Professional Documents

Culture Documents

Astm 4752

Uploaded by

Martin ManriqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm 4752

Uploaded by

Martin ManriqueCopyright:

Available Formats

www.lnternational-Standard.

com

Designation: D 4752 - 03

__111 _

INTERNATIONAL

Standard Test Method for

Measuring MEK Resistance of Ethyl Silicate (Inorganic)

Zinc-Rich Primers by Solvent Rub

This standard is issued under the fixed designation D 4752; the number immediately following the designation indicates the year of

original adoption or, in the case of reVISIOn, the year oflast revision. A number in parentheses indicates the year oflast reapproval. A

superscnpt epsilon (E) indicates an editorial change since the last revision or reapproval.

1. Scope ness of Protective Coating Systems by Destructive Means"

1.1 This test method describes a solvent rub technique for D 5402 Practice for Assessing the Solvent Resistance of

assessing the MEK resistance of ethyl silicate (inorganic) Organic Coatings Using Solvent Rubs5

zinc-rich primers. The MEK resistance of some two-

3. Terminology

component ethyl silicate zinc-rich primers has been shown to

correlate well with the cure of the primer as determined by 3.1 Definitions of Terms Specific to This Standard:

diffuse reflectance infrared spectroscopy? The technique can 3.1.1 double rub-lhe act of rubbing a solvenl saturated

be used in the laboratory, field, or in the fabricating shop. cloth in one complete forward and backward motion over a

Practice D 5402 is the preferred method for organic coatings. coaled surface.

1.2 The values stated in SI units are to be regarded as the 4. Significance and Use

standard. The values given in parentheses are for information

only. 4.1 Ethyl silicate zinc-rich primers cure by the reaction of

1.3 This standard does not purport to address all of the the vehicle with moisture, thereby providing a binder. As

safety concerns, if any, associated with its use. It is the relative humidity and temperature vary during the day, so does

responsibility of the user of this standard to establish. appro- the rate of cure. A certain minimum degree of cure is necessary

priate safety and health practices and determine the applica- prior to topcoating. It has been shown that the degree of cure

hility of regulatory limitations prior to use. Specific hazard of ethyl silicate zinc-rich primers can be measured by the

statements are given in Section 6. Consult supplier's Material chemical changes occurring using diffuse reflectance infrared

Safety Data Sheet(s) for specific hazard information relating to spectroscopy? This solvent rub test has been shown to corre-

the solvent used. late well with the infrared spectroscopic results of some

two-component ethyl silicate inorganic zinc systems.

2. Referenced Documents 4.2 The cure rating required for the application of specific

2.1 AS1M Standards: topcoats must be agreed upon before the test method is used.

D 740 Specification for Methyl Ethyl Ketone.' 5. Reagents and Materials

D 1186 Test Methods tor Nondestructive Measurement of

Dry Film Thickness of Nonmagnetic Coatings Applied to 5.1 Methyl Ethyl Ketone (MEK), in accordance with Speci-

a Ferrous Base" fication D 740.

D 1400 Test Method for Nondestructive Measurement of 5.2 Cheesecloth, 100 % cotton mesh size grade 28 by 24

Dry Film Thickness of Nonconductive Coatings Applied to approximately 300- by 300-mm (12- by 12-in.) and contrasting

a Nonferrous Metal Base4 in color to the coating being evaluated, or other mutually

D 4138 Test Methods for Measurement of Dry Film Thick- agreed upon cloth.

5.3 Squeeze Bottle.

5.4 Proper Safety Equipment, as determined from the sol-

vent MSDS, for example, solvent resistant gloves, respirator.

I This test method is under the jurisdiction of ASTM Committee DOI on Paint

and Related Coatings, Materials, and Applications and is the direct responsibility of 6. Procedure

Subcommittee DO1.46 on Industrial Protective Coatings.

Current edition approved Jan. 10, 2003. Published March 2003. Originally 6.1 Select areas on the primer surface at least 150 mm (6 in.)

approved in 1987. Last previous edition approved in 1998 as D 4752 - 98. long on which to run the tests. Clean the surface with tap water

2 Starr, T. L., Henton, L. E., Lewis, W. S., and Rideout, F. A., "Improved Field

or dry cloth to remove loose material.

Reliability of High Performance Coating Systems: Phase II-Develop Procedures

and Criteria in Critical Performance Areas," available from SSPC: The Society for

Protective Coatings, 40 24th St., Sixth Floor, Pittsburgh, PA 15213, www.sspc.org.

3 Annual Buuk ufASTM Standards, Vol 06.04.

4 Annual Book ofASTM Standards, Vol 06.01. 5 Annual Book ofASTM Standards, Vol 06.02.

Copyright©ASTM International, 100 Barr Harbor Drive, PO Box ClOD, West Conshohocken, PA 19428-2959, United States

Copyright by the ASTM International

Fri Jan 28 10:10:572005

www.lnternational-Standard.com

c6 04752-03

'1.111

NOTE i-Tap water may influence the cure of the zinc-rich primer. TABLE 1 Scale for Resistance Rating

6.2 Measure the dry film thickness of the primer in the Resistance Rating Description

selected areas in accordance with Test Methods D 1186, 5 No effect on surface; no zinc on cloth after 50 double

rubs

D 1400 or D4138. Mark a 150- by 25-nml (6- by I-in.) 4 Burnished appearance in rubbed area; slight amount of

rectangular test area on the undamaged cleaned surface using a zinc on cloth after 50 double rubs

pencil or other suitable solvent resistant marker. 3 Some marring and apparent depression of the film after

50 double rubs

6.3 Fold the cheesecloth into a pad of double thickness and 2 Heavy marring; obvious depression in the film after 50

saturate it to a dipping wet condition with the methyl ethyl double rubs

ketone. Do not allow more than 10 s to elapse before Heavy depression in the film but no actual penetration to

the substrate after 50 double rubs

proceeding to the next steps. o Penetration to the substrate in 50 double rubs or less

6.4 Place the properly protected index finger into the center

of the pad while holding excess cloth with the thumb and

remaining fingers of the same hand. With the index finger at a

45° angle to the test surface, rub the rectangular test area with 7.1.3 Number of tests conducted.

moderate pressure first away from the operator and then back 7.1.4 Resulting ratings.

Lowards the operator. Complete each double rub (one forward 7.1.5 In the case of a zero rating, number of double rubs

and back motion) in about 1 s. required to expose the substrate.

6.5 ConLinue rubbing the surface with the MEK saturated 7.1.6 Field and Fabricating Shop Tests- Identification of

pad, wetting the pad as necessary without lifting it from the the area or piece tested.

surface, until either the metal substrate is exposed or 50 double

rubs have been completed. If the former, record the number of 8. Precision and Bias

rubs when the substrate is exposed. 8.1 Precision-It is not practicable to specify the precision

6.6 Select an adjacent area to be used as a control. Repeat of this procedure since the rating scale is arbitrary and standard

6.1-6.5, except use a dry cheesecloth to establish the effect of methods for conducting round-robin studies and analyzing data

burnishing without the influence ofMEK. Use this area as the based on an arbitrary rating scale are not available. See

control to visually show the appearance of No Effect. Appendix Xl "Goodness."

6.7 Inspect the test areas and the cheesecloths. Rate the 8.2 Bias-Since there is no acceptable reference material,

results in accordance with Table 1. bias cannot be determined.

7. Report 9. Keywords

7.1 Report, as a minimum, the following information: 9.1 curing characteristics; double rub method; drying or

7.1.1 Dry film thickness of the primer. curing; ethyl silicate (inorganic) primer; methyl ethyl ketone;

7.1.2 Elapsed time between the application of the primer MEK (methyl ethyl ketone) resistance; primer; solvent rub

and the running of the tests. method; visual examination; zinc-rich primer

APPENDIX

(N onmandatory Information)

Xl.

Xl. 1 An intra-lab round-robin evaluation was conducted in operator. The 95 % confidence limits of the overall mean score

order to access the "goodness" of this test method. Using the (combined average score of the eight operators) are represented

procedure ouLlines in this test method, eight different operators on each of the figures by dashed lines. The following obser-

were asked to rate, in triplicate, the methyl ethyl ketone (MEK) vations were made through this analysis:

rub resistance of a particular inorganic zinc-rich primer. The

X1.2.1 Rub results arc cure time dependent, that is, higher

primer was separately applied to multiple test panels at two

rub scores are associated with longer cure periods, lower rub

different dry film thickness ranges; 2.7-4.5 mils and 6.8-8.0

scores are associated with shorter cure periods.

mils. Separate test panels corresponding to each coating

thickness category were scored after a 6-h cure period and a X1.2.2 Rub results are dependent on coating thickness, that

24-h cure period. Performance ratings and general statistical is, higher rub scores are associated with thick coatings films,

information have been in Table X1.1 for each cure period/film lower rub scores are associated with thinner coating films.

thickness combination. X1.2.3 From the plots, the largest number of operators

whose mean score deviated from the 95 % confidence limits of

X1.2 An analysis of the means, (ANOM), was conducted the overall mean score was found to occur when this test

on the performance data of Table XU. Figs. XU-X1.4 method is applied to thin film, 6-h cured primers. The second

illustrate the raw scores and the mean score reported by each largest number of operators whose mean score deviated from

Copyright by the ASTM International

Fri Jan 2810:11:042005

www.lnternational-Standard.com

eO 04752-03

TABLE X1.1 Round Robin Resistance Rating

Case 1: Thin Film, 6-hr cure

Operator ID Rub 1 Rub 2 Rub 3 Range Mean Standard Deviation

A 0 3 3 3 2.0 1.4

B 3 3 3 0 3.0 0.0

C 0 0 1 1 0.3 0.5

D 3 3 3 0 3.0 0.0

E 4 2 3 2 3.0 0.8

F 0 1 a 1 0.3 0.5

G 3 3 3 a 3.0 0.0

H 1 a 1 1 0.7 0.5

Overall Average 1.9 0.5

Case 2: Thin Film, 24-h cure

Operator ID Rub 1 Rub 2 Rub 3 Range Mean Standard Deviation

A 5 4 4 1 4.3 0.5

B 5 4 4 1 4.3 0.5

D 4 4 4 a 4.0 0.0

F 4 5 5 1 4.7 0.5

G 5 5 5 a 5.0 0.0

H 4 4 5 1 4.3 0.5

I 4 4 4 a 4.0 0.0

J 4 4 4 a 40 00

Overall Average 0.5 4.3 0.2

Case 3: Thick Film, 6-h cure

Operator ID Rub1 Rub2 Rub3 Range Mean Standard Deviation

A 4 4 4 a 4.0 0.0

B 4 4 4 a 4.0 0.0

C 4 4 4 a 4.0 0.0

D 3 3 3 a 3.0 0.0

E 4 3 3 1 3.3 0.5

F 0 4 5 5 3.0 2.2

G 3 3 3 a 3.0 0.0

H 3 4 3 1 3.3 0.5

Overall Average 0.9 3.5 0.4

Case 4: Thick Film, 24-h cure

Operator ID Rub1 Rub 2 Rub 3 Range Mean Standard Deviation

A 4 4 5 1 4.3 0.5

B 5 4 4 1 4.3 0.5

D 4 3 4 1 3.7 0.5

F 4 5 4 1 4.3 0.5

G 5 5 5 a 5.0 0.0

H 4 5 5 1 4.7 0.5

I 5 3 4 2 4.0 0.8

J 4 4 4 a 4.0 0.0

Overall Average 0.9 4.3 0.4

the 95 % limits of the overall score was found to occur in the

case of the thin film 24-h cured primers.

X1.2.4 All operators had mean scores within the 95 %

confidence limits of the overall mean score when this test

method was applied to either thick, 6-h cured primers or thick,

24-h cured primers.

X1.3 The findings of this test method's round-robin evalu-

ation have been offered in this appendix to serve as a reference

or guide for operators wishing to utilize this test method,

Copyright by the ASTM International

Fri Jan 2810:11:052005

www.lnternational-Standard.com

eO 04752-03

..

• •

Gl

[4: UJ

..

:::I

U

C

-

:::I

0

:I:

0 rD

nJ .§

CI) i.L

Q. c

:.c

0 I-

M: c "":

....

><

ci

u::

.:

N

- o

-e

Copyright by the ASTM International

Fri Jan 2810:11:052005

www.lnternational-Standard.com

eO 04752-03

-,

c

ltl

CIl

E

CIl

-

>

0

0

III

Ql

u

III e

en Ql

e 0

U

"t'

II:

c::

en 8

c::

I ftI i!-

• M

• a:

Ql

::E

It)

en

• M

e

:::l

III C-' U

ci

- :i

-

0

:I:

0 .,j.

N

l! .§

GJ i.i:

Q.

0 .5

• :M • u, ..I:

l-

t'!

....

X

ci

u:::

II o

• M

•

.. ... o

<

Copyright by the ASTM International

Fri Jan 2810:11:052005

www.lnternational-Standard.com

eO 04752-03

• M

•

C

III

4l

E

...4l

iii

-

M >

C

e

J!l

'E

"'"

III

B

e

III CII

!! !!

• • M 0

tJ

en e

C

B

LI.

i lIS

CII <fl.

Cll II)

C7l

• M

e

• M

• W

Q

u

:::l

:i

-

0

:I:

0 <h

l! .§

CD u:::

a.

""

0 .s

..r::

It C I-

...."'!

><

ci

u:::

.... <

N c

Copyright by the ASTM International

Fri Jan 2810:11:052005

www.lnternational-Standard.com

eO 04752-03

c:

III

ell

E

76

Cii

c>

C

• l4

•

B

III

l!!

0

..

III

ell

C

(J

C

ell

"C

Ie:

c

(J

en en 8

c

it III ;;e.

•. M

• III

a::

Q)

::::E

It'

01

• M

e

:::l

If (!) (J

-ci... ..;.

:;

0

-

:I:

0 N

ftI

... E-

CD ::

o

• M

• u..

.s

..c::

t-

'<I:

><

ci

u::

• M • c

• M •

<:

.... c

Copyright by the ASTM International

Fri Jan 2810:11:052005

www.lnternational-Standard.com

eO 04752-03

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright by the ASTM International

Fri Jan 2810:11:052005

You might also like

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetajuhaseenNo ratings yet

- SP 18 Thoro Spot & Sweep 12-30-20Document7 pagesSP 18 Thoro Spot & Sweep 12-30-20Donzt Dontz FaujiNo ratings yet

- Painting of Structure Piping Equipment 22Document5 pagesPainting of Structure Piping Equipment 22Saurabh Kumar VermaNo ratings yet

- Protective Coating and Lining Work For Power Generation FacilitiesDocument2 pagesProtective Coating and Lining Work For Power Generation FacilitiesLuizao CabeloNo ratings yet

- Determining Abrasion Resistance of Inks and Coatings On Substrates Using Dry or Wet Abrasive MediumDocument3 pagesDetermining Abrasion Resistance of Inks and Coatings On Substrates Using Dry or Wet Abrasive MediumwerrteNo ratings yet

- ASTM D 3002 - 97 Evaluation of Coatings Applied To PlasticsDocument2 pagesASTM D 3002 - 97 Evaluation of Coatings Applied To Plasticsalin2005100% (1)

- D4940 15 (Reapproved 2020) REDDocument3 pagesD4940 15 (Reapproved 2020) REDcarlos_k1555alejo100% (1)

- Araldite Epoxy Adhesive - 2Document4 pagesAraldite Epoxy Adhesive - 2SatyamEngNo ratings yet

- D4060.37296 - Taber Abraser TestDocument6 pagesD4060.37296 - Taber Abraser TestJeremyNo ratings yet

- Astm D4228 05R17Document3 pagesAstm D4228 05R17Johana Rivadeneira100% (1)

- Polymer Lab ManualDocument48 pagesPolymer Lab ManualShaukat AliNo ratings yet

- SSPC - Paint 41 PDFDocument5 pagesSSPC - Paint 41 PDFIvanSanchez100% (1)

- 18-ASTM E2174-14bDocument7 pages18-ASTM E2174-14bAli Adnaan RazaNo ratings yet

- SSPC Protective Coatings InspectorDocument731 pagesSSPC Protective Coatings InspectorTeymur RegenmaisterNo ratings yet

- D1414-22 9.02 Standard Test Methods For Rubber O-RingsDocument24 pagesD1414-22 9.02 Standard Test Methods For Rubber O-RingsHamidreza AraghianNo ratings yet

- 11.03 Iso-6272-1-2011Document9 pages11.03 Iso-6272-1-2011hoanvuNo ratings yet

- Evaluating Degree of Flaking (Scaling) of Exterior Paints: Standard Test Method ForDocument4 pagesEvaluating Degree of Flaking (Scaling) of Exterior Paints: Standard Test Method ForSudharsanNo ratings yet

- Astm e 1182Document7 pagesAstm e 1182Ricardo Paz SoldanNo ratings yet

- As NZS 1580.481.1.10-1998 Paints and Related Materials - Methods of Test Coatings - Exposed To Weathering - DDocument2 pagesAs NZS 1580.481.1.10-1998 Paints and Related Materials - Methods of Test Coatings - Exposed To Weathering - DSAI Global - APAC100% (1)

- Data Sheet Proguard CN 200 A.SDocument3 pagesData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieNo ratings yet

- Setup Guide No 4 Weld Inspection WeldcheckDocument7 pagesSetup Guide No 4 Weld Inspection WeldcheckcarlosNo ratings yet

- Certificate of Analysis: National Institute of Standards & TechnologyDocument3 pagesCertificate of Analysis: National Institute of Standards & Technologylehdruk7100No ratings yet

- Paints and Varnishes Pull-Off For Adhesion: First EditionDocument9 pagesPaints and Varnishes Pull-Off For Adhesion: First EditionmirzazubairNo ratings yet

- Astm D-4214Document4 pagesAstm D-4214Ahmad RoyaniNo ratings yet

- Bs en Iso Astm 52915-2017Document38 pagesBs en Iso Astm 52915-2017KaterynaNo ratings yet

- SSPC SP 1 - 2000 PDFDocument2 pagesSSPC SP 1 - 2000 PDFmalika_00No ratings yet

- Astm D4000 2004 PDFDocument19 pagesAstm D4000 2004 PDFHARSHANo ratings yet

- SSPC Guide 16 PDFDocument15 pagesSSPC Guide 16 PDFkishorekumar.animu100% (1)

- Exova Coating System Compliance StatementDocument1 pageExova Coating System Compliance StatementSaravan KumarNo ratings yet

- Astm C868-85 (R95)Document4 pagesAstm C868-85 (R95)Ian HsuNo ratings yet

- Mil DTL 24441 - 35aDocument4 pagesMil DTL 24441 - 35aSinghalukKlumsatianNo ratings yet

- Sspc-Pa2 PDFDocument13 pagesSspc-Pa2 PDFEdgarDavidDiazCamposNo ratings yet

- ASTM G14 - 04 (Reapproved 2010)Document6 pagesASTM G14 - 04 (Reapproved 2010)Sofia YuliNo ratings yet

- PRC-0008 CurrentDocument50 pagesPRC-0008 CurrentbeyNo ratings yet

- F 941 - 99 - RJK0MQ - PDFDocument3 pagesF 941 - 99 - RJK0MQ - PDFRománBarciaVazquezNo ratings yet

- Astm E1558.24503Document13 pagesAstm E1558.24503Juan Shevchenko100% (1)

- Iso 8502 6 2006Document9 pagesIso 8502 6 2006Evan YushavaNo ratings yet

- Nuclear Containment FailuresDocument10 pagesNuclear Containment FailuresskdonaldsNo ratings yet

- ASTM D3299 Tanques Fabricados em Fibra de VidroDocument17 pagesASTM D3299 Tanques Fabricados em Fibra de VidroAugusto André100% (1)

- Astm D4417Document3 pagesAstm D4417claudiaNo ratings yet

- F1088 1479757-1Document2 pagesF1088 1479757-1Thaweekarn ChangthongNo ratings yet

- AS 3894-5 Method 5 Surface-ProfileDocument6 pagesAS 3894-5 Method 5 Surface-Profilejonathan nachiroNo ratings yet

- SUBJECT: Corrossion Problems Associated With Stainless Steel 4-1Document11 pagesSUBJECT: Corrossion Problems Associated With Stainless Steel 4-1Mufleh IdrisNo ratings yet

- Astm D6670-2018Document21 pagesAstm D6670-2018damaso taracenaNo ratings yet

- Structural Steel Painting DFT Inspection Record (Beams) : Readings ( )Document5 pagesStructural Steel Painting DFT Inspection Record (Beams) : Readings ( )Amer Y KNo ratings yet

- Sikaproof Membrane: Safety Data SheetDocument6 pagesSikaproof Membrane: Safety Data SheetSamuel CastilloNo ratings yet

- Astm A 123 - 2013Document8 pagesAstm A 123 - 2013JOSENo ratings yet

- Jotun TDSDocument2 pagesJotun TDSBiju_PottayilNo ratings yet

- Astm17 0303Document5 pagesAstm17 0303Edgardo Emilio CantillanoNo ratings yet

- SSPC Pa 14Document6 pagesSSPC Pa 14mithileshNo ratings yet

- SoniCell ASTM E85 Fire TestDocument10 pagesSoniCell ASTM E85 Fire TestAvs CrNo ratings yet

- Aircraft and Support Equipment Polyurethane Coating SpecificationDocument24 pagesAircraft and Support Equipment Polyurethane Coating SpecificationmurphygtNo ratings yet

- Astm G85Document6 pagesAstm G85Abdul MunirNo ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument5 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForOscar Rodrigo LopezNo ratings yet

- ASTM D4752 Rub Test PDFDocument8 pagesASTM D4752 Rub Test PDFhelioxavier280% (5)

- Vdocuments - MX - Astm d4752 Mek Test Zinc Test PDFDocument8 pagesVdocuments - MX - Astm d4752 Mek Test Zinc Test PDFLê Thái ThuậnNo ratings yet

- Astm D4752 20Document8 pagesAstm D4752 20Nguyên Nguyễn CaoNo ratings yet

- MANUFACTURING AGRICULTURAL MACHINES WITH WELDINGDocument9 pagesMANUFACTURING AGRICULTURAL MACHINES WITH WELDINGJordan YapNo ratings yet

- LKVF Coarse StrainerDocument2 pagesLKVF Coarse StrainerPeterNo ratings yet

- European Patent Application: Vinyl Acetate/aromatic Vinyl Ester Copolymer Binder ResinsDocument23 pagesEuropean Patent Application: Vinyl Acetate/aromatic Vinyl Ester Copolymer Binder ResinschinmaydabkeNo ratings yet

- Biodegradable Therapeutic Mofs For The Delivery of Bioactive MoleculesDocument4 pagesBiodegradable Therapeutic Mofs For The Delivery of Bioactive MoleculesJavier NeriNo ratings yet

- Andros, Aruba and Bali ceramic tile collectionDocument20 pagesAndros, Aruba and Bali ceramic tile collectionPilar DosNo ratings yet

- Injection Molded Part DefectsDocument2 pagesInjection Molded Part DefectsTrieubinhan NguyenNo ratings yet

- Nanotechnology For KidsDocument4 pagesNanotechnology For KidsDek RestyNo ratings yet

- Heat and Mass Transfer by S K Mondal T&Q (1) .0001 PDFDocument110 pagesHeat and Mass Transfer by S K Mondal T&Q (1) .0001 PDFankitgaurav3497No ratings yet

- Balancing Chemical Equations 1Document4 pagesBalancing Chemical Equations 1luis martinezNo ratings yet

- Aramco Specific Evaluations For WeldingDocument6 pagesAramco Specific Evaluations For WeldingTrived MahankaliNo ratings yet

- Waste ManagementDocument7 pagesWaste Managementwongsc70No ratings yet

- Natural SilkDocument3 pagesNatural Silkapi-302611547No ratings yet

- A2-Multitrac A2TFDocument2 pagesA2-Multitrac A2TFJuan RodriguezNo ratings yet

- Reinforced Concrete Slab DesignDocument8 pagesReinforced Concrete Slab Designone hundredNo ratings yet

- Predominance Area DiagramDocument5 pagesPredominance Area Diagramnaresh naikNo ratings yet

- Welding Lecture1 2Document34 pagesWelding Lecture1 2Dr Abhijeet GangulyNo ratings yet

- Business Letter - 1Document4 pagesBusiness Letter - 1Sofyan IrawanNo ratings yet

- Mr. Bharath Gowda Option 2Document6 pagesMr. Bharath Gowda Option 2bharath gowdaNo ratings yet

- 08029ft ASTMDocument3 pages08029ft ASTMmadmaxberNo ratings yet

- Experimental theatre's acoustic design optimizes sound diffusionDocument18 pagesExperimental theatre's acoustic design optimizes sound diffusionrinshaNo ratings yet

- Henry Dee Taking Off Beme For Office Building of 40m October 2016Document257 pagesHenry Dee Taking Off Beme For Office Building of 40m October 2016Henry DiyokeNo ratings yet

- Is 4075Document8 pagesIs 4075Sai PrakashNo ratings yet

- BV206 Composite Rubber Track SystemDocument3 pagesBV206 Composite Rubber Track SystemSsNo ratings yet

- MLS-3750 MLS-3780: Instruction ManualDocument32 pagesMLS-3750 MLS-3780: Instruction Manualfelix bazan100% (1)

- Han Solar and The Green Supply ChainDocument12 pagesHan Solar and The Green Supply ChainSaujanyaNo ratings yet

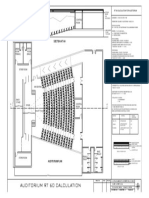

- RT 60 Calculation for AuditoriumDocument1 pageRT 60 Calculation for AuditoriumAniket WayalNo ratings yet

- Solubility ListDocument6 pagesSolubility ListpomegranatesoupNo ratings yet

- Glycerol: Lecture:16 Glycerol Dr. N. K. PatelDocument7 pagesGlycerol: Lecture:16 Glycerol Dr. N. K. PatelEvansChombaNo ratings yet

- Ravi CellDocument45 pagesRavi Cellapi-3725726100% (1)

- Dyeing DefectsDocument12 pagesDyeing DefectsHARRY1765No ratings yet

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- Meltdown: Nuclear disaster and the human cost of going criticalFrom EverandMeltdown: Nuclear disaster and the human cost of going criticalRating: 5 out of 5 stars5/5 (5)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- Chemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastFrom EverandChemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastNo ratings yet

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeRating: 4 out of 5 stars4/5 (9)

- Stuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldFrom EverandStuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldRating: 4 out of 5 stars4/5 (289)

- The Periodic Table: A Very Short IntroductionFrom EverandThe Periodic Table: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (3)

- Chemical Elements Pocket Guide: Detailed Summary of the Periodic TableFrom EverandChemical Elements Pocket Guide: Detailed Summary of the Periodic TableNo ratings yet