Professional Documents

Culture Documents

Speed and Feed - Roughers

Uploaded by

03sri03Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Speed and Feed - Roughers

Uploaded by

03sri03Copyright:

Available Formats

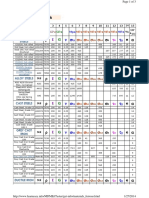

ROUGHING END MILLS

Material

Chip Load per Tooth

1/4

1/2

LIST OF SYMBOLS

SFM

1/8

Aluminum Alloys

Magnesium

125-250

125-250

.0010

.0010

.0020

.0020

.0025

.0025

.0030

.0030

Copper

Brass

Bronze

Cast Iron

Cast Steel

Malleable Iron

Stainless Steel

Free Machining

Other

Steel

Annealed

Rc 18-24

Rc 25-37

Titanium

Up to Rc 30

Rc 30+

High Temp Alloys

Austenitic

Ferritic

Nickel Base

Cobalt Base

75-100

85-110

75-100

100-125

75-100

80-120

.0008

.0008

.0008

.0008

.0008

.0008

.0015

.0015

.0015

.0015

.0015

.0015

.0030

.0030

.0030

.0025

.0025

.0025

.0060

.0060

.0060

.0050

.0050

.0050

75-90

50-75

.0005

.0005

.0007

.0007

.0012

.0012

.0020

.0020

100-125

75-100

40-75

.0010

.0070

.0005

.0020

.0012

.0010

.0040

.0030

.0020

.0060

.0050

.0040

40-75

20-25

.0005

.0005

.0012

.0010

.0025

.0020

.0050

.0035

12-20

50-75

20-25

8-15

*

.0004

.0004

*

.0007

.0007

.0007

.0007

.0015

.0020

.0015

.0015

.0030

.0050

.0030

.0030

1

F

D

R.P.M.

S.F.M.

I.P.M.

I.P.R.

=

=

=

=

=

=

NUMBER OF FLUTES

DIAMETER OF CUTTER

REVOLUTIONS PER MINUTE

SURFACE FEET PER MINUTE

FEED RATE: INCHES PER MINUTE

FEED RATE: INCHES PER REVOLUTION

MACHINING FORMULAS

S.F.M. = 0.262 x D x R.P.M.

R.P.M. = 3.82 x S.F.M.

D

I.P.R. = I.P.M.

R.P.M.

or

CHIP LOAD x F

TECHNICAL INFORMATION

Speed and Feed Data

I.P.M. = R.P.M. x I.P.R.

CHIP LOAD =

I.P.M.

R.P.M. x F

or

I.P.R.

F

1

www.endmill.com n Phone 800/521-1078 n 216/362-4200 n Fax 800/521-1558 n 216/362-4230

You might also like

- Speed and Feed-Variable Helix and RoughersDocument1 pageSpeed and Feed-Variable Helix and RoughersabyzenNo ratings yet

- Speed and Feed - Carbide End Mills and DrillsDocument1 pageSpeed and Feed - Carbide End Mills and DrillsenricoNo ratings yet

- Speed and Feed - Countersink DataDocument1 pageSpeed and Feed - Countersink DataenricoNo ratings yet

- SM SeriesDocument36 pagesSM SeriesGiorgiana RosuNo ratings yet

- Carbon and Low Alloy SteelsDocument3 pagesCarbon and Low Alloy Steelspratapkumar333No ratings yet

- Alloy 625 Wire & Rod: U.S. Alloy CoDocument1 pageAlloy 625 Wire & Rod: U.S. Alloy CowinstonsequeiraNo ratings yet

- Reaming Speeds and Feeds PDFDocument1 pageReaming Speeds and Feeds PDFWarrior TempurNo ratings yet

- Product CatalogueDocument2 pagesProduct CatalogueHibozoNo ratings yet

- Materials FerrousDocument3 pagesMaterials Ferrousjohnson_regoNo ratings yet

- Alloy 5556 Weld Data Sheet: Typical ApplicationsDocument2 pagesAlloy 5556 Weld Data Sheet: Typical Applicationsvishal bailurNo ratings yet

- NTK General TechnicalDocument32 pagesNTK General TechnicalsathishelakkiyaNo ratings yet

- Milling Speeds and FeedsDocument1 pageMilling Speeds and FeedsMahesh Deivasiga Mani DNo ratings yet

- A 447Document27 pagesA 447superman3kNo ratings yet

- Keyseat Cutters Speeds and FeedsDocument1 pageKeyseat Cutters Speeds and FeedsdbaNo ratings yet

- 3Document4 pages3Madirley PimentaNo ratings yet

- LME Specification Steelbillet 040511Document3 pagesLME Specification Steelbillet 040511rhuezo8492No ratings yet

- Drilling Speeds and FeedsDocument1 pageDrilling Speeds and FeedsLe Hoang HiepNo ratings yet

- Oem Hotline 1-800-394-4804: Busbar Electrical Ampacity Chart SeriesDocument2 pagesOem Hotline 1-800-394-4804: Busbar Electrical Ampacity Chart SeriesSINU0607IITEEENo ratings yet

- Weldability of Cr-Mo SteelsDocument20 pagesWeldability of Cr-Mo SteelsNitin Bajpai100% (2)

- Chemical Composition of Carbon SteelDocument2 pagesChemical Composition of Carbon SteelAkilanNo ratings yet

- 5183 Aluminum Welding WireDocument1 page5183 Aluminum Welding Wiresank79No ratings yet

- Cosmos Alminium-Technical SpecificationsDocument2 pagesCosmos Alminium-Technical SpecificationsmindsopenNo ratings yet

- Handbook of Oceanographic Engineering MaterialsDocument97 pagesHandbook of Oceanographic Engineering MaterialssleonNo ratings yet

- Cutting Data BoringDocument4 pagesCutting Data BoringFabricio0310No ratings yet

- (Note: All Speeds Are in Feet/min) - Multiply The Listed Speeds by A Factor of 2 To 4 When Using Carbide ToolingDocument2 pages(Note: All Speeds Are in Feet/min) - Multiply The Listed Speeds by A Factor of 2 To 4 When Using Carbide ToolingSanjay KumarNo ratings yet

- Astm Standards Master ListDocument9 pagesAstm Standards Master Listraobabar210% (1)

- Raex 500Document4 pagesRaex 500chara459254No ratings yet

- A36 Asme/Astm: Carbon Structure Steel To ASTM A36/A36M Standard UseDocument1 pageA36 Asme/Astm: Carbon Structure Steel To ASTM A36/A36M Standard Useadam150161No ratings yet

- Sites Process Steelcastings Pages MaterialsDocument9 pagesSites Process Steelcastings Pages Materialschand_yelNo ratings yet

- Flange Pressure Ratings Per Asme b16.5 - K-TekDocument1 pageFlange Pressure Ratings Per Asme b16.5 - K-TekbinhogatoNo ratings yet

- EA Material SpecificationsDocument1 pageEA Material SpecificationssubbusenthilNo ratings yet

- DAF AlloyGuideDocument2 pagesDAF AlloyGuidesureshjeevaNo ratings yet

- Metal Table JISDocument1 pageMetal Table JISNakkolopNo ratings yet

- 817m40 PDFDocument4 pages817m40 PDFjeyakumarNo ratings yet

- SOW 09380SB2T SpecSheetDocument2 pagesSOW 09380SB2T SpecSheetAi NayNo ratings yet

- Userguide For SSDocument26 pagesUserguide For SSehsan4uNo ratings yet

- 1100 Aluminum Welding Wire: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Document1 page1100 Aluminum Welding Wire: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Ilham Alwi KhunaefiNo ratings yet

- Aluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Document1 pageAluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Valli RajuNo ratings yet

- Day-1 LECTURE 2-Welding TechnologyDocument64 pagesDay-1 LECTURE 2-Welding TechnologySamNo ratings yet

- Steel GradesDocument8 pagesSteel GradesvijayguravNo ratings yet

- Aluminium SummaryDocument1 pageAluminium SummaryArvind ViswanathanNo ratings yet

- Materilal AlloysDocument2 pagesMaterilal AlloysNiranjan KumarNo ratings yet

- Grey Cast Iron CompareDocument4 pagesGrey Cast Iron CompareagustingrtNo ratings yet

- Aluminio BRONMETAL enDocument12 pagesAluminio BRONMETAL enPerica RakićNo ratings yet

- ASTM A249/A249M-04a and UI: Not For Production Use (For Reference Only)Document1 pageASTM A249/A249M-04a and UI: Not For Production Use (For Reference Only)nieav280No ratings yet

- Speeds and Feeds 1053 1054Document1 pageSpeeds and Feeds 1053 1054P CHNo ratings yet

- Aisi 4140Document3 pagesAisi 4140BayuPrasetyaPutraNo ratings yet

- Et ChantsDocument27 pagesEt ChantsAlonsoTezkRodrichSalcedoNo ratings yet

- Standard ThreadmillsDocument1 pageStandard ThreadmillsshawntsungNo ratings yet

- SAILMA Grades Steel Plates & SheetsDocument2 pagesSAILMA Grades Steel Plates & SheetsElumalai SrinivasanNo ratings yet

- Copper Alloy Spec SheetsDocument1 pageCopper Alloy Spec SheetsvinodmysoreNo ratings yet

- Kaiser Aluminum Soft Alloy Tube PDFDocument31 pagesKaiser Aluminum Soft Alloy Tube PDFGunnie PandherNo ratings yet

- Technical DataDocument17 pagesTechnical Datat_syamprasadNo ratings yet

- 1050 Aluminum CircleDocument2 pages1050 Aluminum Circlewei huaNo ratings yet

- Peeled Round Steel BarsDocument9 pagesPeeled Round Steel BarsaxgasaNo ratings yet

- 6082 Aluminium AlloyDocument3 pages6082 Aluminium AlloyWeiso ChenNo ratings yet

- AstmDocument29 pagesAstmMohd Zulfadli Mohamad IzaraeeNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- MPC 002 Life Span Psychology SyllabusDocument10 pagesMPC 002 Life Span Psychology Syllabus03sri03No ratings yet

- Ms Dhoni: Yearly Dhoni Rank Yearly RunsDocument1 pageMs Dhoni: Yearly Dhoni Rank Yearly Runs03sri03No ratings yet

- Click Here To Download Ipython Notes For This Chapter Eda: The Output of This Above ProgramDocument1 pageClick Here To Download Ipython Notes For This Chapter Eda: The Output of This Above Program03sri03No ratings yet

- MPC 001 Cognitive Psychology SyllabusDocument10 pagesMPC 001 Cognitive Psychology Syllabus03sri03No ratings yet

- HackerRank Python Practice TopicsDocument14 pagesHackerRank Python Practice Topics03sri030% (1)

- Python Interview Questions 1Document32 pagesPython Interview Questions 103sri03100% (1)

- Natural Language Processing (NLP) Introduction:: Top 10 NLP Interview Questions For BeginnersDocument24 pagesNatural Language Processing (NLP) Introduction:: Top 10 NLP Interview Questions For Beginners03sri03No ratings yet

- R13 SWM Apr 2018Document4 pagesR13 SWM Apr 201803sri03No ratings yet

- SQ L Practice ProblemsDocument118 pagesSQ L Practice Problemsninh100% (6)

- Top 30 NLP Interview Questions and Answers: 1. What Do You Understand by Natural Language Processing?Document18 pagesTop 30 NLP Interview Questions and Answers: 1. What Do You Understand by Natural Language Processing?03sri03No ratings yet

- Mechanical SealDocument8 pagesMechanical Seal03sri03No ratings yet

- Welding FormulaDocument13 pagesWelding Formula03sri03No ratings yet

- IMOR FormulaeDocument12 pagesIMOR Formulae03sri03No ratings yet

- 14-02-24 ATZ Lightweight Design Potential With ForgingDocument6 pages14-02-24 ATZ Lightweight Design Potential With Forging03sri03No ratings yet

- 66102EDocument197 pages66102E03sri03No ratings yet