Professional Documents

Culture Documents

Technical data on carbide end mills and drills

Uploaded by

enricoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical data on carbide end mills and drills

Uploaded by

enricoCopyright:

Available Formats

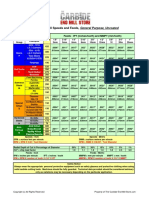

TECHNICAL DATA

CARBIDE END MILLS

Speed and Feed Data - Applications in Various Materials

Material

Aluminum Alloys

Brass

Bronze

Carbon Steel

Cast Iron

Cast Steel

Cobalt Base Alloys

Copper

Die Steel

Graphite

Inconel/Monel

Magnesium

Malleable Iron

Nickel Base Alloys

Plastic

Stainless Steel - Free Machining

Stainless Steel - Other

Steel - Annealed

Steel - Rc 18-24

Steel - Rc 25-37

Titanium

SFM

600-1200

200-350

200-350

100-600

80-350

200-350

20-80

350-900

50-300

600-1000

30-50

900-1300

200-500

50-100

600-1200

100-300

50-250

100-350

100-500

25-120

100-200

1/8"

.0010

.0010

.0010

.0010

.0010

.0005

.0005

.0010

.0005

.0020

.0005

.0010

.0005

.0002

.0010

.0005

.0005

.0010

.0004

.0003

.0005

Chip Load per Tooth

1/4"

1/2"

.0020

.0040

.0020

.0030

.0020

.0030

.0015

.0030

.0015

.0030

.0010

.0020

.0008

.0010

.0020

.0030

.0010

.0020

.0050

.0080

.0010

.0015

.0020

.0040

.0010

.0030

.0008

.0010

.0030

.0060

.0010

.0020

.0010

.0020

.0020

.0030

.0008

.0015

.0005

.0010

.0008

.0015

1"

.0080

.0050

.0050

.0060

.0060

.0040

.0020

.0060

.0040

.0100

.0030

.0080

.0070

.0020

.0100

.0030

.0030

.0050

.0045

.0030

.0030

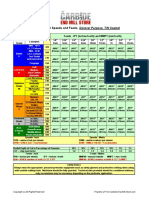

CARBIDE DRILLS

Speed and Feed Data - Applications in Various Materials

Material

Aluminum Alloys

Brass & Bronze

Low Carbon Steel

Cast Iron

Hardened Steel RC-50

Copper

Die Steel

Inconel/Monel

Magnesium

Malleable Iron

Nickel Base Alloys

Plastic

Stainless Steel - Soft

Stainless Steel - Hard

Titanium - Soft

Titanium - Hard

SFM

150-400

100-300

85-150

100-300

30-90

150-400

50-250

30-90

200-650

80-250

30-90

250-600

50-150

30-90

60-200

45-200

1/16"

.0010

.0005

.0005

.0010

.0005

.0010

.0005

.0005

.0015

.0010

.0005

.0015

.0005

.0005

.0005

.0005

Feed Rate (IPR)

1/8"

1/4"

.0050

.0030

.0010

.0020

.0010

.0020

.0020

.0030

.0010

.0020

.0030

.0050

.0005

.0020

.0005

.0010

.0030

.0050

.0020

.0030

.0006

.0010

.0030

.0040

.0005

.0020

.0005

.0010

.0020

.0040

.0008

.0020

1/2"

.0050

.0040

.0040

.0050

.0030

.0060

.0040

.0015

.0080

.0050

.0015

.0060

.0040

.0015

.0050

.0040

Note: All speed and feed data are suggested starting points. They may be increased or decreased depending on machine condition, hole depth, nish required, coolant, etc. If drill depth

exceeds 3 diameters, reduce speed and feed for carbide drills.

114

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Captured and Converted French Vehicles in German ServiceWWIIDocument14 pagesCaptured and Converted French Vehicles in German ServiceWWIIaxiswarlordhcv100% (2)

- Speed and Feed-Variable Helix and RoughersDocument1 pageSpeed and Feed-Variable Helix and RoughersabyzenNo ratings yet

- Milling Speeds and FeedsDocument1 pageMilling Speeds and FeedsMahesh Deivasiga Mani DNo ratings yet

- Speed and Feed - RoughersDocument1 pageSpeed and Feed - Roughers03sri03No ratings yet

- Technical Information on Speed Charts and Insert MaterialsDocument32 pagesTechnical Information on Speed Charts and Insert MaterialssathishelakkiyaNo ratings yet

- Ingersoll CAT-009 HoleM TechDocument30 pagesIngersoll CAT-009 HoleM TechLLNo ratings yet

- Standard ThreadmillsDocument1 pageStandard ThreadmillsshawntsungNo ratings yet

- Materilal AlloysDocument2 pagesMaterilal AlloysNiranjan KumarNo ratings yet

- Speed and Feed - Countersink DataDocument1 pageSpeed and Feed - Countersink DataenricoNo ratings yet

- Copper Bonded Ground RodDocument7 pagesCopper Bonded Ground RodAmiableimpexNo ratings yet

- ARTY - Aubert Et Duval - Produits - Longs - GB PDFDocument6 pagesARTY - Aubert Et Duval - Produits - Longs - GB PDFScott_B4UNo ratings yet

- SAF Welding Cutting GuideDocument165 pagesSAF Welding Cutting GuideSelvem0% (1)

- Carbide End Mill Speeds and Feeds, General Purpose, UncoatedDocument1 pageCarbide End Mill Speeds and Feeds, General Purpose, UncoatedMihir SevakNo ratings yet

- Asmd Cross IndexDocument24 pagesAsmd Cross IndexDeepak GovindanNo ratings yet

- Aladin SDocument4 pagesAladin SJeffrey BeanNo ratings yet

- Speed and feed recommendations for solid carbide end millsDocument1 pageSpeed and feed recommendations for solid carbide end millsP CHNo ratings yet

- Copper Clad Earth ElectrodDocument7 pagesCopper Clad Earth Electrodkvramanan_1No ratings yet

- Mcode and Mname: Material - Cross - IndexDocument24 pagesMcode and Mname: Material - Cross - IndexSama UmateNo ratings yet

- Copper Bonded Grounding Rod ManufacturerDocument7 pagesCopper Bonded Grounding Rod ManufacturerUjjwal ShahNo ratings yet

- EarthingDocument19 pagesEarthingraoNo ratings yet

- Metco 470AW 10-632Document8 pagesMetco 470AW 10-632JSH100No ratings yet

- Speeds & Feeds DrillsDocument9 pagesSpeeds & Feeds DrillsHolleyMooreNo ratings yet

- Profile MFGT 1Document52 pagesProfile MFGT 1RangaNo ratings yet

- Trimet Wire Catalog 2016Document67 pagesTrimet Wire Catalog 2016Akaruii BowoNo ratings yet

- Counterboring Speeds and FeedsDocument1 pageCounterboring Speeds and FeedsMahesh Deivasiga Mani DNo ratings yet

- Carbide End Mill Feeds and Speeds General Purpose TiNDocument1 pageCarbide End Mill Feeds and Speeds General Purpose TiNjoshNo ratings yet

- Tech Info - Reamers Speeds and FeedsDocument2 pagesTech Info - Reamers Speeds and FeedsRavi DahiwalaNo ratings yet

- BS 970 steel specifications and European standards comparisonDocument5 pagesBS 970 steel specifications and European standards comparisonaezeadNo ratings yet

- En 8Document10 pagesEn 8KarthikRajuNo ratings yet

- Handbook of Oceanographic Engineering MaterialsDocument97 pagesHandbook of Oceanographic Engineering MaterialssleonNo ratings yet

- Machining Guide for Dura-Bar Ductile IronDocument4 pagesMachining Guide for Dura-Bar Ductile IronricassterNo ratings yet

- Guide for Cutting Speeds and Feeds for DrillsDocument1 pageGuide for Cutting Speeds and Feeds for DrillsleonboneNo ratings yet

- Copper Bonded Earthing Rod ManufacturerDocument7 pagesCopper Bonded Earthing Rod ManufacturerUjjwal ShahNo ratings yet

- Corus Aerospace Spec BookletDocument14 pagesCorus Aerospace Spec BookletColinG7750% (1)

- 24UTP Railway GBDocument8 pages24UTP Railway GBwpsssamsungNo ratings yet

- Pipes Tubes of Nippon Steel Sumitomo MetalDocument16 pagesPipes Tubes of Nippon Steel Sumitomo Metalsiva_nagesh_2No ratings yet

- A07-297 OD Expanded Small PartsDocument12 pagesA07-297 OD Expanded Small PartsKyle DriscollNo ratings yet

- Peeled Round Steel BarsDocument9 pagesPeeled Round Steel BarsaxgasaNo ratings yet

- Alloy 4643 welding dataDocument2 pagesAlloy 4643 welding databastosgabiNo ratings yet

- Userguide For SSDocument26 pagesUserguide For SSehsan4uNo ratings yet

- All Types of MaterialsDocument8 pagesAll Types of MaterialsAniket KabadeNo ratings yet

- Millermatic 350P: The Power of BlueDocument4 pagesMillermatic 350P: The Power of BlueVic HernandezNo ratings yet

- AFNOR 42 CD 4 SteelDocument2 pagesAFNOR 42 CD 4 SteelMagoroku D. YudhoNo ratings yet

- C45 - Specification1Document7 pagesC45 - Specification1gowtham_venkat_4No ratings yet

- Flat Steel BarDocument2 pagesFlat Steel BarsteelplateguangNo ratings yet

- Sds Eng PDFDocument8 pagesSds Eng PDFdaviko313No ratings yet

- CJ AmarosaDocument23 pagesCJ AmarosaAirlangga GoonersNo ratings yet

- Valve Material EquivalentsDocument3 pagesValve Material EquivalentsAndre Villegas Romero100% (1)

- Copper Bonded Earthing Rod ManufacturerDocument7 pagesCopper Bonded Earthing Rod ManufacturerUjjwal ShahNo ratings yet

- Swagelok Gaugeable Tube Fittings Alloy 400Document8 pagesSwagelok Gaugeable Tube Fittings Alloy 400totcsabNo ratings yet

- Copper Bonded Earth Rod ManufacturerDocument7 pagesCopper Bonded Earth Rod ManufacturerUjjwal ShahNo ratings yet

- Cutting Data - Greenwood Tools LTDDocument3 pagesCutting Data - Greenwood Tools LTDJayakrishnaNo ratings yet

- Bars, Rods & RebarsDocument9 pagesBars, Rods & RebarskxalxoNo ratings yet

- Radial Drilling MachinesDocument4 pagesRadial Drilling MachinesMichael Adu-boahenNo ratings yet

- Copper Bonded Grounding Rod ManufacturerDocument7 pagesCopper Bonded Grounding Rod ManufacturerUjjwal ShahNo ratings yet

- Asmd Cross IndexDocument24 pagesAsmd Cross IndexPrabishNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- American Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingFrom EverandAmerican Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingNo ratings yet

- Electrolytic Rust RemovalDocument15 pagesElectrolytic Rust RemovalenricoNo ratings yet

- How Do I Set Up My TIG Welder?: Owner's ManualDocument2 pagesHow Do I Set Up My TIG Welder?: Owner's ManualenricoNo ratings yet

- Garmin Maps TutorialDocument6 pagesGarmin Maps TutorialenricoNo ratings yet

- Procedures - Copper WeldingDocument6 pagesProcedures - Copper WeldingenricoNo ratings yet

- Procedures - Copper WeldingDocument6 pagesProcedures - Copper WeldingenricoNo ratings yet

- Drill & Tap SizesDocument2 pagesDrill & Tap SizesenricoNo ratings yet

- Metric Thread - Coarse Pitch - MDocument3 pagesMetric Thread - Coarse Pitch - MenricoNo ratings yet

- Amm 0.303 BritishDocument9 pagesAmm 0.303 Britishenrico0% (1)

- Amm 105mm x617 TK L7 CN105F1 MecarDocument4 pagesAmm 105mm x617 TK L7 CN105F1 MecarenricoNo ratings yet

- Ammunition TablesDocument7 pagesAmmunition Tablesenrico100% (1)

- Amm 25mm Apfsds Mecar m935Document1 pageAmm 25mm Apfsds Mecar m935enricoNo ratings yet

- ODN 784 Handbook On Trench Mortar Fuzes 1918Document16 pagesODN 784 Handbook On Trench Mortar Fuzes 1918enricoNo ratings yet

- Garmin Map Converter InstructionsDocument3 pagesGarmin Map Converter InstructionsenricoNo ratings yet

- Amm 3.7cm BK LDV 4000 10 COL 1944Document21 pagesAmm 3.7cm BK LDV 4000 10 COL 1944enricoNo ratings yet

- Amm 105mm x617 TK M1060Document1 pageAmm 105mm x617 TK M1060enricoNo ratings yet

- Amm 90mm x580 Mk8 Mecar M690Document1 pageAmm 90mm x580 Mk8 Mecar M690enricoNo ratings yet

- Headstamp codes and manufacturers of .303 British calibre ammunitionDocument14 pagesHeadstamp codes and manufacturers of .303 British calibre ammunitionenrico100% (2)

- Cost-effective 105mm tank gun training roundsDocument1 pageCost-effective 105mm tank gun training roundsenricoNo ratings yet

- Italian Artillery TablesDocument2 pagesItalian Artillery TablesEnrico959No ratings yet

- Tank Ammunition: 105mm Tk. HE M1010Document1 pageTank Ammunition: 105mm Tk. HE M1010enricoNo ratings yet

- 105mm Tk TPFSDS-T M1056 for 105mm Tank Guns TrainingDocument1 page105mm Tk TPFSDS-T M1056 for 105mm Tank Guns TrainingenricoNo ratings yet

- FM 4-30.16 - EOD - Multi-Service Tactics, Techniques and Procedures For Explosive Ordnance Disposal in A Joint Environment (2005)Document96 pagesFM 4-30.16 - EOD - Multi-Service Tactics, Techniques and Procedures For Explosive Ordnance Disposal in A Joint Environment (2005)defendercc130100% (2)

- BIOS 365 Paint of German AircraftsDocument29 pagesBIOS 365 Paint of German AircraftsenricoNo ratings yet

- Amm 3.7cm x264 BK Stuka PDFDocument8 pagesAmm 3.7cm x264 BK Stuka PDFenricoNo ratings yet

- Amm 4.5inch British HowitzerDocument6 pagesAmm 4.5inch British HowitzerenricoNo ratings yet

- MIL-STD-1168B (Ammunition Lot Numbering and Amm. Data Card) PDFDocument50 pagesMIL-STD-1168B (Ammunition Lot Numbering and Amm. Data Card) PDFzorlon1No ratings yet

- French Guns Technical Data 1940Document4 pagesFrench Guns Technical Data 1940enrico100% (1)

- Amm 3cm Mk108 Komet CannonDocument9 pagesAmm 3cm Mk108 Komet CannonenricoNo ratings yet

- Amm 12.7mm x81 JapaneseDocument8 pagesAmm 12.7mm x81 JapaneseenricoNo ratings yet