Professional Documents

Culture Documents

Osobine Mn12 Celika

Osobine Mn12 Celika

Uploaded by

Goran ErakovicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Osobine Mn12 Celika

Osobine Mn12 Celika

Uploaded by

Goran ErakovicCopyright:

Available Formats

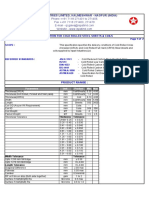

THE PERFORMANCE OF HADFIELDS

MANGANESE STEEL

AS IT RELATES TO MANUFACTURE

By: Nigel W. Peters, Ph.D., P. Eng.

CN

THE PERFORMANCE OF HADFIELDS MANGANESE

STEEL AS IT RELATES TO MANUFACTURE

By Nigel W. Peters, Ph.D., P. Eng., CN

Abstract

In 1992 AREMA introduced solidity standards for austenitic manganese steel (AMS)

castings, due to complaints by the Railways of the presence of gas, shrinkage and

porosity in special trackwork castings. Between 1992 and 1995 the North American

Class 1 Railways increased their gross car loading (on 4 axles) from 263,000 lb.

(119,295 kg.) to 286,000 lb. (129,727 kg.). In 1996 CN began to see a marked

increase in the failure of its railbound manganese frogs (RBMs). Subsequent

investigation and research has revealed that AMS is extremely sensitive to section

size, heat treatment and the apidity and effectiveness of quenching. Poor quench

compounded by large section size results in an unstable, in-homogenous structure,

subject to transformation to martensite under increased loading and strain rate.

Keywords: austenite, martensite, annealing, quenching, transformation, segregation,

grain size, carbides, grain boundaries, mechanical twinning.

Introduction

Hadfields manganese steel was invented by Sir Robert Hadfield in 1882. The first

British patent for AMS, number 200 was granted to Hadfield in 1883. The first US

patents, numbers 303150 and 303151, were granted in 1884.

This austenitic steel contains approximately 1.2% carbon and 12% manganese in a 1

to 10 ratio. It was unique in that it exhibited high toughness, high ductility, high work

hardening ability and excellent wear resistance. Because of these properties

Hadfields austenitic manganese steel (AMS) gained rapid acceptance as a useful

Engineering material. It is still extensively used in the following heavy industries, in

the form of castings or rolled shapes:

Earthmoving

Mining

Quarrying

Oil and gas drilling

Steel making

Dredging

Logging and lumber

Railways

In the railway industry AMS has been used successfully in special trackwork, namely

frogs, diamond crossings, guardrail wear bars and replaceable switch point tips.

Mechanical Properties

AMS has a yield strength between 50,000 psi (345 MPa) to 60,000 psi (414 MPa).

Although stronger than low carbon steel, it is not as strong as medium carbon steel. It

is however, much tougher than medium carbon steel. Yielding in AMS signifies the

onset of work hardening and accompanying plastic deformation.

The modulus of elasticity for AMS is 27 x 10

6

psi. (186 x 10

3

MPa) and is somewhat

below that of carbon steel, which is generally taken as 29 x 10

6

psi. (200 x 10

3

MPa).

The ultimate tensile strength of AMS varies but is generally taken as 140,000 psi (965

MPa). At this tensile strength, AMS displays elongation in the 35 to 40% range. The

fatigue limit for manganese steel is about 39,000 psi. (269 MPa).

Nevertheless, the mechanical properties of AMS listed above vary significantly with

section size. Properties affected are tensile strength, elongation, reduction of area and

impact resistance. For example, a 1 inch (25.4 mm) thick section properly heat

treated, will display higher mechanical properties than 4 inch (102 mm) section.

Grain size is the primary reason for these mechanical differences. Fine-grained

specimens exhibit tensile strengths and elongations up to 30% greater than course

grained specimens. The effect of section size on grain structure and therefore

mechanical properties will be discussed later.

The ability of AMS to work harden up to its ultimate tensile strength is its main

feature. In this regard AMS has no equal. The range of work hardening of AMS from

yield to ultimate tensile is approximately 200%. This however is accompanied by

large dimensional instability. See Figure 1 for a typical stress strain curve for

austenitic manganese steel.

Composition

Essentially, AMS is a solid solution of carbon and manganese in iron. Figure 2

indicates a phase diagram for steel containing 13% manganese.

While the nominal composition of AMS is 1.2% carbon and 12 to 13% manganese, in

commercial AMS products, the carbon will range between 1.0 and 1.4%, while the

manganese will range between 10 to 14% in accordance with ASTMA128

specification

Carbon content affects the yield strength of AMS. Carbon levels below 1% cause

yield strengths to decrease. The optimum carbon content has been found to be

between 1 and 1.2%. Above a 1.2 % carbon content, yield strength is unaffected.

Other alloying elements such as chromium will increase the yield strength, but

decrease ductility. Silicon is generally added as a de-oxidizer. Carbon contents above

1.4% are not generally used as the carbon segregates to the grain boundaries as

carbides and is detrimental to both strength and ductility [1].

Manganese has very little effect on the yield strength of AMS, but does affect both

the ultimate tensile strength and ductility. Maximum tensile strengths are attained

with 12 to 13% manganese contents. Although acceptable mechanical properties can

be achieved up to 20% manganese content, there is no economical advantage in using

manganese contents greater than 13%.

Manganese acts as an austenitic stabilizer in AMS and delays isothermal

transformation. For example, a carbon steel containing 1% manganese begins

isothermal transformation about 15 seconds after quenching to 700F (371C),

whereas a steel containing 12% manganese begins isothermal transformation about 48

hours after quenching to 700F (371C) [1], [2].

Essentially, AMS structure is one of carbon in solution in austenite. The practical

limit of carbon in solution is about 1.2%. Thereafter, excess carbon precipitation to

the grain boundaries results, especially in heavier sections.

As Cast Properties

AMS in the as-cast condition is too brittle for normal usage. As section thickness

increases, the cooling rate within the molds decreases. This decreased cooling rate

results in increased embrittlement due to carbon precipitation. In as cast castings, the

tensile strength will range from approximately 50,000 psi. (345 MPa) to 70,000 psi.

(483 MPa) and will display elongation values below 1%.

Heat treatment is used to strengthen and increase the mechanical properties of AMS.

The normal heat treatment method consists of solution annealing and rapid quenching

in a water bath.

Solution annealing generally consists of re-heating the steel to a high enough

austenitizing temperature above 1850F (1010C) for a sufficient time period of time

to complete the solution of carbon. Usually railway frogs and crossings are heat

treated at 2000F (1093C) and held for 2 hours for each inch (925 mm) of thickness

before quenching.

Quenching is accomplished by immersion in a water bath agitated by air, as agitation

reduces the tendency for the formation of a vapour coating (known as the Leidenfrost

effect) on the casting surfaces, and therefore a more uniform rate of cooling is

obtained. The speed of quench is an important factor in the final mechanical

properties. The maximum rate of quench is fixed by the heat absorption from the

casting surface by agitated water and by the rate of thermal conductivity of the AMS.

AMS has low thermal conductivity.

A lower rate of quench, results in lower mechanical properties in the centre of heavier

section. This results in a practical maximum thickness for castings of about 6 inches

(152 mm). Another reason for limiting casting size to 6 inches (152 mm) is that

castings larger than 6 inches (152 mm) develop large residual stresses upon cooling in

the mold. Such stresses acting on a brittle steel structure are prone to cause cracking

in heavier sections prior to heat treatment [3].

Heat treatment at high temperature causes surface decarburisation and some loss of

manganese. This decarburisation layer can be as much as 1/8 inch (3 mm) and can be

slightly magnetic. This is not usually a problem, as most railway frog and crossing

running surfaces are machined by either milling or grinding, which removes this

decarburisation layer.

As treated AMS has an as cast as heat-treated hardness of approximately 190 to 200

brinell. It also possesses relatively low yield strength. As hardness is a measure of

resistance to plastic flow (yielding), work hardening of the cast wear surface of

railway castings for frogs and crossings is required. This hardness increase in turn

increases the yield strength and results in a surface more resistant to impact and flow.

The current generally accepted practice is to explosive depth harden railway castings

for heavy haul use. This process results in surface hardness of 370 to 385 brinell.

Early Problems with AMS

In the mid to late 1980s, the Class 1 Railways were experiencing problems with

AMS castings, primarily frogs. Castings were not 100% homogenous with respect to

internal discontinuities. These were in the form of solidification shrinkage cavities,

gas, porosity and sand inclusions and were the result of riser and gating practice and

moulding and pouring methods employed by the foundries. Also contributing, but not

to the same degree was the difference in pouring rate, poring temperatures, mold

strength and type of sand used. Such defects were shortening the life of the castings.

Resulting repair welding by Railway welders was both time consuming and

uneconomical.

To counter this, both CN and BN (now BNSF) introduced their own solidity

specifications in the late 1980s, based on ASTM reference radiographs, namely

ASTM E186, E-280 and E-446.

Subsequently AREA Committee 5 (now AREMA Committee 5) undertook to develop

an industry radiographic standard for solidity of ASMS castings. An ad-hoc

committee consisting of Class 1 Railway Engineers, manufacturers and foundry

experts was formed. The Committee developed the standard based on a compromise

between the CN and BN specifications. The AREMA Solidity specification was

introduced in 1992 and can be found on drawings 100-96 and 1012-03 to 1017-03

inclusive in the AREMA Portfolio of Trackwork Plans [4].

In order to achieve the higher solidity levels required by the Railways and AREMA,

the manufacturers decreased the spacing between risers and consequently increased

the number of risers in the castings. These risers act as a secondary feed source and

reservoir of molten steel from which the casting is fed as it shrinks during

solidification. This practice achieved the desired results and the solidity of casting

improved markedly. This worked well from about 1988 to 1995. Figure 3 and 4 show

a recently de-molded RBM casting as viewed from the underside prior to and after the

removal of the knock-off risers.

Between 1992 and 1995, the North American Class 1 Railways increased their axle

loading from 65,750 lb. (29,823 kg.) to 71,500 lb. (32,432 kg.). With this increase in

wheel loading, CN noted a sharp increase in the failure rate of its frogs.

The failure mode of the frogs was predominantly in the point and wing area. In the

point, subsurface cracks, about 1/4 inch (3 mm) below the surface of the point,

starting approximately 2 inches (51 mm) from the inch point of frog, ran towards

the heel of the frog. Cracks propagated parallel to the running surface and towards the

heel of the frog until a 4 (102 mm) to 6 inch (152 mm) piece broke out. The surfaces

of the cracks were serrated indicating a start- arrest nature of the propagation. Further

examination at high magnification revealed crack propagation with pools of

ductility characteristic of fatigue cracking [5]. Figure 5 and 6 indicate typical point

failures. Note the depth and the surface texture of the failed surface.

Magnitude of the Problem

The type and appearance of the failures was consistent and indicative of a systemic

problem with the manufacture of the castings. CN monitored the situation and

determined the magnitude of the problem to be as follows [6]:

10% of its mainline frogs were failing and required weld repair before

reaching 40 MGT.

An additional 40% of its mainline frogs were failing and required weld repair

before reaching 100 MGT.

Relatively few (less than 10%) of its mainline frogs were able to carry in

excess of 200 MGT. Of those that did, 250 MGT appeared to be the

maximum attainable life in a mainline.

At the tonnages being carried by CN at that time, this meant that the average

life expectancy of a mainline frog was approximately 4 years.

Compounding the original failure problem of the AMS castings was that weld

repairs on these failed castings were short lived.

Failure Investigation

Originally it was thought that either poor foundry practice or repair welding at either

the foundry or trackwork manufacturer was the source of the problem. Metallurgical

investigation and quality assurance traceability indicated that only a small percentage

of the castings had been repair welded by the foundry or trackwork manufacturer.

More frustrating were the results of numerous metallurgical investigations that

indicated the manganese structure was considered acceptable (although not optimum)

[7], and the best achievable given the section thickness of these castings [5], [7].

Generally, these metallurgical reports indicated an austenitic grain structure with

small continuous grain boundary carbides. At much higher magnification a

continuous lamellar phase was seen. Cracking as seen under scanning electron

microscope, was along grain boundaries with carbide precipitation and consistent

with inter-granular fracture [14].

A theoretical investigation on the contact stresses on the points and wings of the frogs

was carried out at McGill University in Montreal [8]. This investigation indicated that

the Hertzian stresses in the point would be in he order of 500,00 psi (3,447 MPa) and

on the wings 475,000 psi. (3,275 MPa). Such stresses exceed the ultimate tensile

strength of AMS, however due to confinement of the material in the contact area, the

material does not fail immediately. Nevertheless, under such loading, rapid straining

would exist. Strain rate may play a more important role than the magnitude of the

Hertzian stresses in the failure of AMS.

As deformation under such service loading continues, the yield strength of the AMS

rises to equal the imposed service stress creating a condition of equilibrium. Given

current casting practice, it may well be that the imposed loading has now exceeded

the ability of AMS to reach a stable condition and fatigue cracking results. Avery [2]

predicted such behaviour in AMS in 1981.

Discussion

The desired result after quenching is a fully austenitic structure, carbide free and

completely homogenous with respect to both carbon and manganese. This however, is

the ideal and can only be achieved in lighter sections. More often than not, carbides

will exist at the grain boundaries. Grain size at the outer skin of the casting is fine

while towards the centre of heavier sections it becomes coarser grained.

In many cases, in heavier sections only partial transformation at the centre due to an

ineffective quenching. If homogeneity of the matrix with respect to carbon and

manganese is not achieved, the inner matrix may contain, pearlite, acicular carbides,

martensite, meta-stable austenite and other unstable austenitic compositions. Also

carbide precipitation due to ineffective quenching has a marked effect on reducing the

toughness of AMS. Figure 7 indicates a cross-sectional view through a casting

removed from track for examination. Note the size of the cross-section and impaired

ability for proper quench towards the centre.

It has been commonly accepted that AMS subjected to rapid work hardening is stable

during plastic strain. However, there is now evidence to suggest that under rapid work

hardening and plastic deformation, AMS undergoes strain induced stress

transformation from austenite to ferrite or martensite. It has been shown that the

transformation from austenite to martensite is dependent on the strain rate. For

example increasing the strain from 6 x 10

-3

to 60 x 10

-3

min.

1

at room temperature

has been shown to cause martensite transformation on unstable austenite [9].

There appears therefore to be a fundamental relationship in the transformation of

austenite (an fcc structure) to ferrite (a bcc structure) or to martensite (an hcp

structure) between strain rate, temperature and the stability of the austenite. Strain

induced transformation of austenite to martensite is primarily caused by the localized

segregation of both carbon and manganese during quench, leading to unstable

austenitic compositions. It has been shown that stress induced transformation only

occurs on these unstable compositions [10], [11]. It has been found that segregation

can cause local variations in carbon from 0.2 to 0.3% and manganese from 4 to 6%. It

is these local segregations that lead to unstable austenitic compositions

The widely accepted theory of the mechanism for work hardening in AMS is fine

mechanical twinning [2], [10], [11], [13]. Twinning is not driven by chemical reaction

but rather applied stress or strain energy. It is this strain energy that provides the

driving force towards complete transformation from austenite to martensite. The

two types of steels most susceptible to type of transformation are Hadfields

manganese and austenitic stainless steel [13]. The transformation to martensite is not

large scale, however, if enough twins are produced, localized transformation products

throughout the crystal can coalesce and act as initiation points for fracture planes.

Conclusion

In an attempt to correct problems associated with manganese castings in the 1980,

such as shrink, porosity, gas and inclusions, manufacturers decreased the distance

between risers and increased the number of risers on any given frog or crossing

casting. In so doing, the steel within the castings stayed hotter for longer leading to

both larger grain size and dendritic structure upon cooling. In addition, the cross-

sectional size was increased at the riser locations resulting in an ineffective quench

and consequently reduced mechanical properties.

Ineffective quench results in partially transformed austenite and meta stable austenite

and other compositions. Such constituents are non-stable and will transform to

martensite. This transformation from austenite to martensite is not driven by chemical

reaction but rather applied stress or strain energy. The increased rate of strain due to

increased loading also plays an important part in spontaneous transformation of

austenite to martensite.

Some manufacturers have already recognized this problem and have or are working

on finding the optimum placement of risers to prevent gas, shrink, and porosity, while

at the same time obtaining a rapid and effective quench.

If foundry and casting design practice cannot obtain an effective quench of castings, it

may well be time to start looking at other materials orcompositions.

REFRENCES

1) Subramanyam, D.K., Swansieger, A.E. and Avery, H.S., Austenitic Manganese

Steels, ASM Metal Handbook, American Society of Metals, Volume 1, Tenth

Edition, 1990, pp. 822 to 840.

2) Avery, H.S., Austenitic Manganese Steel for Railway Trackwork, Case

Report Number 429-12, Abex Corporation Research Center, Mahwah, New

Jersey, September 1981, 39 pp

3) Avery, H.S., Austenitic Manganese Steel, Metals Handbook, American

Society for Metals, Volume 1, 8

th

edition, 1961 pp. 834 to 842.

4) Portfolio of Trackwork Plans, Plans 1012-96 to 1017-96 American Railway

and Maintenance of Way Association, Maryland, 2005.

5) Johnson, W., Manganese Steel Frog Evaluation, Metallurgical Report

Number 8E0312, Bacon Donaldson, Richmond, B.C., April 1998, 16 pp.

6) Peters, N.W., Hadfields Manganese Steel and its Performance Under

Increased Wheel Loads, Presentation to the 83rd Transportation Research

Board Annual Meeting, Washington, D.C., January 2004, 30 pp.

7) Jones, T., Assessment of Manganese Steel Frogs, Metallurgical Report

Number 7E0207, Bacon Donaldson, Richmond, B.C., July 1997, 58 pp.

8) Chan, E. and Monat, P., Stress Analysis and Design of Railway Frogs, Project

Report, Department of Civil Engineering and Applied Mechanics, McGill

University, Montreal, 1999.

9) Powell, G.W., Marshall, E.R. and Backofen, W.A., Strain Hardening of

Austenitic Stainless Steel, Transactions of the American Society of Metals,

Volume 50, 1958, pp. 479 to 497.

10) Dastur, Y.N. and Leslie, W.C., Mechanisms of Work Hardening in Hadfields

Manganese Steel, Metallurgical Transactions A, American Society of Metals

and the Metallurgical Society of AIME, Volume 12A, May 1981, pp. 749 to

758.

11) Zuidema, B.K, Subramanyam, D.K. and Leslie, W.C, The Effect of

Aluminium on the Work Hardening and wear Resistance of Hadfielss

Manganese Steel, Metallurgical Transactions A, American Society of Metals

and the Metallurgical Society of AIME, Volume 18A, September 1987, pp.

1629 to 1639.

12) Subramanyam, D.K., Grube, G.W. and Chapin, H.J., Austenitic Manganese

Castings, Metals Handbook, American Society of Metals, Volume 9, Ninth

Edition, 1978, pp. 237 to 240.

13) Raghavan, M.J., Sastri, A.S. and Marcinkowski, M.J., The Nature of Work

Hardening Behaviour in Hadfields Manganese Steel, Transactions of the

Metallurgical Society of AIME, American Institute of Metallurgical Engineers,

Volume 245, July 1969, pp. 1568 to 1575.

14) Povilaitis, L., Metallurgical Examination of Fragments Spalled off Frog Point -

Serial Number 239, Metallurgical Report, CANAC International, Montreal,

January 1998, 9 pp.

0

20

40

60

80

100

120

140

160

-5 0 5 10 15 20 25 30 35 40 45 50 55

Strain (%)

S

t

r

e

s

s

(

k

s

i

)

Figure 1 Stress-strain curve for austenitic manganese steel

Figure 2 Phase diagram for a steel containing 13% manganese

Figure 3 RBM frog casting removed from mold

viewed from underside with knockoff risers still in place

Figure 4 RBM frog casting as viewed from underside with knock-off risers removed

Figure 5 View indicating typical casting failure in the frog point.

Figure 6 Top view of typical casting failure in point of frog. Note the texture

of the fracture surface out area, indicative of fatigue cracking.

Figure 7 Cross section of RBM casting removed from service. Note that section

is through a riser location placed to feed the point. Also note the size

of cross section.

List of Figures

1) Figure 1 Stress-strain curve for austenitic manganese steel.

2) Figure 2 Phase diagram for a steel containing 13% manganese

3) Figure 3 RBM frog casting removed from mold as viewed from

underside with knockoff risers still in place.

4) Figure 4 RBM frog casting as viewed from underside with knock-off

risers removed

5) Figure 5 View indicating typical casting failure in the frog point.

6) Figure 6 Top view of typical casting failure in point of frog. Note the

texture of the fracture surface out area, indicative of fatigue

cracking.

7) Figure 7 Cross section of RBM casting removed from service. Note that

section is through a riser location, placed to feed the point.

Also note the size of cross section.

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ASM Subject Guide - HeatTreating PDFDocument7 pagesASM Subject Guide - HeatTreating PDFJhon Alexander VilladaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Crankshaft NotesDocument68 pagesCrankshaft Notestharad67% (3)

- Failure Analysis at Deep Drawing of Low Carbon SteelsDocument7 pagesFailure Analysis at Deep Drawing of Low Carbon SteelsPaul RosiahNo ratings yet

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocument4 pagesIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- Chemical Composition: ASTM A36 Mild/Low Carbon SteelDocument2 pagesChemical Composition: ASTM A36 Mild/Low Carbon SteelNathanNo ratings yet

- Aisi 1045 Carbon Steel (Uns g10450)Document2 pagesAisi 1045 Carbon Steel (Uns g10450)Juan Francisco Marin MendiolaNo ratings yet

- h1 PDFDocument124 pagesh1 PDFMuhammad AminNo ratings yet

- Drills / Reamers / End Mills: Solid Carbide & Carbide Tipped & Coolant Fed Cutting ToolsDocument113 pagesDrills / Reamers / End Mills: Solid Carbide & Carbide Tipped & Coolant Fed Cutting ToolsKonstantina GlezakouNo ratings yet

- AISI 1045 Medium Carbon Steel - AZoMDocument4 pagesAISI 1045 Medium Carbon Steel - AZoMLuis NunesNo ratings yet

- AISI 1010 Steel, Cold DrawnDocument2 pagesAISI 1010 Steel, Cold DrawnYume YumeNo ratings yet

- Ch1 Ferrous AlloysDocument7 pagesCh1 Ferrous Alloysباسمي العشقNo ratings yet

- Din en 912-2001Document37 pagesDin en 912-2001Armenak BaghdasaryanNo ratings yet

- Aircraft Structural MaterialDocument30 pagesAircraft Structural MaterialRiggs Marasigan100% (2)

- Japanese Iron and Steel Certified Reference Materials: I. Crms For Chemical Analysis I-1. Pure Iron SeriesDocument10 pagesJapanese Iron and Steel Certified Reference Materials: I. Crms For Chemical Analysis I-1. Pure Iron SeriesrizaedlysamNo ratings yet

- Internals For Fixed Bed Reactors (Project Standards and Specifications)Document6 pagesInternals For Fixed Bed Reactors (Project Standards and Specifications)Suprio KamalNo ratings yet

- 1018Document1 page1018Alonso ReynaNo ratings yet

- COLOR CODING FOR PIPING MATERIAL 10318-00-131-ES-0009 - Rev02Document11 pagesCOLOR CODING FOR PIPING MATERIAL 10318-00-131-ES-0009 - Rev02Ananthakrishnan VNo ratings yet

- Heat Treatment - NewDocument67 pagesHeat Treatment - Newsyamimi balkhisNo ratings yet

- Buckling Analysis of Submarines With Hull ImperfectionsDocument77 pagesBuckling Analysis of Submarines With Hull ImperfectionsNufail Muhamed BasheerNo ratings yet

- Masoneilan Type 87/88 Actuators: Pneumatic Spring Diaphragm ActuatorsDocument12 pagesMasoneilan Type 87/88 Actuators: Pneumatic Spring Diaphragm ActuatorsjoseNo ratings yet

- Steel AISI S7Document1 pageSteel AISI S7edraelmxNo ratings yet

- Met 205Document9 pagesMet 205DrRoja A RNo ratings yet

- Manual Secolor Turning CalculatorDocument12 pagesManual Secolor Turning CalculatorHeineken Ya PraneetpongrungNo ratings yet

- SFS Suruburi Panouri Sandwich EngDocument26 pagesSFS Suruburi Panouri Sandwich EngMircea BotezNo ratings yet

- Aisi 1043 Steel - Hot Rolled Bar (Uns g10430) PDFDocument1 pageAisi 1043 Steel - Hot Rolled Bar (Uns g10430) PDFfeltofsnakeNo ratings yet

- Airflex® Technical Information: Section YDocument21 pagesAirflex® Technical Information: Section YArturo suzan arvizuNo ratings yet

- Heat TreatmentDocument33 pagesHeat TreatmentIsrael HailuNo ratings yet

- Design and Modification of Hand Garlic PlanterDocument43 pagesDesign and Modification of Hand Garlic PlanterMikias TewachewNo ratings yet

- Types of Steel-Grades of SteelDocument7 pagesTypes of Steel-Grades of SteelmabroukNo ratings yet

- A New Role For Micro Alloyed SteelsDocument11 pagesA New Role For Micro Alloyed SteelsJasbir S RyaitNo ratings yet