Professional Documents

Culture Documents

Conveyor Belt

Uploaded by

Sholhan AzizOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conveyor Belt

Uploaded by

Sholhan AzizCopyright:

Available Formats

Address: Boling road 63#, Rubber Industry Development Park, BaoDing city, China Tel:+86 312 2236070 Fax:

+86 312 5936800

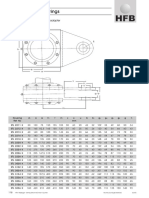

EP ply conveyor belt

EP conveyor composed of multi polyester canvas layers (or with polyester toward longitudinal and polyurethanes for latitude), with high intensity top and bottom coating, applying in granular, powdery material, and suitable for middle-long distance transmission EP conveyor belt has the same merit as Nylon conveyor belt, also with tensibility and keep high intensity in humidity condition, which would be very helpful for transfering the washy material or working on wet condition. Our EP conveyor belt products has five types according to coating difference: Anti-split type, Anti-abrasion type, common type, acid-alkali resistant type and heat-resistant type.

EP layer Type No.:NN80, EP100, EP125, EP150, EP200,EP250,EP300,EP400

Technical parameters for EP conveyor belt:

Address: Boling road 63#, Rubber Industry Development Park, BaoDing city, China Tel:+86 312 2236070 Fax: +86 312 5936800 Belt width 400 500 600 650 800 1000 1200 1400 1600 1800 2000 3~4 3~6 3~5 3~5 3~6 3~7 4~7 4~7 4~7 5~7 5~7 Layers Top coating 4.5 3.0 4.5 3.0 6.0 4.5 6.0 4.5 3.0 6.0 4.5 3.0 6.0 4.5 3.0 6.0 4.5 6.0 4.5 6.0 4.5 6.0 4.5 6.0 4.5 Coating thickness Bottom coating 3.0 1.5 3.0 1.5 3.0 1.5 3.0 1.5 4.5 3.0 1.5 4.5 3.0 1.5 4.5 3.0 1.5 4.5 3.0 4.5 3.0 4.5 3.0 4.5 3.0

Nylon conveyor longitudinal pulling intensity: N/mm 315 400 500 600 630 800 900 1000 Coating physical performance

Coating rank

Code

Stretch intensity MPa

Intensity to rupture MPa >450 >400 >350

Abrasion rate mm

3

After 70C*7days aging, changing rate for stretch intensity

Anti-split Anti-abrasion Common

H D L

>24.0 >18.0 >15.0

120< 100< 200<

-25~+25 -25~+25 -25~+25

Agglutinating intensity between layers

Item Among layers N/mm Among layers and coat Coating thickness 0.8~1.5mm Average data: N/mm Minimum data: N/mm >4.5 >3.9 >3.2 >2.4 >1.5mm >3.5 >2.9 Coating thickness

You might also like

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- Conveyor BeltDocument13 pagesConveyor BeltRajesh KumarNo ratings yet

- 2009 Catalogue: Conveyor BeltingDocument25 pages2009 Catalogue: Conveyor BeltingSaswita SaktiNo ratings yet

- Belt ConveyorsDocument10 pagesBelt ConveyorsRaja PalasaNo ratings yet

- Is 8531 1986Document6 pagesIs 8531 1986Srini KumarNo ratings yet

- Mato Belt Cleaner CatalogueDocument12 pagesMato Belt Cleaner Catalogueleeyod100% (1)

- Dura FlexDocument16 pagesDura FlexJohn ChivNo ratings yet

- Fenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesDocument22 pagesFenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesSubramanian ChidambaramNo ratings yet

- Cold Vulcanizing SolutionDocument4 pagesCold Vulcanizing Solutionritesh shrivastav0% (1)

- Iso 3684 1990Document8 pagesIso 3684 1990joaquin fuentealba moralesNo ratings yet

- Eriez-Vibratory Feeders PDFDocument16 pagesEriez-Vibratory Feeders PDFruben quedo salazarNo ratings yet

- Rema Tip Top Product Portfolio - Material Processing 2019Document268 pagesRema Tip Top Product Portfolio - Material Processing 2019Alexandre RogerNo ratings yet

- Mechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期Document1 pageMechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期saidNo ratings yet

- Covered (Stick) Electrodes (SMAW)Document5 pagesCovered (Stick) Electrodes (SMAW)Hanny Dewi SaragihNo ratings yet

- Helix Delta T-5 - HelpDocument274 pagesHelix Delta T-5 - Helpgkforoghan100% (1)

- Splice Belt DesignDocument9 pagesSplice Belt DesignriteshsamantrayNo ratings yet

- Gravity ConveyorsDocument49 pagesGravity ConveyorsAdriel Aron DiazNo ratings yet

- Design and Analysis of Screw ConveyorDocument21 pagesDesign and Analysis of Screw Conveyoravinash1987No ratings yet

- Conveyor Belt Cover GradesDocument1 pageConveyor Belt Cover GradessuraiaNo ratings yet

- Dunlop Conveyor Belt Design Manual - P2Document15 pagesDunlop Conveyor Belt Design Manual - P2perdhana2000No ratings yet

- 4 PulleysDocument14 pages4 PulleysMuhammadTaufikAliRahmanNo ratings yet

- Papers - Some Design Aspects For Selection of Heavy Duty Apron FeedersDocument5 pagesPapers - Some Design Aspects For Selection of Heavy Duty Apron FeedersarsanioseNo ratings yet

- Print Close: Machine DesignDocument5 pagesPrint Close: Machine DesignAnonymous CYdagINo ratings yet

- Presentación Equipo 2Document62 pagesPresentación Equipo 2Ruben Lopez RicoNo ratings yet

- Belt Feeder Properly DesignedDocument2 pagesBelt Feeder Properly DesignedCarlos Ediver Arias Restrepo100% (1)

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFWilliam VillamizarNo ratings yet

- Dunlop Conveyor Belt Design ManualDocument16 pagesDunlop Conveyor Belt Design ManualTabor TamiruNo ratings yet

- Bucket ElevatorDocument6 pagesBucket ElevatorbetojulioNo ratings yet

- SME 2017 Design and Analysis of Conveyor Pulleys - A HustrulidDocument34 pagesSME 2017 Design and Analysis of Conveyor Pulleys - A Hustrulidtadela_553439598No ratings yet

- Rexnord® High Performance Bucket Elevators PDFDocument12 pagesRexnord® High Performance Bucket Elevators PDFJavier Alejandro Rodriguez MelgozaNo ratings yet

- Dunlop Conveyor Belt Design Manual. Page 2 PDFDocument17 pagesDunlop Conveyor Belt Design Manual. Page 2 PDFMuthuvel VivekNo ratings yet

- 5 Roll Paper Conti James Ellton V14m PDFDocument21 pages5 Roll Paper Conti James Ellton V14m PDFRahmatwalNo ratings yet

- AVE PodV4Document3 pagesAVE PodV4hali10No ratings yet

- Belt Slippage SPWP1178ENPR-01Document2 pagesBelt Slippage SPWP1178ENPR-01JrbritoNo ratings yet

- ConyevorsDocument9 pagesConyevorsRohan MalkarNo ratings yet

- Belt Jointing ProcedureDocument5 pagesBelt Jointing ProcedureproxywarNo ratings yet

- Bearing Centre and Face Width in Conveyor PulleyDocument8 pagesBearing Centre and Face Width in Conveyor PulleyPrashant MishraNo ratings yet

- ABB CatalogueDocument6 pagesABB CatalogueNavneet SinghNo ratings yet

- High Performance Bucket Elevator CatalogDocument12 pagesHigh Performance Bucket Elevator CatalogcachorrexNo ratings yet

- A Review On Numerical and Experimental Study of Screw ConveyorDocument4 pagesA Review On Numerical and Experimental Study of Screw ConveyorMangatur SimamoraNo ratings yet

- Presented at The 2010 Annual SME Meeting in Phoenix, AZDocument15 pagesPresented at The 2010 Annual SME Meeting in Phoenix, AZassaNo ratings yet

- Conveyor Gallery - Structural Design ParameterDocument21 pagesConveyor Gallery - Structural Design Parametershailendra rathoreNo ratings yet

- Soportes Take UP STL Series - Rodamientos SmilovicDocument4 pagesSoportes Take UP STL Series - Rodamientos SmilovicAlejandro SmilovicNo ratings yet

- Brochure - Slide Gate Valve - Pubc-0502-SvDocument2 pagesBrochure - Slide Gate Valve - Pubc-0502-SvedgarspalaciosNo ratings yet

- Makron Fibretec 1000-2000 EngDocument10 pagesMakron Fibretec 1000-2000 EngMAKRONNo ratings yet

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Document19 pagesKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasNo ratings yet

- Lecture 4 - Belt Conveying - Trans CurvesDocument18 pagesLecture 4 - Belt Conveying - Trans CurvesFabio MiguelNo ratings yet

- Automatic Samplers: Proven & DependableDocument6 pagesAutomatic Samplers: Proven & DependableHarish KumarNo ratings yet

- PROK Product CatalogueDocument32 pagesPROK Product CatalogueDiego AndradeNo ratings yet

- CB Selecting The Proper Conveyor BeltDocument18 pagesCB Selecting The Proper Conveyor BeltdineshNo ratings yet

- Materials For Hip Prostheses: A Review of Wear and Loading ConsiderationsDocument26 pagesMaterials For Hip Prostheses: A Review of Wear and Loading ConsiderationsEka NatsvlishviliNo ratings yet

- Belt Tracking GuideDocument4 pagesBelt Tracking Guidekeira_designNo ratings yet

- Manual Helix Delta t6Document309 pagesManual Helix Delta t6Ricardo Garay Reinoso100% (2)

- Iso 5293 1981Document8 pagesIso 5293 1981Rajaram JayaramanNo ratings yet

- Standard Equipment: Welding Package Selection GuideDocument27 pagesStandard Equipment: Welding Package Selection GuidePCNo ratings yet

- Belt Tension TheoryDocument6 pagesBelt Tension TheoryPedro ViegasNo ratings yet

- ContiTech Select Catalog 2018 enDocument92 pagesContiTech Select Catalog 2018 enJuan Altamirano Rojas JarNo ratings yet

- Fatigue Failures of Welded Conveyor DrumsDocument11 pagesFatigue Failures of Welded Conveyor DrumsWashington MoraisNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Siemen HMS 9200en PDFDocument44 pagesSiemen HMS 9200en PDFSholhan AzizNo ratings yet

- ContSleeve Lovejoy C Gear CouplingDocument4 pagesContSleeve Lovejoy C Gear CouplingSholhan AzizNo ratings yet

- Operating and Installation Instructions For HYDAC AccumulatorsDocument4 pagesOperating and Installation Instructions For HYDAC AccumulatorsSholhan AzizNo ratings yet

- Shell Omala S2 G 2202 PDFDocument2 pagesShell Omala S2 G 2202 PDFSholhan AzizNo ratings yet

- Consolidated Bearing PDFDocument26 pagesConsolidated Bearing PDFSholhan AzizNo ratings yet

- Conveyor Belt Cover StandardDocument12 pagesConveyor Belt Cover StandardSholhan AzizNo ratings yet

- Fludex EOC SystemDocument11 pagesFludex EOC SystemSholhan Aziz100% (2)

- CASAR - Wire Rope End ConnectionsDocument76 pagesCASAR - Wire Rope End ConnectionsSholhan Aziz100% (4)

- OCA 130-20 Vickers Air Oil CoolerDocument3 pagesOCA 130-20 Vickers Air Oil CoolerSholhan AzizNo ratings yet

- Special Steel AISI 4140Document2 pagesSpecial Steel AISI 4140Sholhan AzizNo ratings yet

- Belt Conveyor Rubber GradeDocument1 pageBelt Conveyor Rubber GradeSholhan AzizNo ratings yet

- Special Steel Book AISI 1045Document2 pagesSpecial Steel Book AISI 1045Sholhan AzizNo ratings yet

- Shell Omala S2 G 2202Document2 pagesShell Omala S2 G 2202Sholhan AzizNo ratings yet

- Bourdon Tube Pressure Gauges Economical Stainless Steel Gauge Type 132.53 - Dry Case Type 133.53 - Liquid-Filled CaseDocument2 pagesBourdon Tube Pressure Gauges Economical Stainless Steel Gauge Type 132.53 - Dry Case Type 133.53 - Liquid-Filled CaseSholhan AzizNo ratings yet

- ST52-3 (Plate)Document1 pageST52-3 (Plate)Sholhan AzizNo ratings yet

- Conveyor Belt Basic Presentation and DiscussionDocument1 pageConveyor Belt Basic Presentation and DiscussionSholhan AzizNo ratings yet

- 13.standard For Conveyor Belt CoversDocument13 pages13.standard For Conveyor Belt CoversSholhan AzizNo ratings yet

- En Calculo de La Capacidad de Transporte de Bandas en GeneralDocument5 pagesEn Calculo de La Capacidad de Transporte de Bandas en GeneralSholhan AzizNo ratings yet