Professional Documents

Culture Documents

Mathcad - Roark's Formulas For Stress and Strain Table 26, Case 2a

Mathcad - Roark's Formulas For Stress and Strain Table 26, Case 2a

Uploaded by

Chhagan PatilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mathcad - Roark's Formulas For Stress and Strain Table 26, Case 2a

Mathcad - Roark's Formulas For Stress and Strain Table 26, Case 2a

Uploaded by

Chhagan PatilCopyright:

Available Formats

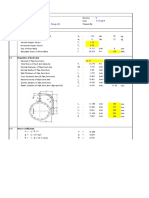

Table 26 Formulas for maximum deflection and maximum stress in flat plates with straight boundaries and constant

thickness

Case 2a Rectangular plate, three edges simply supported, one edge (b) free; uniform load over entire plate

Rectangular plate, three edges simply supported, one edge (b) free

Notation file

Provides a description of Table 26 and the notation used.

Enter dimensions, properties and loading

Plate dimensions: length: width: thickness: Uniformly distributed load:

a 15 in b 12 in t 0.25 in q 100 lbf in

2

Modulus of elasticity: Poisson's ratio:

E 30 10 0.3

6 lbf

in

Calculation procedure

For a plate material with approximately = 0.3, the maximum stress () and deflection (y) are functions of and which are defined after these calculations.

max := q b t y max :=

2 4 2

max = 1.659 10

5 lbf

in y max = 0.664 in

q b E t

3

Interpolate data values

0.5 0.667 1 Table 1.5 2 4

0.36 0.08 0.67 0.14

0.45 0.106

The transpose of this data can be found in 0.77 0.16 the file "d02a.prn". 0.79 0.165 0.8 0.167

4 0.5 0.667 1 1.5 2 0.8 Table = 0.36 0.45 0.67 0.77 0.79 0.08 0.106 0.14 0.16 0.165 0.167

T

and are interpolated from the above data table.

a b = 1.25

0 2 a linterp Table , Table , b 0 1 a linterp Table , Table , b

= 0.15 = 0.72

Large deflection condition check

Check to verify that the absolute value of the maximum deflection is less than one-half the plate thickness (an assumption stated in the notation file which must hold true):

t 2 = 0.125 in y max = 0.664 in

Table 26a Notation file

If ymax is greater than t/2 (large deflection), the equations in this table are subject to large errors. For large deflections, use the equations provided in Table 26a. Read the Notation file for more specific information.

References

Ref. 8. Wojtaszak, I. A.: Stress and Deflection of Rectangular Plates, ASME Paper A-71, J. Appl. Mech., vol. 3, no. 2, 1936.

You might also like

- Swing Bolt Closure Design - Pressure VesselDocument12 pagesSwing Bolt Closure Design - Pressure VesselRasatja Yongskulrote100% (2)

- Pressure Vessel Lifting Lug CalculationDocument2 pagesPressure Vessel Lifting Lug Calculationtekstep767% (3)

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- Calculation of BuckstayDocument8 pagesCalculation of BuckstaydehriyaNo ratings yet

- KEC plant pressure vessel training manual 1 of 5 권1 PDFDocument83 pagesKEC plant pressure vessel training manual 1 of 5 권1 PDFJinho LeeNo ratings yet

- Zick Analysis For Saddle SupportDocument8 pagesZick Analysis For Saddle Supportfuransu777100% (1)

- Bolted Flanged Connections For Non-Circular Pressure VesselsDocument8 pagesBolted Flanged Connections For Non-Circular Pressure VesselsKenneth BeerNo ratings yet

- SAS Cheat SheetDocument2 pagesSAS Cheat SheetKapil NandwanaNo ratings yet

- SAS Cheat SheetDocument2 pagesSAS Cheat SheetKapil NandwanaNo ratings yet

- Assignment Shaft DesignDocument4 pagesAssignment Shaft DesignHasham Mehmood100% (1)

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Saddle v1-5: Fixed Saddle Sliding SaddleDocument9 pagesSaddle v1-5: Fixed Saddle Sliding Saddleduf fuNo ratings yet

- Cdo CalcDocument3 pagesCdo CalcJeric FarinNo ratings yet

- PD5500 - 133 - RectangularFlange CalculationDocument9 pagesPD5500 - 133 - RectangularFlange CalculationDarshan PanchalNo ratings yet

- Saddle Reaction Summary - For Empty CaseDocument12 pagesSaddle Reaction Summary - For Empty CasesridharNo ratings yet

- Allowable Nozzle LoadingsDocument3 pagesAllowable Nozzle Loadingskemo10No ratings yet

- Code Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsDocument1 pageCode Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsguravdrNo ratings yet

- E.4 Leg Support CalculationDocument2 pagesE.4 Leg Support Calculationnaim100% (1)

- Longitudinal Bending Stress: M1 Allowable Limit RemarkDocument16 pagesLongitudinal Bending Stress: M1 Allowable Limit RemarkSandal JepitNo ratings yet

- SEISMIC ANALYSIS KazzincDocument14 pagesSEISMIC ANALYSIS KazzincArees KhambattaNo ratings yet

- Roark's Formulas For Excel Universal Technical Systems, IncDocument26 pagesRoark's Formulas For Excel Universal Technical Systems, Incktejankar100% (1)

- Cover Pages For PV Elite VenvelDocument14 pagesCover Pages For PV Elite VenvelSakthi VelNo ratings yet

- ANCHOR BOLT DESIGN - Gulf Publishing - Pressure Vessel Design Manual 3rd Edition 195Document1 pageANCHOR BOLT DESIGN - Gulf Publishing - Pressure Vessel Design Manual 3rd Edition 195Alessio BarboneNo ratings yet

- Lug Analysis - MechaniCalcDocument21 pagesLug Analysis - MechaniCalcArunkumar RackanNo ratings yet

- Beam Design CalculationDocument33 pagesBeam Design CalculationsmijusNo ratings yet

- What Is An ASME Appendix 2 Flange Design PDFDocument1 pageWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleNo ratings yet

- Stack Wind CalculationsDocument5 pagesStack Wind CalculationsJosé García100% (2)

- Saddle LoadsDocument11 pagesSaddle LoadsAnthony Dudley0% (1)

- Roark Excel 8thed Rev 005Document25 pagesRoark Excel 8thed Rev 005Amaro Moraes100% (2)

- Ccsviiid1 2260Document2 pagesCcsviiid1 2260DieguitoOmarMoralesNo ratings yet

- Spring Design: GD N PC yDocument2 pagesSpring Design: GD N PC yAshokNo ratings yet

- Design of Large Opening Nozzle by Bulletin WRC-107Document12 pagesDesign of Large Opening Nozzle by Bulletin WRC-107ALONSO GOMEZNo ratings yet

- Screeing Method Fea FatigueDocument34 pagesScreeing Method Fea FatigueGokul Amarnath0% (1)

- Fatigue and Machine Design Excel Spreadsheet CalculatorDocument3 pagesFatigue and Machine Design Excel Spreadsheet CalculatorKeith AdminNo ratings yet

- Saddle CalculationDocument10 pagesSaddle Calculationpharis_chrisNo ratings yet

- Cover Plate CalculationDocument1 pageCover Plate CalculationSachin5586No ratings yet

- 1830 - Fea Fatigue Analysis Report PDFDocument19 pages1830 - Fea Fatigue Analysis Report PDFGabbar SinghNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- .Document7 pages.Darshan Panchal100% (1)

- Tank DesignDocument89 pagesTank Designpatrickandreas77No ratings yet

- 2400 Tema DCDocument7 pages2400 Tema DCMasoodMiyanNo ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- 28 Roark Flat PlatesDocument14 pages28 Roark Flat Platesgutmont0% (1)

- Nozzle Reinforcement CalculationsDocument11 pagesNozzle Reinforcement CalculationsmshNo ratings yet

- Roark's Circular PlateDocument2 pagesRoark's Circular PlatePaulo MoreiraNo ratings yet

- HE Header E535Document91 pagesHE Header E535rizal mubarokNo ratings yet

- NozzleDocument11 pagesNozzleharyfadlyNo ratings yet

- Lug SupportDocument2 pagesLug SupportSachin5586No ratings yet

- Topics: Equilibrium and Stability Criteria, The VDW Equation of State, The MaxwellDocument9 pagesTopics: Equilibrium and Stability Criteria, The VDW Equation of State, The MaxwellAkshat GuptaNo ratings yet

- ProjetDocument22 pagesProjetNadia ZoubirNo ratings yet

- Mechanical Vibrations - Solved Examples PDFDocument93 pagesMechanical Vibrations - Solved Examples PDFSherlockNo ratings yet

- Physics 210A: Statistical Physics HW Assignment #4 SolutionsDocument7 pagesPhysics 210A: Statistical Physics HW Assignment #4 SolutionsGhadendra BhandariNo ratings yet

- Graetz ProblemDocument13 pagesGraetz ProblemBelialVKWWNo ratings yet

- ME 6230: Theory of PlatesDocument7 pagesME 6230: Theory of PlatesTousif MahmoodNo ratings yet

- Solved ATP Paper WorkbookDocument82 pagesSolved ATP Paper Workbookraidah iftikharNo ratings yet

- Apdx03Document5 pagesApdx03Ayman_Elmasry_9107No ratings yet

- Graetz ProblemDocument13 pagesGraetz ProblemvilandraaNo ratings yet

- A Note On The Relationship of Primal and Dual Simplex: SFU-CMPT TR 1998-21Document14 pagesA Note On The Relationship of Primal and Dual Simplex: SFU-CMPT TR 1998-21amitangrauNo ratings yet

- Modelling and Simulation MidDocument2 pagesModelling and Simulation MidPranshu DixitNo ratings yet

- Modeling: Vibrating String, Wave Equation: Pdes Solvable As OdesDocument7 pagesModeling: Vibrating String, Wave Equation: Pdes Solvable As OdesSergioNo ratings yet

- 2.2 Transient Conduction in Semi-Infinite SlabDocument3 pages2.2 Transient Conduction in Semi-Infinite SlabteorikdeliNo ratings yet

- Notes PDFDocument3 pagesNotes PDFpraveen4ubvsNo ratings yet

- Swagelok VibrationDocument21 pagesSwagelok VibrationKapil NandwanaNo ratings yet

- Structural Analysis of Automotive Chassis Frame and Design Modification For Weight ReductionDocument7 pagesStructural Analysis of Automotive Chassis Frame and Design Modification For Weight ReductionKapil NandwanaNo ratings yet

- Floor Covering Tarkett Acczent ExcellenceDocument1 pageFloor Covering Tarkett Acczent ExcellenceKapil NandwanaNo ratings yet

- Table 3 A Ubc Vol 1Document1 pageTable 3 A Ubc Vol 1Kapil NandwanaNo ratings yet

- SSE Horz. and Vert (X, Y & Z) EFRS at 3% Damping: Frequency (HZ)Document2 pagesSSE Horz. and Vert (X, Y & Z) EFRS at 3% Damping: Frequency (HZ)Kapil NandwanaNo ratings yet

- Guidelines For Development of In-Cabinet Seismic Demand For Devices Mounted in Electrical CabinetsDocument74 pagesGuidelines For Development of In-Cabinet Seismic Demand For Devices Mounted in Electrical CabinetsKapil NandwanaNo ratings yet

- Selecting The Right Vibro-Isolators - Karman Rubber CompanyDocument3 pagesSelecting The Right Vibro-Isolators - Karman Rubber CompanyKapil NandwanaNo ratings yet

- Guidelines For Development of In-Cabinet Seismic Demand For Devices Mounted in Electrical CabinetsDocument74 pagesGuidelines For Development of In-Cabinet Seismic Demand For Devices Mounted in Electrical CabinetsKapil NandwanaNo ratings yet

- Piping Stress Calculation Per B31.3-2010Document1 pagePiping Stress Calculation Per B31.3-2010Kapil NandwanaNo ratings yet

- Viola 24K 2Document139 pagesViola 24K 2Kapil NandwanaNo ratings yet

- ANSYS CLASS 3 Error RPT TemplateDocument2 pagesANSYS CLASS 3 Error RPT TemplateKapil NandwanaNo ratings yet

- Market Research Transportation of Large Household Items: RequiredDocument3 pagesMarket Research Transportation of Large Household Items: RequiredKapil NandwanaNo ratings yet

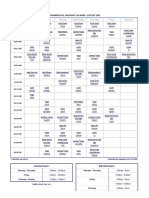

- Schedule CE - KNDocument1 pageSchedule CE - KNKapil NandwanaNo ratings yet

- LA Fitness - Class Schedule (Print Version) - OAKLEY - CINCINNATI, OHDocument2 pagesLA Fitness - Class Schedule (Print Version) - OAKLEY - CINCINNATI, OHKapil NandwanaNo ratings yet

- API 650 - Using WRC 297 With RepadDocument1 pageAPI 650 - Using WRC 297 With RepadGuochao SongNo ratings yet

- Class Xii Test PapersDocument124 pagesClass Xii Test PapersVivek RaiNo ratings yet

- NSEP ArchiveDocument114 pagesNSEP ArchiveAjiteshNo ratings yet

- Bend Loss in PenstockDocument22 pagesBend Loss in PenstockAan ShresthaNo ratings yet

- Tang, Sing C. - Pan, Jwo - Mechanics Modeling of Sheet Metal Forming (2007, Society of Automotive Engineers, Inc.)Document335 pagesTang, Sing C. - Pan, Jwo - Mechanics Modeling of Sheet Metal Forming (2007, Society of Automotive Engineers, Inc.)Claudio RodriguesNo ratings yet

- Crumple Zones VocabDocument2 pagesCrumple Zones VocabJoy GeorgeNo ratings yet

- Waves TestDocument4 pagesWaves TestPhilip MooreNo ratings yet

- Distance, DisplacementDocument17 pagesDistance, DisplacementJah AR DagtingNo ratings yet

- Griffith Luo IbfemNDocument26 pagesGriffith Luo IbfemNRizwan AhNo ratings yet

- Topic 1: Real Fluid Flow: Learning OutcomesDocument25 pagesTopic 1: Real Fluid Flow: Learning Outcomesfauzan1698No ratings yet

- 28.11.22 - SR - STAR CO-SC (MODEL-A) - Jee - Adv - 2022 - P2 - CTA-5 - KEY & SOLDocument14 pages28.11.22 - SR - STAR CO-SC (MODEL-A) - Jee - Adv - 2022 - P2 - CTA-5 - KEY & SOLzaid khanNo ratings yet

- Physics: - NEET Dropper Exam PaperDocument4 pagesPhysics: - NEET Dropper Exam PaperDivyansh KhatediyaNo ratings yet

- 04 - Temperature and Pressure Dependency For ViscosityDocument11 pages04 - Temperature and Pressure Dependency For ViscosityImran UnarNo ratings yet

- Homework #5 MomentumDocument10 pagesHomework #5 MomentumNordiana IdrisNo ratings yet

- Civil Engineering SET ADocument16 pagesCivil Engineering SET Aishak789No ratings yet

- 2D Numerical Simulations of Soil Nail WallsDocument12 pages2D Numerical Simulations of Soil Nail WallsShahab KhaledNo ratings yet

- Marine Engineering Mtech AssignmentDocument3 pagesMarine Engineering Mtech AssignmentDaniel Inemugha100% (1)

- CE-5542 4542 Syllabus EarthqkEng F2019Document4 pagesCE-5542 4542 Syllabus EarthqkEng F2019Majid ShahbaziNo ratings yet

- Vibration Sources Identification GuideDocument1 pageVibration Sources Identification GuideMURALINo ratings yet

- Tutorial 3Document2 pagesTutorial 3AmrinaAkmal0% (1)

- New Belt Truck TiresDocument17 pagesNew Belt Truck TiressiritapeNo ratings yet

- 2006 Int Ansys Conf 134Document15 pages2006 Int Ansys Conf 134bamboolNo ratings yet

- SDDocument4 pagesSDRuben García Ferrer100% (1)

- Lesson 06 Potential Flow and Elementary FlowsDocument23 pagesLesson 06 Potential Flow and Elementary FlowsAlmukhtar AlkinanyNo ratings yet

- Thermodynamics Somanath GoshDocument93 pagesThermodynamics Somanath Goshmamidivinay kumarNo ratings yet

- Wind Tunnel DataDocument4 pagesWind Tunnel DataNdumiso DlaminiNo ratings yet

- Ermiyas Ketema PDFDocument92 pagesErmiyas Ketema PDFsadam mohamedNo ratings yet

- Quiz - Motion in A Straight Line Class 11thDocument1 pageQuiz - Motion in A Straight Line Class 11thSantoshPathakNo ratings yet