olt indicates a normal switching 3%/8# P;;0; - Lac$ o! 3%/8-;; 8witch' 8ensor Indicates Lean A 39+% sensor indicating lean at the end o! a test is tr ing to correct !or an o"er-rich condition# The test !ails when the !uel control s stem no longer detects switching !or a calibrated amount o! time# 8ee Possible Causes !or DTC P;;0. P1132 - Lac$ o! 3%/8-;; 8witch' 8ensor Indicates *ich A 39+% sensor indicating rich at the end o! a test is tr ing to correct !or an o"er-lean condition# The test !ails when the !uel control s stem no longer detects switching !or a calibrated amount o! time# 8ee

Possible Causes !or DTC P;;0. P1137 - Lac$ o! 3%/8-;/ 8witch' 8ensor Indicates Lean The downstream 3%/8 sensors are !orced rich and lean and monitored b the PCM# The test !ails i! the PCM does not detect the output o! the 3%/8 in a calibrated amount o! time# Pinched' shorted' and corroded wiring and pins Crossed sensor wires 94haust lea$s Contaminated or damaged sensor P1138 - Lac$ o! 3%/8-;/ 8witch' 8ensor Indicates *ich 8ee DTC P;;0A P11 0 - Lac$ o! 3%/8-/; 8witch' Fuel Trim at Limit 8ee DTC P;;0. P11 1 - Lac$ o! 3%/8-/; 8witch' 8ensor Indicates Lean A 39+% sensor indicating lean at the end o! a test is tr ing to correct !or an o"er-rich condition# The test !ails when !uel control s stem no longer detects switching !or a calibrated amount o! time# 8ee Possible Causes !or DTC P;;0. P11 2 - Lac$ o! 3%/8-/; 8witch' 8ensor Indicates *ich A 39+% sensor indicating rich at the end o! a test is tr ing to correct !or an o"er-lean condition# The test !ails when the !uel control s stem no longer detects switching !or a calibrated amount o! time# 8ee Possible Causes !or DTC P;;0. P11 7 - Lac$ o! 3%/8-// 8witch' 8ensor Indicates Lean 8ee DTC P;;0A P11 8 - Lac$ o! 3%/8-// 8witch' 8ensor Indicates *ich 8ee DTC P;;0A P1168 - Fuel *ail Pressure 8ensor in *ange 7ut Low The comprehensi"e component monitor (CCM) monitors the F*P pressure !or acceptable !uel pressure# The test !ails when the !uel pressure !alls below a calibrated "alue# Low !uel pressure Damaged F*P sensor 94cessi"e resistance in circuit Low or no !uel A F*P PID "alue below ::; $pa (=. psi) indicates a !ailure Low or no !uel A F*P PID "alue greater than =E6 $pa (;0. psi) indicates a !ailure

You might also like

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Ford DTCDocument35 pagesFord DTCAmina K. KhalilNo ratings yet

- Diagnostic Trouble CodesDocument133 pagesDiagnostic Trouble Codesraid91No ratings yet

- Trouble Codes OBDIIDocument55 pagesTrouble Codes OBDIIDanyel MoralesNo ratings yet

- Trouble Codes OBDIIDocument55 pagesTrouble Codes OBDIIFrancisco Cordova SandovalNo ratings yet

- Wiring Diagram (Single Alt.) Reference Only: Refer To Ford Wiring Diagrams For WiringDocument14 pagesWiring Diagram (Single Alt.) Reference Only: Refer To Ford Wiring Diagrams For WiringBryan Edgardo Pineda Galan100% (5)

- Diagnostic Trouble CodesDocument6 pagesDiagnostic Trouble CodesTaras KNo ratings yet

- Codigos International 2001Document6 pagesCodigos International 2001Scan DieselNo ratings yet

- 2007 PCED Powertrain DTC ChartsDocument147 pages2007 PCED Powertrain DTC ChartsefasaravananNo ratings yet

- Automatic Transaxle Fluid Temperature Sensor TroubleshootingDocument4 pagesAutomatic Transaxle Fluid Temperature Sensor Troubleshootingromelr100% (1)

- 4Hk1 6HK1 Engine Diagnostic and Drivability Student PDF (015 020)Document6 pages4Hk1 6HK1 Engine Diagnostic and Drivability Student PDF (015 020)luigiNo ratings yet

- DTC Table: DTC DTC Name DTC Detecting Condition DTC Detection Logic MILDocument3 pagesDTC Table: DTC DTC Name DTC Detecting Condition DTC Detection Logic MILJorge LeitesNo ratings yet

- Kia Code Retrieval: Accessing Diagnostic Trouble Codes Models Up To 95Document9 pagesKia Code Retrieval: Accessing Diagnostic Trouble Codes Models Up To 95mounir20No ratings yet

- DTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance ProblemDocument2 pagesDTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance Problempeter_nicks5441No ratings yet

- XL CodesDocument3 pagesXL CodesAntonioPalloneNo ratings yet

- Group 9 Self-Diagnostic System: Outline 1Document3 pagesGroup 9 Self-Diagnostic System: Outline 1giapy0000No ratings yet

- Opel Omega B CodesDocument12 pagesOpel Omega B CodesRazvan Secarianu100% (5)

- Codes ObdDocument38 pagesCodes ObdJany OliveroNo ratings yet

- Toyota Inputs & SensorsDocument22 pagesToyota Inputs & Sensorsfasdomingo100% (1)

- Tier 3 Engine Error Codes v1-01Document1 pageTier 3 Engine Error Codes v1-01Amnuay CharoenklaNo ratings yet

- Dodge 2001 Computer CodesDocument9 pagesDodge 2001 Computer Codespaul_a_rodriguezNo ratings yet

- Mitsubishi Códigos Error.Document9 pagesMitsubishi Códigos Error.Juan Manuel LaraNo ratings yet

- Ford Powertrain Control System Diagnostic GuideDocument4 pagesFord Powertrain Control System Diagnostic GuideFEF77757% (7)

- 2006trans13 ADocument10 pages2006trans13 Aeurospeed2No ratings yet

- 2006 3.5L (L52) Engine Diagnostic Parameters: 2006file14Document31 pages2006 3.5L (L52) Engine Diagnostic Parameters: 2006file14eurospeed20% (1)

- 2002 Pontiac Firebird DTC CODESDocument6 pages2002 Pontiac Firebird DTC CODESMaster XeotoNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P2135Document4 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P2135PeterNo ratings yet

- Interpret OBD II Data with this GuideDocument8 pagesInterpret OBD II Data with this GuideMohamed WahiebNo ratings yet

- Toyota Camry V6 Oxygen Sensor CodesDocument17 pagesToyota Camry V6 Oxygen Sensor CodesMuhammad Attohar Ibnu RafiNo ratings yet

- Tabela de Erros MotosDocument5 pagesTabela de Erros Motosmarcus9patricNo ratings yet

- Comprehensive Component Monitor Diagnosis OverviewDocument18 pagesComprehensive Component Monitor Diagnosis OverviewmongongoNo ratings yet

- GM OBD1 Code GuideDocument17 pagesGM OBD1 Code GuideMiguel RondónNo ratings yet

- CodigosDocument6 pagesCodigosAdán Castro GallegosNo ratings yet

- Felkoder Jeep Grand Cherokee 1993Document41 pagesFelkoder Jeep Grand Cherokee 19931LEFFENo ratings yet

- Manual Inyeccion Chery S11 SiemensDocument20 pagesManual Inyeccion Chery S11 SiemensJose RengelNo ratings yet

- DTC P0101 Mass Air Flow Circuit Range / Performance Problem: DescriptionDocument3 pagesDTC P0101 Mass Air Flow Circuit Range / Performance Problem: Descriptioncarlos gil100% (1)

- Kode Error Honda Pre ObdDocument11 pagesKode Error Honda Pre ObdSabri Bprf HuarrNo ratings yet

- Códigos Voyager DieselDocument4 pagesCódigos Voyager DieselJuan Carlos LlonaNo ratings yet

- Vehicle Sensors WiringDocument8 pagesVehicle Sensors WiringAudrick RussellNo ratings yet

- Caterpillar ADEM II 3176C 3406E C10 C12 Completo PDFDocument2 pagesCaterpillar ADEM II 3176C 3406E C10 C12 Completo PDFOmar Garcia Cazares100% (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Analog Circuit Design Volume Three: Design Note CollectionFrom EverandAnalog Circuit Design Volume Three: Design Note CollectionRating: 3 out of 5 stars3/5 (2)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Gen 0168536Document1 pageGen 0168536Adi Berari AdrianNo ratings yet

- Construction Manual For Transmission LinesDocument122 pagesConstruction Manual For Transmission Lineslatrociny95% (58)

- Learn French - Book 3 of 3Document20 pagesLearn French - Book 3 of 3Ber WeydeNo ratings yet

- Learn French - Book 2 of 3Document25 pagesLearn French - Book 2 of 3Ber WeydeNo ratings yet

- Programare AppDocument2 pagesProgramare AppAdi Berari AdrianNo ratings yet

- VSA Application Form March 2011Document9 pagesVSA Application Form March 2011Adi Berari AdrianNo ratings yet

- ACAD Elec 2009 GetStartDocument291 pagesACAD Elec 2009 GetStartNandan GowdaNo ratings yet

- Fileshare - Ro HackedDocument312 pagesFileshare - Ro HackedAdi Berari AdrianNo ratings yet

- Monitoring of BioprocessDocument41 pagesMonitoring of BioprocessSandiyaNo ratings yet

- Magnetic Properties of Iron-Oxide and (Iron, Cobalt) - Oxide Nanoparticles Synthesized in Polystyrene Resin MatrixDocument3 pagesMagnetic Properties of Iron-Oxide and (Iron, Cobalt) - Oxide Nanoparticles Synthesized in Polystyrene Resin MatrixPpa Gpat AmitNo ratings yet

- Astm C 473-03 Standard Test Methods For Physical Testing ofDocument13 pagesAstm C 473-03 Standard Test Methods For Physical Testing ofCharwin Picao100% (1)

- Membrane ReactorDocument9 pagesMembrane ReactorAzharuddin Ehtesham FarooquiNo ratings yet

- Statistical Treatment of Some Properties of Beans: Chemistry 3225 K. PierceDocument2 pagesStatistical Treatment of Some Properties of Beans: Chemistry 3225 K. Piercespiff spacemanNo ratings yet

- MRES216 Physical Techniques For The Study of Biological SystemsDocument10 pagesMRES216 Physical Techniques For The Study of Biological SystemsSaurabh ShineNo ratings yet

- Pit and Fissure SealantsDocument35 pagesPit and Fissure SealantsshrutiNo ratings yet

- Phono Par PDFDocument8 pagesPhono Par PDFvranceanu.ovidiu-1No ratings yet

- Grupo 5. LCA Chemical SolventDocument9 pagesGrupo 5. LCA Chemical SolventJuan Manuel FlorezNo ratings yet

- 3rd International Conference On The Advancement of Materials and Nanotechnology 2013 - ICAMN III 2013Document5 pages3rd International Conference On The Advancement of Materials and Nanotechnology 2013 - ICAMN III 2013Khairol Anuar MohammedNo ratings yet

- Macroetch Testing of Tool Steel Bars: Standard Practice ForDocument2 pagesMacroetch Testing of Tool Steel Bars: Standard Practice ForAmir AlikhaniNo ratings yet

- Electrochemical Cleaningof Artificially Tarnished SilverDocument11 pagesElectrochemical Cleaningof Artificially Tarnished SilverRahmi Nur Anisah Nasution 2003114489No ratings yet

- SymmetryDocument43 pagesSymmetryDeepa Kapadia0% (1)

- Elements Compounds and MixturesDocument24 pagesElements Compounds and MixturesMegan SarahNo ratings yet

- Atomoxetine HydrochlorideDocument3 pagesAtomoxetine Hydrochlorideehsan050628No ratings yet

- Xylene Methanol VLEDocument34 pagesXylene Methanol VLEAbubacker SiddieqNo ratings yet

- Cricket ThermometerDocument1 pageCricket ThermometerS. SpencerNo ratings yet

- 8 Mechanical VibrationsDocument10 pages8 Mechanical VibrationsTsihatesfaNo ratings yet

- IPS PressVESTDocument64 pagesIPS PressVESTToma IoanaNo ratings yet

- INSPECTION of Galvanize Product PDFDocument24 pagesINSPECTION of Galvanize Product PDFNasikhatul AmanahNo ratings yet

- Unit 3 Exam-SolutionsDocument8 pagesUnit 3 Exam-SolutionsbrunosipodNo ratings yet

- Venturi EffectDocument21 pagesVenturi Effectmuhammad ridNo ratings yet

- k2) Luxatherm5200 5219Document2 pagesk2) Luxatherm5200 5219Syed FaridNo ratings yet

- Development and Validation of A GC-FID Method For The Analysis of Short Chain Fatty Acids in Rat and Human Faeces and in Fermentation FluidsDocument9 pagesDevelopment and Validation of A GC-FID Method For The Analysis of Short Chain Fatty Acids in Rat and Human Faeces and in Fermentation Fluidsjuanda.scienceNo ratings yet

- Depolymerization of Tire and Natural Rubber Using Supercritical FluidsflaDocument8 pagesDepolymerization of Tire and Natural Rubber Using Supercritical FluidsflaAli DueNo ratings yet

- Class X Science Question PaperDocument24 pagesClass X Science Question PaperKalpna RaniNo ratings yet

- Comet Assay: From Wikipedia, The Free EncyclopediaDocument11 pagesComet Assay: From Wikipedia, The Free EncyclopediasuryasivNo ratings yet

- Lab - Properties of Carboxylic AcidsDocument2 pagesLab - Properties of Carboxylic Acidsapi-209270909No ratings yet

- Linx Duct Friction CalculatorDocument12 pagesLinx Duct Friction CalculatorLeonardo Martinho DobrianskyjNo ratings yet

- Theory of Solutions BasicsDocument34 pagesTheory of Solutions BasicsSiddharth DhurandharNo ratings yet