Professional Documents

Culture Documents

Certificate of Analysis: National Institute of Standards & Technology

Uploaded by

lehdruk7100Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificate of Analysis: National Institute of Standards & Technology

Uploaded by

lehdruk7100Copyright:

Available Formats

National Institute of Standards & Technology

Certificate of Analysis

Standard Reference Material® 1362b

Coating Thickness Standard

(Nonmagnetic Coating on Steel)

Set Serial No. Sample

This Standard Reference Material (SRM) is designed for calibrating coating thickness gauges that employ magnetic

principles. These gauges are used to measure the thickness of nonmagnetic coatings on steel including paint and other

organic coatings, as well as nonmagnetic metallic coatings. A unit of SRM 1362b consists of a preconfigured set of

five 45 mm × 45 mm coupons: a bare substrate, and four coupons with metallic coatings certified for total coating

thickness (nominal coating thicknesses of 40 µm, 80 µm, 140 µm, and 205 µm). Each coupon consists of an AISI 1010

cold-rolled sheet-steel substrate with the coated coupons possessing an additional uniform coating of copper that is

overplated with a thin protective layer of chromium. This SRM is one in a series of SRMs prepared to cover a coating

thickness range from 6 µm to 1935 µm.

Certified Coating Thickness Values: Certified coating thickness values are provided in Table 1. A NIST certified

value is a value for which NIST has the highest confidence in its accuracy in that all known or suspected sources of

bias have been investigated or taken into account [1]. The analytical methods used for the characterization and

subsequent certification of this SRM included flame atomic absorption spectrometry, optical microscopy, and magnetic

induction. The resulting certified values are based upon results from the magnetic induction method and are reported

as the mean coating thickness of each coupon of the SRM unit. The uncertainty in the certified value for each coupon

is expressed as the expanded uncertainty, U, of the mean at the 95 % level of confidence and is calculated according to

the GUM Guide [2], where U = kuc, with a coverage factor, k = 2, and uc, a combined uncertainty including the

estimated uncertainty of the primary standards and the imprecision of the intercomparison of the primary standards to

the coupon.

Information Coating Thickness Values: Information coating thickness values reported in Table 2 were obtained by

converting the coating thickness values reported in micrometers from Table 1 to mils. An information value is

considered to be a value that will be of interest to the SRM user, but insufficient information is available to assess the

uncertainty associated with the value.

Certified and information coating thickness values listed in Tables 1 and 2 of this certificate are considered the official

values, should a discrepancy exist between the values listed in the certificate and the label affixed to the sleeve holding

the coupon.

Expiration of Certification: The certification of SRM 1362b is valid indefinitely, within the uncertainty specified,

provided the SRM is used infrequently as a primary standard and the unit is handled and stored in accordance with the

guidelines given in this certificate (see “Notice and Warnings to Users”). The wear induced by the contact

measurement of the magnetic gauges will alter the thickness values stated in this certificate. The frequency of

replacement or verification of this SRM is determined by the user, based upon the number of uses and the severity of

wear. If excessive wear is suspected, the SRM may be returned to NIST for verification. To verify certification of this

SRM unit, contact the NIST Thin Film and Nanostructure Processing Group by e-mail at Coating.Thickness@nist.gov,

by telephone at (301) 975-6400, or by fax at (301) 926-7679.

Maintenance of SRM Certification: NIST will monitor this SRM over the period of its certification. If substantive

technical changes occur that affect the certification, NIST will notify the purchaser. Registration (see attached sheet)

will facilitate notification.

Eric K. Lin, Chief

Materials Science and Engineering Division

Gaithersburg, MD 20899 Robert L. Watters, Jr., Director

Certificate Issue Date: 23 April 2013 Office of Reference Materials

Certificate Revision History on Last Page

SRM 1362b Page 1 of 3

The overall direction of the technical measurements leading to the certification of this SRM was provided by

C.R. Beauchamp of the Thin Film and Nanostructure Processing Group of the NIST Materials Science and Engineering

Division.

This SRM was produced by D.R. Kelley and measured by H.B. Gates of the Thin Film and Nanostructure Processing

Group of the NIST Materials Science and Engineering Division.

Statistical analysis was provided by S.D. Leigh of the NIST Statistical Engineering Division.

Support aspects involved in the issuance of this SRM were coordinated through the NIST Office of Reference

Materials.

NOTICE TO USERS

Notice to Users: This SRM should not be left unprotected in a corrosive laboratory environment or undergo any

treatment that would scratch or remove material from the surface of the coupon. The surfaces of these coupons require

careful preservation and care during storage and use in order to maintain the stated coating thickness within the

uncertainty reported on this certificate. The SRM unit may be cleaned with ethyl alcohol and soft wipe materials. The

surface polish should be protected from abuse. The certification is nullified if the coupons are repolished.

Instrument Calibration: The current published standard magnetic methods for measuring coating thicknesses [3,4]

should be used as guidelines to maximize the accuracy in coating thickness measurements. In general, it is not possible

for the user to achieve the same uncertainty as reported in Table 1 of this certificate when using magnetic-type coating

thickness gauges calibrated with this SRM. The overall uncertainty of the measurement by the user will include the

contribution due to the uncertainty of this SRM, as well as the uncertainty inherent in the measurements performed by

the user. The standard deviation of the measurements performed during the certification process is listed on the label

affixed to the sleeve containing each coupon. It is reported to enable the user to gauge the contribution due to

non-uniformity of the coating, since this will be a major contributor to the uncertainty of the values. This standard

deviation should not be used when performing an error analysis. Instead, the user is instructed to use the expanded

uncertainty listed in Table 1, since all known or suspected sources of bias have been investigated or taken into account

in this uncertainty.

Table 1. Certified Coating Thickness Values for Each Coupon

Individual Coupon Certified Coating Thickness

Serial Number (µm)

111111111111 38.36 ± 0.58

222222222222 76.6 ± 1.1

333333333333 137.1 ± 2.1

444444444444 201.8 ± 3.0

Table 2. Information Values for Coating Thickness of Each Coupon

Individual Coupon Coating Thickness

Serial Number (mils)

111111111111 ≈ 1.510

222222222222 ≈ 3.02

333333333333 ≈ 5.40

444444444444 ≈ 7.95

Assembly Date: Monday, July 26, 1999

All sets also include an uncoated steel coupon that originated from the same lot of the steel used as the substrate for

these SRMs. The coupon is intended for instruments that have the capability of adjusting their internal calibration

based on the substrate material used. When applicable, please refer to the appropriate manufacturer’s instrument

manual for instructions on how to perform the adjustment.

SRM 1362b Page 2 of 3

REFERENCES

[1] May, W.; Parris, R.; Beck II, C; Fassett, J.; Greenberg, R.; Guenther, F.; Kramer, G.; Wise, S.; Gills, T.;

Colbert, J.; Gettings, R.; MacDonald, B.; Definitions of Terms and Modes Used at NIST for Value-Assignment of

Reference Materials for Chemical Measurements; NIST Special Publication 260-136; U.S. Government Printing

Office: Washington, DC (2000); available at: http://www.nist.gov/srm/publications.cfm (accessed Apr 2013).

[2] JCGM 100:2008; Evaluation of Measurement Data - Guide to the Expression of Uncertainty in Measurement;

(GUM 1995 with Minor Corrections), Joint Committee for Guides in Metrology (JCGM) (2008); available at

http://www.bipm.org/utils/common/documents/jcgm/JCGM_100_2008_E.pdf (accessed Apr 2013); see also

Taylor, B.N.; Kuyatt, C.E.; Guidelines for Evaluating and Expressing the Uncertainty of NIST Measurement

Results; NIST Technical Note 1297, U.S. Government Printing Office: Washington, DC (1994); available at

http://www.nist.gov/pml/pubs/index.cfm (accessed Apr 2013).

[3] ASTM B 499; Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method:

Nonmagnetic Coatings on Magnetic Basis Metals; Annu. Book of ASTM Stand., Vol. 02.05.

[4] ISO 2178; Nonmagnetic Coatings on Magnetic Substrate-Measurement of Coating Thickness-Magnetic Method;

available at http://www.ansi.org/ (accessed Apr 2013).

Certificate Revision History: 23 April 2013 (Revision history corrected; editorial changes); 19 October 2012 (Moved coating thickness

information values [in mils] in Table 1 to a new table [Table 2]; references updated; editorial changes); 13 November 2001 (Editorial changes);

18 June 1999 (Original certificate date).

Users of this SRM should ensure that the Certificate of Analysis in their possession is current. This can be

accomplished by contacting the SRM Program: telephone (301) 975-2200; fax (301) 948-3730;

e-mail srminfo@nist.gov; or via the Internet at http://www.nist.gov/srm.

SRM 1362b Page 3 of 3

You might also like

- BCS 406 - 2Document2 pagesBCS 406 - 2lehdruk7100100% (1)

- Beginners Guide To CorrosionDocument10 pagesBeginners Guide To Corrosionshamu081No ratings yet

- Tk3e2 ManualDocument44 pagesTk3e2 ManualDuyệt Đinh Xuân67% (3)

- Astm17 0303Document5 pagesAstm17 0303Edgardo Emilio CantillanoNo ratings yet

- Physics Study MaterialDocument164 pagesPhysics Study MaterialgauravNo ratings yet

- Engineering Metrology InstrumentsDocument17 pagesEngineering Metrology InstrumentsAnilChauvanNo ratings yet

- Motor c4Document32 pagesMotor c4Rosa Ch100% (5)

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Document4 pagesApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawNo ratings yet

- F 941 - 99 - RJK0MQ - PDFDocument3 pagesF 941 - 99 - RJK0MQ - PDFRománBarciaVazquezNo ratings yet

- ASTM - D522 - 1993 Reapproved 2008 - Standard Test Methods For Mandrel Bend Test of Attached Organic CoatingsDocument4 pagesASTM - D522 - 1993 Reapproved 2008 - Standard Test Methods For Mandrel Bend Test of Attached Organic CoatingsArmaghan ShiekhNo ratings yet

- Mechanical Hydrogen Embrittlement Evaluation of Plating/ Coating Processes and Service EnvironmentsDocument19 pagesMechanical Hydrogen Embrittlement Evaluation of Plating/ Coating Processes and Service EnvironmentsLeo Costa100% (1)

- Physics Gce o Level Syllabus 2010 2Document44 pagesPhysics Gce o Level Syllabus 2010 2abi_5dec94100% (3)

- Hi - Temp 900Document5 pagesHi - Temp 900bhavesh solankiNo ratings yet

- SSPC Guide 16 PDFDocument15 pagesSSPC Guide 16 PDFkishorekumar.animu100% (1)

- Interline 925 - Potable Water TanksDocument21 pagesInterline 925 - Potable Water TanksSahab DeenNo ratings yet

- Sspc-Pa 16-2012 PDFDocument2 pagesSspc-Pa 16-2012 PDFRaul Sebastiam100% (2)

- ASTM D4708 - 12 Purchased VersionDocument3 pagesASTM D4708 - 12 Purchased VersionnishanthNo ratings yet

- SDFSDFDocument328 pagesSDFSDFRua MinkatoriNo ratings yet

- Machine Tool Testing - RaviDocument4 pagesMachine Tool Testing - RaviRavi AgarwalNo ratings yet

- IR Spectroscopy Problem Set 2Document5 pagesIR Spectroscopy Problem Set 2Jules BrunoNo ratings yet

- Sspc-Pa2 PDFDocument13 pagesSspc-Pa2 PDFEdgarDavidDiazCamposNo ratings yet

- Outside Micrometer CalibrationDocument2 pagesOutside Micrometer CalibrationJJNo ratings yet

- SP 18 Thoro Spot & Sweep 12-30-20Document7 pagesSP 18 Thoro Spot & Sweep 12-30-20Donzt Dontz FaujiNo ratings yet

- SSPC Pa 14Document6 pagesSSPC Pa 14mithileshNo ratings yet

- ASTM G14 - 04 (Reapproved 2010)Document6 pagesASTM G14 - 04 (Reapproved 2010)Sofia YuliNo ratings yet

- SUBJECT: Corrossion Problems Associated With Stainless Steel 4-1Document11 pagesSUBJECT: Corrossion Problems Associated With Stainless Steel 4-1Mufleh IdrisNo ratings yet

- Araldite Epoxy Adhesive - 2Document4 pagesAraldite Epoxy Adhesive - 2SatyamEngNo ratings yet

- SSPC Protective Coatings InspectorDocument731 pagesSSPC Protective Coatings InspectorTeymur RegenmaisterNo ratings yet

- SSPC - Paint 41 PDFDocument5 pagesSSPC - Paint 41 PDFIvanSanchez100% (1)

- Surface Preparation Standard No. 1: SSPC: The Society For Protective Coatings Solvent CleaningDocument2 pagesSurface Preparation Standard No. 1: SSPC: The Society For Protective Coatings Solvent CleaningKrishna VachaNo ratings yet

- Paint Specification No.: Steel Structures Painting CouncilDocument6 pagesPaint Specification No.: Steel Structures Painting CouncilanoopkumarNo ratings yet

- Astm D4228 05R17Document3 pagesAstm D4228 05R17Johana Rivadeneira100% (1)

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data Sheetajuhaseen100% (1)

- Astm D5162-15Document5 pagesAstm D5162-15maxpan maxNo ratings yet

- Astm D714Document5 pagesAstm D714Boris AguilarNo ratings yet

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتNo ratings yet

- SSPC Pa2Document12 pagesSSPC Pa2Robinson Cesar De la VegaNo ratings yet

- ASTM F21 Atomiser Test For Surface FilmsDocument5 pagesASTM F21 Atomiser Test For Surface Filmsazam RazzaqNo ratings yet

- Evaluating Degree of Flaking (Scaling) of Exterior Paints: Standard Test Method ForDocument4 pagesEvaluating Degree of Flaking (Scaling) of Exterior Paints: Standard Test Method ForSudharsanNo ratings yet

- ASTM D7091-05 DFT of Non Magnetic Coatings To Ferrous MetalsDocument7 pagesASTM D7091-05 DFT of Non Magnetic Coatings To Ferrous MetalsChris ParkinsonNo ratings yet

- Structural Steel Painting DFT Inspection Record (Beams) : Readings ( )Document5 pagesStructural Steel Painting DFT Inspection Record (Beams) : Readings ( )Amer Y KNo ratings yet

- Irish Standard I.S. EN ISO 11126-3:2018Document14 pagesIrish Standard I.S. EN ISO 11126-3:2018Nitin KawareNo ratings yet

- Mil DTL 24441 - 35aDocument4 pagesMil DTL 24441 - 35aSinghalukKlumsatianNo ratings yet

- D1414-22 9.02 Standard Test Methods For Rubber O-RingsDocument24 pagesD1414-22 9.02 Standard Test Methods For Rubber O-RingsHamidreza AraghianNo ratings yet

- Setup Guide No 4 Weld Inspection WeldcheckDocument7 pagesSetup Guide No 4 Weld Inspection WeldcheckcarlosNo ratings yet

- Vdocuments - MX Elcometer Fitz Atlas 2 of Coating DefectsDocument1 pageVdocuments - MX Elcometer Fitz Atlas 2 of Coating DefectsEdgarDavidDiazCamposNo ratings yet

- Iso 8502 6 2006Document9 pagesIso 8502 6 2006Evan YushavaNo ratings yet

- Aircraft and Support Equipment Polyurethane Coating SpecificationDocument24 pagesAircraft and Support Equipment Polyurethane Coating SpecificationmurphygtNo ratings yet

- ASTM D 3023 - 98 Determination of Resistance of Factory-Applied Coatings On Wood Products To Stains and ReagentsDocument2 pagesASTM D 3023 - 98 Determination of Resistance of Factory-Applied Coatings On Wood Products To Stains and Reagentsalin2005No ratings yet

- D4940 15 (Reapproved 2020) REDDocument3 pagesD4940 15 (Reapproved 2020) REDcarlos_k1555alejo100% (1)

- Testing Water Resistance of Coatings Using Water Fog ApparatusDocument3 pagesTesting Water Resistance of Coatings Using Water Fog ApparatusAlexander Franco CastrillonNo ratings yet

- Astm D4752Document8 pagesAstm D4752TEJAS GADKARINo ratings yet

- AS 3894-5 Method 5 Surface-ProfileDocument6 pagesAS 3894-5 Method 5 Surface-Profilejonathan nachiroNo ratings yet

- Astm 4752Document8 pagesAstm 4752Martin ManriqueNo ratings yet

- Exova Coating System Compliance StatementDocument1 pageExova Coating System Compliance StatementSaravan KumarNo ratings yet

- SSPC QP 3Document6 pagesSSPC QP 3anoopkumarNo ratings yet

- D 333 - 96Document6 pagesD 333 - 96PoyoeberNo ratings yet

- Replica Tape Unlocking Hidden InformationDocument17 pagesReplica Tape Unlocking Hidden InformationTrịnh Minh KhoaNo ratings yet

- GBE-CW6 Part-2-1993Document36 pagesGBE-CW6 Part-2-1993Gustavo CunhaNo ratings yet

- 11.03 Iso-6272-1-2011Document9 pages11.03 Iso-6272-1-2011hoanvuNo ratings yet

- 3 6077 RTVDocument2 pages3 6077 RTVgkretroNo ratings yet

- Standard Specification For: Designation: B6 13Document3 pagesStandard Specification For: Designation: B6 13Ahmed BilalNo ratings yet

- Protective Coating and Lining Work For Power Generation FacilitiesDocument2 pagesProtective Coating and Lining Work For Power Generation FacilitiesLuizao CabeloNo ratings yet

- Din 50018 Sulfur Dioxide Corrosion TestDocument3 pagesDin 50018 Sulfur Dioxide Corrosion TestJoao Pedro Rendeiro Correia de SousaNo ratings yet

- SSPC Guide 3 - Paint Safety PDFDocument19 pagesSSPC Guide 3 - Paint Safety PDFAlexander SaulNo ratings yet

- Evaluate paint film cure with solvent rub testDocument3 pagesEvaluate paint film cure with solvent rub testNisa_nisheNo ratings yet

- ASTM D4541 and ISO 4624: ?/sup InstrumentsDocument2 pagesASTM D4541 and ISO 4624: ?/sup InstrumentsTeguh SilaNo ratings yet

- Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied To Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied To Non-Ferrous MetalsDocument11 pagesNondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied To Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied To Non-Ferrous MetalsIvan AlanizNo ratings yet

- Guia para La Medición de Espesores SSPC - PA2Document11 pagesGuia para La Medición de Espesores SSPC - PA2robertabarreiroNo ratings yet

- NIST 1363b COADocument3 pagesNIST 1363b COAlehdruk7100No ratings yet

- Post Graduate Department of Business Administration Presents The 13th Edition ofDocument1 pagePost Graduate Department of Business Administration Presents The 13th Edition oflehdruk7100No ratings yet

- Jio - The Camel Is Inside The TentDocument12 pagesJio - The Camel Is Inside The Tentlehdruk7100No ratings yet

- Digital Optical PyrometerDocument1 pageDigital Optical Pyrometerlehdruk7100No ratings yet

- Aterials For 21'st Century: Paradigm Shift in Materials Development and ManufacturingDocument1 pageAterials For 21'st Century: Paradigm Shift in Materials Development and Manufacturinglehdruk7100No ratings yet

- Arjun 30Document8 pagesArjun 30lehdruk7100No ratings yet

- SS-CRM No. 493/3 High Manganese Steel: Certificate of AnalysisDocument2 pagesSS-CRM No. 493/3 High Manganese Steel: Certificate of Analysislehdruk7100No ratings yet

- Tests For Stress Corrosion Amp15908p036 PDFDocument3 pagesTests For Stress Corrosion Amp15908p036 PDFlehdruk7100No ratings yet

- Aterials For 21'st Century: Paradigm Shift in Materials Development and ManufacturingDocument1 pageAterials For 21'st Century: Paradigm Shift in Materials Development and Manufacturinglehdruk7100No ratings yet

- Qfiesta - Qfi Chennai'S Carnival of Quizzing: R. Jayakanthan / Samanth Subramanian / Gopal KidaoDocument1 pageQfiesta - Qfi Chennai'S Carnival of Quizzing: R. Jayakanthan / Samanth Subramanian / Gopal Kidaolehdruk7100No ratings yet

- Voelker Michelle UPDATED COPY 4.26.16Document133 pagesVoelker Michelle UPDATED COPY 4.26.16Carlin BabuchasNo ratings yet

- Geoheritage MonographDocument148 pagesGeoheritage Monographlehdruk7100No ratings yet

- Iarm 2HDocument2 pagesIarm 2Hlehdruk7100No ratings yet

- High Manganese Steel Certified Reference MaterialDocument2 pagesHigh Manganese Steel Certified Reference Materiallehdruk7100No ratings yet

- Refunds Under Gst02june2017Document2 pagesRefunds Under Gst02june2017lehdruk7100No ratings yet

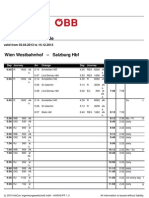

- Wien SalzburgDocument4 pagesWien Salzburglehdruk7100No ratings yet

- Ss CRM 495 - 4Document2 pagesSs CRM 495 - 4lehdruk7100No ratings yet

- A Quiz On Board Games From Business LineDocument2 pagesA Quiz On Board Games From Business Linelehdruk7100No ratings yet

- Penguin ManiRatnamInviteDocument1 pagePenguin ManiRatnamInvitelehdruk7100No ratings yet

- Lambic - Oxford ReferenceDocument5 pagesLambic - Oxford Referencelehdruk7100No ratings yet

- Wien SalzburgDocument4 pagesWien Salzburglehdruk7100No ratings yet

- Ghetto Warz 2006 House Packet 2Document7 pagesGhetto Warz 2006 House Packet 2lehdruk7100No ratings yet

- Claremont Packet2006Document1 pageClaremont Packet2006lehdruk7100No ratings yet

- Pipe Specification Api5lDocument1 pagePipe Specification Api5lmrzodNo ratings yet

- FacilitiesGrand ResidenceDocument1 pageFacilitiesGrand Residencelehdruk7100No ratings yet

- Ghetto Warz House Packet 1Document9 pagesGhetto Warz House Packet 1lehdruk7100No ratings yet

- Claremont Packet2006Document1 pageClaremont Packet2006lehdruk7100No ratings yet

- AP - Lab 02 - Measurement Using Screw GuageDocument3 pagesAP - Lab 02 - Measurement Using Screw GuagesalihaNo ratings yet

- Physics Lab Manual GuideDocument86 pagesPhysics Lab Manual Guiderqu3lNo ratings yet

- Mec 314Document14 pagesMec 314Vinu ThomasNo ratings yet

- WSU Instrumentation and Measurement Course NotesDocument97 pagesWSU Instrumentation and Measurement Course NotesSeido YadetaNo ratings yet

- MEASUREMENTS IN PHYSICSDocument225 pagesMEASUREMENTS IN PHYSICSSechelanji siwilaNo ratings yet

- Physics As Unit 3Document12 pagesPhysics As Unit 3Muaaz IqbalNo ratings yet

- V-14 ManualDocument24 pagesV-14 Manualluroguita-1100% (1)

- CNC CONTOUR VALIDATION WITH LASER BALL BARDocument15 pagesCNC CONTOUR VALIDATION WITH LASER BALL BARNitin DaduNo ratings yet

- C490 Practice For Use of Apparatus For The Determination ofDocument5 pagesC490 Practice For Use of Apparatus For The Determination ofCarineMolzNo ratings yet

- Producing Componants Using Hand Fitting TechniquesDocument10 pagesProducing Componants Using Hand Fitting TechniquesChris WoodsNo ratings yet

- Engineering MetrologyDocument2 pagesEngineering MetrologyAditi RoyNo ratings yet

- AutocollimatorsDocument14 pagesAutocollimatorsMuddaser Nawaz100% (2)

- Table of Contents and Introduction to Physics ChaptersDocument37 pagesTable of Contents and Introduction to Physics ChaptersEng Bahanza80% (5)

- Tune Up Engine Konvensional NO Tools Dan Alat UkurDocument5 pagesTune Up Engine Konvensional NO Tools Dan Alat UkurAlby AchmadNo ratings yet

- L - 12 CHT (MM) - VDocument7 pagesL - 12 CHT (MM) - Vmagneto gamingNo ratings yet

- TM-9-1290-262-10 Aiming CircleDocument95 pagesTM-9-1290-262-10 Aiming CircleHari IswantoNo ratings yet

- Dimensi & Toleransi Ulir TrapesiumDocument7 pagesDimensi & Toleransi Ulir TrapesiumHadi HendrariyantoNo ratings yet

- Fizik SBP Akhir Tahun f4Document70 pagesFizik SBP Akhir Tahun f4Mat MinNo ratings yet

- Measuring inside diametersDocument2 pagesMeasuring inside diametersRaquel RochaNo ratings yet

- EngineDocument695 pagesEngineazizmcp2No ratings yet

- Micrometers Calipers WorksheetDocument4 pagesMicrometers Calipers WorksheetAuliaNo ratings yet