Professional Documents

Culture Documents

10may Jun Sf6

Uploaded by

Meliana Butar-ButarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10may Jun Sf6

Uploaded by

Meliana Butar-ButarCopyright:

Available Formats

CHIMNEY

AND POWER

POSSIBILITY

OF ELEcTRIcITY GENERATION FROM INDUSTRIAL cHIMNEYS

Mr. K.V. Avinash,

Software Engineer

Infosys Tech. Ltd. Plot numberr: E/4, Info city, Bhubaneswar, Orissa, India, 751024. Tel: +91-801 884 5252 E-mail: avi.vzm05@gmail.com; avi_vzm05@yahoo.com

Introduction

The root of the idea for generation of electricity from industrial chimneys lies in the solar updraft towers commonly called solar chimneys. Solar chimneys work on the basic principle that when air is heated it moves up. A tall tower is used as a passage for the hot gases from the large solar collector. As the heated air moves away from the system through the tower, suction is created at the base of the tower which helps to draw more air from the surrounding atmosphere and thus ensures continuous supply of air into the system. As the heated air moves up from the tower, it imparts some of its energy to the turbine present at the tower base which converts the mechanical energy into electrical energy. How does energy generation take place in the solar updraft tower? To understand how energy generation actually happens in the solar chimney let us rst see various components of a solar tower and their importance. Collector: This is a huge arrangement of at glass plates over the earth surface, which heats the air inside them through greenhouse effect. Glass is transparent to shorter wavelengths of light radiations coming from the sun, but the earths surface reects the radiations with longer wavelengths to which glass is not transpar-

ent and hence, the air present in between earths surface and glass surface gets heated. Normally the temperature rise is to the tune of 30-35 degree C. Tower or Chimney: This acts as a thermal engine of the solar updraft tower transforming the heat energy into mechanical energy. As the air gets heated up in the collector it rises up and is released into higher layers of atmosphere through a chimney present at the centre of the collector. Now, as the air moves up through the tower, it creates pressure difference between surrounding atmosphere and the tower base which are connected through the collector and hence sucks in more air from surroundings. Turbines: Turbine is generally housed at the centre of collector below the chimney. As the heated air moves up from the collector to atmosphere through the chimney it imparts some of its up-drafting energy to the turbine which is converted to mechanical energy, which is later converted into electrical energy. Turbines in this case are more related to hydro electric turbines which convert static pressure drop of the water from a certain height into electricity as in this case also the mechanical energy generated is proportional to the height of the tower through which the heated air has to be up-drafted. When the hot air moves up at the turbines, it imparts a part of total

Abstract

Solar updraft tower is one such source of renewable energy which works on the basic principle that hot air moves up. The tower acts as a giant chimney and generates necessary pressure drop to rotate a turbine at the entrance of the tower which is further converted to electrical energy. Turbines in case of solar updraft tower generally run not using the kinetic energy of gases as in the case of wind turbines. Therefore, with the presence of a turbine in an industrial chimney, a component of total pressure drop (static pressure drop) will be used up for rotating the turbine. A study is needed to explore the effect of using this principle of energy production in industrial chimneys in terms of loss of pressure drop, increase in frictional losses, and impact on the draught.

46

TECH MONItOR

May-Jun 2010

Chimney and Power pressure drop called static pressure drop to turbines which is converted into mechanical energy. Usually with no turbine in between, total pressure drop generated would be converted into kinetic energy, but in this case with a turbine in between a part of total pressure drop would be used up by the turbine to convert it into mechanical energy. Net efciency of tower is given by the Back Storms work as: Power output from the system is given as: P = Q

Conclusion

Chimneys in any industries are used for two purposes: 1. To ush off the ue gases away from the surroundings so that they get diluted and spread in the atmosphere. 2. To provide necessary draught such that necessary air (O2) is driven into the combustion chamber. Points given below summarise the above discussion: Solar updraft tower uses a simple concept that hot air rises up. The energy associated with rising air is used to generate energy. Chimneys on the other hand use the same principle but to serve a different purpose - of driving the ue gases away from the combustion chamber. Finally, with installation of a turbine in a chimney there will be a loss of total up-drafting energy of ue gases which would further affect the draught produced by the chimney. So, further study would be needed to assess the effect on the entire system and do the necessary cost analysis. Also, some of the important points to be considered are: Effect of particulate matter in flue gases on the turbine blades; Cost analysis of amount of energy produced in a given time frame vs. actual cost of installation and maintenance; and Effect on draught produced by using a turbine in the chimney.

hTower hTurbine ......... 3

Efciency of collector term is not needed here assuming that ue gases are at combustion temperature. So, from the above equations, we can surmise that power output from this kind of system depends on height of chimney, mass ow rate of ue gases and temperature rise in collector/combustion chamber.

hTower = gH/(cpT0) ....................1

where g is gravitational acceletation, H is height and cp is specic heat at contant pressure. Net power output from the system: P=Q hTower hTurbine hCollector. .. 2 Q is the rate of heat input to the system = M cp DT where M = mass ow rate of air into the system, and DT is the temperature rise between ambient and collector outlet (= tower inow)

How to t in a turbine in Chimney? Is it really possible?

These questions need an answer as we should also consider how to install a turbine such that it would not impact the present design of the chimney and also need to take into account the amount needed for this. A considerable amount of research has to be devoted in this direction. As stated earlier, the turbines in this system are not similar to ones used in the wind power generation which rotate using the kinetic energy of incoming air. These use the static pressure drop at the turbine blades to generate electricity. Hence are more similar to the hydroelectric turbines which also use the same principle. Also, for present case of generation of electricity from an already existing industrial chimney, use of horizontal axis turbine might prove more effective by taking into consideration few design modications to the existing chimney. This rotational energy can then be converted into electrical energy outside the chimney system which is not the case with solar updraft tower with large amount of space available beneath the chimney for installation of a generator.

Similarities between solar updraft towers and industrial chimneys

Industrial chimneys are used to ush out the waste hot ue gases from combustion into outside atmosphere. Here, combustion chamber takes the place of collector as in solar updraft tower which performs the task of heating the input gases to the tower/chimney. Usually the temperature of the hot ue gases is higher than what is attained from the air in the collector. So, with a turbine employed at the entrance of tower/chimney a part of total pressure drop between tower base and ambient air will be converted into energy as in case of a solar updraft tower. The equations used for calculation of power in case of solar updraft tower hold good here also. Efciency of tower is the same as that of equation 1 given earlier for solar updraft tower.

References

Details on solar updraft tower from prototype of solar updraft tower constructed in Manzanares (about 150 km south of Madrid) in 1981/82. www.visionengineer.com o

TECH MONItOR

May-Jun 2010

47

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 8 Elements of Digital LiteracyDocument5 pages8 Elements of Digital LiteracyShiela Mendoza100% (1)

- Throughput Limitation Issue: February, 2019Document4 pagesThroughput Limitation Issue: February, 2019Ahmed KenzyNo ratings yet

- Indian Standard: Rules For Rounding Off Numerical ValuesDocument14 pagesIndian Standard: Rules For Rounding Off Numerical ValuesAvishek DeyNo ratings yet

- Steps For Signing Up On The NGO-DARPAN Portal New UserDocument1 pageSteps For Signing Up On The NGO-DARPAN Portal New UserGaurav TiwariNo ratings yet

- A Transaction in The Context of Database Management SystemsDocument13 pagesA Transaction in The Context of Database Management SystemskmapukeNo ratings yet

- Frank Whittle 1945Document3 pagesFrank Whittle 1945DUVAN FELIPE MUNOZ GARCIANo ratings yet

- The Innovation Management of Microsoft: Submitted byDocument16 pagesThe Innovation Management of Microsoft: Submitted byCarolina Moncada ValderramaNo ratings yet

- (KtabPDF Com) xrwA7TEBGpDocument32 pages(KtabPDF Com) xrwA7TEBGpشجن الزبيرNo ratings yet

- Yealink W70B DECT IP Phone Release Notes of Version 85Document9 pagesYealink W70B DECT IP Phone Release Notes of Version 85tristan.zfrNo ratings yet

- Big Book of Data Warehousing and Bi v9 122723 Final 0Document88 pagesBig Book of Data Warehousing and Bi v9 122723 Final 0AblekkNo ratings yet

- Technical Specifications: Easy. Efficient. ReliableDocument2 pagesTechnical Specifications: Easy. Efficient. ReliableZahid RasoolNo ratings yet

- An ASCII Value Based Text Data Encryption System: Udepal Singh, Upasna GargDocument5 pagesAn ASCII Value Based Text Data Encryption System: Udepal Singh, Upasna GargEmma RachelNo ratings yet

- TOPSOLID Flyer DESIGN 2020 ANGLAIS - 1 - PDFDocument2 pagesTOPSOLID Flyer DESIGN 2020 ANGLAIS - 1 - PDFSalvador Severino CascoNo ratings yet

- The Efficacy of Coconut Coir FiberDocument20 pagesThe Efficacy of Coconut Coir FiberRenz GamingNo ratings yet

- British Airways Advance Ticketing RuleDocument1 pageBritish Airways Advance Ticketing RuleAhmad MansourNo ratings yet

- How To Setup A Group Tax in R12 E-Business Tax (EBTax) (Doc ID 1604480.1)Document18 pagesHow To Setup A Group Tax in R12 E-Business Tax (EBTax) (Doc ID 1604480.1)Lo JenniferNo ratings yet

- Functional Testing For .NET Core APIDocument6 pagesFunctional Testing For .NET Core APICristopher Coronado MoreiraNo ratings yet

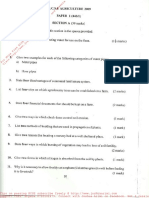

- KCSE 2009 Agriculture P1Document7 pagesKCSE 2009 Agriculture P1Urex ZNo ratings yet

- Богданов А.А. Из психологии общества. - 1905 PDFDocument341 pagesБогданов А.А. Из психологии общества. - 1905 PDFspirospotNo ratings yet

- 12 Commerce Public Question Paper - Sep 2020 K.expDocument13 pages12 Commerce Public Question Paper - Sep 2020 K.expmalathi SNo ratings yet

- Performance Simulation of FTTH Devices PDFDocument10 pagesPerformance Simulation of FTTH Devices PDFJuan CarlosNo ratings yet

- Artificial Intelligence OopDocument5 pagesArtificial Intelligence OopJed MorellNo ratings yet

- Gmail - FW - Receipt For Your E-Ticket Request 14391559 - DINITHI - ALAGIYADURAGEMS, PNR# KJGLYJ, CAT A SUBLOADDocument3 pagesGmail - FW - Receipt For Your E-Ticket Request 14391559 - DINITHI - ALAGIYADURAGEMS, PNR# KJGLYJ, CAT A SUBLOADDanidu KaveenNo ratings yet

- Advanced Power Electronics Interfaces For Distributed Energy Workshop SummaryDocument255 pagesAdvanced Power Electronics Interfaces For Distributed Energy Workshop SummaryPaola Correa MoncadaNo ratings yet

- Captain Sim FMC TutorialDocument21 pagesCaptain Sim FMC TutorialcuriouspaxNo ratings yet

- Chiques Roller Mill Dam Removal Design PlansDocument8 pagesChiques Roller Mill Dam Removal Design PlansLiz DeOrnellasNo ratings yet

- Lecturenote - 1938410780chapter 9 - Emerging Trends in Software Engineering (Lecture 15)Document20 pagesLecturenote - 1938410780chapter 9 - Emerging Trends in Software Engineering (Lecture 15)Miretu JaletaNo ratings yet

- 2022-2023 COMP1602 Course OutlineDocument4 pages2022-2023 COMP1602 Course OutlineLiann MaicooNo ratings yet

- What Is A Road MapDocument2 pagesWhat Is A Road MapShenivelChimChimNo ratings yet

- Encyclopedia BritannicaDocument12 pagesEncyclopedia Britannicatomas diazNo ratings yet