Professional Documents

Culture Documents

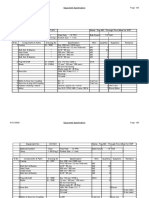

Design Data Performance (Dryer) : Client

Uploaded by

EDUARDOOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Data Performance (Dryer) : Client

Uploaded by

EDUARDOCopyright:

Available Formats

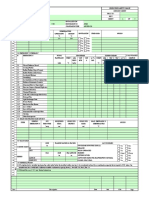

1 Rev

2 Air Dryer

3

o

C

o

C

4 Design Pressure kPa(g)

o

C

5 kPa(g)

6 min kPa(g)

7 max kPa

8 sm

3

/h

9 sm

3

/h Desiccant type/PSA type:

10

o

C kgs.

11 years

12 Filters

13 Prefilter

14 Design Pressure: kPa(g) kPa(g)

15 Design Temperature:

o

C

o

C

16 Pressure Drop Max.: kPa kPa

17

o

C

o

C

18

19 Air Dryer sm

3

/h

20 Number of air dryers (Twin Type) sm

3

/h

21 Manufacturer Drying Capacity (actual at C) sm

3

/h

22 Type: Design drying Capacity @ (*) sm

3

/h

23 Model: MAWP kPa(g)

24 No of Towers per air dryer Length (Max.): mm

25 Drying Medium Width (Max.) mm

26 Height (Max.) mm

27 Weight (Max) Kgs.

28

29 Manufacturer: Pressure Rating (kPa)

30 Model # Operating Temperature (C):

31 Type: Operating Temperature (C):

32 Alarms:

33

34

35 Locally Mounted Controls

36 Alarms

37 Panel Mounted

38 Control Gas (pressure)

39 Control gas source

40

41 Manufacturer: Inlet Size

42 Model # Outlet

43 Sound Level @ 1m distance (with Hush Muffler) Material:

44

45

46 Type: Type

47 Quantity / Chamber: Quantity / Chamber:

48 Type:

49 Quantity / Chamber:

Design Data

Dryer Cycle:

Outlet Pressure Time Between Regenerations

Minimum Design Metal Temprature (MDMT) Amount of Desiccant per tower:

Inlet Pressure

Client: DATA SHEET

Project: DRYER

Equip. No:

WO #: Equip. Name:

Plant/Area:

ADL Doc. No: ENG-DAT-000395

Rev: 0

Performance (Dryer)

Air Inlet Working Temperature Design Temperature: oC

Mechanical Data

Time for Regenerations

Dew Point Analyzer

Minimum design Metal Temprature (MDMT) Minimum design Metal Temprature (MDMT)

Design Pressure:

Hush Muffler (Silencer)

Adsorbent

Other Instrumentation

minutes

Expected changeout rate of desiccant:

minutes

minutes

Dew Point:

Purge Air Consumption at kPa(g) Inlet Pressure

Purge Air Consumption at kPa(g) Inlet Pressure

Design Temperature:

Pressure Drop

Pressure Drop Max.:

Drying Capacity (actual at C)

Afterfilter

Controls and Alarms

Drying Capacity (Required)

1 of 2

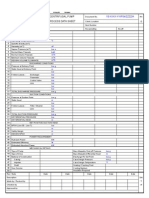

Design Data

Client: DATA SHEET

Project: DRYER

Equip. No:

WO #: Equip. Name:

Plant/Area:

ADL Doc. No: ENG-DAT-000395

Rev: 0

1

2 Numbers Numbers

3 Working Capacity : sm

3

/h Working Capacity : sm

3

/h

4 Tag Number Tag Number

5 Manufacturer Manufacturer:

6 Model # Model Number

7 Time between Filter element changeout or cleaning: Time Between Filter Element Cleaning

8 Effective Filter Area (m

3

) Effective Filter Area (m

3

)

9 Nominal Removal Rating:

10 micron micron

11 micron micron

12

13 Code of Costruction

14 Stamping

15 Registration

16

17 Heads: Thick (mm): Shell: Thick (mm):

18 Supports: Legs Flanges:

19 Nozzle Necks: Manway Necks:

20 Bolting (Pressure):

21 Gaskets:

DATE BY CHK'D

Construction Details

First Stage

Second Stage Second Stage

Material

First Stage

Prefilters Afterfilters

Notes:

APP'D REV: DESCRIPTION

Revision Log

2 of 2

You might also like

- Air Compressor Technical SpecificationDocument6 pagesAir Compressor Technical SpecificationdgmprabhakarNo ratings yet

- Mechanical Specification - Instrument Air CompressorDocument7 pagesMechanical Specification - Instrument Air Compressorsajeesh5113699No ratings yet

- Heat of Compression Dryer ArticleDocument5 pagesHeat of Compression Dryer ArticleAshwin ChandaranaNo ratings yet

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Mihir’s handbook of Chemical Process Engineering equipment listDocument14 pagesMihir’s handbook of Chemical Process Engineering equipment listHa LongNo ratings yet

- Control Valve Data SheetDocument2 pagesControl Valve Data SheetRSNo ratings yet

- Fgas Refrigerant CalculatorDocument10 pagesFgas Refrigerant CalculatorKumar sssssNo ratings yet

- N2 Regulator and Gauges DatasheetDocument4 pagesN2 Regulator and Gauges DatasheetpavanNo ratings yet

- Api 674,2Nd Edition: Reciprocating Pump Data Sheet Revision Record SheetDocument22 pagesApi 674,2Nd Edition: Reciprocating Pump Data Sheet Revision Record SheetmaruthigabbitaNo ratings yet

- (API 674-2nd) Reciprocating PumpDocument6 pages(API 674-2nd) Reciprocating PumpadistiNo ratings yet

- Mechanical Data Sheet For Nitrogen ReceiverDocument8 pagesMechanical Data Sheet For Nitrogen ReceiversudjonoNo ratings yet

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariNo ratings yet

- Air Filtration ParkerDocument20 pagesAir Filtration Parkerpanosh12No ratings yet

- Limpet Coil On Dish Design As Per PD5500Document1 pageLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNENo ratings yet

- Equivalent Length Calculator - RevADocument10 pagesEquivalent Length Calculator - RevArkrajan1502No ratings yet

- Data SheetDocument6 pagesData Sheetmkfe2005No ratings yet

- 25nb y StrainerDocument1 page25nb y StrainerKailas NimbalkarNo ratings yet

- Ejector Data SheetDocument5 pagesEjector Data SheetFatih FıratNo ratings yet

- Volume of Water for Test SectionDocument2 pagesVolume of Water for Test SectionFerinoviardi100% (1)

- Heat Exchanger Calculations: Inside Heat Trasfer CoefficientDocument4 pagesHeat Exchanger Calculations: Inside Heat Trasfer CoefficientBimal DeyNo ratings yet

- Process Design of Solid-Liquid Separators (Project Standards and Specifications)Document10 pagesProcess Design of Solid-Liquid Separators (Project Standards and Specifications)nabilaNo ratings yet

- No Yes No Yes No Yes No Yes No Yes No YesDocument8 pagesNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnNo ratings yet

- TG Temperature GaugeDocument2 pagesTG Temperature GaugeAr RahmanNo ratings yet

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocument2 pagesE-03.0) General Static-Mixing Customer Specification QuestionnaireimyourscinNo ratings yet

- Control Valve DatasheetDocument2 pagesControl Valve Datasheetcv.ekaputra 04No ratings yet

- Erbil Refinery Diesel Filling Pump Data SheetDocument5 pagesErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodNo ratings yet

- Pipe Size For Cooling Water SystemDocument5 pagesPipe Size For Cooling Water Systemnagu108No ratings yet

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocument1 pageCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNo ratings yet

- Air Receiver SizingDocument3 pagesAir Receiver Sizinglutfi awnNo ratings yet

- Instrument AirDocument9 pagesInstrument AirRaja Ahsan Azan JanjuaNo ratings yet

- PSV Sizing Tool API Based Calc Sheets PDFDocument11 pagesPSV Sizing Tool API Based Calc Sheets PDFLucas Farias0% (1)

- (HOW TO) Select Required Vacuum Pump Capacity - Pharma EngineeringDocument11 pages(HOW TO) Select Required Vacuum Pump Capacity - Pharma EngineeringpratikNo ratings yet

- Calculate supercharger parametersDocument1 pageCalculate supercharger parametersAnonymous QiMB2lBCJLNo ratings yet

- Liquid Overfeed Systems by R. P. ParanjpeyDocument15 pagesLiquid Overfeed Systems by R. P. Paranjpeyurp30234No ratings yet

- Instrument Air Dryer Sizing Calculation FactorsDocument1 pageInstrument Air Dryer Sizing Calculation FactorsAravind Kannan100% (2)

- Heat Loss From A Pipe Calculator - Engineers Edge - WWW - EngineersedgeDocument2 pagesHeat Loss From A Pipe Calculator - Engineers Edge - WWW - EngineersedgetiarrubuhNo ratings yet

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDocument9 pagesHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeNo ratings yet

- Compressed Air Dryer: Industrial Ammonia SystemsDocument8 pagesCompressed Air Dryer: Industrial Ammonia Systemsfernando_tkm_65065No ratings yet

- Relief 5Document5 pagesRelief 5Mo ZeroNo ratings yet

- Orifice Flow Calculator For Gases, Steam, and VaporsDocument2 pagesOrifice Flow Calculator For Gases, Steam, and Vaporsbakhtyar21No ratings yet

- Pressure Transmitter Specification Sheet: GeneralDocument1 pagePressure Transmitter Specification Sheet: GeneralFranklin J Talero BNo ratings yet

- Flash Tank Calculation ReportDocument29 pagesFlash Tank Calculation Reporttauqeer100% (1)

- Air CompressorDocument37 pagesAir Compressorsamal_biswaNo ratings yet

- Ref Pipe Sizing Ver 02 21 11Document12 pagesRef Pipe Sizing Ver 02 21 11Ahmef100% (1)

- Air Receivers Volume CalculationDocument123 pagesAir Receivers Volume CalculationsdgthdtrtretNo ratings yet

- Input From Simulation Result From Table or Chart AssumptionDocument31 pagesInput From Simulation Result From Table or Chart AssumptionMohamed Mamdouh AbdelHameed100% (1)

- Pipeline Pressure Drop Per 100 M - BAK - 14062011Document3 pagesPipeline Pressure Drop Per 100 M - BAK - 14062011Bharat A. KaduNo ratings yet

- P&ID Process Cooling Symbols and Their Usage PDFDocument4 pagesP&ID Process Cooling Symbols and Their Usage PDFHV UioNo ratings yet

- Pug MillDocument4 pagesPug Millprashant mishraNo ratings yet

- PG Pressure GaugeDocument2 pagesPG Pressure GaugeAr RahmanNo ratings yet

- Air CompressorsDocument44 pagesAir CompressorsZYJA DLANE MALITNo ratings yet

- Submittal ChillersDocument16 pagesSubmittal ChillersIngenieriaNo ratings yet

- Compressed Air ReceiversDocument6 pagesCompressed Air Receiverstruong sanh NguyenNo ratings yet

- PSV Calcs PDFDocument8 pagesPSV Calcs PDFatulNo ratings yet

- (How To) Calculate The Required Blower Capacity For FBD - Pharma EngineeringDocument11 pages(How To) Calculate The Required Blower Capacity For FBD - Pharma EngineeringTerrence Terry BhengoeNo ratings yet

- Performance NT100M HVDocument1 pagePerformance NT100M HVAnonymous 3fTYXaW7WNo ratings yet

- Water Treatment DegasifierDocument6 pagesWater Treatment DegasifierEDUARDONo ratings yet

- Silencer Data Sheet ReviewDocument2 pagesSilencer Data Sheet ReviewEDUARDONo ratings yet

- BoilerDocument13 pagesBoilerEDUARDONo ratings yet

- Data Sheet: Hydraulic Power UnitDocument3 pagesData Sheet: Hydraulic Power UnitEDUARDONo ratings yet

- 820 CB 120G WM26 - Rev0Document1 page820 CB 120G WM26 - Rev0EDUARDONo ratings yet

- 820 CB 120G WM25 - Rev0Document1 page820 CB 120G WM25 - Rev0EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- Dry CobbingDocument1 pageDry CobbingEDUARDONo ratings yet

- Durban Classic Cover + Caposide in One Side (Shougang Project)Document4 pagesDurban Classic Cover + Caposide in One Side (Shougang Project)EDUARDONo ratings yet

- 5921 D E DWG 0205 - RevADocument6 pages5921 D E DWG 0205 - RevAEDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014EDUARDONo ratings yet

- 830 CB 120 M07 - Rev0Document1 page830 CB 120 M07 - Rev0EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document12 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- 5921 D E DWG 0205 - RevADocument6 pages5921 D E DWG 0205 - RevAEDUARDONo ratings yet

- 5720 D E DWG 0201 - RevADocument4 pages5720 D E DWG 0201 - RevAEDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit PlantDocument10 pagesMine Operation Expansion Project and Benefit PlantEDUARDONo ratings yet

- StrainerDocument3 pagesStrainerEDUARDONo ratings yet

- 830 CB 120 M06 - Rev0Document1 page830 CB 120 M06 - Rev0EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document12 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit PlantDocument10 pagesMine Operation Expansion Project and Benefit PlantEDUARDONo ratings yet

- Silencer Data Sheet ReviewDocument2 pagesSilencer Data Sheet ReviewEDUARDONo ratings yet

- Data Sheet: DescriptionDocument6 pagesData Sheet: DescriptionEDUARDONo ratings yet

- Steam BoilerDocument10 pagesSteam BoilerEDUARDONo ratings yet

- 5921 D E DWG 0105 - RevADocument6 pages5921 D E DWG 0105 - RevAEDUARDONo ratings yet

- Sewage Treatment PlantDocument2 pagesSewage Treatment PlantEDUARDONo ratings yet

- Schedule Levels - Major Projects: Core Scheduling Papers: #6Document5 pagesSchedule Levels - Major Projects: Core Scheduling Papers: #6EDUARDONo ratings yet

- Sewage Treatment FloculantDocument1 pageSewage Treatment FloculantEDUARDONo ratings yet

- Sewage Treatment Ultraviolet DeinfectionDocument1 pageSewage Treatment Ultraviolet DeinfectionEDUARDONo ratings yet

- Sewagw Treatment FilterDocument1 pageSewagw Treatment FilterEDUARDONo ratings yet

- Sewage Treatment EfluentDocument5 pagesSewage Treatment EfluentEDUARDONo ratings yet

- Sewage Treatment Tank MixerDocument1 pageSewage Treatment Tank MixerEDUARDONo ratings yet

- Sewage Treatment MenbraneDocument1 pageSewage Treatment MenbraneEDUARDONo ratings yet

- Separation CellDocument11 pagesSeparation CellEDUARDONo ratings yet