Professional Documents

Culture Documents

DTC P0101 Mass Air Flow Circuit Range / Performance Problem: Description

Uploaded by

carlos gilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DTC P0101 Mass Air Flow Circuit Range / Performance Problem: Description

Uploaded by

carlos gilCopyright:

Available Formats

ES–102 1GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Mass Air Flow Circuit Range / Performance

DTC P0101

Problem

DESCRIPTION

Refer to DTC P0100 (See page ES-90).

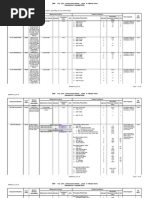

DTC No. DTC Detection Conditions Trouble Areas

Conditions (a), (b), (c), (d) and (e) are met (2 trip detection

logic):

(a) Engine running

(b) Engine coolant temperature 70°C (158°F) or higher

(c) Throttle Position (TP) sensor voltage 0.4 V or more • Mass Air Flow (MAF) meter

P0101 (d) Average engine load value ratio less than 0.85, or more • Air induction system

than 1.17 (varies with estimated engine load) • PCV hose connections

ES Average engine load value ratio = Average engine load based

on MAF meter output / Average engine load estimated from

driving conditions

(e) Average air-fuel ratio less than -20 %, or more than 20 %

MONITOR DESCRIPTION

The MAF meter is a sensor that measures the amount of air flowing through the throttle valve. The ECM

uses this information to determine the fuel injection time and to provide an appropriate air-fuel ratio. Inside

the MAF meter, there is a heated platinum wire which is exposed to the flow of intake air. By applying a

specific electrical current to the wire, the ECM heats it to a specific temperature. The flow of incoming air

cools both the wire and an internal thermistor, affecting their resistance. To maintain a constant current

value, the ECM varies the voltage applied to these components of the MAF meter. The voltage level is

proportional to the airflow through the sensor, and the ECM uses it to calculate the intake air volume.

The ECM monitors the average engine load value ratio to check the MAF meter for malfunctions. The

average engine load value ratio is obtained by comparing the average engine load calculated from the

MAF meter output to the average engine load estimated from the driving conditions, such as the engine

speed and the throttle opening angle. If the average engine load value ratio is below the threshold value,

the ECM determines that the intake air volume is low, and if the average engine load value ratio is above

the threshold value, the ECM determines that the intake air volume is high.

If this is detected in 2 consecutive driving cycles, the MIL is illuminated and a DTC is set.

MONITOR STRATEGY

Related DTCs P0101: Mass air flow meter rationality

Required Sensors/Components (Main) Mass air flow meter

Crankshaft Position (CKP) sensor, Engine Coolant Temperature

Required Sensors/Components (Related)

(ECT) sensor and Throttle Position (TP) sensor

Frequency of Operation Continuous

Duration 20 seconds or more

MIL Operation 2 driving cycles

Sequence of Operation None

TYPICAL ENABLING CONDITIONS

P0115 - P0118 (ECT sensor)

P0120 - P0223, P2135 (TP sensor)

Monitor runs whenever following DTCs not present P0125 (Insufficient ECT for closed loop)

P0335 (CKP sensor)

P0340 (CMP sensor)

Throttle position (TP sensor voltage) 0.4 V or more

Engine Running

Battery voltage 10.5 V or more

1GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM ES–103

Engine coolant temperature 70°C (158°F) or more

IAT sensor circuit OK

ECT sensor circuit OK

CKP sensor circuit OK

TP sensor circuit OK

Canister pressure sensor circuit OK

EVAP leak detection pump OK

EVAP vent valve OK

TYPICAL MALFUNCTION THRESHOLDS

Both of following conditions 1 and 2 met -

1. Averaged engine load value ratio

2. Averaged air-fuel ratio

Less than 0.85, or more than 1.17 (varies with estimated engine load)

Less than -20 %, or more than 20 %

ES

WIRING DIAGRAM

Refer to DTC P0100 (See page ES-92).

CONFIRMATION DRIVING PATTERN

HINT:

Performing this confirmation pattern will activate the mass air flow performance monitor.

Vehicle Speed

Approximately 62 mph

(100 km/h)

Idling

Time

Warming Up 20 seconds or more

A112632E01

1. Connect the intelligent tester to the DLC3.

2. Turn the ignition switch to ON.

3. Turn the tester ON.

4. Clear DTCs (See page ES-38).

5. Start the engine, and warm it up until the engine coolant temperature reaches 70°C (158°F) or higher.

6. Drive the vehicle at approximately 62 mph (100 km/h) for 20 seconds or more.

7. On the tester, select the following menu items: DIAGNOSIS / ENHANCED OBD II / DTC INFO /

PENDING CODES and check if any DTCs (any pending DTCs) are set.

ES–104 1GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

INSPECTION PROCEDURE

HINT:

Read freeze frame data using an intelligent tester. Freeze frame data record the engine condition when

malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was

moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other

data, from the time the malfunction occurred.

1 CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0101)

(a) Connect an intelligent tester to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the tester ON.

ES (d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(e) Read DTCs.

Result

Display (DTC Output) Proceed To

P0101 A

P0101 and other DTCs B

HINT:

If any DTCs other than P0101 are output, troubleshoot those

DTCs first.

B GO TO DTC CHART

2 CHECK AIR INDUCTION SYSTEM

(a) Check the air induction system for vacuum leakage.

OK:

No leakage from air induction system.

NG REPAIR OR REPLACE AIR INDUCTION

SYSTEM

OK

3 CHECK PCV HOSE CONNECTIONS

OK:

PCV hose is connected correctly and is not damaged.

NG REPAIR OR REPLACE PCV HOSE

OK

REPLACE MASS AIR FLOW METER (See page ES-409)

You might also like

- TCU Schematic and Control System ExplainedDocument52 pagesTCU Schematic and Control System ExplainedRoe De HardtoknowNo ratings yet

- Trouble Codes OBDIIDocument55 pagesTrouble Codes OBDIIDanyel MoralesNo ratings yet

- ECM Input/Output Components Diagnosis GuideDocument17 pagesECM Input/Output Components Diagnosis GuideFlorin BodroghinăNo ratings yet

- Glossary of Sae and Toyota TermsDocument3 pagesGlossary of Sae and Toyota TermsKevin StrongNo ratings yet

- Engine Data ListDocument48 pagesEngine Data ListPham Tuan AnhNo ratings yet

- ENGINE CONTROL INPUT & OUTPUT OVERVIEWDocument30 pagesENGINE CONTROL INPUT & OUTPUT OVERVIEWDangLuyenNo ratings yet

- Daihatsu Fault Codes DTCDocument1 pageDaihatsu Fault Codes DTCمحمد عبد الفتاح محمدNo ratings yet

- ECM/PCM Input and Output TestsDocument2 pagesECM/PCM Input and Output TestsDhami NongNo ratings yet

- GM ChargingDocument20 pagesGM ChargingMihai TacheNo ratings yet

- OBD II Trouble CodesDocument15 pagesOBD II Trouble CodesJETTISTNo ratings yet

- Toyota Obd CodesDocument4 pagesToyota Obd CodesAlexander MartinezNo ratings yet

- cx5 MitsubichiDocument554 pagescx5 MitsubichiJULIAN VALDERRAMA50% (2)

- Remove - Install Intelligent Servo ModuleDocument3 pagesRemove - Install Intelligent Servo ModuleJosephNo ratings yet

- Toyota Diagnostic Trouble Codes Full List Obdii365Document2 pagesToyota Diagnostic Trouble Codes Full List Obdii365kabuye NicholasNo ratings yet

- Glossary of SAE and Toyota TermsDocument3 pagesGlossary of SAE and Toyota TermsTomas FleitasNo ratings yet

- Kode Error Honda Pre ObdDocument11 pagesKode Error Honda Pre ObdSabri Bprf HuarrNo ratings yet

- OBD2 Diagnostic Code GuideDocument29 pagesOBD2 Diagnostic Code GuidecalvinyewNo ratings yet

- Trouble Codes OBDIIDocument55 pagesTrouble Codes OBDIIFrancisco Cordova SandovalNo ratings yet

- 2az-Fe Engine Control System Sfi SystemDocument6 pages2az-Fe Engine Control System Sfi SystemMarcelo DecimaNo ratings yet

- DTC Check ClearDocument2 pagesDTC Check ClearDaniel Mamani ParedezNo ratings yet

- Engine Compartment Fuse Box (Type 2) : 1 - 2 Head (RH) 10 Right Hand Headlight 3 Head (LH) 10 Left Hand HeadlightDocument7 pagesEngine Compartment Fuse Box (Type 2) : 1 - 2 Head (RH) 10 Right Hand Headlight 3 Head (LH) 10 Left Hand HeadlightCarlos Alberto LopezNo ratings yet

- Panasonic CS-E9CKP CS-E12CKP Service Manual Log PDFDocument94 pagesPanasonic CS-E9CKP CS-E12CKP Service Manual Log PDFvicentbort81No ratings yet

- Engine Control SystemDocument7 pagesEngine Control SystemFaisal Al HusainanNo ratings yet

- Abbreviations Used in Honda ManualDocument5 pagesAbbreviations Used in Honda ManualLazarus GutaNo ratings yet

- On-Board Diagnostics II OBDIIDocument9 pagesOn-Board Diagnostics II OBDIIJordan Teo Yong CiaNo ratings yet

- Nissan 1991-1993 Silvia S13 SR20DET, 1991-1995 180SX SR20DETDocument2 pagesNissan 1991-1993 Silvia S13 SR20DET, 1991-1995 180SX SR20DETElectronica Ave FenixNo ratings yet

- Eypad Verview: K636 - User's Quick Reference GuideDocument2 pagesEypad Verview: K636 - User's Quick Reference Guidesyaf rudyNo ratings yet

- 2006fileaveo MTDocument63 pages2006fileaveo MTeurospeed2100% (1)

- Yaris 1ar - Fe - Engine - Control PDFDocument36 pagesYaris 1ar - Fe - Engine - Control PDFCristhian CamposNo ratings yet

- Identification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaDocument54 pagesIdentification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaJuan Carlos Martinez NuñezNo ratings yet

- ECM I/O Signals DiagnosticsDocument5 pagesECM I/O Signals Diagnosticskofo3000No ratings yet

- J3 Meter Removal Installation and Troubleshooting GuideDocument32 pagesJ3 Meter Removal Installation and Troubleshooting GuideWaqar KhattakNo ratings yet

- ECT-Engine Coolant TempDocument4 pagesECT-Engine Coolant TempĐức HòangNo ratings yet

- OD Main Switch & OD OFF Indicator Light CircuitDocument4 pagesOD Main Switch & OD OFF Indicator Light Circuitcelestino tuliaoNo ratings yet

- Cadillac Escalade 2007-2009Document60 pagesCadillac Escalade 2007-2009Владимир ЛеонгардиNo ratings yet

- Electrochemi Toyota Land Cruiser Prado 2004 DemoDocument15 pagesElectrochemi Toyota Land Cruiser Prado 2004 DemoVinsensius Agus Priyono100% (1)

- Toyotabbreviationhare.qclt.com/汽车论坛免费资料第四期/TOYOTA-CAMRY/camry.pdf TOYOTA CAMRY. ELECTRICAL ... OVERALL ELECTRICAL WIRING DIAGRAM . .... WIRING ROUTING This section is closely related to the wiring diagram. ... ABBREVIATIONS. The following abbreviations are used in this manual. ABS. A/C.hare.qclt.com/汽车论坛免费资料第四期/TOYOTA-CAMRY/camry.pdf TOYOTA CAMRY. ELECTRICAL ... OVERALL ELECTRICAL WIRING DIAGRAM . .... WIRING ROUTING This section is closely related to the wiring diagram. ... ABBREVIATIONS. The following abbreviations are used in this manual. ABS. A/C.hare.qclt.com/汽车论坛免费资料第四期/TOYOTA-CAMRY/camry.pdf TOYOTA CAMRY. ELECTRICAL ... OVERALL ELECTRICAL WIRING DIAGRAM . .... WIRING ROUTING This section is closely related to the wiring diagram. ... ABBREVIATIONS. The following abbreviations are used in this manual. ABS. A/C.a AbbreviationsDocument3 pagesToyotabbreviationhare.qclt.com/汽车论坛免费资料第四期/TOYOTA-CAMRY/camry.pdf TOYOTA CAMRY. ELECTRICAL ... OVERALL ELECTRICAL WIRING DIAGRAM . .... WIRING ROUTING This section is closely related to the wiring diagram. ... ABBREVIATIONS. The following abbreviations are used in this manual. ABS. A/C.hare.qclt.com/汽车论坛免费资料第四期/TOYOTA-CAMRY/camry.pdf TOYOTA CAMRY. ELECTRICAL ... OVERALL ELECTRICAL WIRING DIAGRAM . .... WIRING ROUTING This section is closely related to the wiring diagram. ... ABBREVIATIONS. The following abbreviations are used in this manual. ABS. A/C.hare.qclt.com/汽车论坛免费资料第四期/TOYOTA-CAMRY/camry.pdf TOYOTA CAMRY. ELECTRICAL ... OVERALL ELECTRICAL WIRING DIAGRAM . .... WIRING ROUTING This section is closely related to the wiring diagram. ... ABBREVIATIONS. The following abbreviations are used in this manual. ABS. A/C.a AbbreviationsJustin LeoNo ratings yet

- 4 AfeDocument36 pages4 AfeJuan ContrerasNo ratings yet

- DTC C1554/23 Power Supply Relay Failure DTC C1555/25 Motor Relay Welding FailureDocument3 pagesDTC C1554/23 Power Supply Relay Failure DTC C1555/25 Motor Relay Welding FailureOswaldo Sierra100% (1)

- SensorDocument25 pagesSensorlyndorNo ratings yet

- 1mz Ecu Wiring DiagramDocument7 pages1mz Ecu Wiring Diagram12volt bayNo ratings yet

- Trouble Codes OBDIIDocument55 pagesTrouble Codes OBDIIdaniwesa100% (1)

- Acronyms ENGDocument20 pagesAcronyms ENGMichele ColomboNo ratings yet

- DTC C1267/67 Brake Pedal Load Sensing Switch: DescriptionDocument4 pagesDTC C1267/67 Brake Pedal Load Sensing Switch: DescriptionbakriramziNo ratings yet

- Daftar Kode DTC-WPS OfficeDocument3 pagesDaftar Kode DTC-WPS OfficeJannu Ageng100% (1)

- Scan Trouble Code Tanpa ScannerDocument8 pagesScan Trouble Code Tanpa Scannergene_t007233No ratings yet

- Heater & Air Conditioning Control System: SectionDocument230 pagesHeater & Air Conditioning Control System: SectionАндрей НадточийNo ratings yet

- Electronic Throttle ControlDocument67 pagesElectronic Throttle Controlmkisa70100% (1)

- Ec Engine Control SystemDocument503 pagesEc Engine Control SystemUALU333100% (1)

- Toyota Trouble Code GuideDocument1 pageToyota Trouble Code GuideFluke Ranza100% (2)

- 2014 Toyota Corolla Battery Charging System Service Information 2ZR-FAEDocument40 pages2014 Toyota Corolla Battery Charging System Service Information 2ZR-FAERubenNo ratings yet

- OBD2 Connector Location and Code Troubleshooting GuideDocument36 pagesOBD2 Connector Location and Code Troubleshooting GuideJorge Alfonso RodriguezNo ratings yet

- Kia Code Retrieval: Accessing Diagnostic Trouble Codes Models Up To 95Document9 pagesKia Code Retrieval: Accessing Diagnostic Trouble Codes Models Up To 95mounir20No ratings yet

- Electrically Controlled Shift Lock SystemDocument3 pagesElectrically Controlled Shift Lock SystemMayobanex Moya MartinezNo ratings yet

- Fuel Supply SystemDocument56 pagesFuel Supply Systemmkisa70No ratings yet

- Directechs DirectWire - 2023 Toyota Corolla Cross (Smart Key)Document15 pagesDirectechs DirectWire - 2023 Toyota Corolla Cross (Smart Key)almacen AutoperiquitoNo ratings yet

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- DTC P0101 Mass or Volume Air Flow Circuit Range/Performance ProblemDocument1 pageDTC P0101 Mass or Volume Air Flow Circuit Range/Performance ProblemClodoaldo BiassioNo ratings yet

- Mass or Volume Air Flow Range ProblemDocument2 pagesMass or Volume Air Flow Range ProblemDaniel Mamani ParedezNo ratings yet

- IPM (Intelligent Power Module) Industrial Inverter Operate at High Ambient Temperatures Up To 125°CDocument10 pagesIPM (Intelligent Power Module) Industrial Inverter Operate at High Ambient Temperatures Up To 125°CMr.K chNo ratings yet

- PSSE ReleaseDocument34 pagesPSSE ReleaseAshutosh SharmaNo ratings yet

- Idirect COTM Design Considerations - White PaperDocument9 pagesIdirect COTM Design Considerations - White Paperkira019No ratings yet

- Electrical Systems & Components: Power Factor, Loads, Alternators, Generators, Starters, Transformers, Motors, Batteries, Cables, Relays & MoreDocument4 pagesElectrical Systems & Components: Power Factor, Loads, Alternators, Generators, Starters, Transformers, Motors, Batteries, Cables, Relays & MoreNirjhar Ganguly100% (1)

- Temperature Trouble Shootings and Maintance of WS-100Document8 pagesTemperature Trouble Shootings and Maintance of WS-100Mohamad Niko BSTINo ratings yet

- Sumitomo HF-430 Guìa RápidaDocument31 pagesSumitomo HF-430 Guìa RápidaJohancito Valencia100% (2)

- Extremewireless Wing 7532 802.11ac Access Point: Maximum Speed. Minimum CostDocument7 pagesExtremewireless Wing 7532 802.11ac Access Point: Maximum Speed. Minimum Costjarko tarrilloNo ratings yet

- PHYSICS Paper 3 - Section BDocument7 pagesPHYSICS Paper 3 - Section BChc Physics PllNo ratings yet

- Krautkrämer Ultrasonic Transducers: For Flaw Detection and SizingDocument48 pagesKrautkrämer Ultrasonic Transducers: For Flaw Detection and SizingBahadır Tekin100% (1)

- Throttle Position Sensor Circuit TestDocument8 pagesThrottle Position Sensor Circuit TestDaniel AmanorNo ratings yet

- Day 1.2 PHYSICAL TOPOLOGIESDocument20 pagesDay 1.2 PHYSICAL TOPOLOGIESGorvam Saddar100% (1)

- CM570 Wiring Diagram Sheets for 31-Pin & 50-Pin OEM ConnectorsDocument5 pagesCM570 Wiring Diagram Sheets for 31-Pin & 50-Pin OEM ConnectorsJose Alanis85% (20)

- Control Valve For Irrigation PurposeDocument38 pagesControl Valve For Irrigation PurposeAjit KalasaitNo ratings yet

- MAX-7 / NEO-7: U-Blox 7 GNSS ModulesDocument52 pagesMAX-7 / NEO-7: U-Blox 7 GNSS ModulesMax MustermannNo ratings yet

- Katalog Techn Unterlagen Ex Grossantriebe enDocument260 pagesKatalog Techn Unterlagen Ex Grossantriebe enNathanNo ratings yet

- Catalogue tr-7578Document2 pagesCatalogue tr-7578arupamguria05No ratings yet

- Pressure Measurement: Performance Characteristics Ambient ConditionsDocument6 pagesPressure Measurement: Performance Characteristics Ambient ConditionsAl GCNo ratings yet

- Thesis Power Factor CorrectionDocument5 pagesThesis Power Factor CorrectionYolanda Ivey100% (2)

- Lamp MatrixDocument1 pageLamp MatrixrelaxjackNo ratings yet

- Unit IDocument69 pagesUnit IThangam MaheshNo ratings yet

- VIISemester2016-2017ODD - Handbook - EEE PDFDocument126 pagesVIISemester2016-2017ODD - Handbook - EEE PDFsaiNo ratings yet

- IEEE STD 1243-1997 - Lightning Performance For Trasnmission LinesDocument45 pagesIEEE STD 1243-1997 - Lightning Performance For Trasnmission LinesmilagrosNo ratings yet

- Tesla CoilDocument12 pagesTesla CoilVeerath தமிழன்100% (1)

- SDH CompleteDocument118 pagesSDH CompletePrashant SrivastavaNo ratings yet

- Digital Image Enhancement TechniquesDocument42 pagesDigital Image Enhancement TechniquesJahanvi VyasNo ratings yet

- CAT-5940 FleX-Net Intelligent Fire Alarm and Audio Network System PDFDocument12 pagesCAT-5940 FleX-Net Intelligent Fire Alarm and Audio Network System PDFJahzel VillamoresNo ratings yet

- Syllabus (ME Applied Elect)Document3 pagesSyllabus (ME Applied Elect)Hari Ram KNo ratings yet

- Schem e For Tie, Trafo, MotorDocument52 pagesSchem e For Tie, Trafo, Motormukesh_kht1No ratings yet

- SF Gas Insulated Ring Main Unit RMUDocument24 pagesSF Gas Insulated Ring Main Unit RMUr_mukuyuNo ratings yet

- Gas power plant and AC distribution system analysisDocument2 pagesGas power plant and AC distribution system analysisB.Neelakanteshwar Rao100% (1)