Professional Documents

Culture Documents

Weber Float Leveling Instructions

Uploaded by

cafuso100%(1)100% found this document useful (1 vote)

440 views2 pagesThe document provides instructions for leveling the float on various Weber carburetor models. It discusses that the float level is critical for proper carburetor calibration and affects drivability and fuel consumption. General instructions are given that the float level is measured from the face of the carburetor cover with the float pivot at the top and the float tab resting on the needle valve spring. The float level is adjusted by carefully bending the float tab, and float stroke is adjusted by bending tab A. Specific instructions are then given for 40, 46, 48 IDA carburetor models which differ in that the float is retained in the body and not removed with the top cover.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides instructions for leveling the float on various Weber carburetor models. It discusses that the float level is critical for proper carburetor calibration and affects drivability and fuel consumption. General instructions are given that the float level is measured from the face of the carburetor cover with the float pivot at the top and the float tab resting on the needle valve spring. The float level is adjusted by carefully bending the float tab, and float stroke is adjusted by bending tab A. Specific instructions are then given for 40, 46, 48 IDA carburetor models which differ in that the float is retained in the body and not removed with the top cover.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

440 views2 pagesWeber Float Leveling Instructions

Uploaded by

cafusoThe document provides instructions for leveling the float on various Weber carburetor models. It discusses that the float level is critical for proper carburetor calibration and affects drivability and fuel consumption. General instructions are given that the float level is measured from the face of the carburetor cover with the float pivot at the top and the float tab resting on the needle valve spring. The float level is adjusted by carefully bending the float tab, and float stroke is adjusted by bending tab A. Specific instructions are then given for 40, 46, 48 IDA carburetor models which differ in that the float is retained in the body and not removed with the top cover.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

DCOE, DCNF, DGV, IDF

WEBER FLOAT LEVELING INSTRUCTIONS

WEBER

3

DCOE Series

(measure with gasket in place)

DCNF Series

DGV Series

(with Brass Float) (with Plastic Float)

IDF Series

The float level is a critical part of any carburetor calibration. Varying the level of fuel in the bowl will change the point at which the main circuit starts to

feed, alter the characteristics of an emulsion tube, and affects both drivability and fuel consumption. Follow these general instructions for float

leveling.

GENERAL INSTRUCTIONS . Float level, expressed in mm, generally refers to the distance of the float from the face of the carburetor cover. When

the top cover is held vertical with the float pivot at the top and the float tab (Lc) resting, against, but not compressing, the spring-loaded ball in the

needle valve, measurement is made between the top or bottom of the float to the face of the top cover. On carburetors where it it necessary to

remove the float in order to replace the top-cover gasket, the measurement should be made to the gasket face, with the gasket in place.

To adjust the float level, tab (Lc) should be carefully bent until the required dimension is achieved. Float stroke is the dimension from the top cover to

the top or bottom of the float when the float is at the bottom of its travel. Adjust this dimension by bending tab (A).

WEBER

WEBER

40,46, 48 IDA

WEBER FLOAT LEVELING INSTRUCTIONS

4

These carburetors differ from others in that the float is retained in the body and is not removed with the top

cover. Two tools are required for float leveling operations-Needle & Seat Gauge, pt.# 98014.200 & Spring

Retainer, pt. # 98013.800. The needle and seat gauge can be used to determine Dimension A, which should

be 18mm on 3 Bbl. carburetors, and 24mm on 2 Bbl. carburetors (48 IDA). Retaining the needle and seat

gauge and holding the float in this position with the spring check distance from top of carburetor body to top of

float. This should be 12.5-13mm on 3 Bbl. models, and 5.5-6mm on 2 Bbl. carbs. Repeat the above process

on each float. Should the float be incorrectly placed, modify the position of tabs (Lc), until they are

perpendicular to the axis of tab (A) and make sure there are no indentations on the contact surface which

might affect the free movement of the needles with ball (Sf) of the valves (V).

40, 46 IDA

3 Bbl. Models

48 IDA

2 Bbl. Models

WEBER

You might also like

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Dragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)From EverandDragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)No ratings yet

- Building a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendFrom EverandBuilding a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendNo ratings yet

- Adjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersDocument13 pagesAdjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersJ.d. LangleyNo ratings yet

- Cam Selection - Jim McFarland HRM March 1966Document3 pagesCam Selection - Jim McFarland HRM March 1966garagepunkfanNo ratings yet

- FC Edit User ManualDocument106 pagesFC Edit User Manualgnsl276802No ratings yet

- Saab V4 Sport and Rally Competition ModificationsDocument10 pagesSaab V4 Sport and Rally Competition Modificationsaakk75No ratings yet

- Ducati Desmodromic Variable Timing (DVT) EngineDocument3 pagesDucati Desmodromic Variable Timing (DVT) EngineRushLaneNo ratings yet

- Porsche 356 Owners Workshop Manual 1957-1965: Porsche 356A 1957 - 59, Porsche 356B 1959 - 63, Porsche 356C 1963 - 65From EverandPorsche 356 Owners Workshop Manual 1957-1965: Porsche 356A 1957 - 59, Porsche 356B 1959 - 63, Porsche 356C 1963 - 65No ratings yet

- Cylinder Head InstallDocument2 pagesCylinder Head InstallMiguel Moreno FernándezNo ratings yet

- G50 and G55 Manual Transmissions: DescriptionDocument7 pagesG50 and G55 Manual Transmissions: DescriptionCarlos Machado100% (1)

- Desmo Drom IDocument5 pagesDesmo Drom IWilliamNo ratings yet

- Aj6 Engineering IgnitionDocument9 pagesAj6 Engineering IgnitionBo BoboNo ratings yet

- Subaru Mod. 501 Brake Systems PDFDocument56 pagesSubaru Mod. 501 Brake Systems PDFDavid VelazquezNo ratings yet

- SS1 Dellorto Carburetor Technical ManualDocument10 pagesSS1 Dellorto Carburetor Technical ManualLSNo ratings yet

- 1997 Solectria Force Service ManualDocument72 pages1997 Solectria Force Service ManualRobert Strattan100% (1)

- GM 5 W 40Document84 pagesGM 5 W 40bluesysNo ratings yet

- Chassis Dynamometer Testing: Addressing the Challenges of New Global LegislationFrom EverandChassis Dynamometer Testing: Addressing the Challenges of New Global LegislationNo ratings yet

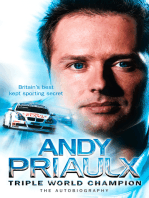

- Andy Priaulx: The Autobiography of the Three-time World Touring Car ChampionFrom EverandAndy Priaulx: The Autobiography of the Three-time World Touring Car ChampionRating: 3 out of 5 stars3/5 (1)

- Turbo Tech 102 - Advanced: Understanding Air FlowDocument10 pagesTurbo Tech 102 - Advanced: Understanding Air FlowrodrigoracingNo ratings yet

- Weber Carb Buyers GuideDocument2 pagesWeber Carb Buyers Guideclaudio_sorianoNo ratings yet

- Tomos Streetmate A55 - Information and Tuning ManualDocument29 pagesTomos Streetmate A55 - Information and Tuning ManualAdamLomazoff100% (1)

- Banshee ElectricalDocument23 pagesBanshee ElectricalBrett SonnierNo ratings yet

- Speeduino ManualDocument118 pagesSpeeduino ManualFreddy CamposNo ratings yet

- InjectorsDocument339 pagesInjectorsKapil AppyNo ratings yet

- Tillotson HD & HR Service ManualDocument11 pagesTillotson HD & HR Service ManualBeckyNo ratings yet

- Holley 1909 Carb ManualDocument9 pagesHolley 1909 Carb ManualALMOST610No ratings yet

- TP30432-2 Ignition SystemsDocument86 pagesTP30432-2 Ignition SystemsAchim Maximilian Naumann d'Alnoncourt100% (1)

- GFB V2 - VNT Boost Controller: (Part # 3009)Document2 pagesGFB V2 - VNT Boost Controller: (Part # 3009)blumng100% (1)

- SOHC Head Flow Data + CarburetorsDocument62 pagesSOHC Head Flow Data + CarburetorsVincenzo SepeNo ratings yet

- Lancia Scorpion Tecnhnical TipsDocument11 pagesLancia Scorpion Tecnhnical Tipsphantom fiatNo ratings yet

- Spark Plug CrossDocument99 pagesSpark Plug Crossabelmonte_geotecniaNo ratings yet

- Weber PrinciplesDocument7 pagesWeber PrinciplesŽiga PosediNo ratings yet

- Turbo Bricks - High Performance Volvo ClubDocument3 pagesTurbo Bricks - High Performance Volvo Clubmostafafouad19707723No ratings yet

- MZ TuningDocument24 pagesMZ TuningJawaCz100% (2)

- Emission Control PDFDocument63 pagesEmission Control PDFoz23100% (1)

- 95 Egge KatlogDocument196 pages95 Egge KatlogMartin J.No ratings yet

- Understanding Crankshaft BalancingDocument5 pagesUnderstanding Crankshaft BalancingVontrex DergonNo ratings yet

- F500 ManualDocument128 pagesF500 ManualBruno Pilieci100% (1)

- LH2.2 & EZ-F User Manual Issue 2bDocument73 pagesLH2.2 & EZ-F User Manual Issue 2bphilro52No ratings yet

- 325ix - E30 Zone WikiDocument6 pages325ix - E30 Zone WikiFlaviu CosminNo ratings yet

- Volkswagen Beetle: General HistoryDocument6 pagesVolkswagen Beetle: General HistoryIsanahsadNo ratings yet

- DCOE 40 MM Carb SettingDocument24 pagesDCOE 40 MM Carb SettingBrandon GilsonNo ratings yet

- Weber CarburatorDocument2 pagesWeber CarburatorDaniel HaaschNo ratings yet

- 9913 Ap 34Document108 pages9913 Ap 34احمدميدوNo ratings yet

- Power Steering System ComponentsDocument10 pagesPower Steering System ComponentsAbraham PejovésNo ratings yet