Professional Documents

Culture Documents

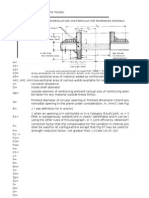

Thickness Calculation of Cylindrical Shell and Tube: Design Data

Uploaded by

skalimuthu190Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thickness Calculation of Cylindrical Shell and Tube: Design Data

Uploaded by

skalimuthu190Copyright:

Available Formats

Item No.

Part

Material SA-516-70

Code ASME Section VIII Division 1; UG-27,UG-28 Shape Cylindrical shell

Design data

Symbols Descriptions Values

Pi Internal design pressure ,Bar 12

Pe External design pressure ,Bar 1

Temp Design temperature ,Degree C 100

Ci Corrosion allowance at inside surface,mm 1.5

Ce Corrosion allowance at outside surface,mm 1.5

E Joint efficiency 0.85

Di Shell inside diameter in uncorroded condition ,mm 1900

Tnom Shell nominal thickness ,mm 16

Tol Permissible variation under specified thickness ,mm 0.25

L Design length of shell ,mm 2500

Calculations

Under internal pressure

Maximum allowable stress value ,S = 120.66 MPa

Required thickness ,Treq = 0.05*Pi*(Di+2*Ci) = 11.21 mm

S*E-0.06*Pi

Design thickness ,Tdes = Treq+Ci+Ce = 14.21 mm < Tnom

Under external pressure

Required thickness ,Treq = 13.00 mm

Shell outside diameter in corroded ,Doc = Di+2*(Tnom-Ce) = 1929.00 mm

L/Doc = 1.30

Doc/Treq = 148.38 >= 10

Factor determined from Fig.G ,A = 0.0005611

Factor determined from Fig.CS-2 ,B = 56.131 MPa

If Doc/Treq >= 10

Maximum allowable external pressure = 40*B = 5.04 Bar > Pe

3*(Doc/Treq)

If Doc/Treq < 10

Yield strength ,Y = -

Se = MIN(2*S,0.9*Y) = -

Pa1 = = -

Pa2 = = -

Maximum allowable external pressure = MIN(Pa1,Pa2) = -

Satisfactory

[

.

/

. ]* *

2 167

0 0833 10

Doc Treq

B

]

/

1

1 [ *

/

* 20

Treq Doc Treq Doc

Se

Thickness calculation of cylindrical shell and tube

You might also like

- Weight Estimation of Vessels AppsDocument39 pagesWeight Estimation of Vessels Appsmacwan23No ratings yet

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsVinoth Rajendra100% (3)

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- External Pressure - Pressure Vessel EngineeringDocument15 pagesExternal Pressure - Pressure Vessel Engineeringarjun100% (1)

- Super CalculationsDocument9 pagesSuper CalculationsNoé MarínNo ratings yet

- Cameron Riser Slip JointDocument118 pagesCameron Riser Slip JointНикита ПромиснкийNo ratings yet

- Tata Toyo Case StudyDocument117 pagesTata Toyo Case StudyGokulraju Rangasamy0% (1)

- Nozzle Reinforcement Calculation Excel SheetDocument3 pagesNozzle Reinforcement Calculation Excel Sheetramesh punjabiNo ratings yet

- Design Calc S ManualDocument285 pagesDesign Calc S ManualGustavNo ratings yet

- Design Calculations For Pressure VesselsDocument32 pagesDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- Design Calculations For Pressure VesselsDocument24 pagesDesign Calculations For Pressure VesselsMichael Lageman93% (15)

- Pipe Thickness CalculationDocument1 pagePipe Thickness Calculationananyo_senguptaNo ratings yet

- Field Installation Handbook: I-300 Cover - QXD 3/16/04 2:43 PM Page 2Document84 pagesField Installation Handbook: I-300 Cover - QXD 3/16/04 2:43 PM Page 2vickersNo ratings yet

- Design Calculations For Pressure ShellDocument33 pagesDesign Calculations For Pressure ShellGeorge GeorgianNo ratings yet

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Design Calculations For Pressure VesselsDocument28 pagesDesign Calculations For Pressure VesselsUmair AwanNo ratings yet

- Relief Valve Load CalculationDocument6 pagesRelief Valve Load Calculationdebu1985100% (1)

- Wake Frequency Calculation: Customer: Tag No: Reference: DateDocument1 pageWake Frequency Calculation: Customer: Tag No: Reference: DateShakeel AhmedNo ratings yet

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanNo ratings yet

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariNo ratings yet

- Stress Sample Calculation On Base EllDocument1 pageStress Sample Calculation On Base EllLionel TorradoNo ratings yet

- Design Calculations For Pressure VesselsDocument73 pagesDesign Calculations For Pressure Vesselsshani5573No ratings yet

- NaturalConvectionHeatTransferCoefficients SI Units Final ProtectedDocument44 pagesNaturalConvectionHeatTransferCoefficients SI Units Final ProtectedFabio MiguelNo ratings yet

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocument1 pageK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjNo ratings yet

- Vessel Calculation 200Document37 pagesVessel Calculation 200Phát NguyễnNo ratings yet

- API Spec 5CT IntroductionDocument37 pagesAPI Spec 5CT IntroductionChandrasekhar Sonar100% (2)

- Trunnion CalculationDocument92 pagesTrunnion CalculationkarunaNo ratings yet

- Orifice Flow Calculator For Gases, Steam, and VaporsDocument2 pagesOrifice Flow Calculator For Gases, Steam, and Vaporsbakhtyar21No ratings yet

- ASME Air Tank DesignDocument2 pagesASME Air Tank Designchethan100% (1)

- MAWP Calculation SpreadsheetDocument9 pagesMAWP Calculation SpreadsheetLawrence Osuvwe OfuokuNo ratings yet

- Method Statement MechanicalDocument17 pagesMethod Statement MechanicalUpali Karunarathne100% (1)

- Din 5510-22009 (E)Document58 pagesDin 5510-22009 (E)edflsilva100% (1)

- Air Cooled ExchangerDocument4 pagesAir Cooled Exchangermayurjannu100% (1)

- Jet Mixing CalculationDocument3 pagesJet Mixing CalculationRachel FloresNo ratings yet

- Design Data Sheet For Air ReceiverDocument3 pagesDesign Data Sheet For Air ReceivergksakthiNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- Heat Exchanger CalcDocument34 pagesHeat Exchanger Calcميثة الغيثيةNo ratings yet

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Pipe Wall Thickness (Complete)Document40 pagesPipe Wall Thickness (Complete)Andri PutraNo ratings yet

- Line Sizing With Example PDFDocument15 pagesLine Sizing With Example PDFAmol100% (1)

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Document17 pagesNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoNo ratings yet

- 39.pipe Cap Thickness Calculation: EVS-DC-AR-001 REV.01Document2 pages39.pipe Cap Thickness Calculation: EVS-DC-AR-001 REV.01masaminathanNo ratings yet

- Insulation ThicknessDocument2 pagesInsulation ThicknessShashi Kant KumarNo ratings yet

- GRP Lamination Processing - Instructions PDFDocument34 pagesGRP Lamination Processing - Instructions PDFmuhammadkashikNo ratings yet

- Orifice SizingDocument2 pagesOrifice SizingAvinav Kumar100% (1)

- Orifice Calculation Sheet Service Fluid Oxygen: G Mass Flow RateDocument2 pagesOrifice Calculation Sheet Service Fluid Oxygen: G Mass Flow RateGovind RaoNo ratings yet

- Calculation of Height of The Siphon SystemDocument2 pagesCalculation of Height of The Siphon SystemPhyu Mar Thein Kyaw100% (1)

- Nozzle Neck CalculationDocument4 pagesNozzle Neck CalculationAkshat JainNo ratings yet

- GC11 Pipe Thickness CalcDocument1 pageGC11 Pipe Thickness CalcsrinivasanNo ratings yet

- ASME VIII Calc - Shell - HeadsDocument4 pagesASME VIII Calc - Shell - HeadsMuh Safaat100% (1)

- Nozzle ReinforcementDocument8 pagesNozzle ReinforcementHafizi HZnumismatic0% (1)

- Top Pipe MomentDocument2 pagesTop Pipe Momentrsubramani100% (1)

- Pipe DataDocument2 pagesPipe DataPawan Kumar Gangwar100% (2)

- Expansion LoopDocument54 pagesExpansion Loopsteepa22No ratings yet

- Volume Calculation For Pressure Vessel TankDocument2 pagesVolume Calculation For Pressure Vessel Tanksai srikarNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- 04 Training Proposal TemplateDocument41 pages04 Training Proposal TemplateMohd Syahidie60% (5)

- Expansion Loop 1Document3 pagesExpansion Loop 1reach_arindomNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Technal Submittal For Ug Tank Water ProofingDocument43 pagesTechnal Submittal For Ug Tank Water ProofingArunashish Mazumdar100% (3)

- Gas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, TeesDocument4 pagesGas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, Teesusaid saifullahNo ratings yet

- AD2000 (31barg) CalculationDocument10 pagesAD2000 (31barg) CalculationMagdaline Matabang100% (1)

- Vertical Separator SizingDocument4 pagesVertical Separator SizingnemprrNo ratings yet

- SU 300 - Service Manual - 2003Document158 pagesSU 300 - Service Manual - 2003Centrifugal SeparatorNo ratings yet

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsPeña Eepesa100% (2)

- Liquid Orifice SizingDocument4 pagesLiquid Orifice SizingrmaganNo ratings yet

- ASME ImpDocument6 pagesASME ImpMarc AnmellaNo ratings yet

- Din 2403Document9 pagesDin 2403Mauricio FernándezNo ratings yet

- Colusi U31 User ManualDocument90 pagesColusi U31 User ManualFredi Panci100% (2)

- Ejemplo Tubesheet Asme UHXDocument14 pagesEjemplo Tubesheet Asme UHXPedro Montes MarinNo ratings yet

- Type of Element Connected To The Shell: Nozzle: The Pressure Design Option Was Design Pressure + Static HeadDocument1 pageType of Element Connected To The Shell: Nozzle: The Pressure Design Option Was Design Pressure + Static HeadwhngomjNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- External Friction Angle On The Geotechnical Information WebsiteDocument2 pagesExternal Friction Angle On The Geotechnical Information WebsiteAnonymous DJrec2100% (1)

- 117 Excerpts 2004Document7 pages117 Excerpts 2004Anonymous DJrec2No ratings yet

- Circulating Fluidized Bed Boiler Development Situation and ProspectsDocument4 pagesCirculating Fluidized Bed Boiler Development Situation and ProspectsAnonymous DJrec2No ratings yet

- BEM Code of EthicsDocument11 pagesBEM Code of EthicsAbdul Hakim AbdullahNo ratings yet

- BEM Code of Ethics - Ir. Yim Hon WaDocument53 pagesBEM Code of Ethics - Ir. Yim Hon WaAnonymous DJrec2No ratings yet

- Industrial LowbayDocument8 pagesIndustrial LowbayAnonymous DJrec2No ratings yet

- CiMB Research Report On REITDocument6 pagesCiMB Research Report On REITAnonymous DJrec2No ratings yet

- Power Amps Efficiency PFDocument5 pagesPower Amps Efficiency PFAnonymous DJrec2No ratings yet

- Dry-Type Transformers: Codes and Standards Enhancement (CASE) StudyDocument22 pagesDry-Type Transformers: Codes and Standards Enhancement (CASE) StudyAnonymous DJrec2No ratings yet

- Sportage SL Pen-010112 PDFDocument1 pageSportage SL Pen-010112 PDFAnonymous DJrec2No ratings yet

- Third Quarter 2016 Investment Outlook: Asset Class SectorDocument6 pagesThird Quarter 2016 Investment Outlook: Asset Class SectorAnonymous DJrec2No ratings yet

- Vol3 No2 Art1Document13 pagesVol3 No2 Art1Hariadi IrwansyahNo ratings yet

- Moncat Fatty Acid BookDocument10 pagesMoncat Fatty Acid BookAnonymous DJrec2No ratings yet

- Zoning Plan Model1Document1 pageZoning Plan Model1Anonymous DJrec2No ratings yet

- Aircraft Pipes and Unions: Technical TrainingDocument52 pagesAircraft Pipes and Unions: Technical TrainingnabilasattarNo ratings yet

- FS Brochure 2019Document2 pagesFS Brochure 2019sydiaNo ratings yet

- Volume V - Financial BidDocument14 pagesVolume V - Financial BidStephen Rajkumar JayakumarNo ratings yet

- 2012 DOT Wellhead Conductor and Casing Fatigue Causes and MitigiationDocument14 pages2012 DOT Wellhead Conductor and Casing Fatigue Causes and MitigiationjoakimNo ratings yet

- W501 - Window ScheduleDocument1 pageW501 - Window ScheduleAr Hanz Gerome SuarezNo ratings yet

- Operation and Maintenance ManualDocument14 pagesOperation and Maintenance ManualmehtahemalNo ratings yet

- 01 SY CRT 0001 0A-General Requirements For Welding and NDT PDFDocument42 pages01 SY CRT 0001 0A-General Requirements For Welding and NDT PDFSanjeev Sahota100% (1)

- TP 6790Document88 pagesTP 6790Mohamed SalamaNo ratings yet

- Notable Clarifications To Directive 077 RequirementsDocument5 pagesNotable Clarifications To Directive 077 RequirementsgefNo ratings yet

- SEC Running Guidelines PDFDocument11 pagesSEC Running Guidelines PDFMurdani SirajoNo ratings yet

- References Are in Agreement With Umrl in Pipelines, Liquid Process PipingDocument110 pagesReferences Are in Agreement With Umrl in Pipelines, Liquid Process PipingrafieeNo ratings yet

- Handtool AigoDocument10 pagesHandtool AigoDennis SetiawanNo ratings yet

- Efficient Test Setup For Determining The Water-Permeability of ConcreteDocument6 pagesEfficient Test Setup For Determining The Water-Permeability of ConcreteRabish ANo ratings yet

- QCVN 042019BXD National Technical Regulation On Apartment Buildings (Eng)Document17 pagesQCVN 042019BXD National Technical Regulation On Apartment Buildings (Eng)lwin_oo2435No ratings yet

- Ep31492 PDFDocument11 pagesEp31492 PDFJilJilNo ratings yet

- Installation and Maintenance Instructions: Resilient Seat Butterfly ValvesDocument12 pagesInstallation and Maintenance Instructions: Resilient Seat Butterfly ValvesBhargav PatelNo ratings yet

- Tica SpecDocument29 pagesTica SpecCong ThanhNo ratings yet

- Methodology - Statement For PHE Work - DRA Homes ProjectDocument12 pagesMethodology - Statement For PHE Work - DRA Homes ProjectKumaravel MuruganandhamNo ratings yet