Professional Documents

Culture Documents

Jump Start: Rigorous Shell & Tube Exchanger Sizing in Aspen Plus V8

Jump Start: Rigorous Shell & Tube Exchanger Sizing in Aspen Plus V8

Uploaded by

Marta VidiellaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jump Start: Rigorous Shell & Tube Exchanger Sizing in Aspen Plus V8

Jump Start: Rigorous Shell & Tube Exchanger Sizing in Aspen Plus V8

Uploaded by

Marta VidiellaCopyright:

Available Formats

2013 Aspen Technology, Inc.

AspenTech

, aspenONE

, the Aspen leaf logo, the aspenONE logo, and OPTIMIZE are trademarks of Aspen Technology, Inc. All rights reserved. 11-3814-0713

Jump Start: Rigorous Shell & Tube Exchanger

Sizing in Aspen Plus

V8

A Brief Tutorial (and sample case for interactive sizing in Aspen Plus V8.0)

Lauren Sittler, Product Management, Aspen Technology, Inc.

Tom Ralston, Director of Equipment Design and Rating, Aspen Technology, Inc.

2013 Aspen Technology, Inc. AspenTech

, aspenONE

, the Aspen leaf logo, the aspenONE logo, and OPTIMIZE are trademarks of Aspen Technology, Inc. All rights reserved. 11-3814-0713

Jump Start: Rigorous Shell & Tube Exchanger Sizing in Aspen Plus

V8

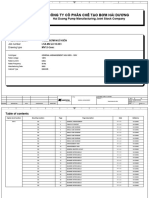

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Tutorial Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview of the Example Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Interactive Sizing in Aspen Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Using the EDR Sizing Console. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2013 Aspen Technology, Inc. AspenTech

, aspenONE

, the Aspen leaf logo, the aspenONE logo, and OPTIMIZE are trademarks of Aspen Technology, Inc. All rights reserved. 11-3814-0713

Jump Start: Rigorous Shell & Tube Exchanger Sizing in Aspen Plus

V8

1

Introduction

Aspen Plus V8 features a unique integrated workflow for transforming Shell and Tube Exchangers and Air Cooled

Exchangers from simple models to rigorous models in the simulation environment. This new functionality utilizes the same

rigorous Aspen Exchanger Design & Rating (EDR) methods as the stand-alone product. This integration enables process

engineers to create designs that are more energy efficient prior to consulting Energy Optimization Experts and Costing

departments and also serve as an excellent basis for subsequent detailed thermal and mechanical designs. Process

designs created using rigorous heat exchanger designs are more precise and automatically adapt to changes in process

design or process operation changes.

This is not meant to be used as a stand-alone reference document. We recommend that a range of other resources be

called upon to give the new user a comprehensive view of how to complete rigorous exchanger sizing in Aspen Plus.

These may include:

AspenTech support website (support.aspentech.com)

AspenTech courseware available in on-line and in-person versions

AspenTech business consultants

Additional Jump Start Guides

This Jump Start Guide is mainly focused on the preliminary design of heat exchangers where the objective is to rapidly

assess the size and cost of exchangers required for a given process duty, including requirements for multiple shells in

series and in parallel. It assumes that the user has Aspen Plus V8.0 or higher installed on her or his computer and has a

basic understanding of modeling in Aspen Plus.

Tutorial Overview

This Jump Start guide will provide step-by-step instructions for completing interactive sizing in Aspen Plus using an

example Aspen Plus case file to demonstrate the integrated workflow. The EDR Solution Case for the final EDR design has

also been included. The files associated with Aspen Shell & Tube Knowledge Base are available for download on the

Customer Support & Training website.

Overview of the Example Case

Open the case Shell&TubeforInteractiveSizing.bkp and Click on the Main Flowsheet tab. This case models a petroleum

separation process in which the feed is flashed, heated in the tube side of a shell and tube exchanger, and sent to a

distillation column. The lighter components are distilled off as gas and the heavier components enter the shell side of the

exchanger, providing the heat source for the cold oil. The warm Natural Gas Liquid (NGL) is then cooled in a cooler and

pumped as Liquid Natural Gas (NLG). This tutorial will focus on sizing the SHELLTUB exchanger. Currently, this shell and

tube exchanger is specified using the shortcut method. The tutorial guides you through opening the EDR interactive sizing

console, using default parameters to generate a preliminary design, and then makes adjustments to the design to make it

better suited for the process application.

2013 Aspen Technology, Inc. AspenTech

, aspenONE

, the Aspen leaf logo, the aspenONE logo, and OPTIMIZE are trademarks of Aspen Technology, Inc. All rights reserved. 11-3814-0713

2

Jump Start: Rigorous Shell & Tube Exchanger Sizing in Aspen Plus

V8

Figure 1. Petroleum Separation Flowsheet

Interactive Sizing in Aspen Plus

Getting Started

1. Open the file Shell&TubeforInteractiveSizing.bkp. Run Aspen Plus from the Home Ribbon > Run group or by pressing F5.

2. Run the simulation and ensure there arent errors by looking at the Control Panel. If a simulation does contain any errors

these must be fixed before EDR rigorous sizing can be used.

3. Locate the SHELLTUB exchanger, immediately downstream of the first separator. Double-click on the exchanger icon on

the flowsheet to open the setup form. On the Specifications tab of the set up form, youll see the Calculation box. Notice

that the calculation mode is currently set to Shortcut.

Figure 2. Size Shell&Tube in Aspen Plus

4. Click on the Size Shell&Tube button to begin interactive sizing. The EDR Sizing Console will open inside of Aspen Plus.

2013 Aspen Technology, Inc. AspenTech

, aspenONE

, the Aspen leaf logo, the aspenONE logo, and OPTIMIZE are trademarks of Aspen Technology, Inc. All rights reserved. 11-3814-0713

Jump Start: Rigorous Shell & Tube Exchanger Sizing in Aspen Plus

V8

3

Using the EDR Sizing Console

5. On the EDR Sizing Console, you will see that the default parameters (which appear in red) have already been set for the

geometry. Click the Size Exchanger button to run the optimization and find the first preliminary design. The run status

tab will become active while calculations are running.

Figure 3. Size the Exchanger with Default Parameters

6. When the calculation is complete, the results will be displayed on the Geometry Tab shown in Figure 3. Here, you will

see the setting plan and stream temperature profiles, as well as the exchanger dimensions and cost information. The

first design is the default BEM TEMA type with 1 shell, 110 tubes, 1 tube pass, and a 30-Triangular tube pitch. It has a

total cost of $19,397.

7. Next, changes will be made to the exchanger to make it better suited for our process. Since we have petroleum oil

entering the tube side, it is recommended that a removable cover with a floating head and a 90 degree tube pattern be

used to make defouling the exchanger easy. For greater accuracy, a realistic fouling factor will be specified. Set the

specifications as shown in Figure 4.

Figure 4. Geometry Tab Results

Geometry Tab

TEMA Type AES

Tube Pattern 90-Square

Process Tab

Fouling Resistance (Hotside and Coldside) 0.001 hF/BTU

2013 Aspen Technology, Inc. AspenTech

, aspenONE

, the Aspen leaf logo, the aspenONE logo, and OPTIMIZE are trademarks of Aspen Technology, Inc. All rights reserved. 11-3814-0713

4

Jump Start: Rigorous Shell & Tube Exchanger Sizing in Aspen Plus

V8

Figure 5. EDR Sizing Console Results

9. Click the Size Exchanger button again to run the second design.

10. After the optimization is complete, we can compare the new design with our preliminary sizing. In the middle columns

as shown in Figure 5, you can see the new design side-by-side with the previous run. In this case, adding a removable

cover and a floating head has made our design more expensive. Our shell diameter has increased, as well as the

number of tubes and tube passes. Compare your design with the EDR solution file provided, SHELLTUB Solution.edr.

11. At this stage, you could continue redesigning the exchanger until it satisfies the desired cost and performance, but for

now we will keep this as the final design, save it, and update the model in our simulation.

12. To save this rigorous exchanger design in the Aspen Plus flowsheet, click Accept Design from the EDR Console, as

shown in Figure 6. The other options available on the console are to cancel the design, open another EDR file or

template (to start a new design), or save the current results as an EDR standalone file without exiting the interactive

console in Aspen Plus.

2013 Aspen Technology, Inc. AspenTech

, aspenONE

, the Aspen leaf logo, the aspenONE logo, and OPTIMIZE are trademarks of Aspen Technology, Inc. All rights reserved. 11-3814-0713

Jump Start: Rigorous Shell & Tube Exchanger Sizing in Aspen Plus

V8

5

Figure 6. EDR Sizing Console Options

13. Run the Aspen Plus case again to update the Shell&Tube results within simulation. When calculations have completed,

click on the EDR Shell&Tube Results form from the navigation pane. This will provide a summary (shown in Figure 7) of

overall design results, thermal results, pressure drop, setting plan, tubesheet layout, and profile plots.

Figure 7. EDR Shell&Tube Results in Aspen Plus

About AspenTech

AspenTech is a leading supplier of software that optimizes process manufacturingfor energy, chemicals,

engineering and construction, and other industries that manufacture and produce products from a

chemical process. With integrated aspenONE

solutions, process manufacturers can implement best

practices for optimizing their engineering, manufacturing, and supply chain operations. As a result,

AspenTech customers are better able to increase capacity, improve margins, reduce costs, and become

more energy efficient. To see how the worlds leading process manufacturers rely on AspenTech to

achieve their operational excellence goals, visit www.aspentech.com.

2013 Aspen Technology, Inc. AspenTech

, aspenONE

, the Aspen leaf logo, the aspenONE logo, and OPTIMIZE are trademarks of Aspen

Technology, Inc. All rights reserved. 11-3814-0713

Worldwide Headquarters

Aspen Technology, Inc.

200 Wheeler Road

Burlington, MA 01803

United States

phone: +17812216400

fax: +17812216410

info@aspentech.com

Regional Headquarters

Houston, TX | USA

phone: +12815841000

So Paulo | Brazil

phone: +551134436261

Reading | United Kingdom

phone: +44(0)1189226400

Singapore | Republic of Singapore

phone: +6563953900

Manama | Bahrain

phone: +97317503000

For a complete list of offices, please visit

www.aspentech.com/locations

Additional Resources

Check out other training materials specifically for this product:

Public Website

http://www.aspentech.com/products/aspen-edr.aspx

Online Training

www.aspentech.com/products/aspen-online-training

Video Tutorials

Autosizing Shell & Tube Exchangers in Aspen HYSYS V8.0

https://www.brainshark.com/aspentech1/autosize-shell-tube-HYSYS

New Interactive Sizing in Aspen Plus

https://www.brainshark.com/aspentech1/edr-integration-aspen-plus

Jump Start Tutorials Series

Jump Start: Aspen Shell & Tube Exchanger V8.0

Getting Started in Aspen Shell & Tube Exchanger V8.0

You might also like

- Shivani Carriers Session 5 Case Study SummaryDocument3 pagesShivani Carriers Session 5 Case Study SummaryPheko P (PK)No ratings yet

- Tables s4 HanaDocument68 pagesTables s4 Hanasurajit biswas100% (6)

- Using Aspen To Evaluate Process EconomicsDocument15 pagesUsing Aspen To Evaluate Process EconomicspallaviNo ratings yet

- BSMS-Safety Culture Roadmap - pdf0 PDFDocument86 pagesBSMS-Safety Culture Roadmap - pdf0 PDFCarlos Cueva GallegosNo ratings yet

- Htfs ManualsDocument151 pagesHtfs Manualsgion_ro401100% (4)

- Study Guide-Aspen HYSYS ExpertDocument6 pagesStudy Guide-Aspen HYSYS ExpertSam100% (1)

- Aspen Basic Engineering V7.0-SmartPlant MappingDocument18 pagesAspen Basic Engineering V7.0-SmartPlant MappingKong LingweiNo ratings yet

- Chemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsFrom EverandChemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsRating: 2 out of 5 stars2/5 (1)

- Modeling in Transport Phenomena: A Conceptual ApproachFrom EverandModeling in Transport Phenomena: A Conceptual ApproachRating: 3 out of 5 stars3/5 (2)

- Pivot Table Cheat SheetDocument1 pagePivot Table Cheat SheetNguyễnVũHoàngTấnNo ratings yet

- 11-4005 HYSYS Acid Gas Cleaning JSG RefreshDocument16 pages11-4005 HYSYS Acid Gas Cleaning JSG Refresh1youb tvNo ratings yet

- Self Guided Demo - Aspen Shell and Tube Exchanger V8.8Document45 pagesSelf Guided Demo - Aspen Shell and Tube Exchanger V8.8HarySetiyawanNo ratings yet

- 11-3842 PSV Jump StartDocument20 pages11-3842 PSV Jump StartchikukotwalNo ratings yet

- Aspen Energy Analyzer Reference Guide v7Document148 pagesAspen Energy Analyzer Reference Guide v7Francois VoeuxNo ratings yet

- Aspen HysysDocument314 pagesAspen HysysAntonio VargasNo ratings yet

- Air Cooler Design With Aspen EDR PDFDocument26 pagesAir Cooler Design With Aspen EDR PDFNicandroGonzales0% (1)

- ACM 111 SPEEDUP® 5 Source ConverterDocument100 pagesACM 111 SPEEDUP® 5 Source Convertermehranlnjd100% (1)

- Advanced Recycle Operations 1Document44 pagesAdvanced Recycle Operations 1Kajer quemarNo ratings yet

- Hysys Tutorials RevisedDocument33 pagesHysys Tutorials RevisedAkhi Sofi100% (2)

- Using Calc LevelsDocument16 pagesUsing Calc LevelsSyed Muzamil Ahmed100% (1)

- Hysys User GuideDocument168 pagesHysys User GuideAmine NitroNo ratings yet

- PIPEPHASE Application BriefsDocument219 pagesPIPEPHASE Application Briefsarmando0212-1No ratings yet

- Aspen HYSYS V8 Test Case Certification 21 Jan 13-FinalDocument26 pagesAspen HYSYS V8 Test Case Certification 21 Jan 13-FinalJuan Alejandro100% (1)

- Aspen Fired Heater Models Embedded in HYSYSDocument11 pagesAspen Fired Heater Models Embedded in HYSYSВалентин СелищевNo ratings yet

- Tutorial 13 ASPEN PLUS Aspen DistillationDocument18 pagesTutorial 13 ASPEN PLUS Aspen DistillationramsrivatsanNo ratings yet

- Case Studies HysysDocument39 pagesCase Studies Hysysbrujula24100% (1)

- UniSim Design TutorialDocument92 pagesUniSim Design Tutorialsolo660% (1)

- HYSYS2016Document254 pagesHYSYS2016Lizet Daniela Chambi100% (1)

- Dyn 006H DepressuringDocument14 pagesDyn 006H DepressuringNicandroGonzalesNo ratings yet

- HYSYS - Course EA1000 Advanced Process ModelingDocument210 pagesHYSYS - Course EA1000 Advanced Process Modelingnagymate0% (1)

- 1.3.9 Rating Heat ExchangerDocument18 pages1.3.9 Rating Heat ExchangerMelva NainggolanNo ratings yet

- LNG Dynamic HysysDocument52 pagesLNG Dynamic HysysSrihari Kodimela75% (4)

- D. Reactions in HYSYS - NewDocument12 pagesD. Reactions in HYSYS - NewRafael FaioliNo ratings yet

- Aspen Plus GuideDocument745 pagesAspen Plus GuideReza Anggara0% (1)

- Aspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACDocument13 pagesAspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACRavi Kant TripathiNo ratings yet

- At-05197 Hysys Study GuideDocument22 pagesAt-05197 Hysys Study Guidewf4sr4r100% (1)

- Getting Started - Aspen HYSYS Shell and Tube ExchangerDocument9 pagesGetting Started - Aspen HYSYS Shell and Tube ExchangerAndy ChongNo ratings yet

- Aspen Plus, Reaction Engineering and DesignDocument45 pagesAspen Plus, Reaction Engineering and Designnikhilgoyal4100% (1)

- Aspen Estimating Physical PropertiesDocument12 pagesAspen Estimating Physical PropertiesStheh Ka NkosiNo ratings yet

- Advanced Simulation Case Using HysysDocument232 pagesAdvanced Simulation Case Using HysysridhajamelNo ratings yet

- DYNSIM Best Practices 3 - FurnaceDocument56 pagesDYNSIM Best Practices 3 - FurnaceJorge Luis HernándezNo ratings yet

- Module#3-Heat ExchangersDocument19 pagesModule#3-Heat ExchangersLa Casa JordanNo ratings yet

- AFHEWebinar29-Nov-2011 - Final Fired HeaterDocument26 pagesAFHEWebinar29-Nov-2011 - Final Fired HeaterAmit Goel100% (3)

- 4528 R451 01 (Fundamentals - 1) PDFDocument238 pages4528 R451 01 (Fundamentals - 1) PDFMikhail TarabrinNo ratings yet

- Acid Gas Sweetening With DEADocument20 pagesAcid Gas Sweetening With DEAEfer Cuadros BNo ratings yet

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Chemical Engineering Process SimulationFrom EverandChemical Engineering Process SimulationDominic FooNo ratings yet

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- 11-3532-Rigorous Sizing Shell and Tube - Aspen HYSYSDocument12 pages11-3532-Rigorous Sizing Shell and Tube - Aspen HYSYSRashesh ShahNo ratings yet

- Jump Start Shell Tube PDFDocument14 pagesJump Start Shell Tube PDFHoang-Vu BuiNo ratings yet

- Activated Exchanger Design & Rating Aspen 8.4Document12 pagesActivated Exchanger Design & Rating Aspen 8.4cacardenasmaNo ratings yet

- 11-4607 Js Activatededr HysysDocument12 pages11-4607 Js Activatededr Hysysmich0pNo ratings yet

- S-138777-Activated Energy Analysis Jump Start GuideDocument18 pagesS-138777-Activated Energy Analysis Jump Start Guidegion_ro401No ratings yet

- Jump Start Shell TubeDocument14 pagesJump Start Shell TubetrantheanNo ratings yet

- 11-4080 HYSYS Relief Valve Sizing Demo Guide FinalDocument18 pages11-4080 HYSYS Relief Valve Sizing Demo Guide FinalNoman Abu-FarhaNo ratings yet

- Webinar FAQ - Shell and Tube Heat ExchangersDocument8 pagesWebinar FAQ - Shell and Tube Heat Exchangersrameshkarthik810No ratings yet

- 11-3085 Energy Analyzer Jump StartDocument26 pages11-3085 Energy Analyzer Jump StartOmesh BoroleNo ratings yet

- Getting Started - Aspen Shell and Tube ExchangerDocument12 pagesGetting Started - Aspen Shell and Tube ExchangerSean ChoiNo ratings yet

- 11-2194 Integrated BriefDocument15 pages11-2194 Integrated BriefLiney Gutiérrez OrozcoNo ratings yet

- Jump Start Modeling Convective Dryers Aspen Plus v8 - DownLoadLy - IrDocument14 pagesJump Start Modeling Convective Dryers Aspen Plus v8 - DownLoadLy - IrMarcoiNo ratings yet

- Multiple ValveDocument16 pagesMultiple ValveSiddharth AthalyeNo ratings yet

- Jazz Happy Birthday (Part 1)Document1 pageJazz Happy Birthday (Part 1)Marta VidiellaNo ratings yet

- Jazz Happy Birthday (Part 1)Document1 pageJazz Happy Birthday (Part 1)Marta Vidiella100% (2)

- Happy Birthday Jazz (Part 1)Document1 pageHappy Birthday Jazz (Part 1)Marta VidiellaNo ratings yet

- Manias PDFDocument29 pagesManias PDFMarta VidiellaNo ratings yet

- Motivation Letter - CorrectionDocument2 pagesMotivation Letter - CorrectionAbner PlNo ratings yet

- 2ND QuizDocument2 pages2ND QuizGina Mae LeeNo ratings yet

- Procurement AgreementsDocument9 pagesProcurement AgreementsGeorge Koo Chee KangNo ratings yet

- Airconditioning Services: QuotationDocument3 pagesAirconditioning Services: QuotationJem LiatNo ratings yet

- Merchandising Operations - CRDocument21 pagesMerchandising Operations - CRNicole CagasNo ratings yet

- Why Create A Center of ExcellenceDocument4 pagesWhy Create A Center of ExcellenceRafael SantosNo ratings yet

- Infocast Service Enrolment Form2Document4 pagesInfocast Service Enrolment Form2Tawagin Mo Akong MertsNo ratings yet

- ZEESHAN ALI (B.Sc. Civil) : EducationDocument1 pageZEESHAN ALI (B.Sc. Civil) : EducationzeeshanNo ratings yet

- Leak Investigation and DetectionDocument5 pagesLeak Investigation and DetectionClarissa Riñon PerezNo ratings yet

- 2012 Book InformationAndBusinessIntelligDocument785 pages2012 Book InformationAndBusinessIntelligmelkam abrhamNo ratings yet

- 10 Average and Marginal Propensity To ConsumeDocument5 pages10 Average and Marginal Propensity To ConsumeChenkual ThazualaNo ratings yet

- Forms Collect 10847-fDocument10 pagesForms Collect 10847-fCona mathianNo ratings yet

- 1 The Basis of Strategy: StructureDocument17 pages1 The Basis of Strategy: StructureAlliah Gianne JacelaNo ratings yet

- Franchise OptionsDocument15 pagesFranchise OptionsHaisham AhmedNo ratings yet

- Monopoly EssayDocument2 pagesMonopoly EssayjonNo ratings yet

- Marketing Management: Channel Management Decision & Channel Integration SystemDocument15 pagesMarketing Management: Channel Management Decision & Channel Integration Systemsuketupatel_19No ratings yet

- 04 Homework 1Document4 pages04 Homework 1Juan AlcantaraNo ratings yet

- Jorg R. MenesesDocument3 pagesJorg R. MenesesKevin JugaoNo ratings yet

- Magaya Cargo System User ManualDocument283 pagesMagaya Cargo System User Manualvmnyuvaraj rajNo ratings yet

- NBP Karobar: Personal InformationDocument1 pageNBP Karobar: Personal InformationWasim NaqviNo ratings yet

- Planos Eléctricos JumboDocument108 pagesPlanos Eléctricos Jumbocarlos farfanNo ratings yet

- World Citizens The Solar MonmatiaDocument2 pagesWorld Citizens The Solar MonmatiaRamon Martinez100% (4)

- Mv.22.10.003 - Cty Hapuma - Tram Bom Ngu Kien - 7.2kv - Dien - Rev02Document222 pagesMv.22.10.003 - Cty Hapuma - Tram Bom Ngu Kien - 7.2kv - Dien - Rev02luonghv3110No ratings yet

- ACEEU Request For Accreditation Letter v1.0Document1 pageACEEU Request For Accreditation Letter v1.0Asad KhawajaNo ratings yet

- CH.2, MENG420 Updated 3.0Document6 pagesCH.2, MENG420 Updated 3.0SANo ratings yet

- Hanif BhattiDocument5 pagesHanif BhattiAhmed ButtNo ratings yet