Professional Documents

Culture Documents

Footstep Generator

Footstep Generator

Uploaded by

raghunandanr1993Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Footstep Generator

Footstep Generator

Uploaded by

raghunandanr1993Copyright:

Available Formats

International Journal of Scientific and Research Publications, Volume 3, Issue 3, March 2013 ISSN 2250-3153

Electricity Generation from Footsteps; A Regenerative Energy Resource

Tom Jose V*, Binoy Boban*, Sijo M T*

*SCMS School of Engineering and Technology, Kochi

Abstract A slab of concrete harnesses kinetic energy whenever it is stepped on. This energy, created by 5 millimeters of flex in the material, is then either stored by lithium polymer batteries contained within the slabs or transmitted immediately to streetlights or other electronics located close by. The current model, made from stainless steel, recycled car tires and recycled aluminum, also includes a lamp embedded in the pavement that lights up every time a step is converted into energy (using only 5 percent of the generated energy).

Index Terms- Accidents, Companies, Production, Safety

I. INTRODUCTION

web site is to install slabs in subway turnstiles where thousands of people about 36,000 per hour walk a day to power station electronics. The system from Pavegen makes a lot of sense in very busy public areas as it will constantly be generating energy which will no doubt mean the system pays for itself very quickly and then continues to cut energy costs, the need for extended power wires and carbon emissions. It also helps that they are self-contained units meaning no expensive digging up of the ground surrounding them, thus making them easy to install [5]. Pavegen is not the only company thinking this way and along their direct competition, were bound to see many other companies trying to develop their energy harvesting products for all the other activities we carry out regularly. II. WORKING MECHANISM As per our reference we are using same technique in our work as shown below. We use one rick and pinion gear system with dynamo fixing with its gear mechanism.

ue to a need to reduce carbon emissions and keep costs down, producing renewable energy is increasingly important for most governments and the tech industry at the moment. With that in mind investments are being made in the popular green energy sectors such as wind, solar, and wave energy. However, peoples steps (thousands upon thousands a day) utilize and channel kinetic energy too [1]. An emerging startup called Pavegen has installed such squares of energy-generating pavement in London. In an effort to keep the production of the pavement as green and sustainable as possible, Pavegen partnered with Ryburn Rubber Limited and Advanced LEDs (which has also invested in the idea) to make sure that its components create as small an environmental impact as possible [4]. The average square of pavement produces about 2.1 watts of electricity. And according to Pavegen, any one square of pavement in a high-foot traffic area can see 50,000 steps a day. Based on this data, only five units of Pavegen pavement can be enough to keep the lights on at a bus stop all night [2]. The company, led by 24-year old founder Laurence Kemball-Cook, says it eventually wants its slabs to power automatic doors, ticket machines, neon signs, and even computers and major appliances. Pavegen isnt targeting its product exclusively at municipalities. One of its big ideas is to have stores located on busy sidewalks install them in front of their locations to power their signage or any internal electronics. To encourage this adoption, the company says it will brand its slabs for its commercial customers. The slabs installed in East London happen to be green (thus suggesting its clean-tech solution) but they come in a variety of colors [3]. The company believes the embedded lamp is important to inform passersby of their contribution to the clean energy movement. The startup plans to roll out more Pagevgen units in the United Kingdom in the next year, but it envisions installing them one day in Times Square in New York think of all the electronic displays it could help power there and other frequented locations in the U.S. One of the ideas pitched on its

Fig.1

www.ijsrp.org

III. COMPONENTS REQUIRED Dynamo: A dynamo, originally another name for an electrical generator, now means a generator that produces direct current with the use of a commutator. Dynamos were the first electrical generators capable of delivering power for industry, and the foundation upon which many other later electric-power conversion devices were based, including the electric motor, the alternating-current alternator, and the rotary converter. They are rarely used for power generation now because of the dominance of alternating current, the disadvantages of the commutator, and the ease of converting alternating to direct current using solid state methods. The word still has some regional usage as a replacement for the word generator. A small electrical generator built into the hub of a bicycle wheel to power lights is called a Hub dynamo. Rotary Converter Development: After dynamos were found to allow easy conversion back and forth between mechanical or electrical power, the new discovery was used to develop complex multi-field single-rotor devices with two or more commutators. These were known as a rotary converter. These devices were usually not burdened by mechanical loads, but watched just spinning on their own. The rotary converter can directly convert, internally, any power source into any other. This includes direct current (DC) into alternating current (AC), 25 cycle AC into 60 cycle AC, or many different output currents at the same time [7]. The size and mass of these was very large so that the rotor would act as a flywheel to help smooth out any sudden surges or dropouts. The technology of rotary converters ruled until the development of vacuum tubes allowed for electronic oscillators. This eliminated the need for physically spinning rotors and commutators. Rack and pinion system: A rack and pinion is a type of linear actuator that comprises a pair of gears which convert rotational motion into linear motion. The circular pinion engages teeth on a linear "gear" bar the rack. Rotational motion applied to the pinion will cause the rack to move to the side, up to the limit of its travel. For example, in a rack railway, the rotation of a pinion mounted on a locomotive or a railcar engages a rack between the rails and pulls a train along a steep slope. The rack and pinion arrangement is commonly found in the steering mechanism of cars or other wheeled, steered vehicles. This arrangement provides a lesser mechanical advantage than other mechanisms such as recirculating ball, but much less backlash and greater feedback, or steering "feel". The use of a variable rack (still using a normal pinion) was invented by Arthur E Bishop, so as to improve vehicle response and steering "feel" especially at high speeds, and that has been fitted to many new vehicles, after he created a specialised version of a net-shape warm press forging process to manufacture the racks to their final form, thus eliminating any subsequent need to machine the gear teeth. For every pair of conjugate involute profile, there is a basic rack. This basic rack is the profile of the conjugate gear of infinite pitch radius.A generating rack is a rack outline used to indicate tooth details and dimensions for the design of a generating tool, such as a hob or a gear shaper cutter. IV. DESIGN OF MECHANISM Board (base):- length=56 cm width=40 cm thickness=1cm First stair block:- length=33cm width=21cm

Fig.2 When we press that slider while walking attach spring push back that slider attach dynamo with slider rack and pinion generate current.

Fig.3 Placement of our project in daily life as a footstep

Fig.4

International Journal of Scientific and Research Publications, Volume 3, Issue 3, March 2013 ISSN 2250-3153

height=9cm Second stair:- length=23cm Third stair:-13cm Foot space:- length=11cm width=21cm Gap from working stair to plate =3cm Tension spring =1 LED (light emitting diode) =5 Dc dynamo (3-volt) =1 Wires =2mtr. Slider block: - width=13cm height=18ccm Rack: length=7cm length of teeth cut=5cm Gear :- teeth=40 pinion :- teeth =12 height = 9cm slider :- width = 12.5cm height = 15cm Black tape=10meters White ply board = 100cmX50cm Femi coal= 0.250 kg V. FUTURE ASPECTS In future aspects we can use this principal in the speed breakers at high ways where are rushes of the vehicles too much thus increase input torque and ultimate output of generator. If we are used this project at very busy stairs palace then we produce efficient useful electrical for large purposes VI. ADVANTAGES To store the electricity in battery. It can be use at any time when it necessary. Easy construction. Less number of parts required. Electricity can used for many purposes VII. APPLICATIONS In street light. In LED light for specific purposes. In air circulation system for room by the small fans. For used in security alarm. REFERENCES

[1] S. Whaley, D. English, E. Hu, P. Barbara, and A. Belcher, Nature, pp 665, 2000. [2] S. Brown, Proceedings of the National Academy of Sciences 89, pp 8651 1992. [3] C. M. Kacher, I. M. Weiss, R. J. Stewart, C. F. Schmidt, P. K. Hansma, M. Radmacher, and M. Fritz, European Biophysics Journal 28,pp 611, 2000. [4] Marc A. Rose, Engineering Health and Safety Module and Case Studies, vol. 1, pp. 1-9, July 2004. [5] PaiviHamalainen, JukkaTakala, KaijaLeenaSaarela, Global estimates of occupational accidents, vol. 1,pp. 2-3, 2005. [6] Marcel Simard, Alain Marchand, A multilevel analysis of organisational factors related to the taking of safety initiatives by work groups vol. 1, pp. 5-9, 1995. [7] Byham, William C., Ph.D., and Jeff Cox, HeroZ: Empower Yourself, Your Coworkers, Your Company. New York: Harmony Books, 1994.

ISBN: 0-517-59860-4. (Available on audiocassette.)Argyris, [8] Muhammad Shahid,Tufail,Hamid, Mehovic, Investigation of the ways to improve the performance of a plant vol. 1, pp. 1-6,June 2007 [9] N.C. Nigam, A.K. Maheshwari, N.P. Rao ;Brief presentation of various facets of Safety and Health in chemical Industries with a special focus at Indian Farmers Fertiliser Cooperative Ltd.,(IFFCO)Aonla unit; vol. 1, pp. 4-9, 2006. [10] J. Leslie Goodier,E. Boudreau,G. Coletta. R. Lucas, Industria Health and Safety Criteria for Abrasive Blast Cleaning Operations . vol. 1, pp. 5-7, June 1996. [11] Dekker S.W.A, Reconstructing human contributions to accidents, The new view on error and performance, Journal of Safety Research, 33, 371-385. 2002, [12] Bell J., Holroyd J., 2009, Review of human reliability assessment methods, Health and Safety Executive books, May 2012. [13] Lawley H.G., Shepherd J.S, Find Plant Hazards Before Accident Happen, Fert. Focus, 4, 57-74, , 1987. [14] Sharit J, Handbook of Human Factors and Ergonomics, John Wiley & Sons, Hoboken, NewJersey, USA, 718-720, 2006. [15] Chris, Good Communication That Blocks Learning, Harvard Business Review, July-August 1994, pp 77-85. [16] Capowski, Genevieve, Anatomy of a Leader, Where Are The Leaders of Tomorrow? Management Review, March 1994, pp 10-17. [17] Lischeid, William E., TQM & Safety : New Buzz Words or Real Understanding?, Professional Safety, June 1994, pp 31-36.

AUTHORS Mr. Tom Jose V - B.tech (Mechanical Engineering), M.tech (Production and Industrial Engineering). SCMS School of Engineering and Technology, Kochi. Email: tomjosev@gmail.com. Mr. Binoy Boban - B.tech (Mechanical Engineering), M.tech (Production and Industrial Engineering). SCMS School of Engineering and Technology, Kochi. Email: binoyboban@gmail.com. Asst Prof. Sijo M T - B.tech (Mechanical Engineering), M.tech (Production). SCMS School of Engineering and Technology, Kochi.

www.ijsrp.org

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Mitsubishi FG15N Electric System ManualDocument42 pagesMitsubishi FG15N Electric System ManualПетр100% (1)

- TechRef EarthingReactor For Digsilent POwer FactoryDocument8 pagesTechRef EarthingReactor For Digsilent POwer FactoryGuillermo CeosNo ratings yet

- Specialqrp Issue: Inernational HAM MagazineDocument39 pagesSpecialqrp Issue: Inernational HAM Magazine1c1b964d100% (3)

- 2013-05-27 Voith Generators PDFDocument5 pages2013-05-27 Voith Generators PDFBruno OliveiraNo ratings yet

- Bose Lifestyle V Class UsMan (EN)Document70 pagesBose Lifestyle V Class UsMan (EN)carlos diazNo ratings yet

- 307t1611 - 1604652 Peecc Arrangement - Vcc-IcoDocument13 pages307t1611 - 1604652 Peecc Arrangement - Vcc-IcoMarcoNo ratings yet

- TrainingDocument55 pagesTrainingTanveer AhmadNo ratings yet

- LR10007.gb.11-09-01 - SA155W - 2-Pole Product Sheet PDFDocument2 pagesLR10007.gb.11-09-01 - SA155W - 2-Pole Product Sheet PDFCesar GilNo ratings yet

- SFCL PDFDocument18 pagesSFCL PDFnagasekhar aakamNo ratings yet

- Penguat BJTDocument44 pagesPenguat BJTMarissa Tania TNo ratings yet

- 4AA12 P4DatasheetsDocument47 pages4AA12 P4DatasheetsalejandroNo ratings yet

- 500kva PCC3201 QSX15 WiringDocument39 pages500kva PCC3201 QSX15 Wiringjesus ontiverosNo ratings yet

- Trihal-1600kva Technical Data SheetDocument2 pagesTrihal-1600kva Technical Data Sheetmohammed abdul QualiqueNo ratings yet

- What Is Surge Impedance Loading and It's Significant in Power SystemDocument4 pagesWhat Is Surge Impedance Loading and It's Significant in Power Systemrohan kumarNo ratings yet

- Saturated Synchronous ReactanceDocument6 pagesSaturated Synchronous Reactancechandra sekrNo ratings yet

- Product Data Sheet: 8000 C Fire Alarm PanelDocument4 pagesProduct Data Sheet: 8000 C Fire Alarm PanelmotaNo ratings yet

- TDA8174A: Vertical Deflection CircuitDocument7 pagesTDA8174A: Vertical Deflection CircuithassanNo ratings yet

- WEG Manual de Instrucoes Abw Abw Manual Portugues BRDocument144 pagesWEG Manual de Instrucoes Abw Abw Manual Portugues BRHermano Mendes100% (1)

- EcE 52013 EquationsDocument10 pagesEcE 52013 EquationsApril MayNo ratings yet

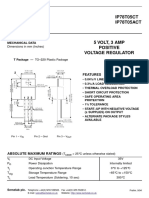

- IP78T05CT IP78T05ACT: FeaturesDocument4 pagesIP78T05CT IP78T05ACT: FeaturesRyn YahuFNo ratings yet

- Cable Design Formulas - Standard Wire & Cable CoDocument3 pagesCable Design Formulas - Standard Wire & Cable CoSathiya Nathan100% (1)

- K3498 ToshibaSemiconductorDocument3 pagesK3498 ToshibaSemiconductorGilmar RodriguesNo ratings yet

- Andrew LBX 6516dsDocument6 pagesAndrew LBX 6516dsrfgabadNo ratings yet

- AVR 1.3-2.5 KW 3kW 5kW Schematic Diagram For GeneratorDocument1 pageAVR 1.3-2.5 KW 3kW 5kW Schematic Diagram For GeneratorAlexandru Daniel Buleu71% (14)

- Chapter 1 - Power Electronics - Circuit Analysis and Design, 2nd Ed. (Batarseh and Harb)Document24 pagesChapter 1 - Power Electronics - Circuit Analysis and Design, 2nd Ed. (Batarseh and Harb)Anmol BatajooNo ratings yet

- ED110 Big Blue 500 Pro EnglishDocument8 pagesED110 Big Blue 500 Pro EnglishAlberto Lobones0% (1)

- Akira 14BM18 Chasis EX-1A3Document42 pagesAkira 14BM18 Chasis EX-1A3derejeNo ratings yet

- 1490 Manual PDFDocument9 pages1490 Manual PDFMarilza CastroNo ratings yet

- Daikin Design Service ManualDocument200 pagesDaikin Design Service Manualjr10003No ratings yet

- Toshiba GF630 - LF620Document18 pagesToshiba GF630 - LF620JAVIER VARGAS ROMANNo ratings yet