Professional Documents

Culture Documents

Heat Loss From Pipe

Uploaded by

deion29Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Loss From Pipe

Uploaded by

deion29Copyright:

Available Formats

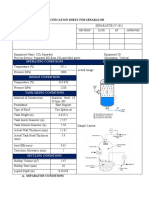

HEAT LOSS / GAIN FROM PIPE By Stephen Hall The heat loss from a pipe is calculated in two parts:

inside the pipe and outside the pipe User inputs are in RED Formulas in Column F are from the reference listed at the bottom of the worksheet Cell names (preceded by underscore_) are listed in Column B Data Inputs G ro mu k c T1 Fluid flowing inside the pipe Flow rate Density Viscosity Thermal conductivity Heat capacity Temperature of fluid entering pipe Pipe parameters inside diameter outside diameter pipe length pipe thermal conductivity emittance of pipe or insulation cover Insulation parameters insulation thickness insulation thermal conductivity Environmental conditions (pipe is outdoors) Temperature of the air Wind velocity 500 1,000 0.005 0.64 4,180 176 m3/h kg/m3 Pa-s W/m-K J/kg-K C

di do L kp e

207.3 219.1 1,000 45 0.80

mm mm m W/m2-K

it ki

25.4 mm 0.035 W/m2-K

T4 w

-5 C 5 m/s

Calculate radial distances from center-line to: R1 inside pipe wall R2 outside pipe wall R3 outside insulation Calculate the Reynolds number inside the pipe Ap Pipe cross sectional area v Velocity Re Reynolds number Calculate the Prandtl number Pr Prandtl number Calculate the Inside heat transfer coefficient

0.1037 m 0.1096 m 0.1350 m

0.0338 m2 4.12 m/s 170,612

32.7

The formula depends on the flow region For Laminar flow (Re < 2100) use Sieder and Tate For this illustration, assume viscosity at wall = bulk viscosity Laminar flow calculation

N/A

For Transition flow (2100 <= Re <= 10000), use Hilpert correlation For this illustration, assume viscosity at wall = bulk viscosity It is NOT RECOMMENDED to be in the transitional region, and the correlation is iffy Transitional flow calculation N/A

For Turbulent flow (Re>10000) use Sieder and Tate (same as Dittus-Boettler, but with viscosity correction) For this illustration, assume viscosity at wall = bulk viscosity Turbulent flow calculation 3,440

Note: alternative turbulent flow correlation from Gnielinski Said to be valid from 3000 < Re < 5,000,000

Because the outside heat transfer coefficient will be so much less than the inside coefficient, it really doesn't make a practical difference if the calculation for inside coefficient is off hi inside heat transfer coefficient 3,440 W/m2-K

Calculate the outside heat transfer coefficient The outside coefficient is calculated differently for the cases of wind or no wind No wind = natural convection Three temperatures to be concerned with, ambient (T4), surface (T3), and average T5 = (T4 + T3)/2 Since T3 is a function of the heat transfer, this is an interative calculation First, assume a value for T3, the surface temperature T3_assume (cell is highlighted if iteration required) Calculate T5 T5

3.13 C

<---- Initial guess between a

Average between surface and ambient

-0.935 C

Get the properties of air for temperature T5 I did a simple linear regression of thermal conductivity for air at atmospheric pressure MW Molecular weight of air 29 P Pressure of air 100 kPa kair cair Thermal conductivity of air Heat capacity of air (treat as constant) 0.0238 W/m2-K 1,006 J/kg-K

dair muair

Density of air (treat as perfect gas) Dynamic viscosity of air

1.30 kg/m3 1.71E-05 Pa-s

estimated with the Sutherl ' kinematic viscosity = dyna

For no wind condition, Coefficient of expansion = 1/T for perfect gas assumption Beta Coefficent of expansion 0.00367 K^-1 Gr Grasoff number (L = pipe OD), abs value 3.32E+07 Prair Prandtl number 0.72 Gr x Pr 2.40E+07 Nuair Nusselt number 37.10 Outside heat transfer coef, no wind 3.27 W/m2-K

Calculation for the case where wind is present Note that for very low wind velocity (<0.5 m/s), use the greater of this calc or the no-wind calc Rewind B n Nuwind Reynolds number Hilpert equation factor B Hilpert equation factor n Nusselt number, wind condition (Hilpert) Outside heat transfer coef, no wind 102,435 0.0239 0.805 258 22.77 W/m2-K

Next, calculate the radiation loss Let's use radiation only when pipe is warmer than environment hrad Radiation heat transfer coefficient 3.66 W/m2-K Add the convection and radiation heat transfer coefficients together ho Outside heat transfer coefficient Calculate surface temperatures and iterate until calculation = assumed Calculate the overall heat transfer coefficient U Next, the heat loss through the wall Q

26.43 W/m2-K

1.2 W/m2-K

214.9 W/m2

Calculate the inside wall and surface temperatures based on the estimated surface temperature from above Calculated inside surface temperature 175.94 C T3calculated Calculated outside surface temperature 3.13 C Calculate the fluid temperature as it exits the pipe segment Assumes constant properties and constant heat flux along pipe length For significant temperature changes, divide pipe into segments and calculate sequentially

Heat loss per meter Downstream temperature Reference:

182.2 W/m 175.7 C

Cao, Eduardo, Heat Transfer in Process Engineering, McGraw-Hill, 2010 4/9/2013 www.pipesizingsoftware.com

Spreadsheet prepared by Stephen Hall This is the calculation method included in PIPESIZE. See

<---- Initial guess between ambient and fluid temperatures, then substitute value from below (_T3calculated)

estimated with the Sutherland equation ' kinematic viscosity = dynamic viscosity / density

Factors for Hilpert Equation Re B n 0.4 0.891 0.33 4 0.821 0.385 40 0.615 0.466 4000 0.174 0.615 40000 0.0239 0.805

e from above

1.012 1.010 1.008 1.006 1.007 1.008 1.008 1.009 1.010 1.011 1.012 1.012 1.013 1.014 1.016 1.018 1.020 1.022

-150 -100 -50 0 20 40 60 80 100 120 140 160 180 200 250 300 350 400

2.793 1.98 1.534 1.293 1.205 1.127 1.067 1 0.946 0.898 0.854 0.815 0.779 0.746 0.675 0.616 0.566 0.524

Sp Ht 1.026 1.009 1.005 1.005 1.005 1.005 1.009 1.009 1.009 1.013 1.013 1.017 1.022 1.026 1.034 1.047 1.055 1.068 7.23714E-05 0.023883641 0.036910488

Therm C 0.0116 0.016 0.0204 0.0243 0.0257 0.0271 0.0285 0.0299 0.0314 0.0328 0.0343 0.0358 0.0372 0.0386 0.0421 0.0454 0.0485 0.0515

3.08 5.95 9.55 13.3 15.11 16.97 18.9 20.94 23.06 25.23 27.55 29.85 32.29 34.63 41.17 47.85 55.05 62.53

8.21 5.82 4.51 3.67 3.43 3.2 3 2.83 2.68 2.55 2.43 2.32 2.21 2.11 1.91 1.75 1.61 1.49

0.76 0.74 0.725 0.715 0.713 0.711 0.709 0.708 0.703 0.7 0.695 0.69 0.69 0.685 0.68 0.68 0.68 0.68

cs = 1.005 + 1.82H where 1.005 kJ/kgC is the heat capacity of dry air, 1.82 kJ/kgC the heat capacity of water vapor, and H is t

0.06 0.05 0.04 0.03 0.02 0.01 0 -200 -100 0 100 200 300 400 500 Series2 Linear (Series2)

acity of water vapor, and H is the specific humidity in kg water vapor per kg dry air in the mixture

below 0

You might also like

- Water Hammer Pressure/ Surge Pressure Calculation : Developed by Engr. Abiodun AsadeDocument2 pagesWater Hammer Pressure/ Surge Pressure Calculation : Developed by Engr. Abiodun Asadecoolsummer1112143100% (1)

- Ergun EquationDocument3 pagesErgun EquationNourAlsawaftahNo ratings yet

- Spreadsheet Heat Loss from a PipeDocument1 pageSpreadsheet Heat Loss from a PipeJogender DhayalNo ratings yet

- Gas/Liquids Separators - Part 2: Quantifying Separation PerformanceDocument13 pagesGas/Liquids Separators - Part 2: Quantifying Separation PerformanceLizbeth Ramirez AlanyaNo ratings yet

- Demister SizingDocument3 pagesDemister SizingD K SNo ratings yet

- Air Receiver Sizing CalculationDocument1 pageAir Receiver Sizing CalculationAziz HaqueNo ratings yet

- API 2000 guidance for inert gas blanketing of tanksDocument2 pagesAPI 2000 guidance for inert gas blanketing of tankssandeshNo ratings yet

- RD 810Document73 pagesRD 810Ashish MishraNo ratings yet

- Calculate Heat Loss from Insulated PipeDocument8 pagesCalculate Heat Loss from Insulated PipeTon PhichitNo ratings yet

- Centrif Pumps1 SpreadsheetDocument2 pagesCentrif Pumps1 SpreadsheetCast Ed Iv0% (1)

- Heat Loss From PipeDocument11 pagesHeat Loss From Pipemlarakahan100% (1)

- Insulated PipeDocument54 pagesInsulated Pipedeion29No ratings yet

- Valve Sizing W IEC Noise - Gas VolumetricDocument64 pagesValve Sizing W IEC Noise - Gas VolumetricskalanidhiNo ratings yet

- Peng Robinson MixturesDocument1 pagePeng Robinson MixturesdckristantoNo ratings yet

- Hydraulics Report for MAKORI FEC ProjectDocument15 pagesHydraulics Report for MAKORI FEC ProjectFarhan AhmedNo ratings yet

- Restriction Orifice Diamater CalculationDocument1 pageRestriction Orifice Diamater CalculationkodeesNo ratings yet

- Experimental Analysis of Heat Transfer Enhancement in Shell and Helical Tube Heat ExchangersDocument9 pagesExperimental Analysis of Heat Transfer Enhancement in Shell and Helical Tube Heat ExchangersKartikAgrawalNo ratings yet

- Process Design Basis Process Design BasisDocument17 pagesProcess Design Basis Process Design Basisdeion29100% (3)

- Pump TrainingDocument15 pagesPump TrainingdalayeliNo ratings yet

- Calculation of a Gas-Liquid Separator Flash Drum DesignDocument2 pagesCalculation of a Gas-Liquid Separator Flash Drum DesignCan YıldırımNo ratings yet

- Heat Transfer Correlations for Internal FlowsDocument18 pagesHeat Transfer Correlations for Internal FlowsarssNo ratings yet

- Water PropertiesDocument4 pagesWater Propertiesaw_aeNo ratings yet

- Case 2 - Tank Heat LossDocument86 pagesCase 2 - Tank Heat Lossahmad santosoNo ratings yet

- Air-Cooled Exchanger Design and SizingDocument19 pagesAir-Cooled Exchanger Design and Sizingnafees ahmadNo ratings yet

- Gas separation design parametersDocument10 pagesGas separation design parametersHamza AliNo ratings yet

- Ppgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Document10 pagesPpgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Tifano KhristiyantoNo ratings yet

- Reciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsDocument9 pagesReciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsSlim Toumi0% (1)

- Demister DatasheetDocument1 pageDemister Datasheetdeion29No ratings yet

- Pump sizing sheetDocument2 pagesPump sizing sheetdeion29No ratings yet

- Heat Loss From PipeDocument18 pagesHeat Loss From PipechaitanyavuraNo ratings yet

- Final Ventury Working For Wet Alkaline ScrubberDocument11 pagesFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapNo ratings yet

- Pipe Insulation THK CalculationDocument3 pagesPipe Insulation THK Calculationnitin_bir67% (3)

- Control of Flow Rates at Startup: GAT2004-GKP-2010.009 September, 2010Document2 pagesControl of Flow Rates at Startup: GAT2004-GKP-2010.009 September, 2010Enyerberht Castañeda BritoNo ratings yet

- Heat loss from a buried oil line: Conduction shape factor and insulation effectDocument20 pagesHeat loss from a buried oil line: Conduction shape factor and insulation effectJuan Pablo ApazaNo ratings yet

- Control Valve Press Drop CalculationDocument3 pagesControl Valve Press Drop CalculationAntony AbirawaNo ratings yet

- 4.1.3 Step-by-Step CalculationDocument11 pages4.1.3 Step-by-Step Calculationmohamed nizal100% (1)

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801No ratings yet

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićNo ratings yet

- Mixer (So3 Jadi H2so4)Document6 pagesMixer (So3 Jadi H2so4)Evi SiswantoNo ratings yet

- Hot Oil System GuideDocument56 pagesHot Oil System GuideleelaramaNo ratings yet

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4From EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Rating: 5 out of 5 stars5/5 (1)

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- Air Pressure and CFM Requirements for Automotive Service EquipmentDocument1 pageAir Pressure and CFM Requirements for Automotive Service Equipmentdeion29No ratings yet

- Air Pressure and CFM Requirements for Automotive Service EquipmentDocument1 pageAir Pressure and CFM Requirements for Automotive Service Equipmentdeion29No ratings yet

- Air Pressure and CFM Requirements for Automotive Service EquipmentDocument1 pageAir Pressure and CFM Requirements for Automotive Service Equipmentdeion29No ratings yet

- Steam VentDocument4 pagesSteam VentShameer MajeedNo ratings yet

- 10.9. Gas Liquid Separators: Chemical EngineeringDocument6 pages10.9. Gas Liquid Separators: Chemical EngineeringsterlingNo ratings yet

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocument6 pagesShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharNo ratings yet

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocument9 pagesL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariNo ratings yet

- PSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipDocument4 pagesPSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipAfees OlajideNo ratings yet

- Fischer Tropsch SynthesisDocument18 pagesFischer Tropsch Synthesisdeion29No ratings yet

- Prediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent CorrelationDocument18 pagesPrediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent Correlationcamilo_ortiz_6No ratings yet

- Nonboiling Liq Outflow F Vertical Cyl VesselDocument26 pagesNonboiling Liq Outflow F Vertical Cyl VesselSrihari KodimelaNo ratings yet

- Section 7 - Separation EquipmentDocument9 pagesSection 7 - Separation Equipmentlulis171No ratings yet

- FMV Spreadsheets-Master-FMVIDocument15 pagesFMV Spreadsheets-Master-FMVIadrianaortizv100% (1)

- Estimate Accentric Fator by Various CorrelationDocument13 pagesEstimate Accentric Fator by Various CorrelationscranderiNo ratings yet

- FV Flash Steam and Flash Vessel CalculationDocument2 pagesFV Flash Steam and Flash Vessel Calculationbeymar_5631No ratings yet

- Test Gas CalculationDocument4 pagesTest Gas CalculationgrabettyNo ratings yet

- NKGSB Prs Ds 006 A4 A Water Spray NozzleDocument52 pagesNKGSB Prs Ds 006 A4 A Water Spray Nozzleahmad santosoNo ratings yet

- Thermophysical PropertiesDocument14 pagesThermophysical PropertiesKalinga BalNo ratings yet

- Raw Gas Venturi Scrubber Design and SizingDocument2 pagesRaw Gas Venturi Scrubber Design and SizingDũng LêNo ratings yet

- TEMA SheetDocument2 pagesTEMA SheetFrancisco RenteriaNo ratings yet

- Condensate Line SizingDocument23 pagesCondensate Line SizingNirnay Patil100% (2)

- Vent Sizing MethodsDocument26 pagesVent Sizing Methodsmieiroluiz12No ratings yet

- Waymouth CalculationDocument8 pagesWaymouth CalculationSURJYA TAMULINo ratings yet

- Moist Air PropertiesDocument12 pagesMoist Air PropertiesLily DianaNo ratings yet

- HETP LectureDocument4 pagesHETP LectureaadipakiNo ratings yet

- Vent Size Imp For Pressure VesselsDocument3 pagesVent Size Imp For Pressure Vesselsthomas_v501925No ratings yet

- Air Ingress CalculationsDocument5 pagesAir Ingress CalculationsMallinatha PNNo ratings yet

- Inerting & BlanketingDocument5 pagesInerting & Blanketingbksree100% (1)

- Butterfly DamperDocument2 pagesButterfly Damperdeion29No ratings yet

- DWG TrueView DWG Convert Conversion ReportDocument1 pageDWG TrueView DWG Convert Conversion ReportCosmin CinciNo ratings yet

- 4 PO 14 SekiguchiDocument10 pages4 PO 14 Sekiguchideion29No ratings yet

- Performance Guarantee NormalisasiDocument5 pagesPerformance Guarantee Normalisasideion29No ratings yet

- Forced ConvectionDocument5 pagesForced Convectionsadiqchem179No ratings yet

- Terminal User ManualDocument51 pagesTerminal User Manualdeion29No ratings yet

- Se Se Se 616Document2 pagesSe Se Se 616deion29No ratings yet

- Up Up AwayDocument1 pageUp Up Awaydeion29No ratings yet

- HYSYS Depressurisation ExampleDocument2 pagesHYSYS Depressurisation ExampleMuhammad Saquib67% (3)

- Undangan Sharing EngDocument1 pageUndangan Sharing Engdeion29No ratings yet

- Algorithm of MainDocument1 pageAlgorithm of Maindeion29No ratings yet

- Whitepaper - Piping Connection ConsiderationsDocument11 pagesWhitepaper - Piping Connection ConsiderationsblindjaxxNo ratings yet

- Level Technology Comparison: 4-20 Ma W/ HART, F Fieldbus, Profibus PaDocument1 pageLevel Technology Comparison: 4-20 Ma W/ HART, F Fieldbus, Profibus Padeion29No ratings yet

- Torp Ship Based LNG RegasificationDocument1 pageTorp Ship Based LNG Regasificationdeion29No ratings yet

- Heating Value of Common FuelsDocument1 pageHeating Value of Common Fuelsscience4uNo ratings yet

- Proxy 1 November 2013Document60 pagesProxy 1 November 2013deion29No ratings yet

- Tricks N Hacks N TipsDocument6 pagesTricks N Hacks N Tipsdeion29No ratings yet