Professional Documents

Culture Documents

Insp and Test Plan Eg Rev2

Insp and Test Plan Eg Rev2

Uploaded by

م.ذكى فضل ذكىCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Insp and Test Plan Eg Rev2

Insp and Test Plan Eg Rev2

Uploaded by

م.ذكى فضل ذكىCopyright:

Available Formats

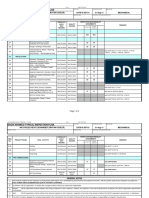

Supplier Name Inspection & Test Plan (ITP) Customer Name: Customer PO #: Part/Drawing #: MLI #: Description: Project Name:

D=Document Review, M=Monitor, W=Witness, H=Hold Point Inspection Level - Customer Representative Inspection Level - GE Representative Inspection Level - Supplier Representative Cusomer Name D D M D Supplier Name D D D W D Document #: Issue Date: Issued By: Approved By (GE): Rev #: Rev Date:

Process/ Step Operation # Description 1 Fabricate Skid Base

Characteristic General Fabrication/ Design Material Traceability Fit up & Alignment Dimensional Checks Welding Materials Inspection

Applicable Procedure Supplier Procedure Supplier Procedure Supplier Procedure Supplier Procedure Supplier Procedure WPS/ Supplier Procedure

Acceptance Criteria AWS D1.1 GE specs

Verifying Documents/ Reference

Freq

Notes

Inspection Performed By: QA Inspector

Inspection Signoff

Comments

Drawings BOM/ AWS D1.1 GE Material Specs Certs AWS D1.1 GE Specs Drawings AWS D1.1 GE Specs Drawings AWS D1.1 ASME Sec II AWS D1.1 GE Specs AWS D1.1 ASTM E-709 Supplier Procedure/ GE Specs GE Spec

Verify material complies Project 100% to PO/BOM upon receipt Manager 100% 100% Verify markings or certificates Operator Operator

D M

W M

Drawings/W PS 100%

Operator QA Inspector QA Inspector QA Inspector QA Inspector

Welding Inspection Magnetic Particle Testing NDE-5.3 Skid Base Blasting Paint/ Preservation

Drawings/W PS 100% All Welds per AWS D1.1 Inspection Reports 100% All Lifting Lugs Inspection Reports Inspection Reports

W M D

Supplier Procedure Supplier Procedure

100% 100% Total DFT 7.0-9.0 mils

W D W D

GE

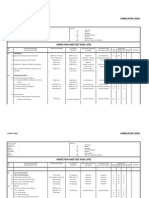

Supplier Name Inspection & Test Plan (ITP) Customer Name: Customer PO #: Part/Drawing #: MLI #: Description: Project Name: D=Document Review, M=Monitor, W=Witness, H=Hold Point Inspection Level - Customer Representative Inspection Level - GE Representative Inspection Level - Supplier Representative 2 Fabricate General Fabrication & Supplier Piping Design Procedure Material Traceability Fit Up/ Alignment Dimensional Checks Supplier Procedure Supplier Procedure Supplier Procedure Document #: Issue Date: Issued By: Approved By (GE): Rev #: Rev Date:

ASME B31.3/ GE Specs ASME B31.3/ GE Specs ASME B31.3/ GE Specs ASME B31.3/ GE Specs ASME B31.3/ GE Specs ASME B31.3/ GE Specs ASME B31.3/ GE Specs Supplier Procedure/GE Spec GE Spec

Pipe Spool Drawings BOM/ Weld Maps Spool Darwings/ Weld Maps Spool Darwings/ Weld Maps WPS/Weld Maps/Spool Drawings Verify material complies Project 100% to PO/BOM upon receipt Manager

100%

Operator

W M

Supplier Weld Inspection Procedure Radiographic Testing Hydrostatic Testing

Operator All butt welds must have GTAW roots/100% visual Operator 100% QA Must include all welders, weld type, & size Inspector 1 Hr test with chart/ test water includes rust QA 100% inhibitor VCI-377 Inspector 5% QA Inspector QA Inspector QA Inspector

100%

W D

W D

NDE-3.5 Supplier Procedure Supplier Procedure Supplier Procedure Supplier Procedure

Test Reports ANSI B16.5/ Drawings Inspection Reports Inspection Reports Inspection Reports

W D

W D

Blasting Paint/ Preservation 3 Skid Assembly- P&ID Mechanical Compliance

100% 100% Total DFT 7.0-9.0 mils Verify components tagged per GE P&ID/BOM

W D D D

D D

GE P&ID

100%

W W W

Supplier Name Inspection & Test Plan (ITP) Customer Name: Customer PO #: Part/Drawing #: MLI #: Description: Project Name: D=Document Review, M=Monitor, W=Witness, H=Hold Point Inspection Level - Customer Representative Inspection Level - GE Representative Inspection Level - Supplier Representative Flange Connections Dimensional 4 Supplier Procedure Supplier Procedure B31.3/ GE Specs ASME B31.3/ GE Specs Flange alignment shall QA 100% be within 1/16" per foot Inspector QA 100% Inspector Document #: Issue Date: Issued By: Approved By (GE): Rev #: Rev Date:

Drawings Drawings

W M W W W

Skid Supplier AssemblyProcedure/ NFPA 70 Drawings/ Instrument & (NEC)/ GE Spec BOM Electrical Junction Boxes GE Spec Supplier Procedure/ GE Spec Supplier Procedure/ GE Spec Supplier Procedure/ GE Spec ASME VIII/ GE Specs GE Spec ASME VIII Supplier Procedure NFPA 70 Drawings/ (NEC)/ GE Spec BOM NFPA 70 Drawings/ (NEC)/ GE Spec BOM Inspection GE Spec Reports ASME VIII/ GE Specs/ ASME Inspection B31.3 Reports GE Spec GE Spec Witness Drawings Inspection Reports

QA 100% Veify Type NEMA 4 or 4X Inspector All components per GE BOM & Drawings, 100% including gauge scales 100% QA Inspector

W M

Components Wire 5 Functional Component Testing Testing System Leak Test System Final Inspection Cleanliness Nameplate Visual Inspection of Paint

W M W w w

QA Verify proper wire labels and confirm no splices Inspector Test all instruments for continuity, short ciruit, QA 100% and "Megger" Inspector 25 psi sensitive leak/soap bubble test QA 100% for 15 min Inspector QA 100% Inspector QA 100% Inspector QA Inspector

H H H

W W W W W W

W W W

GE Spec

100%

W D

Supplier Name Inspection & Test Plan (ITP) Customer Name: Customer PO #: Part/Drawing #: MLI #: Description: Project Name: D=Document Review, M=Monitor, W=Witness, H=Hold Point Inspection Level - Customer Representative Inspection Level - GE Representative Inspection Level - Supplier Representative Visual Inspection of Preservation & Prep for shipment Document #: Issue Date: Issued By: Approved By (GE): Rev #: Rev Date:

Supplier Procedure GE Spec

GE Spec

Witness

100%

Application of rust inhibitor with shipping covers and gaskets QA installed Inspector

W D

You might also like

- Asme CCase 1987-2Document2 pagesAsme CCase 1987-2ADAMJSRAONo ratings yet

- Material Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureDocument1 pageMaterial Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureMohamed RaafatNo ratings yet

- SAT Plan & Procedure VMSDocument47 pagesSAT Plan & Procedure VMSMGHIRBI HAYKELNo ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanVicky Gautam100% (1)

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Tank Erection Itp & Org ChartDocument34 pagesTank Erection Itp & Org Charthasan_676489616100% (2)

- Pt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and ErectionDocument5 pagesPt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and Erectioneldobie3100% (1)

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNo ratings yet

- SAIC-W-2077 Weld Joint Identification SystemDocument1 pageSAIC-W-2077 Weld Joint Identification Systemkarioke mohaNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- Form UT, MT, PT, RTDocument5 pagesForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Air Cooled Condensing Unit Checklist: Mr. Aden LiuDocument45 pagesAir Cooled Condensing Unit Checklist: Mr. Aden LiuADEN LIUNo ratings yet

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- Vessel Final BoxDocument14 pagesVessel Final Boxmanoj thakkarNo ratings yet

- Soal CswipDocument1 pageSoal Cswipakun jeparaNo ratings yet

- ITP-format For VesselsDocument5 pagesITP-format For VesselsHanuman RaoNo ratings yet

- Production Procedure ReportDocument1 pageProduction Procedure ReportHarish SivakumarNo ratings yet

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 pagesRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863No ratings yet

- AB-036386 Hardness Testing For Welding Procedure QualificationDocument1 pageAB-036386 Hardness Testing For Welding Procedure QualificationAmr MahmoudNo ratings yet

- 2.8.2. Indicative QAP - ColumnsDocument12 pages2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Welding Parameters Control PipelineDocument1 pageWelding Parameters Control PipelinemusheerNo ratings yet

- Re-Welding, Expansion & HT ProcedureDocument6 pagesRe-Welding, Expansion & HT Proceduresuria qaqcNo ratings yet

- MST Gravity Test OwsDocument5 pagesMST Gravity Test OwsJenson T VNo ratings yet

- PQR Run SheetDocument1 pagePQR Run SheetsahadNo ratings yet

- Gtaw NC Ii TR PDFDocument62 pagesGtaw NC Ii TR PDFRocz RocoNo ratings yet

- EXternal ITP PDFDocument8 pagesEXternal ITP PDFjaineranaNo ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- QAP For PQR'S - For Impact TestingDocument3 pagesQAP For PQR'S - For Impact TestingDries Vandezande100% (1)

- Bolt Tightening ReportDocument2 pagesBolt Tightening Reportmujahed_muhammedNo ratings yet

- Afi SC03 QRBN Ci 00233Document1 pageAfi SC03 QRBN Ci 00233حسن كاظم ريسان B-4No ratings yet

- Receiving Material Procedure CoverDocument1 pageReceiving Material Procedure Covergst ajahNo ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- Itp - 002 - Duct Installation - IfrDocument3 pagesItp - 002 - Duct Installation - IfrMari BelajarNo ratings yet

- Instrumentation and ControlsDocument2 pagesInstrumentation and ControlsTrí NguyễnNo ratings yet

- Dimensional Inspektion ReportDocument6 pagesDimensional Inspektion Reportdidi sudiNo ratings yet

- Cold Forming ProcedureDocument5 pagesCold Forming ProcedureMassimo FumarolaNo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- Magnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiDocument1 pageMagnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiMurugan Raja100% (1)

- MC L 01A Pre Hydrotest LinewalkDocument1 pageMC L 01A Pre Hydrotest LinewalkMemyhu MahmudahNo ratings yet

- Itp Electrical SwitchgearDocument4 pagesItp Electrical SwitchgearpertmasterNo ratings yet

- ITP Low Tempt Test - RevDocument6 pagesITP Low Tempt Test - RevAgus GunawanNo ratings yet

- Satip e 007 01Document2 pagesSatip e 007 01Anonymous 4e7GNjzGWNo ratings yet

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemssojeckNo ratings yet

- ASME 9 Multi Process Welding Procedures QW200Document2 pagesASME 9 Multi Process Welding Procedures QW200Teodor EzaruNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel Ndifon100% (1)

- Hydrostatic Test ReportDocument1 pageHydrostatic Test ReportibicengNo ratings yet

- Roundness Before Weld TK012-strike 1Document2 pagesRoundness Before Weld TK012-strike 1yuwantoniNo ratings yet

- Daily Receiving Log PDFDocument2 pagesDaily Receiving Log PDFandyjonson007No ratings yet

- WPS & SmawDocument12 pagesWPS & Smawnuke apriyaniNo ratings yet

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- QUALITY CONTROL PROCEDURE FOR Access Control System InstallationDocument8 pagesQUALITY CONTROL PROCEDURE FOR Access Control System InstallationAbdul JabbarNo ratings yet

- PWHT Procedure For Petrol Steel - CoreDocument9 pagesPWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluNo ratings yet

- Welder IdentificationDocument9 pagesWelder Identificationdandiar1No ratings yet

- ITP Format For New PVDocument8 pagesITP Format For New PVDavid LambertNo ratings yet

- Sample Itp For VesselDocument10 pagesSample Itp For VesselWijayanto BekasiNo ratings yet