Professional Documents

Culture Documents

Resistencia Metal Aporte PDF

Resistencia Metal Aporte PDF

Uploaded by

rolandobtOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Resistencia Metal Aporte PDF

Resistencia Metal Aporte PDF

Uploaded by

rolandobtCopyright:

Available Formats

WBldlag faaBatlBa VBl. RfV, NB.

I, IBBI

NBw GtrBag MBBB a WBld

NaB TB BB7

The answer is fairly simple: strong enough to transfer the

loads that are passed between the two interconnected

materials. How strong does the weld metal have to be?

The answer to that question is far more complex.

In order to make a weld of sufficient size, the designer has

three variables that can be changed to affect the weld

strength:

weld length,

weld throat, and

weld metal strength.

Since three variables are involved, there are many combi-

nations that are suitable for obtaining the correct weld

strength. It may be necessary to also consider the loads

imposed on the base metal to ensure that the complete

welded joint has sufficient strength. This edition of

Design File will focus on the variable of weld metal

strength.

For purposes of this discussion, weld metal strength is

defined as the yield and tensile strength of the deposited

weld metal, as measured by an all-weld metal tensile

coupon extracted from a welded joint made in conformance

with the applicable AWS filler metal specification.

Matching weld metal has minimum specified yield and

tensile strengths equal to or higher than the minimum

specified strength properties of the base metal. Notice that

the emphasis is placed on minimum specified properties

because, in the case of both the filler metal and the base

metal, the actual properties are routinely higher. An exam-

ple of matching weld metal would be the use of E70XX

filler metal on A572 grade 50 steel. The weld metal/base

metal properties for this combination would be 60/50 ksi

MBB MadBrMatGklag WBld Btal

WkBrB RdaatagBBdB

(414/345 MPa) yield strength and 75/65 ksi (517/448 MPa)

tensile strength. Even though the weld metal has slightly

higher properties than the base metal, this is considered to

be a matching combination.

All too often, engineers see filler metal recommendations

provided in codes that reference matching combinations

for various grades of steel and assume that this is the only

option available. While this will never generate a noncon-

servative answer, it may eliminate better choices. Matching

filler metal tables were designed to give the recommenda-

tions for one unique situation where matching weld metal is

required, that is, Complete Joint Penetration (CJP) groove

welds in tension applications. All other applications permit

some degree of undermatching, and undermatching may

be a very desirable, cost-effective alternative for applica-

tions such as Partial Joint Penetration (PJP) groove welds

and fillet welds.

The significance of weld metal strength, as compared to

base metal strength, has increased in recent years, as the

number of higher strength steels continues to grow. When

A36 was the predominant steel, commercially available

filler metals would routinely overmatch the weld deposit.

As steels with a 50 ksi (345 MPa) minimum specified yield

strength became more popular (e.g., A572 grade 50 and

A588), the use of the E70XX grades of filler metals provid-

ed for a matching relationship. Steels with minimum speci-

fied yield strengths of 70 ksi (483 MPa) through 100 ksi

(690 MPa) have become more and more popular.

Although matching strength filler metals are available, the

option of using undermatched weld metal, where applica-

ble, is increasingly attractive.

When undermatching weld metal is utilized, the designer

must ensure that weld strength is achieved, but this is

easily done with the standard equations used to determine

the allowable stress on the weld.

Practical Ideas for the Design Professional by Duane K. Miller, P.E.

MBBlga FllB

WBldlag faaBatlBa VBl. RfV, NB. I, IBBI

For fillet welds in 90T-joints, the maximum allowable load

on the weld can be determined from the following equation:

F = (0.3) (0.707) (EXX) L

where,

= weld leg size

EXX = minimum specified tensile strength

of the filler metal

L = length of the weld

By substituting in the strength level of the undermatched

filler metal, the weld strength can be determined.

Undermatching may be used to reduce the concentration

of stresses in the base metal. Lower strength weld metal

will generally be more ductile than higher strength weld

metal. In Figure 1, the first weld was made with matching

filler metal. The second weld utilizes undermatching weld

metal. To obtain the same capacity for the second joint, a

large fillet weld has been specified. Since the residual

stresses are assumed to be of the order of the yield point

of the weaker material in the joint, the first example would

have residual stresses in the weld metal and in the base

metal of approximately 100 ksi (690 MPa) level. In the sec-

ond example, the residual stresses in the base metal would

be approximately 60 ksi (20 MPa), since the filler metal has

a lower yield point. These lower residual stresses will

reduce cracking tendencies, whether they might occur in

the weld metal, in the heat affected zone, or as lamellar

tearing in the base metal.

Overmatching is undesirable and should be discouraged.

Caution must be exercised when overmatching weld metal

is deliberately used. The strength of a fillet weld or PJP

groove weld is controlled by the throat dimension, weld

length, and strength of the weld metal. In theory, over-

matching filler metal would enable smaller weld sizes to be

employed and yet create a weld of equal strength.

However, the strength of a connection is dependent not

only on the weld strength, but also on the strength of the

fusion zone. As the weld size decreases, the fusion zone

is similarly reduced in size. The capacity of the base

metal is not affected by the selection of the filler metal, so

it remains unchanged. The reduction in weld size may

result in overstressing the base metal.

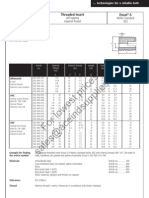

Consider the three PJP groove welds shown in Figure 2.

A load is applied parallel to the weld, that is, the weld is

subject to shear. The allowable stress on the groove weld is

0.30 times the minimum specified tensile strength of the

electrode (i.e., the E number). The allowable stress on the

base metal is required not to exceed 0.40 times the yield

strength of the base metal. The first weld employs a match-

ing combination, namely A572 grade 50 welded with E70

electrode. The second example examines the same steel

welded with undermatching E60 electrodes, and the final

example illustrates overmatching with an E80 electrode.

As shown in Figure 2, the allowable stress on the weld and

the allowable stress on the base metal have both been cal-

culated. In the case of undermatching weld metal, the

weld metal controls the strength of the joint. For matching

weld metal, the allowable load on both the weld and the

base metal is approximately the same. In the case of the

overmatching weld metal, however, the base metal is the

controlling variable. For this situation, it is important to

check the capacity of the base metal to ensure that the

connection has the required strength.

PraGtlGal RppllGatlBaB

Although it is relatively easy to determine which situations

are suitable for the use of undermatching weld metal,

some designers may simply choose to use the conserva-

tive approach and specify matching weld metal for all situ-

ations. However, matching weld metal may actually reduce

overall weld quality, increasing distortion, residual stresses,

Figure 1. Matching and undermatching filler metal.

Figure 2. Effect of filler metal strength level.

WBldlag faaBatlBa VBl. RfV, NB. I, IBBI

and cracking tendencies, including lamellar tearing. The

use of undermatched weld metal is an important option for

successfully joining higher strength steels.

When welding on higher strength steels with undermatch-

ing weld metal, it is important that the level of diffusible

hydrogen in the deposited weld metal be appropriate for

the higher strength steel that is being welded. For exam-

ple, whereas an E6010 electrode is suitable for welding on

lower strength steels that are not subject to hydrogen

assisted cracking, it would be inappropriate to utilize this as

an undermatching weld metal on 100 ksi (690 MPa) yield

strength A514 or A517 since these are highly sensitive to

hydrogen cracking. When undermatched weld metal is

used, it must not exceed the maximum levels of diffusible

hydrogen appropriate for matching strength weld deposits.

Also, any preheat requirements for matching strength rela-

tionships must be maintained even when undermatching

weld metal is utilized.

There are economic considerations as well. While many

filler metals from various welding processes are capable of

delivering 70 ksi (490 MPa) weld deposits, the number of

options available to the fabricator is greatly reduced when

100 ksi (690 MPa) yield strength weld metal is required

(i.e., E110 class filler metals). The metallurgical character-

istics necessary for the deposition of weld metal at this

strength level may impose restrictions on the electrode

designer which limit the attainable welding speeds and/or

operational characteristics. In contrast, the requirements

for lower strength filler metals give the electrode designers

more latitude and may result in improved operational char-

acteristics.

For many beam-like sections that are subject to bending,

the resultant longitudinal shear that must be transmitted

between the web and the flange of a built-up section is rel-

atively small. Weld sizes that are based upon the transfer

of the stress alone may result in surprisingly small welds,

welds so small that they may be difficult to make on a pro-

duction basis. The heat input associated with these small

welds may be so small that weld cracking results. For

these reasons, the D1.1 code has established minimum fil-

let weld sizes that, regardless of the level of stress

imposed on the weld, should be maintained in order to

obtain sound welds. For example, the minimum fillet weld

size for 3/4 in. (18mm) steel is 1/4 in. (6mm). For materials

greater than 3/4 in. (18mm), a 5/16 in. (8mm) fillet weld is

the minimum acceptable size. The implications of this are

that, for most structural fabrications involving built-up sec-

tions, the minimum fillet weld size is 5/16 in. (8mm). This is

often greater than the required fillet weld size necessary to

transfer the longitudinal shear. Particularly in these appli-

cations, undermatched weld metal offers a significant

advantage because the minimum required weld size can

be achieved utilizing the undermatched weld metal, and

this may also satisfy design requirements.

The following welding procedures have assumed that the

governing factor for the design of the members subject to

bending is the minimum weld size, not the allowable stress

on the connection. This will not always be the case.

However, comparing the welding procedures associated

with the two connections shows the benefit of utilizing the

undermatched filler metal.

ENaMplB - atGklag VBrBdB

MadBrMatGklag FlllBr Btal

Given: T-joint formed by 3/8 and 1 plates, 5/16

fillet weld, horizontal position, automatic SAW

Find: Cost savings for using undermatching

versus matching filler metal

Assumptions: SAW Flux/electrode combinations

960/L-61 (undermatching) and

880M/LAC-M2 (matching)

Labor & Overhead = $40.00/hr.

Equations: Cost = Labor + Materials

*Prices based on current Industrial Prices in Lincoln Electric price book (April, 1997)

Solution:

In this particular situation, savings of 40% were achieved

by utilizing the undermatching option. Design requirements

were satisfied, and the likelihood of welding-related prob-

lems such as weld cracking or lamellar tearing has been

reduced.

Cost ($/ft) =

Labor & Overhead ($/hr)

Travel Speed (in/min)

+ [electrode used (lb/ft) x electrode cost ($/lb)]

+ [flux used (lb/ft) x flux cost ($/lb)]

12 in/ft

60 min/hr

Labor & Overhead ($/hr.) $ 40.00 $ 40.00

Travel Speed (in./min.) 20.0 16.0

Electrode Used (lb./ft. of joint) 0.19 0.28

Electrode Cost* ($/lb.) $ 0.87 $ 1.84

Flux Used (lb./ft. of joint) 0.24 0.15

Flux Cost* ($/lb.) $ 0.53 $ 0.93

COST ($/ft.) $ 0.69 $ 1.16

Matching

880M/LAC-M2

Undermatching

960/L-61

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manual, Craftsman Table Saw, Model 113-298720 and 750Document52 pagesManual, Craftsman Table Saw, Model 113-298720 and 750Eng-JR80% (5)

- Pictorial DictionaryDocument20 pagesPictorial DictionaryMOHAMMAD ALINo ratings yet

- 132.3 Flash DistillationDocument26 pages132.3 Flash DistillationKeith SmithNo ratings yet

- Ogive Nose ConesDocument7 pagesOgive Nose ConesEng-JRNo ratings yet

- ARI Standard 780/790-1997, Definite Purpose and Limited Duty Definite Purpose Magnetic ContactorsDocument10 pagesARI Standard 780/790-1997, Definite Purpose and Limited Duty Definite Purpose Magnetic ContactorsEng-JRNo ratings yet

- How To Make Springs Web in PDFDocument191 pagesHow To Make Springs Web in PDFEng-JR100% (3)

- Swagelok HoseDocument28 pagesSwagelok HoseRashi Akmal0% (1)

- 12659358631051Document4 pages12659358631051KamillAL-akhrasNo ratings yet

- Chapter 6 Plumbing Materials Drainage Pipes andDocument11 pagesChapter 6 Plumbing Materials Drainage Pipes andRhey LuceroNo ratings yet

- Asme B36.19MDocument13 pagesAsme B36.19Mdongpc1No ratings yet

- (Solved) at The Instant Shown, 60Document3 pages(Solved) at The Instant Shown, 60marcosbispolimaNo ratings yet

- List of Construction Prices For Truss Works Philippines - PHILCON PRICESDocument1 pageList of Construction Prices For Truss Works Philippines - PHILCON PRICESJohn AlcantaraNo ratings yet

- Ensat Self Tapping Inserts 302 Series ImperialDocument1 pageEnsat Self Tapping Inserts 302 Series ImperialAce Industrial SuppliesNo ratings yet

- Pps 922903 2l Tfsi Caeb Enigine W Acs Eng PDFDocument55 pagesPps 922903 2l Tfsi Caeb Enigine W Acs Eng PDFKandy KnNo ratings yet

- 105 Sorbothane FAQsDocument2 pages105 Sorbothane FAQsMarcNo ratings yet

- Moldflow Analysis ReportDocument20 pagesMoldflow Analysis ReportJOHN TABARESNo ratings yet

- Hydroset Ii Packer: We Know DownholeDocument2 pagesHydroset Ii Packer: We Know DownholeabodolkuhaaNo ratings yet

- Aws Cmws 2005Document448 pagesAws Cmws 2005Ahmed Shaban Kotb100% (1)

- PHY10001 - Energy and Motion - Unit Outline - Sem 2 2023.-1Document14 pagesPHY10001 - Energy and Motion - Unit Outline - Sem 2 2023.-1MKNo ratings yet

- Design of Machinery: Assignment Gear TrainsDocument15 pagesDesign of Machinery: Assignment Gear Trainshasan bishNo ratings yet

- A M15.10 2008.10.21Document52 pagesA M15.10 2008.10.21Mohsen PeykaranNo ratings yet

- Seismic Analysis of Structures With Irregularities: Neha P. Modakwar, Sangita S. Meshram, Dinesh W. GawatreDocument4 pagesSeismic Analysis of Structures With Irregularities: Neha P. Modakwar, Sangita S. Meshram, Dinesh W. Gawatremy09No ratings yet

- Chapter 16 Planar Kinematics of Rigid BodyDocument51 pagesChapter 16 Planar Kinematics of Rigid BodyDawood AbdullahNo ratings yet

- Easa Ar100-2010 1010 PDFDocument34 pagesEasa Ar100-2010 1010 PDFahmad zavyNo ratings yet

- Computational Modeling in Geotechnical EngineeringDocument2 pagesComputational Modeling in Geotechnical EngineeringshivaNo ratings yet

- Hooke S LawDocument5 pagesHooke S Lawخلود البطاحNo ratings yet

- Air Powered CarDocument9 pagesAir Powered CarEarn moneyNo ratings yet

- 5 - G - Aguila Shaft DesignDocument7 pages5 - G - Aguila Shaft DesignJonas M. MagbooNo ratings yet

- Drag Reduction by Microbubble - ShipDocument6 pagesDrag Reduction by Microbubble - ShipKURNIAWANNo ratings yet

- Design, Analysis and Safety Norms of Transmission Systems in SubmarinesDocument29 pagesDesign, Analysis and Safety Norms of Transmission Systems in SubmarinesASHUTOSH CHAURASIANo ratings yet

- Despiece Ehfb10t4ssDocument3 pagesDespiece Ehfb10t4ssCarmen Adriana Garcia MendozaNo ratings yet

- Maxiflow Heat Sink For Full Brick DC-DC Converter: Ats Part # Ats-1151-C1-R0Document1 pageMaxiflow Heat Sink For Full Brick DC-DC Converter: Ats Part # Ats-1151-C1-R0Robert SeredenkoNo ratings yet

- Vag Kssplus Hollow-Jet Discharge Valve: Operation and Maintenance InstructionsDocument12 pagesVag Kssplus Hollow-Jet Discharge Valve: Operation and Maintenance InstructionsJosue Rivera YaresiNo ratings yet

- Welding Penetration Reports ITLDocument31 pagesWelding Penetration Reports ITLHarminder KumarNo ratings yet