Professional Documents

Culture Documents

Welding

Uploaded by

Ahmad UsamaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding

Uploaded by

Ahmad UsamaCopyright:

Available Formats

31.2.11 Weld Confirmation Checks The following definitions will apply to the entirety of rule 31.2.

11: As-Built Vehicle: the vehicle presented at technical inspection Roll Cage Elements: elements of the roll cage as discussed in rule 31.2.1 Roll Cage Welds: any weld joining two or more roll cage elements or one or more roll cage elements and one or more gussets as discussed in rule 31.2.9 Roll Cage Material: tubing of the same geometry and alloy as the roll cage elements of the as-built vehicle Roll Cage Welder: any person that performs welding of the roll cage welds of the as-built vehicle

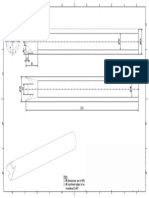

Each roll cage welder must demonstrate sufficient welding skill and craftsmanship with the tools, processes and roll cage material. In addition to visual inspection of the as-built vehicle, the national technical inspectors will collect and inspect welding samples during the technical inspection process to determine dynamic and endurance event competition eligibility. Teams unable to submit welding samples of adequate quality, as defined below, shall not be eligible to compete in any dynamic or endurance event. Each team must submit two (2) samples for each roll cage welder, both of which are constructed of roll cage material which have been welded with the same tools and processes as those of the as-built vehicle and which have also been subject to the following destructive testing and inspection: Sample 1 - Destructive Testing: A structure per made up of roll cage tubing welded at a 90 degree angle, the length of each tube to be determined by the team.< Figure 1 > This joint should be subject to destructive testing causing the joint to fail to which indicates superior weld strength with respect to the base material. (The testing method is left to the team discretion. For example, teams can use pull testing in a lab, or apply a moment to one side of the joint will fixing the other joint.)

Figure 1 Sample 2 Destructive Inspection: A structure made up of roll cage material that has two tubes attached at 30 degree angle with a length of at least 15cm from the center of the weld joint. < Figure 2 > which has been cut, in a band saw, along the length of tube to reveal adequate and uniform weld penetration <Figure 3>.

Figure 2

Figure 3

Final judgment of weld strength with respect to the base material as it described in sample 1 and the adequacy and uniformity of weld penetration as described in sample 2 shall rest with the national technical inspectors. Welding samples constructed of material other than the roll cage material and / or welded with a process other than that of the roll cage welds of the as-built vehicle shall be not be considered sufficient demonstration of welding skill and craftsmanship with the tools, processes and roll cage material.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Orbital WeldingDocument6 pagesOrbital WeldingPramodPradhanNo ratings yet

- ILJIN STEEL Corporation: The First PartnerDocument25 pagesILJIN STEEL Corporation: The First PartnerRyan Goh Chuang HongNo ratings yet

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivNo ratings yet

- AAP S8 SS Buttweld Fittings & Flanges E2 SDocument12 pagesAAP S8 SS Buttweld Fittings & Flanges E2 SMalouk CheniouniNo ratings yet

- Instructions Tifoo Anodization Starterkit enDocument23 pagesInstructions Tifoo Anodization Starterkit enHoang TanNo ratings yet

- AssocSpringBarnes SpringDesignHandbookDocument199 pagesAssocSpringBarnes SpringDesignHandbookTactical Ivan TacticalNo ratings yet

- Norse Material Follow ListDocument82 pagesNorse Material Follow Listözkan yamanNo ratings yet

- CDP 6503Document2 pagesCDP 6503GiovanniNo ratings yet

- Dod-Std-1866 Notice 1 1988Document33 pagesDod-Std-1866 Notice 1 1988liuyx866No ratings yet

- 01 HPT Metric 2018Document164 pages01 HPT Metric 2018Haresh KapadiyaNo ratings yet

- Evaluation of Secondary Steelmaking Slags and Their Relation With Steel CleanlinessDocument10 pagesEvaluation of Secondary Steelmaking Slags and Their Relation With Steel CleanlinessAbhinandan ChatterjeeNo ratings yet

- Xaf 013 HornoDocument2 pagesXaf 013 Hornoanfos.jhmNo ratings yet

- Effects of Thermal Treatment On Mechanical Properties and Grain Size of En8 SteelDocument5 pagesEffects of Thermal Treatment On Mechanical Properties and Grain Size of En8 SteelAjeeth KumarNo ratings yet

- AGSI-RM-DP-003 Stand #10 & #12 Delivery PipeDocument1 pageAGSI-RM-DP-003 Stand #10 & #12 Delivery PipeKumaran RubanNo ratings yet

- Sae J933 2005 (En)Document9 pagesSae J933 2005 (En)Oh No PotatoNo ratings yet

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

- 1584 - LNote - WELDING 2009Document565 pages1584 - LNote - WELDING 2009Anand DevNo ratings yet

- 2000 QP-SPC-L-002 - QP Specification For - Unlocked 46Document1 page2000 QP-SPC-L-002 - QP Specification For - Unlocked 46JITHIN KRISHNAN MNo ratings yet

- Non Traditional Machining PowerpointDocument40 pagesNon Traditional Machining PowerpointKish Shenoy100% (3)

- Induction Hardening - Barber-Pole, Snake-Skin and Fish-Tail PhenomenaDocument4 pagesInduction Hardening - Barber-Pole, Snake-Skin and Fish-Tail PhenomenaDouglas RodriguesNo ratings yet

- Iso 5817Document34 pagesIso 5817ElenaGozunovaNo ratings yet

- Engineering Materials-Istanbul .Technical UniversityDocument21 pagesEngineering Materials-Istanbul .Technical UniversitybuggrraaNo ratings yet

- AB Plastic Mold Steel For Moulds EngDocument28 pagesAB Plastic Mold Steel For Moulds EngHoang LinhNo ratings yet

- Vermont Turning Insert CatalogDocument84 pagesVermont Turning Insert CatalogMann Sales & MarketingNo ratings yet

- Gutters and Rainwater PipesDocument64 pagesGutters and Rainwater PipesBozo IvanovicNo ratings yet

- MSM Module 3Document24 pagesMSM Module 3Nk KumarNo ratings yet

- EnDOtec 310Document2 pagesEnDOtec 310EdwinNo ratings yet

- 02 Precision Pliers and CuttersDocument40 pages02 Precision Pliers and Cutterspavel10082020No ratings yet