Professional Documents

Culture Documents

ASTM G14 - 04 (Reapproved 2010)

Uploaded by

Sofia YuliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM G14 - 04 (Reapproved 2010)

Uploaded by

Sofia YuliCopyright:

Available Formats

Designation: G14 – 04 (Reapproved 2010)

Standard Test Method for

Impact Resistance of Pipeline Coatings (Falling Weight

Test)1

This standard is issued under the fixed designation G14; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of the energy 4.1 The ability of a pipe coating to resist mechanical

required to rupture coatings applied to pipe under specified damage during shipping, handling, and installation will depend

conditions of impact from a falling weight. upon its impact resistance. This test method provides a

1.2 The values stated in SI units to three significant deci- systematic means for screening coating materials with regard

mals are to be regarded as the standard. The values given in to this property.

No reproduction or networking permitted without license from IHS

parentheses are for information only.

1.3 This standard does not purport to address all of the 5. Apparatus

safety concerns, if any, associated with its use. It is the 5.1 This test method can be successfully used with impact

responsibility of the user of this standard to establish appro- apparatus conforming to the following specifications:

priate safety and health practices and determine the applica- 5.1.1 Tup—The tup shall be made up from a tup body and

bility of regulatory limitations prior to use. a tup nose having a combined, fixed weight of 1.361 kg (3.00

lb) and shall be used over a drop range of 0.61 to 1.22 m (2 to

2. Referenced Documents 4 ft). With most coatings, a 1.361-kg (3.00-lb) tup dropped

2.1 ASTM Standards:2 through a distance of 914 mm (3 ft) yields suitable results. The

G12 Test Method for Nondestructive Measurement of Film tup nose shall have a 15.875-mm (5⁄8-in.) hemispherical head.

Thickness of Pipeline Coatings on Steel

NOTE 1—Frequent replacement of the tup nose can be avoided if it is

G62 Test Methods for Holiday Detection in Pipeline Coat- cut from steel capable of being hardened to a hardness of Rockwell C/45

ings while retaining an impact toughness of at least 15 ft·lb (20.34 J). Ball

2.2 SAE Standard: bearings conforming to SAE Grade 52100 have also been found suitable

Grade 52100 Steel3 for this purpose.

5.1.2 Drop Tube—A tube 1.52 m (5 ft) long shall be used to

3. Summary of Test Method

contain the tup and guide it during free fall. The drop tube shall

3.1 This test method uses a falling fixed weight having a be constructed of steel, aluminum, or any other suitably rigid

specified diameter impact surface, tup, which is restrained material and internally sized to provide a minimum of friction

vertically and dropped from varying heights to produce impact to the falling tup. A scale shall be attached for measuring the

energies over the required range. Electrical inspection is used height of drop to the nearest 2.54 mm (0.10 in.).

to detect resultant breaks in the coating. Impact resistance is 5.1.3 Specimen Holder—The base plate of the apparatus

determined as the amount of energy required to cause penetra- shall include a device for positioning and holding the pipe

tion of the coating film. specimen on line with the axis of the vertical drop tube.

NOTE 2—An arrangement using a V-notch vise made of metal with

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint spring clamp is recommended for this purpose. Glancing blows, caused by

and Related Coatings, Materials, and Applications and is the direct responsibility of an out-of-plumb condition between drop tube and pipe sample, will cause

Subcommittee D01.48 on Durability of Pipeline Coating and Linings. erratic test results.

Current edition approved Dec. 1, 2010. Published December 2010. Originally

approved in 1969. Last previous edition approved in 2004 as G14 – 04. DOI: 5.1.4 Apparatus Support—Both the apparatus and sample

10.1520/G0014-04R10. shall be firmly supported and secured to a rigid base to

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

optimize energy transfer from the tup to the specimen.

Standards volume information, refer to the standard’s Document Summary page on 5.2 A design for the test apparatus appears in Figs. X1.1-

the ASTM website. X1.3 of Appendix X1.

3

Available from SAE International (SAE), 400 Commonwealth Dr., Warrendale,

PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International

1Provided by IHS under license with ASTM

Not for Resale, 02/04/2012 04:40:03 MST Licensee=Committee on Institutional Cooperation/5967164001

G14 – 04 (2010)

5.3 Thickness Gage—Measurements of coating thickness 9.4 If the coating film is penetrated on the initial drop, make

will be required for this test, and shall be done in accordance the next test at the next lower height increment. If the first

with Test Method G12. specimen does not fail, make the second test at the next higher

5.4 Holiday Detector—A suitable detector as specified in increment.

Test Methods G62 shall be used to locate breaks in the coating 9.5 In a similar manner, determine the height of fall by the

film. performance of the coating on each preceding drop. Maintain a

constant height increment between readings. Continue to apply

6. Test Specimen this “up-and-down” method4 until 20 successive impact read-

6.1 The test specimen shall be a 406.4 mm (16 in.) long ings have been made.

piece of Schedule 40, 60.325 mm (2.375 in.) outside diameter

coated pipe prepared with its surface preparation and coating 10. Calculation

procedures equivalent to that of production coated pipe. 10.1 Calculate the mean value of impact strength, m, in

6.2 Seven specimens shall be required for the test. g/cm (or in./lb) as follows:

7. Conditioning

7.1 The specimen shall be exposed to a room temperature of

F A 1

m 5 h0 1 d N 6 2 S DG 3W (1)

21 to 25°C (70 to 77°F) for a period of 24 h before beginning where:

the test. h0 = minimum height at which the less frequent event

occurs, cm (or in.),

8. Preliminary Measurements d = increment in height of drop, cm (or in.),

8.1 Measure the applied coating thickness of each specimen A = sum of the frequency of occurrence at each height

in accordance with Test Method G12. increment times the number of increments above the

8.2 Place test specimen in sample holder and lightly place h0 value for each observation in the N total,

tup on surface of the coating. Adjust either the drop tube or the N = total number of the less frequent event (coating

attached scale so that the wing bolt (lifting pin) is at the zero failures or nonfailures), and

W = tup weight, g (or lb).

mark of the scale.

8.3 Make a preliminary set of impact readings to determine NOTE 4—The minus sign is used when the calculation of the mean is

the approximate starting point for the test. This shall be done based on the total number of coating failures and the plus sign when it is

by striking the first specimen from a height sufficient to cause based on the nonfailures.

failure of the coating film. Consider any penetration a failure if 10.2 Calculate the sample standard deviation, s, in gram-

it is detectable with a suitable Holiday Detector as specified in centimetres (or inch-pounds) as follows:

Test Methods G62.

8.3.1 Reduce the height by 50 % and make a second

exploratory drop at a fresh area on the pipe surface. Continue

S 5 1.620 dW S ~NB 2 A 2!

N2

1C D (2)

testing in this manner, with the corresponding reduction in

where:

height between drops, until the coating fails to break.

C = 0.737 when d is in cm, or 0.029 when d is in in., d, N,

No reproduction or networking permitted without license from IHS

NOTE 3—Choose test locations at the specimen surface in a random A, and W are as defined in 10.1, and

manner and keep at least a 76.2 mm (3 in.) distance between adjacent B = sum of the frequency of occurrence at each height

points of impact and within 38 mm (11⁄2 in.) from the ends. Choosing test increment times the square of the number of incre-

points in any regular pattern will bias the experiment and introduce error ments above the h0 value for each observation in the N

into the test results.

total.

8.3.2 Repeat the test at the height immediately preceding

the occurrence of the nonfailure to determine if an approximate NOTE 5—Adequate definition of coating impact strength will result

only if the height increment, d, has been properly chosen. When testing

level for the mean impact strength has been bracketed. Two

polymeric films in the range from 0.254 to 1.016 mm (0.010 to 0.040 in.),

successive reversals of coating performance between failure height increments of from 5.1 to 12.7 mm (0.2 to 0.5 in.) have been found

and nonfailure will give sufficient indication that the point has suitable with the 1.361 kg (3.0 lb) tup. Larger increments may be

been reached. necessary for thicker materials. If after making the calculations of 10.1

and 10.2, the ratio of the height increment to the standard deviation (d/s)

9. Procedure is less than 0.20, the test should be repeated using a larger value for the

increment d. This procedure will result in an improved estimate of the

9.1 Perform the test at a room temperature of 21 to 25°C (70 coating impact strength.

to 77°F).

9.2 Begin testing from the approximate height determined 10.3 An illustration of the use of these equations appears in

in 8.2 and corresponding to the point at which the first Appendix X2.

nonfailure was registered. Maintain a fixed increment between

adjacent testing heights.

9.3 Use a suitable detector, as specified in Test Method G62, 4

This system of testing, nomenclature, and calculation is described by Dixon, W.

to determine penetration or lack thereof of the coating after J. and Mood, A. M., “A Method for Obtaining and Analyzing Sensitivity Data,”

each individual impact. Journal Am. Statistical Assn., JSTNA, Vol 43, March, 1948, p. 109.

Copyright ASTM International

2Provided by IHS under license with ASTM

Not for Resale, 02/04/2012 04:40:03 MST Licensee=Committee on Institutional Cooperation/5967164001

G14 – 04 (2010)

11. Report 11.1.3 Sample standard deviation in g/cm (or in./lb).

11.1 The report shall include the following: 12. Precision and Bias

11.1.1 Complete identification of the specimen including:

12.1 The reproducibility of the impact resistance deter-

11.1.1.1 Name and code number of the coating,

mined by this method should not differ between one laboratory

11.1.1.2 Size of pipe, and another by more than 6 15 %. When the same instrument

11.1.1.3 Source, production date, and production-run num- is used by the same operator, repeatability on the same sample

ber, should not differ more than 6 15 %. Bias cannot be determined

11.1.1.4 Minimum, maximum, and average coating thick- since there is no acceptable standard material available for this

ness, test.

11.1.1.5 Date of test, and

11.1.1.6 Other information that may be pertinent, 13. Keywords

11.1.2 Average impact strength in g/cm (or in./lb), 13.1 falling weight test; impact resistance; pipeline coatings

APPENDIXES

(Nonmandatory Information)

X1. SUGGESTED DESIGN FOR TEST APPARATUS

X1.1 A design for the impact test apparatus is shown in

Figs. X1.1-X1.3.

--``,``,````````,`,,``,,``,``,,-`-`,,`,,`,`,,`---

Copyright ASTM International

3Provided by IHS under license with ASTM

Not for Resale, 02/04/2012 04:40:03 MST Licensee=Committee on Institutional Cooperation/5967164001

G14 – 04 (2010)

FIG. X1.1 Test Apparatus Assembly

--``,``,````````,`,,``,,``,``,,-`-`,,`,,`,`,,`---

Copyright ASTM International

4Provided by IHS under license with ASTM

Not for Resale, 02/04/2012 04:40:03 MST Licensee=Committee on Institutional Cooperation/5967164001

G14 – 04 (2010)

FIG. X1.2 Detailed Design of Test Apparatus

--``,``,````````,`,,``,,``,``,,-`-`,,`,,`,`,,`---

FIG. X1.3 Detailed Design of Test Apparatus

Copyright ASTM International

5Provided by IHS under license with ASTM

Not for Resale, 02/04/2012 04:40:03 MST Licensee=Committee on Institutional Cooperation/5967164001

G14 – 04 (2010)

X2. SAMPLE CALCULATIONS

X2.1 Test results for 20 drops with a 1.361 kg (3 lb) tup are

No reproduction or networking permitted without license from IHS

given in Table X2.1.

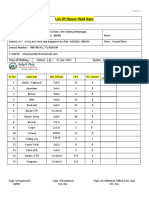

TABLE X2.1 Test Results

Height Height

Test Test

of Drop, Failed of Drop, Failed

No. No.

in. in.

1 14.1 yes 11 13.5 no

2 13.8 no 12 13.8 no

3 14.1 no 13 14.1 yes

4 14.4 yes 14 13.8 yes

5 14.1 yes 15 13.5 no

6 13.8 no 16 13.8 yes

7 14.1 no 17 13.5 yes

8 14.4 yes 18 13.2 no

9 14.1 yes 19 13.5 no

10 13.8 yes 20 13.8 yes

Height increment = 0.3 in.

Failures = 11

Nonfailures = 9

Nonfailures at 13.2 in. (h0) = 1; at 13.5 in. = 3; at 13.8 in. = 3; at 14.1 in. = 2

A = (0 3 1) + (1 3 3) + (2 3 3) + (3 3 2) = 15

B = ((0)2 3 1) + ((1)2 3 3) + ((2)2 3 3) + ((3)2 3 2) = 33

F

m 5 13.2 1 0.3 S 15 1

9

1

2 DG

3.0 5 41.55 in.· lb

mean impact resistance = 41.55 in.·lb

S 5 1.620 3 0.29 3 3.0 S

9 3 33 2 ~15!2

~9!2

D

5 1.338 in.·lbs.

Sample standard deviation = 1.383 in.·lb

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright ASTM International

6Provided by IHS under license with ASTM

Not for Resale, 02/04/2012 04:40:03 MST Licensee=Committee on Institutional Cooperation/5967164001

You might also like

- Astm D714Document5 pagesAstm D714Boris AguilarNo ratings yet

- Evaluating Degree of Flaking (Scaling) of Exterior Paints: Standard Test Method ForDocument4 pagesEvaluating Degree of Flaking (Scaling) of Exterior Paints: Standard Test Method ForSudharsanNo ratings yet

- Mil DTL 24441 - 35aDocument4 pagesMil DTL 24441 - 35aSinghalukKlumsatianNo ratings yet

- Surface Preparation Standard No. 1: SSPC: The Society For Protective Coatings Solvent CleaningDocument2 pagesSurface Preparation Standard No. 1: SSPC: The Society For Protective Coatings Solvent CleaningKrishna VachaNo ratings yet

- Technology Update No. 7Document24 pagesTechnology Update No. 7aRiTo!No ratings yet

- Astm D4228 05R17Document3 pagesAstm D4228 05R17Johana Rivadeneira100% (1)

- ASTM D 3023 - 98 Determination of Resistance of Factory-Applied Coatings On Wood Products To Stains and ReagentsDocument2 pagesASTM D 3023 - 98 Determination of Resistance of Factory-Applied Coatings On Wood Products To Stains and Reagentsalin2005No ratings yet

- SP 18 Thoro Spot & Sweep 12-30-20Document7 pagesSP 18 Thoro Spot & Sweep 12-30-20Donzt Dontz FaujiNo ratings yet

- Astm D4260-88 PDFDocument2 pagesAstm D4260-88 PDFdang2172014No ratings yet

- ASTM G42 Cathodic Disbonment TestDocument8 pagesASTM G42 Cathodic Disbonment TestDuy Linh NguyenNo ratings yet

- Coating International StandardsDocument2 pagesCoating International StandardsAhmed AliNo ratings yet

- SSPC Protective Coatings InspectorDocument731 pagesSSPC Protective Coatings InspectorTeymur RegenmaisterNo ratings yet

- SSPC Guide 3 - Paint Safety PDFDocument19 pagesSSPC Guide 3 - Paint Safety PDFAlexander SaulNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetajuhaseenNo ratings yet

- Nuclear Containment FailuresDocument10 pagesNuclear Containment FailuresskdonaldsNo ratings yet

- Astm D-4214Document4 pagesAstm D-4214Ahmad RoyaniNo ratings yet

- Sspc-Pa2 PDFDocument13 pagesSspc-Pa2 PDFEdgarDavidDiazCamposNo ratings yet

- Sspc-Pa 16-2012 PDFDocument2 pagesSspc-Pa 16-2012 PDFRaul Sebastiam100% (2)

- Adhesion Characteristics of Protective Coatings for Nuclear Power PlantsDocument8 pagesAdhesion Characteristics of Protective Coatings for Nuclear Power PlantsHaidarHussaini100% (1)

- SSPC - Paint 41 PDFDocument5 pagesSSPC - Paint 41 PDFIvanSanchez100% (1)

- William D. Corbett, KTA-Tator, Inc. Chair - SSPC Committee C.3.2 On Dry Film Thickness MeasurementDocument56 pagesWilliam D. Corbett, KTA-Tator, Inc. Chair - SSPC Committee C.3.2 On Dry Film Thickness MeasurementvtjoselineNo ratings yet

- AS 3894-5 Method 5 Surface-ProfileDocument6 pagesAS 3894-5 Method 5 Surface-Profilejonathan nachiroNo ratings yet

- SSPC Paint 18Document5 pagesSSPC Paint 18anoopkumarNo ratings yet

- Profile Measurement WebinarDocument39 pagesProfile Measurement WebinarAlex CarreraNo ratings yet

- ASTM D 1627 - 94 (Reapproved 2000) Chemical Analysis of Acid Copper ChromateDocument3 pagesASTM D 1627 - 94 (Reapproved 2000) Chemical Analysis of Acid Copper Chromatealin2005No ratings yet

- D4940 15 (Reapproved 2020) REDDocument3 pagesD4940 15 (Reapproved 2020) REDcarlos_k1555alejo100% (1)

- Vdocuments - MX Elcometer Fitz Atlas 2 of Coating DefectsDocument1 pageVdocuments - MX Elcometer Fitz Atlas 2 of Coating DefectsEdgarDavidDiazCamposNo ratings yet

- SSPC Pa 14Document6 pagesSSPC Pa 14mithileshNo ratings yet

- 7127 13Document6 pages7127 13Rajib Barua100% (1)

- Technical Data Sheet: Stolevell Thinplast FinishDocument3 pagesTechnical Data Sheet: Stolevell Thinplast FinishAnthony Al Lakiss0% (1)

- Astm C868-02 PDFDocument4 pagesAstm C868-02 PDFIan HsuNo ratings yet

- SSPC Guide 16 PDFDocument15 pagesSSPC Guide 16 PDFkishorekumar.animu100% (1)

- F 941 - 99 - RJK0MQ - PDFDocument3 pagesF 941 - 99 - RJK0MQ - PDFRománBarciaVazquezNo ratings yet

- Power PlantDocument34 pagesPower Plantmiguel0581No ratings yet

- D3276 15 115 1 Standard GuidDocument14 pagesD3276 15 115 1 Standard GuidDavid SalgueroNo ratings yet

- D2200 17Document3 pagesD2200 17Amirhossein LotfiNo ratings yet

- 2 Astm D6943Document16 pages2 Astm D6943Boris CardenasNo ratings yet

- Astm D4417Document3 pagesAstm D4417claudiaNo ratings yet

- Chemical Resistance GuideDocument11 pagesChemical Resistance GuideMohamed NouzerNo ratings yet

- ASTM D4708 - 12 Purchased VersionDocument3 pagesASTM D4708 - 12 Purchased VersionnishanthNo ratings yet

- Astm d7234Document14 pagesAstm d7234manuelguamanNo ratings yet

- SSPC Pa 2 2004 PDFDocument11 pagesSSPC Pa 2 2004 PDFrams789100% (1)

- D 7167 Monitoring Performance of Safety Related Linings PDFDocument7 pagesD 7167 Monitoring Performance of Safety Related Linings PDFImmanuel100% (1)

- TDS - Sonoshield ParkcoatDocument2 pagesTDS - Sonoshield ParkcoatVenkata RaoNo ratings yet

- Section 5.0 - Epoxy Coatin SystemsDocument36 pagesSection 5.0 - Epoxy Coatin SystemsgemotorresNo ratings yet

- Sigmacover 410Document4 pagesSigmacover 410gstketutNo ratings yet

- Certificate of Analysis: National Institute of Standards & TechnologyDocument3 pagesCertificate of Analysis: National Institute of Standards & Technologylehdruk7100No ratings yet

- ASTM - D522 - 1993 Reapproved 2008 - Standard Test Methods For Mandrel Bend Test of Attached Organic CoatingsDocument4 pagesASTM - D522 - 1993 Reapproved 2008 - Standard Test Methods For Mandrel Bend Test of Attached Organic CoatingsArmaghan ShiekhNo ratings yet

- Data Sheet Proguard CN 200 A.SDocument3 pagesData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieNo ratings yet

- Replica Tape Unlocking Hidden InformationDocument17 pagesReplica Tape Unlocking Hidden InformationTrịnh Minh KhoaNo ratings yet

- ASTM E1132-99aDocument27 pagesASTM E1132-99aOmar Bellido ValenciaNo ratings yet

- Astm D 660 - 93 (2019)Document9 pagesAstm D 660 - 93 (2019)Sur VaniNo ratings yet

- ASTM F21 Atomiser Test For Surface FilmsDocument5 pagesASTM F21 Atomiser Test For Surface Filmsazam RazzaqNo ratings yet

- Structural Steel Painting DFT Inspection Record (Beams) : Readings ( )Document5 pagesStructural Steel Painting DFT Inspection Record (Beams) : Readings ( )Amer Y KNo ratings yet

- ASTM For Primer Coating TestingDocument4 pagesASTM For Primer Coating TestingMuhammad Umer Draz100% (1)

- Astm D5162-15Document5 pagesAstm D5162-15maxpan maxNo ratings yet

- G 14 - 04 (2010) E1Document6 pagesG 14 - 04 (2010) E1jose floresNo ratings yet

- D2444-99 (2010) Standard Test Method For DeterminatDocument9 pagesD2444-99 (2010) Standard Test Method For Determinatjavier perezNo ratings yet

- ASTM G16 - 95 (Reapproved 2010)Document14 pagesASTM G16 - 95 (Reapproved 2010)Sofia YuliNo ratings yet

- Astm G13 - G13M 13Document3 pagesAstm G13 - G13M 13Sofia YuliNo ratings yet

- Water Penetration Into Pipeline Coatings: Standard Test Method ForDocument4 pagesWater Penetration Into Pipeline Coatings: Standard Test Method ForGul Hassan AkhunzadaNo ratings yet

- Astm G16 - 13Document14 pagesAstm G16 - 13Sofia YuliNo ratings yet

- Astm G15 - 06Document5 pagesAstm G15 - 06Sofia YuliNo ratings yet

- Astm G10 - 10Document3 pagesAstm G10 - 10Sofia YuliNo ratings yet

- ASTM G8 - 96 (Reapproved 2010)Document9 pagesASTM G8 - 96 (Reapproved 2010)Sofia YuliNo ratings yet

- Atmospheric Environmental Exposure Testing of Nonmetallic MaterialsDocument7 pagesAtmospheric Environmental Exposure Testing of Nonmetallic MaterialsSofia YuliNo ratings yet

- ASTM G2 - G2M - 06 (Reapproved 2011)Document8 pagesASTM G2 - G2M - 06 (Reapproved 2011)Sofia YuliNo ratings yet

- Conventions Applicable To Electrochemical Measurements in Corrosion TestingDocument9 pagesConventions Applicable To Electrochemical Measurements in Corrosion TestingAntonio BarbaNo ratings yet

- Preparing, Cleaning, and Evaluating Corrosion Test SpecimensDocument9 pagesPreparing, Cleaning, and Evaluating Corrosion Test SpecimensRichard De Medeiros CastroNo ratings yet

- ASTM G2 - G 2M - 06 (Reapproved 2011)Document8 pagesASTM G2 - G 2M - 06 (Reapproved 2011)Sofia YuliNo ratings yet

- Astm G7G7M 13Document7 pagesAstm G7G7M 13Sofia YuliNo ratings yet

- Astm G7 - G7M - 13Document7 pagesAstm G7 - G7M - 13Sofia YuliNo ratings yet

- G202Document5 pagesG202Gul Hassan Akhunzada100% (1)

- ASTM G4 - 01 (Reapproved 2008)Document9 pagesASTM G4 - 01 (Reapproved 2008)Sofia YuliNo ratings yet

- G201Document6 pagesG201Gul Hassan AkhunzadaNo ratings yet

- Astm G203 - 10Document8 pagesAstm G203 - 10Sofia YuliNo ratings yet

- Astm G204 - 10Document5 pagesAstm G204 - 10Sofia Yuli100% (1)

- Astm G200 - 09Document4 pagesAstm G200 - 09Sofia YuliNo ratings yet

- Astm G205 - 10Document10 pagesAstm G205 - 10Sofia YuliNo ratings yet

- Astm G207 - 11Document7 pagesAstm G207 - 11Sofia YuliNo ratings yet

- Astm G206 - 11Document5 pagesAstm G206 - 11Sofia YuliNo ratings yet

- Astm F3052 - 14Document20 pagesAstm F3052 - 14Sofia YuliNo ratings yet

- Astm F3007 - 13Document4 pagesAstm F3007 - 13Sofia YuliNo ratings yet

- Astm F3036 - 13Document9 pagesAstm F3036 - 13Sofia YuliNo ratings yet

- Astm G209 - 12Document8 pagesAstm G209 - 12Sofia YuliNo ratings yet

- Astm F3029 - 13Document2 pagesAstm F3029 - 13Sofia YuliNo ratings yet

- Astm F3069 - 14Document4 pagesAstm F3069 - 14Sofia YuliNo ratings yet

- Fjords Blue Web ENG PDFDocument20 pagesFjords Blue Web ENG PDFMoldovan MirceaNo ratings yet

- DCAD OverviewDocument9 pagesDCAD OverviewSue KimNo ratings yet

- Essene Moses Ten CommandmentsDocument4 pagesEssene Moses Ten Commandmentsjeryon91No ratings yet

- Membandingkan Recall 24 Jam Nutri Survey Dengan TkpiDocument7 pagesMembandingkan Recall 24 Jam Nutri Survey Dengan TkpiFransisca SihotangNo ratings yet

- S06 - 1 THC560 DD311Document128 pagesS06 - 1 THC560 DD311Canchari Pariona Jhon AngelNo ratings yet

- I Button Proper TDocument4 pagesI Button Proper TmariammariaNo ratings yet

- 03 - 42 STCP-Ahm AssetDocument46 pages03 - 42 STCP-Ahm AssetARP MEILNo ratings yet

- Plastic Welding: We Know HowDocument125 pagesPlastic Welding: We Know Howprabal rayNo ratings yet

- Millennium Separation ReportDocument3 pagesMillennium Separation ReportAlexandra AkeNo ratings yet

- JTP Brochure - 2Document6 pagesJTP Brochure - 2YAKOVNo ratings yet

- Liquid Analysis v3 Powell-Cumming 2010 StanfordgwDocument28 pagesLiquid Analysis v3 Powell-Cumming 2010 StanfordgwErfanNo ratings yet

- Building and Enhancing New Literacies Across The CurriculumDocument119 pagesBuilding and Enhancing New Literacies Across The CurriculumLowela Kasandra100% (3)

- Interesting Facts (Compiled by Andrés Cordero 2023)Document127 pagesInteresting Facts (Compiled by Andrés Cordero 2023)AndresCorderoNo ratings yet

- 3 - Content - Introduction To Java, JVM, JDK PDFDocument8 pages3 - Content - Introduction To Java, JVM, JDK PDFAnonymous zdY202lgZYNo ratings yet

- How To Pass in University Arrear Exams?Document26 pagesHow To Pass in University Arrear Exams?arrearexam100% (6)

- Presentation of Urban RegenerationsDocument23 pagesPresentation of Urban RegenerationsRafiuddin RoslanNo ratings yet

- Geometric Sculpture From 72 PencilsDocument5 pagesGeometric Sculpture From 72 PencilsHugo Iván Gonzalez CruzNo ratings yet

- Drug Study TramadolDocument7 pagesDrug Study TramadolZyrilleNo ratings yet

- Operating Manual: Please Read These Operating Instructions Before Using Your FreedomchairDocument24 pagesOperating Manual: Please Read These Operating Instructions Before Using Your FreedomchairNETHYA SHARMANo ratings yet

- C11 Strategy DevelopmentDocument30 pagesC11 Strategy DevelopmentPARTI KEADILAN RAKYAT NIBONG TEBALNo ratings yet

- Aerospace Opportunities in SwitzerlandDocument5 pagesAerospace Opportunities in SwitzerlandBojana DekicNo ratings yet

- Jotrun TDSDocument4 pagesJotrun TDSBiju_PottayilNo ratings yet

- Cell Selection ReselectionDocument35 pagesCell Selection ReselectionThiaguNo ratings yet

- Komatsud65ex 16dozerbulldozerservicerepairmanualsn80001andup 200727063646Document26 pagesKomatsud65ex 16dozerbulldozerservicerepairmanualsn80001andup 200727063646juan santa cruzNo ratings yet

- Power Team PE55 ManualDocument13 pagesPower Team PE55 ManualTitanplyNo ratings yet

- Maths SolutionDocument10 pagesMaths SolutionAbhay KumarNo ratings yet

- DLL Grade7 First 1solutions ConcentrationDocument5 pagesDLL Grade7 First 1solutions ConcentrationJaneth de JuanNo ratings yet

- ??????? ?? ??????Document29 pages??????? ?? ??????Aysha ShahabNo ratings yet

- List of household items for relocationDocument4 pagesList of household items for relocationMADDYNo ratings yet

- Structural IfpDocument4 pagesStructural IfpDanny NguyenNo ratings yet