Professional Documents

Culture Documents

ASTM D 610-01 Standard Test Method For Evaluating Degree of Rusting On Painted Steel Surfaces

ASTM D 610-01 Standard Test Method For Evaluating Degree of Rusting On Painted Steel Surfaces

Uploaded by

Pinto Damian0 ratings0% found this document useful (0 votes)

21 views6 pagesOriginal Title

ASTM D 610-01 Standard Test Method for Evaluating Degree of Rusting on Painted Steel Surfaces

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views6 pagesASTM D 610-01 Standard Test Method For Evaluating Degree of Rusting On Painted Steel Surfaces

ASTM D 610-01 Standard Test Method For Evaluating Degree of Rusting On Painted Steel Surfaces

Uploaded by

Pinto DamianCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Designation: D 610 01

Steel Structures Painting Council

SSPC-VIS-2

Standard Test Method for

Evaluating Degree of Rusting on Painted Steel Surfaces

1

This standard is issued under the xed designation D 610; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This test method covers the evaluation of the degree of

rusting on painted steel surfaces. The visual examples which

depict the percentage of rusting given in the written specica-

tions form part of the standard. In the event of a dispute, the

written denition prevails. These visual examples were devel-

oped in cooperation with SSPC: The Society for Protective

Coatings to further standardization of methods.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Adjunct/SSPC: The Society for Protective Coat-

ings

SSPC-VIS 2/ASTM D 610 Standard Method of Evaluating

Degrees of Rusting on Painted Steel Surfaces

2

3. Signicance and Use

3.1 The amount of rusting beneath or through a paint lm is

a signicant factor in determining whether a coating system

should be repaired or replaced. This test method provides a

standardized means for quantifying the amount and distribution

of visible surface rust.

3.2 The degree of rusting is evaluated using a zero to ten

scale based on the percentage of visible surface rust.

3.3 The distribution of the rust is classied as spot rust,

general rust, pinpoint rust or hybrid rust.

4. Interferences

4.1 The visual examples that are part of this test method and

the associated rust-grade scale cover only rusting evidenced by

visible surface rust.

4.2 The use of the visual examples requires the following

cautions:

4.2.1 Some nishes are stained by rust. This staining must

not be confused with the actual rusting involved.

4.2.2 Accumulated dirt or other material may make accurate

determination of the degree of rusting difficult.

4.2.3 Certain types of deposited dirt that contain iron or iron

compounds may cause surface discoloration that should not be

mistaken for corrosion.

4.2.4 Failure may vary over a given area. Discretion must

therefore be used when selecting a single rust grade or rust

distribution that is to be representative of a large area or

structure, or in subdividing a structure for evaluation.

4.2.5 The color of the nish coating should be taken into

account in evaluating surfaces as failures will be more apparent

on a nish that shows color contrast with rust, such as used in

these reference standards, than on a similar color, such as an

iron oxide nish.

5. Procedure

5.1 Select an area to be evaluated.

5.2 Determine the type of rust distribution using denitions

in Table 1 and visual examples in Fig. 1, Fig. 2, and Fig. 3.

5.3 Estimate percentage of surface area rusted using the

visual examples in Fig. 1, Fig. 2, and Fig. 3 or SSPC-VIS 2, or

both, by electronic scanning techniques or other method agreed

upon by contracting parties.

NOTE 1The numerical rust grade scale is an exponential function of

the area of rust. The rust grade versus area of rust is a straight line plot on

semilogarithmic coordinate from rust grade 10 to rust grade 4. The slope

of the curve was changed at 10 % of the area rusted to 100 % rusted to

permit inclusion of complete rusting on the 0 to 10 rust scale.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.46 on Industrial Protective Coatings.

This test method has been jointly approved by ASTM and SSPC: The Society for

Protective Coatings.

Current edition approved May 10, 2001. Published July 2001. Originally

published as D 610 41. Last previous edition D 610 95.

2

Colored visual examples are available at a nominal cost from ASTM Head-

quarters (request Adjunct ADJD0610a), SSPC Publication No. 00-08 from SSPC:

The Society for Protective Coatings, 40 24th Street, Sixth Floor, Pittsburgh, PA

15213, www.sspc.org.

1

*A Summary of Changes section appears at the end of this standard.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

5.4 Use percentage of surface area rusted to identify rust

grade (see Table 1). Assign rust rating using rust grade of 0-10

followed by the type of rust distribution identied by S for

spot, G for general, P for pinpoint or H for Hybrid.

5.5 The visual examples are not required for use of the

rust-grade scale since the scale is based upon the percent of the

area rusted and any method of assessing area rust may be used

to determine the rust grade.

6. Report

6.1 Identify sample or area evaluated.

6.2 Report rust grade using rating of 0-10.

6.3 Report rust distribution using S for Spot, G for General,

P for Pinpoint and H for Hybrid.

7. Precision and Bias

7.1 No precision or bias statement can be made for this test

method.

8. Keywords

8.1 corrosion; rusting

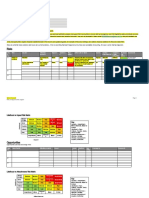

TABLE 1 Scale and Description of Rust Ratings

Visual Examples

Rust Grade Percent of Surface Rusted Spot(s) General (G) Pinpoint (P)

10 Less than or equal to 0.01 percent None

9 Greater than 0.01 percent and up to 0.03 percent 9S 9G 9P

8 Greater than 0.03 percent and up to 0.1 percent 8S 8G 8P

7 Greater than 0.1 percent and up to 0.3 percent 7S 7G 7P

6 Greater than 0.3 percent and up to 1.0 percent 6S 6G 6P

5 Greater than 1.0 percent and up to 3.0 percent 5S 5G 5P

4 Greater than 3.0 percent and up to 10.0 percent 4S 4G 4P

3 Greater than 10.0 percent and up to 16.0 percent 3S 3G 3P

2 Greater than 16.0 percent and up to 33.0 percent 2S 2G 2P

1 Greater than 33.0 percent and up to 50.0 percent 1S 1G 1P

0 Greater than 50 percent None

Rust Distribution Types:

S: Spot RustingSpot rusting occurs when the bulk of the rusting is concentrated in a few localized areas of the painted surface. The visual examples depicting this

type of rusting are labeled 9-S thru 1-S (See Fig. 1, Fig. 2, and Fig. 3).

G: General RustingGeneral rusting occurs when various size rust spots are randomly distributed across the surface. The visual examples depicting this type of rusting

are labeled 9-G thru 1-G. (See Fig. 1, Fig. 2, and Fig. 3).

P: Pinpoint RustingPinpoint rusting occurs when the rust is distributed across the surface as very small individual specks of rust. The visual examples depicting this

type of rusting are labeled 9-P through 1-P. (See Fig. 1, Fig. 2, and Fig. 3).

H: Hybrid RustingAn actual rusting surface may be a hybrid of the types of rust distribution depicted in the visual examples. In this case, report the total percent of

rust to classify the surface. 9-H through 1-H.

D 610 01

2

FIG. 1 Examples of Area Percentages

D 610 01

3

FIG. 2 Examples of Area Percentages

D 610 01

4

FIG. 3 Examples of Area Percentages

D 610 01

5

SUMMARY OF CHANGES

Committee D01 has identied the location of selected changes to this standard since the last date of issue that

may impact the use of this standard.

(1) This test method revised in 2001 to include the rust

distribution information.

(2) The visual examples were changed from nine pictorial

representation to twenty-seven rust grade and rust distribution

visual examples.

(3) Previously numerical rust grade rating of 0-10 were used.

Now rust grade of 0-10 are followed by rust distribution of S,

G,P or H

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

D 610 01

6

You might also like

- Astm B633-23 - Redline Astm B633-23Document7 pagesAstm B633-23 - Redline Astm B633-23somashekar1510No ratings yet

- Knowledge As Resistance: The Feminist International Network of Resistance To Reproductive and Genetic EngineeringDocument323 pagesKnowledge As Resistance: The Feminist International Network of Resistance To Reproductive and Genetic EngineeringProf. Vibhuti PatelNo ratings yet

- Astm D610Document2 pagesAstm D610Melissa Vega Reynoso100% (1)

- Abrasion TaberDocument2 pagesAbrasion TaberDiego Fernado AvendañoNo ratings yet

- Ductile Iron Castings: Standard Reference Radiographs ForDocument2 pagesDuctile Iron Castings: Standard Reference Radiographs ForJorge ToribioNo ratings yet

- Astm A 799 PDFDocument4 pagesAstm A 799 PDFOkinawa TeakNo ratings yet

- Astm A380-17Document13 pagesAstm A380-17EmekaNo ratings yet

- Automotive Gray Iron Castings: Standard Specification ForDocument5 pagesAutomotive Gray Iron Castings: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- A353a353m-17 1.04 PDFDocument3 pagesA353a353m-17 1.04 PDFlean guerrero100% (1)

- The Tale of Ch'UnhyangDocument3 pagesThe Tale of Ch'UnhyangMae Ganate Robles100% (2)

- D610 26390-1Document6 pagesD610 26390-1AntonioNo ratings yet

- ASTM G42 Cathodic Disbonment TestDocument8 pagesASTM G42 Cathodic Disbonment TestDuy Linh NguyenNo ratings yet

- 625 Characterization of Microstructures in Inconel 625 Using X-RAY PDFDocument5 pages625 Characterization of Microstructures in Inconel 625 Using X-RAY PDFKara WhiteNo ratings yet

- Astm B117 1973Document3 pagesAstm B117 1973prasad4ucherukuri11No ratings yet

- Astm D4752 20Document8 pagesAstm D4752 20Nguyên Nguyễn CaoNo ratings yet

- ASTM A780A780M - 09 (Reapproved 2015) Standard Practice For Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings1Document4 pagesASTM A780A780M - 09 (Reapproved 2015) Standard Practice For Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings1Thomas Farfan100% (2)

- D1474Document5 pagesD1474hdanyealNo ratings yet

- Astm C868-02 PDFDocument4 pagesAstm C868-02 PDFIan HsuNo ratings yet

- ASTM D610-01 Grado de Rusting PDFDocument6 pagesASTM D610-01 Grado de Rusting PDFmasv792512No ratings yet

- Evaluating Coatings For High Temperature Service: Standard Test Methods ForDocument3 pagesEvaluating Coatings For High Temperature Service: Standard Test Methods ForFernando Berrospi Garay100% (1)

- GenogramDocument12 pagesGenogramMumtaz KhanNo ratings yet

- ASTM Practice For IGC TestingDocument38 pagesASTM Practice For IGC TestingNest Necture100% (6)

- A204Document3 pagesA204doshi78No ratings yet

- ASTM D610!08!2012 Standard Practice For Evaluating Degree of Rusting On Painted Steel SurfacesDocument6 pagesASTM D610!08!2012 Standard Practice For Evaluating Degree of Rusting On Painted Steel SurfacesYosia GintingNo ratings yet

- Cathodic Disbondment Test of Pipeline Coatings (Attached Cell Method)Document4 pagesCathodic Disbondment Test of Pipeline Coatings (Attached Cell Method)Fernando Berrospi GarayNo ratings yet

- Action Plan For Indigenous Peoples Education (Iped) Program CY 2015Document7 pagesAction Plan For Indigenous Peoples Education (Iped) Program CY 2015Johnny Reglos83% (6)

- Evaluating Degree of Flaking (Scaling) of Exterior Paints: Standard Test Method ForDocument4 pagesEvaluating Degree of Flaking (Scaling) of Exterior Paints: Standard Test Method ForSudharsanNo ratings yet

- An Insight Into The New Austrian Tunnelling Method (NATM)Document14 pagesAn Insight Into The New Austrian Tunnelling Method (NATM)TaiCheong Lee100% (1)

- B343 92a Reapproved 2014 PDFDocument3 pagesB343 92a Reapproved 2014 PDFNinad PawarNo ratings yet

- Astm D610 PDFDocument7 pagesAstm D610 PDFFaisal Doank100% (1)

- SSPC SP14Document6 pagesSSPC SP14longlong3003No ratings yet

- Astm A293-2022Document10 pagesAstm A293-2022CarlosNo ratings yet

- Steel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements ForDocument9 pagesSteel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements FormuhammadNo ratings yet

- Demonstration DLLDocument2 pagesDemonstration DLLJanet GNo ratings yet

- F1130-99R05 Practice For Inspecting The Coating System of A Ship PDFDocument15 pagesF1130-99R05 Practice For Inspecting The Coating System of A Ship PDFVictor Hugo Pexo100% (1)

- Iso16773-1 2007Document12 pagesIso16773-1 2007Andrzej StanNo ratings yet

- ASTM G14 - 04 (Reapproved 2010)Document6 pagesASTM G14 - 04 (Reapproved 2010)Sofia YuliNo ratings yet

- Nickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification ForDocument6 pagesNickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification Forsharon blushteinNo ratings yet

- Measurement of Wet Film Thickness of Organic Coatings: Standard Test Methods ForDocument4 pagesMeasurement of Wet Film Thickness of Organic Coatings: Standard Test Methods FordavidfonsecaNo ratings yet

- Mechanical Hydrogen Embrittlement Evaluation of Plating/ Coating Processes and Service EnvironmentsDocument19 pagesMechanical Hydrogen Embrittlement Evaluation of Plating/ Coating Processes and Service EnvironmentsLeo Costa100% (1)

- Astm A27Document4 pagesAstm A27MAX ALBERTO JUAREZ AVALOSNo ratings yet

- En Iso 3231-1998 PDFDocument8 pagesEn Iso 3231-1998 PDFZbigNo ratings yet

- Immersion Testing of Industrial Protective Coatings: Standard Practice ForDocument6 pagesImmersion Testing of Industrial Protective Coatings: Standard Practice ForJhon Jeiwer SantosNo ratings yet

- Filtered Open-Flame Carbon-Arc Exposures of Paint and Related CoatingsDocument5 pagesFiltered Open-Flame Carbon-Arc Exposures of Paint and Related CoatingsDeepak D MishraNo ratings yet

- ASTM D610 - Standard Practice For Evaluating Degree of Rusting On Painted Steel SurfacesDocument6 pagesASTM D610 - Standard Practice For Evaluating Degree of Rusting On Painted Steel SurfacesRoger SchvepperNo ratings yet

- Standard Specification For: Designation: B6 13Document3 pagesStandard Specification For: Designation: B6 13Ahmed BilalNo ratings yet

- B432Document6 pagesB432Cesar Augusto Vinasco MartinezNo ratings yet

- Astm B571-97 PDFDocument3 pagesAstm B571-97 PDFDillonNo ratings yet

- Astm G58.25944Document8 pagesAstm G58.25944Bryan de BarrosNo ratings yet

- C 297 - C 297M - 04 - Qzi5ny9dmjk3tq - PDFDocument6 pagesC 297 - C 297M - 04 - Qzi5ny9dmjk3tq - PDFAnil100% (1)

- Paint Specification No.: SSPC: The Society For Protective CoatingsDocument5 pagesPaint Specification No.: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- Aws C2Document8 pagesAws C2dehamanezNo ratings yet

- Stainless Chromium Steel-Clad Plate: Standard Specification ForDocument6 pagesStainless Chromium Steel-Clad Plate: Standard Specification Forist93993No ratings yet

- B 900 - 99 - QjkwmaDocument12 pagesB 900 - 99 - QjkwmaLuis AndradeNo ratings yet

- Astm A418Document8 pagesAstm A418edcam13No ratings yet

- D 2511Document2 pagesD 2511Asep TheaNo ratings yet

- Astm A 633 .01Document3 pagesAstm A 633 .01FrengkiNo ratings yet

- Astm A463 2020Document6 pagesAstm A463 2020marjan banoo100% (2)

- A407-07 (2013) Standard Specification For Steel Wire, Cold-Drawn, For Coiled-Type SpringsDocument3 pagesA407-07 (2013) Standard Specification For Steel Wire, Cold-Drawn, For Coiled-Type Springstjt4779No ratings yet

- D610.Degree of RustingDocument6 pagesD610.Degree of RustingHector Aldair Valle RiveraNo ratings yet

- Evaluating Degree of Rusting On Painted Steel Surfaces: Standard Practice ForDocument6 pagesEvaluating Degree of Rusting On Painted Steel Surfaces: Standard Practice Forharpreet singhNo ratings yet

- D610-08 (Reapproved 2012)Document6 pagesD610-08 (Reapproved 2012)ehsan hatamiNo ratings yet

- Astm D610Document6 pagesAstm D610Song Kiet ChooNo ratings yet

- D 610 - 95 - Rdyxmc1sruq - PDFDocument9 pagesD 610 - 95 - Rdyxmc1sruq - PDFPaulo SantosNo ratings yet

- Astm D610Document7 pagesAstm D610kashif ehsanNo ratings yet

- Evaluating Degree of Resistance To Wear of Traffic Paint: Standard Test Method ForDocument3 pagesEvaluating Degree of Resistance To Wear of Traffic Paint: Standard Test Method ForJOHN MARTINNo ratings yet

- B1.1 Guía de Actividades para Repaso Virtual Cursos de Extensión Ilenguas 2020Document9 pagesB1.1 Guía de Actividades para Repaso Virtual Cursos de Extensión Ilenguas 2020jhorman maldonado reyNo ratings yet

- Lecture 8 Notes, Electromagnetic Theory II: 1. Scattering IntroductionDocument10 pagesLecture 8 Notes, Electromagnetic Theory II: 1. Scattering Introduction*83*22*No ratings yet

- JavaScript Export To Excel HTML Table With Input Tags - CodeProjectDocument5 pagesJavaScript Export To Excel HTML Table With Input Tags - CodeProjectgfgomesNo ratings yet

- RI Demand&SupplyDocument15 pagesRI Demand&SupplyKatinti YellaiahNo ratings yet

- HRP Final PPT Seimens Case StudyDocument17 pagesHRP Final PPT Seimens Case StudyAmrita MishraNo ratings yet

- Resume 09Document2 pagesResume 09mmaft74No ratings yet

- New ICD-10-CM Codes For BlindnessDocument6 pagesNew ICD-10-CM Codes For BlindnessdrrskhanNo ratings yet

- Face-To-Face Proximity Estimation Using Bluetooth On SmartphonesDocument5 pagesFace-To-Face Proximity Estimation Using Bluetooth On SmartphonesshanofaNo ratings yet

- KOKO, The Intelligent Gorilla B2-C1 Video Comprehension + Speaking QuestionsDocument3 pagesKOKO, The Intelligent Gorilla B2-C1 Video Comprehension + Speaking QuestionsMartaNo ratings yet

- SDOF - Free VibrationDocument12 pagesSDOF - Free VibrationPaul Bryan GuanNo ratings yet

- VG Glatt PDFDocument14 pagesVG Glatt PDFPankesin WonkaNo ratings yet

- Interllectual PropertyDocument8 pagesInterllectual PropertyTimothy NshimbiNo ratings yet

- Test A Unit 1 Choos A, B, C or D:: Aim High Level 1Document4 pagesTest A Unit 1 Choos A, B, C or D:: Aim High Level 1heartvampireNo ratings yet

- Disaster Prevention and MitigationDocument3 pagesDisaster Prevention and MitigationVinz Hexon BalangueNo ratings yet

- State FlowDocument882 pagesState FlowRajavelu VijayakumarNo ratings yet

- HW11 SolnDocument3 pagesHW11 SolnGreg SzwabowskiNo ratings yet

- Week 5 Notes CMTDocument4 pagesWeek 5 Notes CMTAlfredo MartínezNo ratings yet

- MATLAB Applications in Chemical EngineeringDocument13 pagesMATLAB Applications in Chemical EngineeringJuanMuñozNo ratings yet

- Review of Signals and SystemsDocument11 pagesReview of Signals and SystemsalexxxNo ratings yet

- LCC For Military SystemDocument196 pagesLCC For Military SystemMuzafar Shah Mosam ShahNo ratings yet

- Abb Ret615 v2.0 PTT User Manual EnuDocument7 pagesAbb Ret615 v2.0 PTT User Manual Enum_dh87129No ratings yet

- 1st Revision GR5 3rd Term Model AnswersDocument5 pages1st Revision GR5 3rd Term Model AnswersAhmed ElsayedNo ratings yet

- HPS Virtualization WhitepaperDocument11 pagesHPS Virtualization WhitepaperHamdan SidekNo ratings yet

- Name and Logo of Council: RisksDocument2 pagesName and Logo of Council: RisksAbdur Rauf KhanNo ratings yet