Professional Documents

Culture Documents

Facile Synthesis of CuO Hollow Nanospheres Assembled by Nanoparticles and Their Electrochemical Performance

Facile Synthesis of CuO Hollow Nanospheres Assembled by Nanoparticles and Their Electrochemical Performance

Uploaded by

saleh90Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Facile Synthesis of CuO Hollow Nanospheres Assembled by Nanoparticles and Their Electrochemical Performance

Facile Synthesis of CuO Hollow Nanospheres Assembled by Nanoparticles and Their Electrochemical Performance

Uploaded by

saleh90Copyright:

Available Formats

Applied Surface Science 258 (2011) 13171321

Contents lists available at SciVerse ScienceDirect

Applied Surface Science

j our nal home page: www. el sevi er . com/ l ocat e/ apsusc

Facile synthesis of CuO hollow nanospheres assembled by nanoparticles and

their electrochemical performance

Mei Kong, Weixin Zhang

, Zeheng Yang, Shaoying Weng, Zhangxian Chen

School of Chemical Engineering, Anhui Key Laboratory of Controllable Chemical Reaction and Material Chemical Engineering, Hefei University of Technology, Hefei 230009, China

a r t i c l e i n f o

Article history:

Received 18 May 2011

Received in revised form29 August 2011

Accepted 30 August 2011

Available online 29 September 2011

Keywords:

CuO

Hollownanospheres

Synthesis

Kirkendall effect

Lithiumion batteries

a b s t r a c t

CuO hollow nanospheres with an average diameter of 400 nm and shell thickness of 40 nm have been

successfully synthesized via a simple thermal oxidation strategy with Cu

2

O solid nanospheres as the

precursor. The products have been characterized by X-ray diffraction, transmission electron microscopy

and eld emission scanning electron microscopy. The formation of CuO hollow nanospheres mainly

results from the Kirkendall effect on the basis of temperature-dependent experiments. Furthermore, the

electrochemical performance of CuO hollow nanospheres as anode materials for lithium ion batteries has

been evaluated by cyclic voltammetry and galvanostatic discharge-charge experiments. The as-prepared

CuO hollow nanospheres assembled by nanoparticles exhibit higher initial discharge capacity and better

cycle performance than the reported CuO nanoparticles. The hierarchical hollow nanospheres have been

demonstrated to take the advantages of nanoparticles and hollow architectures, which could not only

shorten the lithium ion transport distance and increase the kinetics of conversion reactions, but also

provide suitable electrode/electrolyte contact area and accommodate the volume change associated with

lithium ion insertion and extraction.

2011 Elsevier B.V. All rights reserved.

1. Introduction

Hollow nanostructures have been paid much attention due

to their high specic surface area, low density and widespread

potential applications in drug delivery, chemical sensors, photonic

devices and lightweight ller [1,2]. A variety of methods have been

developed for the synthesis of nanostructures with hollow interi-

ors including template methods [3,4], hydrothermal treatment [5]

and ultrasonic treatment [6]. In particularly, the Kirkendall effect-

based methods have attracted great interests for the preparation

of hollow nanomaterials in recent years, such as oxidation, sul-

dation and phosphorization of metal nanoparticles, which results

from the different diffusion rates between two components in a

diffusion couple [7,8].

CuO, an important p-type semiconductor with a narrow band

gap (E

g

=1.2eV), has potential applications in sensors, catalysts,

optical switches, lithium ion batteries and solar cells [9,10]. Con-

sidering its wide applications, various CuO hollowstructures have

been prepared. Liu and Zeng [11] synthesized dandelion-like CuO

hollowmicrospheres with diameters of 48m, assembled by CuO

nanoribbons, using Cu(NO

3

)

2

3H

2

O, NH

3

H

2

O, NaOH and NaNO

3

Corresponding author. Tel.: +86 551 2901450; fax: +86 551 2901450.

E-mail address: wxzhang@hfut.edu.cn (W. Zhang).

as reactants by solvothermal method at 100

C for 24h. Liu and

Xue [12] reported the synthesis of porous CuOhollowarchitectures

with diameters of 11.7mby thermal oxidation of CuS and Cu

2

S

solid precursors at 700

C for 4h, respectively. The precursors were

synthesized by solvothermal method using Cu(NO

3

)

2

3H

2

O and

thiourea as reactants with the assistance of PVP at 120

C for 20h.

Bourret and Lennox [13] synthesized porous CuO hollow micro-

spheres assembled by nanoribbons with diameter of 2.55m by

thermolysis of porous Cu(OH)

2

hollow microspheres at 600

C for

15h. The Cu(OH)

2

precursor was fabricated by template method at

room temperature for 35min, using CuCl

2

2H

2

O, n-butylamine as

reactants andwater-in-oil emulsionas soft templateinH

2

O/CH

2

Cl

2

system.

Among all those potential applications, CuO as anode materi-

als for lithiumion batteries have attracted much interests because

of their high theoretical capacity (670mAh g

1

), high safety and

low cost. It has been reported that the morphology and size of

CuO could inuence its electrochemical performances [14,15]. For

instance, Zheng et al. [16] synthesized CuO nanoparticles with an

average size of 10nm via thermal decomposition of CuC

2

O

4

pre-

cursor at 400

C for 4h, which could deliver an initial discharge

capacity of 810mAh g

1

at a current density of 0.1mA cm

2

. The

second and third discharge capacities were about 350mAhg

1

and 120mAh g

1

, respectively. The CuO nanoparticles had a poor

cycle performance. Li et al. reported [17] the synthesis of CuO nan-

otubes by heating Cu nanowires at 600

C for 3h, which showed

0169-4332/$ see front matter 2011 Elsevier B.V. All rights reserved.

doi:10.1016/j.apsusc.2011.08.127

1318 M. Kong et al. / Applied Surface Science 258 (2011) 13171321

an initial discharge capacity of 910mAh g

1

and the 10th dis-

charge capacity of about 100mAh g

1

at a current density of

50mAg

1

.

In this paper, we report a facile route to synthesize CuO hol-

lownanospheres with uniformdiameters in large scale by thermal

oxidation of Cu

2

O solid nanospheres at 400

C for 2h. The uniform

Cu

2

O solid nanospheres as the precursor were prepared in large

scale through a solution-phase method at roomtemperature with-

out any surfactant or organic solvent. The formation mechanismof

CuO hollow nanospheres has been proposed. As anode materials

for lithiumion batteries, the as-prepared CuO hollownanospheres

showhigher initial dischargecapacityandbetter cycleperformance

compared with the reported CuOnanoparticles, which mainly ben-

ets from the hierarchical hollow nanostructures assembled by

nanoparticles.

2. Experimental details

2.1. Synthesis

All the reagents used in the experiments were analytical grade

and used without further purication. The synthesis of Cu

2

O solid

nanospheres as the precursor was referred to our previous report

[18]. The whole reaction was conducted in a beaker at room tem-

perature under constant magnetic stirring. Typically, 0.375g of

CuSO

4

5H

2

O and 2g of glucose were dissolved in 100mL of dis-

tilled water. Then, 25mL of NH

3

H

2

O solution (0.04M) and 25mL

of NaOH solution (0.20M) were added dropwise into the above

solution in turn. 10min later, 50mL of ascorbic acid (0.03M) was

quickly poured into the mixture. After stirring for another 1h, the

yellowprecipitates were collected by centrifugation, washed with

deionized water and ethanol for several times and then dried in air

at 60

C.

The CuO hollownanospheres were prepared by thermal oxida-

tion of Cu

2

O precursor in air at 400

C for 2h at a heating rate of

5

Cmin

1

. After cooling to roomtemperature naturally, the black

product was obtained.

2.2. Characterization

The as-prepared samples were characterized by X-ray powder

diffraction (XRD) in a Rigaku D/max-B X-ray diffractometer with

a CuK radiation source (=0.154178nm) operated at 40kV and

80mA. Field-emissionscanning electronmicroscopy (FESEM) mea-

surement was carried out with a FEI Sirion-200 scanning electron

microscope operated at an acceleration voltage of 5kV. Transmis-

sion electron microscopy (TEM) images and selected area electron

diffraction (SAED) patterns were taken with a Hitachi H-800 trans-

mission electron microscope performed at an accelerating voltage

of 200kV. Fourier TransformInfrared (FTIR) spectra were recorded

on a PerkinElmer Spectrum100 FTIR Spectrometer using the stan-

dard KBr pellet technique in the range of 4004000cm

1

.

2.3. Electrochemical measurements

The electrochemical measurements were carriedout usingcoin-

type cells (CR2032) at room temperature. The working electrodes

werepreparedbymixingtheas-preparedCuOhollownanospheres,

acetylene black and polyvinylidene uoride (PVDF) at a weight

ratio of 80:10:10 in N-methylpyrrolidone (NMP). The resulting

slurry was uniformly spread onto a Cu foil and dried in vacuumat

70

C for 4h. The cells were assembled in an argon-lled glove box

with lithium disk as counter electrode, microporous polypropy-

lene membrane (Celgard-2400) as separator and 1M LiPF

6

in a

mixture of ethylene carbonate (EC) and dimethyl carbonate (DMC)

10 20 30 40 50 60 70

1

1

1 |

(b)

1

1

0

2

2

0

2

0

0

1

1

1

1

1

0 R

e

l

a

t

i

v

e

I

n

t

e

n

s

i

t

y

2 / degree

| |

|

2

2

0

3

1

1

1

1

3

2

0

2

0

2

0

2

0

2

1

1

1

1

1

1

(a)

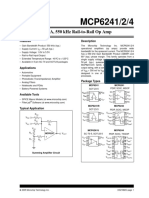

Fig. 1. XRD patterns of (a) the precursor and (b) the nal product after thermal

treatment at 400

C for 2h in air.

(1:1involume) as electrolyte. Galvanostatic chargedischarge tests

were conducted on a BTS battery test system (Shenzhen Neware

Co., China) at a current density of 67mAg

1

in a potential range

of 0.0013.0V. Cyclic voltammetry (CV) measurements were per-

formed on a CHI604C electrochemical analyzer (Shanghai Chenhua

Instrument Co., China) at a scan rate of 0.1mV s

1

in the potential

range of 03.0V.

3. Results and discussion

The composition and phase purity of the products were deter-

mined by X-ray powder diffraction (XRD). Fig. 1a shows the XRD

pattern of the precursor precipitated in the solution at roomtem-

perature. All the diffraction peaks can be indexed to cubic Cu

2

O

(JCPDS No. 05-0667). Fig. 1b displays the XRD pattern of the nal

product obtained by thermal oxidation of Cu

2

Oprecursor at 400

C

for 2h, inwhichall the diffractionpeaks canbe indexedto the mon-

oclinic CuO (JCPDS No. 48-1548). No impurities could be obviously

detected in the XRD patterns.

Typical FESEM images of the as-prepared products are shown

in Fig. 2. As can be seen in Fig. 2a, the Cu

2

O precursor con-

sists of nanospheres with an average diameter of 400nm in large

scale. The high-magnication FESEMimage in Fig. 2b displays the

rough surface of these nanospheres. Fig. 2c and d shows the mor-

phology of CuO prepared through thermal oxidation of the Cu

2

O

nanospheres. The average diameter and shell thickness are about

400nm and 40nm, respectively, without any obvious changes of

diameters compared with Cu

2

O precursor. Many broken hollow

spheres shown in Fig. 2c reveal the existence of hollow nano-

structure. Fromthe high-magnication FESEMimage displayed in

Fig. 2d, it can be seen that the shell of the CuO hollownanospheres

is rough and some small nanoparticles can be clearly observed.

The TEMinvestigation was used to provide further insight into

the CuO hollow structure. Fig. 3a shows the TEM image of the

Cu

2

O precursor, indicating that the Cu

2

O nanospheres have a solid

structure with a diameter of 400nm. The TEM image of CuO is

shown in Fig. 3b. The contrast in brightness between the dark

edges and bright centers conrms the hollowstructure of CuOwith

shell thickness of about 40nm, which is consistent with FESEM

images. The corresponding SAED patterns in Fig. S1a and b (Sup-

porting information) display the characteristic diffraction rings of

cubic Cu

2

O and monoclinic CuO, respectively, indicating the poly-

crystalline nature of the products.

To study the formation mechanism of CuO hollow structure,

samples were collected after heating the Cu

2

O precursor in air at

250

C and 300

C for 2h, respectively. After 2h of thermal treat-

ment inair at 250

C, a core-shell structure witha little voidstarts to

M. Kong et al. / Applied Surface Science 258 (2011) 13171321 1319

Fig. 2. FESEMimages of (a, b) Cu

2

O nanospheres and (c, d) CuO hollownanospheres.

form, indicating condensation of abundant vacancies (Supporting

information, Fig. S2a). When heated at 300

C for 2h, the voids

become larger (Supporting information, Fig. S2b).

Similar phenomena were also observed when the samples were

collected through thermal oxidation of the Cu

2

Osolid nanospheres

at 400

Cfor different time. The TEMimages of the morphologyevo-

lution after heating the samples at 400

C for different time were

shown in Fig. S3 (Supporting information). It can be seen that after

heating at 400

Cfor 5min, a sphere withvoids betweenthe surface

layer and the inside core can be observed (Fig. S3a). When the heat-

ing time at 400

C is prolonged to 8min, the voids become larger

and the core-shell structure becomes more obvious (Fig. S3b). After

15min of heating at 400

C, the core almost disappears and a hol-

lowsphere gradually forms (Fig. S3c). Finally the solid nanospheres

Fig. 3. TEMimages of (a) Cu

2

O nanospheres and (b) CuO hollownanospheres.

are completely transformed into hollow nanospheres after 2h of

heating at 400

C (Fig. 3d).

Onthe basis of above observations, the formationprocess of CuO

hollowstructure is much related with the Kirkendall effect [7,8]. At

the beginning of the thermal oxidation, Cu

2

O reacts with O

2

in air

and a thin CuO layer would be formed on the surface of Cu

2

O solid

nanospheres. Subsequently, the Cu

+

in the core diffuse outward

through the CuO shell, meanwhile the O

2

in air diffuse inward.

Because of the different diffusion rates, Cu

+

diffuse much faster

outward than O

2

inward and the hollow interior forms [19]. Con-

sequently, excess vacancies occur in the core and hollowstructure

appears.

Interestingly, theresult hereis quitedifferent fromthat reported

by Lis group [20], who used a solution-phase method in N,N-

dimethylformamide at 8595

C to get Cu

2

Osolid nanospheres and

transformedthemintoCuOsolidnanospheres bythermal oxidation

in air at 500

C for 2h, without any obvious change of morphology.

The possible reason may be that the Cu

2

O nanosphere precursor

in our work, synthesized at room temperature in the presence of

glucose, is different from the one reported in the literature [20].

To further characterize the as-prepared Cu

2

O nanospheres, FTIR

spectra of the as-prepared Cu

2

O nanospheres and glucose were

investigated, respectively, as shown in Fig. S4 (Supporting infor-

mation). Fig. S4a shows the FTIR spectra of the as-prepared Cu

2

O

nanospheres. The characteristic absorption band at 629cm

1

cor-

responds to the CuOvibrationof the Cu

2

Onanocrystals. The bands

due to adsorptions of water molecules are observed at 3300cm

1

and1610cm

1

, whichare attributedtothe OHstretchingandOH

bending, respectively. Besides, the bands in the 28003000cm

1

region correspond to the CH stretching. The bands located at

1460cm

1

and 1270cm

1

are assigned to the vibrations associ-

ated with the CH

2

group, and typically the band near 1050cm

1

conrms the existence of carbohydrate [21]. Compared with the

FTIR spectra of glucose in Fig. S4b, the result clearly suggests that

there still exist some glucose molecules in the Cu

2

O spheres even

1320 M. Kong et al. / Applied Surface Science 258 (2011) 13171321

0.0 0.5 1.0 1.5 2.0 2.5 3.0

-2.5

-2.0

-1.5

-1.0

-0.5

0.0

0.5

1.0

0.83 V

1.01 V

2.36 V

0.73 V

3rd

2nd

1st

C

u

r

r

e

n

t

/

m

A

Potential / V vs. Li

+

/Li

1.15 V

Fig. 4. Cyclic voltammograms of the CuO/Li cell in the rst, second and third cycles

at a scan rate of 0.1mV s

1

.

after washing the samples with water and ethanol several times

[22,23]. Thus, the aggregates of Cu

2

O nanoparticles with the mod-

ication of the glucose molecules may play an important role in

the facile formation of CuO hollow nanostructures [24,25]. Mean-

while, during the thermal oxidation process, the remnant glucose

molecules inthe Cu

2

Ospheres were decomposed into CO

2

and H

2

O

gases, which would emit out of the spheres and were benecial to

the formation of the CuO hollownanostructures [26].

The electrochemical performances of the as-prepared CuO hol-

low nanospheres have been evaluated as anode materials for

lithiumion batteries. Fig. 4 shows the rst three cyclic voltammo-

grams of the CuO/Li cell at a scan rate of 0.1mV s

1

. In the rst

cycle, two cathodic peaks located at 1.01 and 0.83V (vs. Li

+

/Li)

are attributed to the electrode reaction and growth of solid elec-

trolyte interface, respectively [27,28]. Meanwhile, the anodic peak

at 2.36V is corresponding to the Li extraction fromthe crystal lat-

tice of CuO [29]. In the following cycle, two cathodic peaks shift to

0.73V and 1.15V along with the decrease of each peak intensity,

indicating that the reversible capacity greatly loses. In the third

cycle, the peak potentials remain similar and the peak intensity

decreases slightly.

Fig. 5 displays the dischargecharge curves of the CuO/Li cell

at a current density of 67mAg

1

. During the rst discharge pro-

cess, there are two obvious plateaus at the potential of 1.221.0V

and 0.80.01V (vs. Li

+

/Li), which is consistent with the results of

CV measurement. The rst discharge capacity is 1134mAh g

1

,

0 1 2 3 4 5 6 7 8 9 10

0

200

400

600

800

1000

1200

S

p

e

c

i

f

i

c

c

a

p

a

c

i

t

y

/

m

A

h

g

1

Cycle number

0 200 400 600 800 1000 1200

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

3rd

2nd 3rd

2nd

1st

P

o

t

e

n

t

i

a

l

/

V

v

s

.

L

i

+

/

L

i

Specific capacity / mAh g

1

1st

Fig. 5. The dischargecharge curves of the CuO/Li cell at a current density of

67 mA g

1

in a potential range of 0.0013.0V. The inset is the corresponding cyclic

performance of the cell.

which is higher than the theoretical capacity of CuO(670mAh g

1

).

The extra discharge capacity is mainly attributed to the formation

of a solid electrolyte interface (SEI) lm during the rst dis-

charge/charge process [27,30]. The capacity fades to 425mAh g

1

in the second discharge cycle and after 10 cycles the discharge

capacity gradually decreased to 190mAh g

1

(inset in Fig. 5). The

CuO hollownanospheres assembled by nanoparticles showhigher

initial discharge capacity and better cycle performance than the

previous report of CuOnanoparticles with size of 10nm, which can

only deliver an initial discharge capacity of 810mAhg

1

at a cur-

rent densityof 0.1mA cm

2

andthedischargecapacitydecreasedto

120mAh g

1

after 3 cycles [16]. The results indicate that the hierar-

chical hollownanospheres cantaketheadvantages of nanoparticles

and hollow architectures. The high initial discharge capacity may

result from the nanoparticles, which could shorten the lithium

ion transport distance and increase the kinetics of conversion

reactions. The good cycle performance is much related with the

hierarchical hollow nanostructures, which could provide suitable

electrode/electrolyte contact area and accommodate the volume

change associated with lithiumion insertion and extraction.

4. Conclusions

This work demonstrates the synthesis of CuO hollow

nanospheres with diameters of about 400nm by thermal oxi-

dation of Cu

2

O solid nanospheres as the precursor in air at 400

C

for 2h. The morphology of CuO does not change obviously in

comparison with Cu

2

O precursor and the as-prepared CuO hollow

nanospheres are assembled by nanoparticles. The formation of

CuO hollow nanospheres from Cu

2

O solid nanospheres mainly

results from the Kirkendall effect. The whole process can be

easily achieved without any surfactant, organic solvent or etching

process. This facile, green and low-cost synthesis route may be of

great signicance to prepare other metal oxide hollow structures.

Besides, the as-prepared CuO hollow nanospheres as anode mate-

rials for lithiumion batteries showhigher initial discharge capacity

of 1134mAh g

1

and better cycle performance than the reported

CuO nanoparticles. It is attributed to the hierarchical hollow

nanostructures which could provide enhanced accommodation of

the strain energy associated with lithium insertion/removal and

offer a suitable electrode/electrolyte contact area. Furthermore,

the nanoparticles assembling the hierarchical nanospheres could

reduce the transport or diffusion distances of electrons and lithium

ions and increase the kinetics of conversion reactions.

Acknowledgements

The authors are grateful to the nancial supports of the National

Natural Science Foundation of China (NSFC Grants 20871038,

20976033 and 21176054), the Fundamental Research Funds for the

Central Universities (2010HGZY0012) and the Education Depart-

ment of Anhui Provincial Government (TD200702).

Appendix A. Supplementary data

Supplementary data associated with this article can be found, in

the online version, at doi:10.1016/j.apsusc.2011.08.127.

References

[1] S.W. Cao, Y.J. Zhu, M.Y. Ma, L. Li, L. Zhang, J. Phys. Chem. C 112 (2008) 1851.

[2] Y.F. Zhu, D.H. Fan, W.Z. Shen, Langmuir 24 (2008) 11131.

[3] G. Jia, H.P. You, K. Liu, Y.H. Zheng, N. Guo, H.J. Zhang, Langmuir 26 (2010) 5122.

[4] X.X. Li, Y.J. Xiong, Z.Q. Li, Y. Xie, Inorg. Chem. 45 (2006) 3493.

[5] M.W. Xu, L.B. Kong, W.J. Zhou, H.L. Li, J. Phys. Chem. C 111 (2007) 19141.

[6] J.J. Zhu, S. Xu, H. Wang, J.M. Zhu, H.Y. Chen, Adv. Mater. 15 (2003) 156.

M. Kong et al. / Applied Surface Science 258 (2011) 13171321 1321

[7] Y.D. Yin, R.M. Rioux, C.K. Erdonmez, S. Hughes, G.A. Somorjai, A.P. Alivisatos,

Science 304 (2004) 711.

[8] R.K. Chiang, R.T. Chiang, Inorg. Chem. 46 (2007) 369.

[9] J.Y. Li, S.L. Xiong, J. Pan, Y.T. Qian, J. Phys. Chem. C 114 (2010) 9645.

[10] Y.L. Liu, L. Liao, J.C. Li, C.X. Pan, J. Phys. Chem. C 111 (2007) 5050.

[11] B. Liu, H.C. Zeng, J. Am. Chem. Soc. 126 (2004) 8124.

[12] J. Liu, D.F. Xue, Adv. Mater. 20 (2008) 2622.

[13] G.R. Bourret, R.B. Lennox, J. Am. Chem. Soc. 132 (2010) 6657.

[14] S. Grugeon, S. Laruelle, R.H. Urbina, L. Dupont, P. Poizot, J.M. Tarascon, J. Elec-

trochem. Soc. 148 (2001) A285.

[15] J.C. Park, J. Kim, H. Kwon, H. Song, Adv. Mater. 21 (2009) 803.

[16] X.J. Zhang, D.G. Zhang, X.M. Ni, H.G. Zheng, Solid-State Electron. 52 (2008) 245.

[17] C. Li, W. Wei, S.M. Fang, H.X. Wang, Y. Zhang, Y.H. Gui, J. Power Sources 195

(2010) 2939.

[18] Z.H. Yang, D.P. Zhang, W.X. Zhang, M. Chen, J. Phys. Chem. Solids 70 (2009) 840.

[19] R. Nakamura, D. Tokozakura, H. Nakajima, J. Appl. Phys. 101 (2007) 074303.

[20] J.T. Zhang, J.F. Liu, Q. Peng, X. Wang, Y.D. Li, Chem. Mater. 18 (2006) 867.

[21] S. Pavlovic, P.R.G. Brandao, Miner. Eng. 16 (2003) 1117.

[22] M.B. Mahajan, M.S. Pavan, P.A. Joy, Solid State Commun. 149 (2009) 2199.

[23] A. Ahmed, N.S. Gajbhiyen, A.G. Joshi, J. Solid State Chem. 184 (2011) 2209.

[24] H.T. Zhu, J.X. Wang, G.Y. Xu, Cryst. Growth Des. 9 (2009) 633.

[25] H.T. Zhu, J.X. Wang, D.X. Wu, Inorg. Chem. 48 (2009) 7099.

[26] Z.H. Yang, W.X. Zhang, Q. Wang, X.M. Song, Y.T. Qian, Chem. Phys. Lett. 418

(2006) 46.

[27] A. Dbart, L. Dupont, P. Poizot, J.B. Leriche, J.M. Tarascon, J. Electrochem. Soc.

148 (2001) A1266.

[28] X.P. Gao, J.L. Bao, G.L. Pan, H.Y. Zhu, P.X. Huang, F. Wu, D.Y. Song, J. Phys. Chem.

B 108 (2004) 5547.

[29] P. Novak, Electrochim. Acta 30 (1985) 1687.

[30] F.S. Ke, L. Huang, G.Z. Wei, L.J. Xue, J.T. Li, B. Zhang, S.R. Chen, X.Y. Fan, S.G. Sun,

Electrochim. Acta 54 (2009) 5825.

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Motorola Master Selection Guide Data Book 1975Document223 pagesMotorola Master Selection Guide Data Book 1975oldjanus67% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Laser Types: According To The Wavelength: Infra-Red, Visible, Ultra-Violet (UV) or X-Ray LasersDocument23 pagesLaser Types: According To The Wavelength: Infra-Red, Visible, Ultra-Violet (UV) or X-Ray LasersTitus Samuel SudandararajNo ratings yet

- Cuk Converter State SpaceDocument5 pagesCuk Converter State SpaceEdu Daryl MacerenNo ratings yet

- Solar Wireless Electric Vehicle Charging SystemDocument7 pagesSolar Wireless Electric Vehicle Charging SystemMANISH KUMARNo ratings yet

- Synthesis and Applications of One-Dimensional Nano-Structured Polyaniline An OverviewDocument11 pagesSynthesis and Applications of One-Dimensional Nano-Structured Polyaniline An Overviewsaleh90No ratings yet

- Encapsulation of Triethanolamine As Organic Corrosion Inhibitor Into Nanoparticles and Its Active Corrosion Protection For Steel SheetsDocument9 pagesEncapsulation of Triethanolamine As Organic Corrosion Inhibitor Into Nanoparticles and Its Active Corrosion Protection For Steel Sheetssaleh90No ratings yet

- Intelligent Self-Healing Corrosion Resistant Vanadia Coating For AA2024Document11 pagesIntelligent Self-Healing Corrosion Resistant Vanadia Coating For AA2024saleh90No ratings yet

- Anodic Films Containing Polyaniline and Nanoparticles For Corrosion Protection of AA2024T3 Aluminium AlloyDocument8 pagesAnodic Films Containing Polyaniline and Nanoparticles For Corrosion Protection of AA2024T3 Aluminium Alloysaleh90No ratings yet

- Pic 16 F 628Document20 pagesPic 16 F 628Merényi Oszkár100% (1)

- Junction Phy Tuts 2014Document8 pagesJunction Phy Tuts 2014ESAU0% (1)

- SMD A7Document5 pagesSMD A7jmbernal7487886100% (1)

- Ecm346 - Building Services (Laboratory) Ec1105F: Uitm PahangDocument6 pagesEcm346 - Building Services (Laboratory) Ec1105F: Uitm PahangNurin AdlinaNo ratings yet

- Sick - Ue 43mfDocument4 pagesSick - Ue 43mfchnanduNo ratings yet

- PhysyllDocument48 pagesPhysyllThanviomNo ratings yet

- Evolis Circuit Breakers Up To 17.5kV 2008Document92 pagesEvolis Circuit Breakers Up To 17.5kV 2008Laurentiu CatalinNo ratings yet

- Chapter 2-Field-Effect Transistor (FET)Document37 pagesChapter 2-Field-Effect Transistor (FET)LucasNo ratings yet

- Idosr JST 41 81 105 2019. PuDocument25 pagesIdosr JST 41 81 105 2019. Pujamiu1175No ratings yet

- Programmable Logic Devices 2, TutorialDocument10 pagesProgrammable Logic Devices 2, Tutorialindresh.verma100% (1)

- Avm 1309S PDFDocument0 pagesAvm 1309S PDFcarlosavictoriaNo ratings yet

- 2sa2018 - SMD Marking BW4Document5 pages2sa2018 - SMD Marking BW4julio montenegro100% (1)

- ViewSonic VA1939WADocument72 pagesViewSonic VA1939WAOshun76No ratings yet

- The Cmos Inverter: Jayson C. LoretoDocument9 pagesThe Cmos Inverter: Jayson C. LoretoBjun Curada LoretoNo ratings yet

- List of Instigated CircuitDocument25 pagesList of Instigated CircuitHardik100% (1)

- Chapter 1 PrinciplesDocument66 pagesChapter 1 PrinciplesKristian CzarNo ratings yet

- KEC-151P-251P - Electronics Engg. Lab MicroDocument3 pagesKEC-151P-251P - Electronics Engg. Lab MicroTanishkNo ratings yet

- SN74LS14NDocument4 pagesSN74LS14Nanon_386717813No ratings yet

- Eldora Grand 190PDocument2 pagesEldora Grand 190PAnonymous eCmTYonQ84No ratings yet

- Street Light Glow On Detecting Vechile Movement Using SensorDocument3 pagesStreet Light Glow On Detecting Vechile Movement Using SensorNikhil BhatiNo ratings yet

- Carbon Nanotube: Properties and ApplicationsDocument22 pagesCarbon Nanotube: Properties and ApplicationsmanuNo ratings yet

- Discussion On IGBT Short-Circuit Behavior and Fault Protection SchemesDocument8 pagesDiscussion On IGBT Short-Circuit Behavior and Fault Protection SchemesTheodore KyriakopoulosNo ratings yet

- OpAmp - MCP6241 PDFDocument28 pagesOpAmp - MCP6241 PDFLodewyk KleynhansNo ratings yet

- AC Numericals1Document3 pagesAC Numericals1Pavan KhetrapalNo ratings yet

- Ronch 160arc DV 200arc DV User Manual PDFDocument36 pagesRonch 160arc DV 200arc DV User Manual PDFHenry JaraNo ratings yet