Professional Documents

Culture Documents

The Operation in Relation To Lathe Work Such As Turning Boring

Uploaded by

Nareesh RajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Operation in Relation To Lathe Work Such As Turning Boring

Uploaded by

Nareesh RajCopyright:

Available Formats

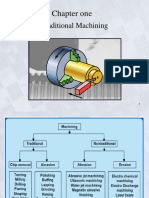

The operation in relation to lathe work such as turning boring, facing drilling, knurling, tread cutting and off-centre

turning.

Turning is an operation of removing excess material from surface of the cylindrical workpiece. Boring is the operation of enlarging and turning holes produced by drilling, punching, forging and casting. Facing is as operation of machining the ends of a workpiece to produce a flat surface square with the axis. Tread cutting - Thread of any pitch, shape and size can be cut on a lathe using single point cutting tool. Thread cutting is operation of producing a helical groove on spindle shape such as V, square or power threads on a cylindrical surface. The job is held in between centres or in a chuck and the cutting tool is held on tool post. The cutting tool must travel a distance equal to the pitch (in mm) as the work piece completes a revolution. Off center turning / taper turning A taper is defined as a uniform increase or decrease in diameter of a piece of work measured along its length. In a lathe machine, taper turning means to produce a conical surface by gradual reduction in diameter from a cylindrical job. Taper in the British System is expressed in taper per foot or taper per inch.

You might also like

- CNC Machine Operation GuideDocument7 pagesCNC Machine Operation GuidepkNo ratings yet

- Machining Operations and Machining ToolsDocument93 pagesMachining Operations and Machining Toolsatta ur rehmanNo ratings yet

- Lathe MachineDocument7 pagesLathe MachineJacTomlinNo ratings yet

- Computer Integrated Manufacturing: Machine ToolsDocument20 pagesComputer Integrated Manufacturing: Machine Toolstayyab40No ratings yet

- CH-5.6 Lathe OperationDocument11 pagesCH-5.6 Lathe OperationBARUN BIKASH DENo ratings yet

- GROUP 3 (Turning, Boring & Related Topics) : Members: Clarice Cabalit Mark Giovanni Cabanero John Clyde Calvo Joseph TeneroDocument7 pagesGROUP 3 (Turning, Boring & Related Topics) : Members: Clarice Cabalit Mark Giovanni Cabanero John Clyde Calvo Joseph TeneroBenz Andrew RegisNo ratings yet

- Operations of Milling MachineDocument9 pagesOperations of Milling MachineSeth Jeremiah A. EusteNo ratings yet

- Milling NotesDocument20 pagesMilling NotesleoandresmessiNo ratings yet

- Lathe OperationDocument13 pagesLathe OperationdevmarineacademyNo ratings yet

- MCE516 MODULE TWO: METAL REMOVAL PROCESSESDocument40 pagesMCE516 MODULE TWO: METAL REMOVAL PROCESSESEdward JNo ratings yet

- Elements of Conventional Machine ToolsDocument77 pagesElements of Conventional Machine ToolsDeepan Raj100% (1)

- Milling MachineDocument37 pagesMilling Machinejaj jaja100% (1)

- Lathe OperationsDocument7 pagesLathe OperationsAnand Balaji0% (1)

- Various Types of Operations Performed in Lathe Machine - Education Discussion PDFDocument13 pagesVarious Types of Operations Performed in Lathe Machine - Education Discussion PDFtinku meenaNo ratings yet

- For More Presentation Go To: Metal Cutting LatheDocument74 pagesFor More Presentation Go To: Metal Cutting Lathebabu319No ratings yet

- LATHEDocument60 pagesLATHEKanchan KumariNo ratings yet

- Module-Iii Machine Tools and Automation Machine Tools OperationsDocument17 pagesModule-Iii Machine Tools and Automation Machine Tools Operationsanil kumarNo ratings yet

- Introduction to Lathe Machine: A Guide to Parts and Operations (Under 40 CharsDocument25 pagesIntroduction to Lathe Machine: A Guide to Parts and Operations (Under 40 CharsMuhammad AbubakarNo ratings yet

- Module 2Document15 pagesModule 2mohammedgousmujahidNo ratings yet

- Milling and Grinding Machines GuideDocument16 pagesMilling and Grinding Machines GuidealysonmicheaalaNo ratings yet

- Metal Cutting ProcessesDocument67 pagesMetal Cutting ProcessesAbhay SontakkeNo ratings yet

- Manufacturing Chapter 2Document66 pagesManufacturing Chapter 2Jibril JundiNo ratings yet

- EME UNIT1 Milling Machine & Its Operations NDocument11 pagesEME UNIT1 Milling Machine & Its Operations NMohd FaizNo ratings yet

- 6 Notes Milling Shaping & PlaningDocument14 pages6 Notes Milling Shaping & PlaningSanket KumarNo ratings yet

- MillingDocument54 pagesMillingNelsan PatelNo ratings yet

- Lathe Machine AslamDocument6 pagesLathe Machine AslamAslam BaigNo ratings yet

- Machine Shop (Ch-4)Document91 pagesMachine Shop (Ch-4)Shubham VermaNo ratings yet

- Secondary Machining GuideDocument17 pagesSecondary Machining GuideKimberley YorkNo ratings yet

- Lab Session Operations of Lathe Machine Part 2Document3 pagesLab Session Operations of Lathe Machine Part 2Aqib Zaman0% (1)

- MI-102Machining 2 PDFDocument34 pagesMI-102Machining 2 PDFVaibhav GuptaNo ratings yet

- Lathe Machine Guide: Parts, Operations & MoreDocument7 pagesLathe Machine Guide: Parts, Operations & MoreDiyaNegiNo ratings yet

- Lathe Machines & OperationsDocument43 pagesLathe Machines & OperationsInder Jeet Kori100% (1)

- Milling MachineDocument80 pagesMilling Machineravi upadhyayNo ratings yet

- Lathe OperationsDocument35 pagesLathe Operationsdvshadow0004No ratings yet

- Lathe OperationsDocument29 pagesLathe OperationsWaqas AhmadNo ratings yet

- ManufProc2 2MachiningOperationsDocument85 pagesManufProc2 2MachiningOperationsUzair KhanNo ratings yet

- Milling Machines: - Column-And-Knee Milling Machines - Bed Type Milling Machines - Machining CentersDocument10 pagesMilling Machines: - Column-And-Knee Milling Machines - Bed Type Milling Machines - Machining Centersrk_kamatchi3483No ratings yet

- Form turning - The tool is ground to shape workpieceDocument10 pagesForm turning - The tool is ground to shape workpieceJohn Paul DomingoNo ratings yet

- Lathe Machine Operation GuideDocument16 pagesLathe Machine Operation GuidearulsivagiriNo ratings yet

- Milling and Turning OperationsDocument17 pagesMilling and Turning OperationsMuhammad ArifNo ratings yet

- Elements of Mechanical EngineeringDocument52 pagesElements of Mechanical EngineeringJoseph SajanNo ratings yet

- Experiment 03Document5 pagesExperiment 03Ritik agarwalNo ratings yet

- MTM Lab Report..501Document96 pagesMTM Lab Report..501Usman BajwaNo ratings yet

- 01 Center LatheDocument7 pages01 Center LathekabbirhossainNo ratings yet

- Ch5-Milling MachineDocument77 pagesCh5-Milling MachineYash OramNo ratings yet

- Lathe Machine OperationDocument38 pagesLathe Machine OperationInilazi JimmyNo ratings yet

- Unit - V: Manufacturing TechnologyDocument54 pagesUnit - V: Manufacturing TechnologyIjanSahrudinNo ratings yet

- Lathe Machine Workshop PracticesDocument3 pagesLathe Machine Workshop PracticesSujay Das SonuNo ratings yet

- MillingDocument11 pagesMillingAb SiNo ratings yet

- WORKSHOP PRACTICE-B.Tech IIDocument46 pagesWORKSHOP PRACTICE-B.Tech IIrawat7233abhayNo ratings yet

- Machining OperationsDocument7 pagesMachining OperationsbazilNo ratings yet

- Lathe 150826222523 Lva1 App6892Document75 pagesLathe 150826222523 Lva1 App6892jbcNo ratings yet

- End Mill Design Criteria and FeaturesDocument4 pagesEnd Mill Design Criteria and FeaturesdkkNo ratings yet

- MCP 101 Product Realization Lab ManualDocument75 pagesMCP 101 Product Realization Lab ManualjasvindersinghsagguNo ratings yet

- Machining ProcessesDocument44 pagesMachining Processesregassa rajiNo ratings yet

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- 8.0 Brake by Wire Ja505Document16 pages8.0 Brake by Wire Ja505Nareesh RajNo ratings yet

- 6.0 Anti Theft Protection JA505Document14 pages6.0 Anti Theft Protection JA505Nareesh RajNo ratings yet

- Final ReportDocument7 pagesFinal ReportNareesh RajNo ratings yet

- Mechanical Engineering Course Outlines Workshop Service ManagementDocument2 pagesMechanical Engineering Course Outlines Workshop Service ManagementNareesh RajNo ratings yet

- Emission Control SystemDocument17 pagesEmission Control SystemNareesh RajNo ratings yet

- Fuel Delivery SystemDocument4 pagesFuel Delivery SystemNareesh RajNo ratings yet

- StarterDocument8 pagesStarterNareesh RajNo ratings yet

- Fuel Delivery SystemDocument4 pagesFuel Delivery SystemNareesh RajNo ratings yet

- Kaadhal en Kaadhal Adhu KanneerulaDocument2 pagesKaadhal en Kaadhal Adhu KanneerulaNareesh RajNo ratings yet