Professional Documents

Culture Documents

Bollards Catalogue en V1.3

Uploaded by

loicdertyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bollards Catalogue en V1.3

Uploaded by

loicdertyCopyright:

Available Formats

www.trelleborg.

com/marine

Tee

Horn

Kidney

Bollards

Ref. M1100-S10-V1-3-EN

Section 10

Trelleborg Marine Systems

SO14750_TMS_text.indd 149 13/04/2011 2:48 PM

M1100-S10-V1-3-EN

Trelleborg AB, 2011

102

BOLLARDS

Trelleborg bollards come in many

popular shapes and sizes to suit

most docks, jetties and wharves.

Standard material is spheroidal

graphite (commonly called

SG or ductile iron) which is both

strong and resistant to corrosion,

meaning Trelleborg bollards enjoy a

long and trouble free service life.

The shape of Trelleborg bollards

has been refned with fnite element

techniques to optimize the geometry

and anchor layout. Even at full

working load, Trelleborg bollards

remain highly stable and provide a

safe and secure mooring.

Features

High quality SG iron as standard B

Strong and durable designs B

Very low maintenance B

Large line angles possible B

Standard and custom anchors B

available

Tee Horn Kidney

SO14750_TMS_text.indd 150 13/04/2011 2:48 PM

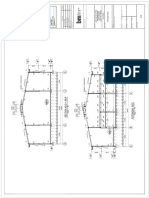

TEE BOLLARDS

M1100-S10-V1-3-EN

Trelleborg AB, 2011

103

[ Units: mm ]

Features

General purpose applications up to 200 tonnes B

Suitable for steeper rope angles B

recommended

line angle

180

P

c

L

c

L

D

G

G

G

L3

L2

L1

F

E

J K

C

B

A

I

seaward side

Dimension

Bollard capacity (tonnes)

15 30 50 80 100 150 200

A 40 40 50 70 80 90 90

B 235 255 350 380 410 435 500

C 340 350 500 550 600 700 800

D 410 450 640 640 790 900 1000

E 335 375 540 550 640 750 850

F 80 100 150 160 175 200 225

G 155 175 250 250 325 350 375

I 160 200 260 280 350 400 450

J 205 225 320 320 395 450 500

K 130 150 220 230 245 300 350

L1 30 30 30 15 10 10 0

L2 45 40 40 36

L3 60 60 60 N/A 80 80 72

Bolts M24 M30 M36 M42 M42 M48 M56

Bolt length 500 500 500 800 800 1000 1000

P* 55 55 65 85 95 105 105

Qty 5 5 5 6 7 7 8

*P = bolt protrusion = recess depth

SO14750_TMS_text.indd 151 13/04/2011 2:48 PM

HORN BOLLARDS

M1100-S10-V1-3-EN

Trelleborg AB, 2011

104

L3

L4

L2

L1

D

E

F

C

I

B

A

J K

G G

c

L

c

L

G

seaward side

recommended

line angle

180

P

Features

General purpose applications up to 200 tonnes B

Suitable for steep rope angles B

Two lines may share a single bollard B

(subject to bollard capacity)

Dimension

Bollard capacity (tonnes)

15 30 50 80 100 150 200

A 40 40 50 70 80 90 90

B 370 410 500 520 570 585 660

C 400 440 600 660 750 850 930

D 410 480 640 650 800 920 1000

E 335 405 540 560 650 770 850

F 80 100 150 160 175 200 225

G 155 175 250 250 325 350 375

I 160 200 260 300 350 400 450

J 205 240 320 325 400 460 500

K 130 165 220 235 250 310 350

L1 30 30 30 15 10 10 0

L2 45 40 40 36

L3 60 60 60 N/A 80 80

L4 36

Bolts M24 M30 M36 M42 M42 M48 M56

Bolt length 500 500 500 800 800 1000 1000

P* 55 55 65 85 95 105 105

Qty 5 5 5 6 7 7 8

[ Units: mm ] *P = bolt protrusion = recess depth

SO14750_TMS_text.indd 152 13/04/2011 2:48 PM

KIDNEY BOLLARDS

M1100-S10-V1-3-EN

Trelleborg AB, 2011

105

D

H

C

E

F

G

L

B

A

J K

I

seaward side

Features

General purpose applications up to 200 tonnes B

Avoid steep rope angles where possible B

Suitable for warping operations B

180

recommended

line angle

P

Dimension

Bollard capacity (tonnes)

15 30 50 80 100 150 200

A 40 40 50 70 70 80 90

B 260 280 320 330 350 405 435

C 340 370 480 530 550 728 800

D 320 360 540 560 590 760 1000

E 320 360 540 460 490 660 850

F 175 250 300

G 175 250 300

F+G 220 260 400 320 350 500 600

H 220 260 400 420 450 600 750

I 160 200 260 280 300 400 450

J 160 180 270 280 295 380 475

K 160 180 270 180 195 280 375

L 50 50 50 50

Bolts M24 M30 M36 M42 M42 M48 M56

Bolt length 500 500 500 800 800 1000 1000

P* 55 55 65 85 85 95 105

Qty 4 4 4 5 7 7 7

[ Units: mm ] *P = bolt protrusion = recess depth

SO14750_TMS_text.indd 153 13/04/2011 2:48 PM

BOLLARD SELECTION

M1100-S10-V1-3-EN

Trelleborg AB, 2011

106

Installation and grout flling requires extra care to avoid

damage to factory applied coatings. Bollards are supplied

as factory standard with a bituminous protective coating

suitable for most projects. High performance epoxy or

other specifed paint systems can be factory applied on

request in a choice of colours and thicknesses.

Protective coatings

Bollards and holding down bolts are designed with a

minimum Factor of Safety against failure of 3.0 for

SG Iron material grade 65-45-12.

Designs are typically based on the following:

BS 5950: 2000 Structural Use of Steelwork

BS 6349 Part 2: 1988 Marine Structures

AS 3990: 1993 Mechanical Equipment Design

Detailed calculations can be supplied on request.

Different factors of safety can be used to suit other

national standards and regulations.

Grey iron Ductile cast iron (SG)

Design

Micro structure

Trelleborg bollards are offered in Spheroidal Graphite Cast

Iron (SG Iron), referred to as Ductile Cast Iron, because of

its superior strength and resistance to corrosion. Ductile

cast iron combines the best attributes of grey cast iron

and cast steel without the disadvantages.

Materials

Ductile cast iron is the preferred material for all bollard

applications. Grey cast iron is cheaper per unit weight,

but the need for thicker wall sections and poor impact

strength outweigh this. Cast steel remains popular in some

countries but needs regular painting to prevent corrosion.

Benefts Disadvantages

Ductile

Cast Iron

(Spheroidal

Graphite)

Lowest service life cost

High strength

Good impact resistance

High corrosion resistance

Grey Cast

Iron

Low cost per weight

Excellent corrosion

resistance

Low strength

Low impact

resistance

Cast Steel

High strength

High impact resistance

Good cost per weight

Regular maintenance

to prevent corrosion

Trelleborg bollards are produced to the highest

specifcations. The table gives indicative standards and

grades but many other options are available on request.

Material specications

Material Standards* Grade(s)*

Ductile Cast Iron

(Spheroidal Graphite Iron)

BS EN 1563

ASTM A 536

EN-GJS-450 or 500

65-45-12 or 80-55-6

Anchor bolts (galvanised) ISO 898

BS 3692

ASTM

Gr 8.8 (galvanised)

Gr 8.8 (galvanised)

A325 (galvanised)

Blasting (standard)

Blasting (high

performance)

N/A

ISO 12944

Sweep blast

SA2.5

Paint (standard)

Paint (high performance)

BS3416

ISO 12944

Black bitumen (1 coat)

Class C5M

* In all cases equivalent alternative standards may apply.

Other high performance paint systems available on request.

Wear and abrasion from ropes means paint coatings need

regular maintenance. Ductile iron bollards are far less

susceptible to corrosion than cast steel bollards, which

can rust quickly and will need frequent painting to retain

full strength.

SO14750_TMS_text.indd 154 13/04/2011 2:48 PM

BOLLARD SELECTION

M1100-S10-V1-3-EN

Trelleborg AB, 2011

107

Mooring loads should be calculated where possible, but

in the absence of information then the following table can

be used as an approximate guideline.

Bollards should be selected and arranged according to

local regulations or recognised design standards. The

design process should consider:

Mooring pattern(s) B

Changes in draft due to loading and discharge B

Wind and current forces B

Swell, wave and tidal forces B

Mooring line types, sizes and angles B

Ice forces (where relevant) B

Displacement Approx. bollard rating

Up to 2,000 tonnes 10 tonnes

2,000 10,000 tonnes 30 tonnes

10,000 20,000 tonnes 60 tonnes

20,000 50,000 tonnes 80 tonnes

50,000 100,000 tonnes 100 tonnes

100,000 200,000 tonnes 150 tonnes

over 200,000 tonnes 200 tonnes

Where strong winds, currents or other adverse loads are

expected, bollard capacity should be increased by 25% or more.

Stern line

After breast

line

Forward breast

line

Spring

lines

Bollards

Head line

Mooring line angles

Mooring line angles are normally calculated as part of

a comprehensive mooring simulation. Standards and

guidelines such as BS6349 : Part 4, ROM 0.2-90 and

PIANC suggest mooring line angles are kept within the

limits given in the table below. In some cases much larger

line angles can be expected.

Trelleborg bollards can cope with horizontal angles of

90 and vertical angles up to 75. Please check with

your local offce about applications where expected line

angles exceed those given in the table as these may need

additional design checks on anchorages and concrete

stresses.

Suggested Line Angles

(BS6349, ROM 0.2-90, PIANC)

Head & stern lines* 45 15

Breast lines* 90 30

Spring lines* 510

Vertical line angle () <30

Low tide

Mean tide

High tide

Low tide

Mean tide

High tide

F

max

F

min

Fully laden case

Light draught case

* Relative to mooring angle

SO14750_TMS_text.indd 155 13/04/2011 2:48 PM

INSTALLATION

M1100-S10-V1-3-EN

Trelleborg AB, 2011

108

Embedded Through Retrot (epoxy

grouted bolts)

D+30

E+30

P

grout

bollard

P

Concrete recess

Fixing options

* refer to dimensions tables

Recessing the bollard is generally recognised as superior

to surface mounting. Recessing the base prevents the

bollard from working loose on its bolts or cracking the

grout bed especially relevant for high use locations.

Bollards must be installed correctly for a long and trouble-

free service life. Anchors should be accurately set out

with the supplied template. Bollards can be recessed (as

shown) or alternatively surface mounted. Once the grout

has reached full strength, anchors can be fully tightened.

Mastic is often applied around exposed threads to ease

future removal.

Quality assurance

Bollards are safety critical items and quality is paramount.

A typical quality documentation package will include:

Dimensioned drawings of bollard and accessories B

Bollard and anchorage calculations (if required) B

Factory inspection report B

Physical properties report for casting B

Installation instructions B

ROM 0.2-90 (1990)

Actions in the Design of Maritime and Harbor Works

BS6349: Part 4 (1994)

Code of Practice for Design of Fendering and Mooring

Systems

PIANC Report of WG24 (1995)

Criteria for Movements of Moored Ships in Harbours

A Practical Guide (1995)

EAU (1996)

Recommendations of the Committee for Waterfront

Structures

PIANC Report of PTC II-30 (1997)

Approach Channels: A Guide for Design (Appendix B

Typical Ship Dimensions)

Ministry of Transport, Japan (1999)

Technical Note No.911 Ship Dimensions of Design Ships

under given Confdence Limits

ROSA Defenses Daccostage (2000)

Recommandations pour Le Calcul Aux Etats-Limitesdes

Ouvrages En Site Aquatique defenses Daccostage

PIANC Report of WG33 (2002)

Guidelines for the Design of Fender Systems (2002)

Codes and guidelines

Fuse bolts available on special request.

SO14750_TMS_text.indd 156 13/04/2011 2:48 PM

PROJECT REQUIREMENTS

M1100-S10-V1-3-EN

Trelleborg AB, 2011

109

PROJECT DETAILS

Port

Project

Designer

Contractor

PROJECT STATUS

TMS Ref:

Preliminary

Detail design

Tender

BOLLARD TYPE Quantity ___________ No. Quantity ___________ No.

Tee Horn Kidney

Capacity/SWL _________t Capacity/SWL _________t

Tee

Horn

Kidney

Tee

Horn

Kidney

VESSEL INFORMATION L

OA

__________________m L

OA

__________________m

Overall length (L

OA

)

Displacement (M

D

)

Deadweight (DWT)

M

D

__________________m M

D

__________________m

DWT _________________t DWT _________________t

OTHER INFORMATION FURTHER DETAILS AVAILABLE FROM

Name

Position

Company

Tel

Fax

Email

LINE ANGLE

Min _______________ deg Max _______________ deg

Min _______________ deg Max _______________ deg

MOUNTING

Recessed Surface

Recessed

Surface

Recessed

Surface

SO14750_TMS_text.indd 157 13/04/2011 2:48 PM

SO14750_TMS_text.indd 158 13/04/2011 2:48 PM

You might also like

- APPENDIX C Worked ExampleDocument20 pagesAPPENDIX C Worked Examplenorsam1511No ratings yet

- @ - Breakwater Foundation StabilityDocument9 pages@ - Breakwater Foundation Stabilityapi-3709579100% (1)

- FenderTeam Product CatalogueDocument67 pagesFenderTeam Product Cataloguejukkajee26No ratings yet

- Do 050 S2007-Mse SpecsDocument12 pagesDo 050 S2007-Mse SpecsCarol SantosNo ratings yet

- Dam Foundation Treatment: GroutingDocument27 pagesDam Foundation Treatment: GroutingZeleke TaimuNo ratings yet

- Polish Maritime ResearchDocument32 pagesPolish Maritime ResearchparatonerqNo ratings yet

- Coastal Shoreline Defence StructuresDocument19 pagesCoastal Shoreline Defence StructuresdjajadjajaNo ratings yet

- Sea Level RiseDocument14 pagesSea Level RiseVivek ParsekarNo ratings yet

- Tables Design Tables and EquationsDocument23 pagesTables Design Tables and Equationsامين الزريقيNo ratings yet

- Empirical Equations For Deformation Capacity of Conventional RC Shear WallsDocument12 pagesEmpirical Equations For Deformation Capacity of Conventional RC Shear WallsCarsonBakerNo ratings yet

- Extension of Existing Quay Wall - ACRPS - Cadiz - SpainDocument4 pagesExtension of Existing Quay Wall - ACRPS - Cadiz - SpainIgnatius SamrajNo ratings yet

- Rock Riprap Design Methods and Their Applicability To Long-Term Protection of Uranium Mill Tailings ImpoundmentsDocument98 pagesRock Riprap Design Methods and Their Applicability To Long-Term Protection of Uranium Mill Tailings ImpoundmentsAhmed Samir SalimNo ratings yet

- Manual HS 2023 - BS VersionDocument416 pagesManual HS 2023 - BS VersionSander KosterNo ratings yet

- Derrick LighterDocument2 pagesDerrick Lighterhessian123No ratings yet

- PIANC Bulletin116aDocument12 pagesPIANC Bulletin116aIgnatius SamrajNo ratings yet

- Steel Sheet Piles Ing.D.Kohnen-DK PDFDocument33 pagesSteel Sheet Piles Ing.D.Kohnen-DK PDFSaravanan MuthuramanNo ratings yet

- Emr 2411 Lecture Notes 1Document27 pagesEmr 2411 Lecture Notes 1yassinNo ratings yet

- Column - Pile Design PDFDocument3 pagesColumn - Pile Design PDFPriodeep ChowdhuryNo ratings yet

- Wave Runup and Overtopping Over Structur PDFDocument25 pagesWave Runup and Overtopping Over Structur PDF허윤호No ratings yet

- Key Points On Design and Construction For The Replacement of Jetty A Boat Pens at Geraldton, WADocument3 pagesKey Points On Design and Construction For The Replacement of Jetty A Boat Pens at Geraldton, WAMadhu KumarNo ratings yet

- Report Group 2Document40 pagesReport Group 2Ignatius SamrajNo ratings yet

- RC Simple Notions of Moment DistributionDocument136 pagesRC Simple Notions of Moment Distributionامين الزريقيNo ratings yet

- Harbour Works (Break Water) 15. - 17.01.2023 PDFDocument50 pagesHarbour Works (Break Water) 15. - 17.01.2023 PDFFahim ShahriarNo ratings yet

- Master Thesis Arjan GalemaDocument72 pagesMaster Thesis Arjan GalemaAnonymous PibYPghNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- TocDocument8 pagesTocdikiNo ratings yet

- M21MT SciDocDocument42 pagesM21MT SciDocAhmad Safii MaarifNo ratings yet

- Quay Wall Bottom Protection PDFDocument12 pagesQuay Wall Bottom Protection PDFdndudcNo ratings yet

- 10 Stability of SlopesDocument18 pages10 Stability of Slopesامين الزريقيNo ratings yet

- Chapter 10. Hydraulic Failure 185Document1 pageChapter 10. Hydraulic Failure 185Yasonsky CaptainNo ratings yet

- Retaining Wall DesignDocument12 pagesRetaining Wall Designhellios8502100% (1)

- SeismicWavesLab 2017 IA RDocument6 pagesSeismicWavesLab 2017 IA Rishtiaque_anwarNo ratings yet

- 2012 Design Piers&Wharves Loads PDFDocument175 pages2012 Design Piers&Wharves Loads PDFran2315570No ratings yet

- Crest Modifications To Reduce Wave OvertDocument20 pagesCrest Modifications To Reduce Wave OvertDinar IstiyantoNo ratings yet

- SDRT Coastal Activity FINALDocument33 pagesSDRT Coastal Activity FINALCoastNet91% (11)

- Wave Attenuators Info PDFDocument32 pagesWave Attenuators Info PDFMicah Ironfalcon ArceñoNo ratings yet

- CEM Part-I Chap-1Document5 pagesCEM Part-I Chap-1Ignatius SamrajNo ratings yet

- Brochure Ej BeanDocument5 pagesBrochure Ej Beanipman99No ratings yet

- Floating Dolphins Floating Dolphins Floating Dolphins: 650.01 GeneralDocument12 pagesFloating Dolphins Floating Dolphins Floating Dolphins: 650.01 GeneralsivakumarNo ratings yet

- Quay Walls - Combined - Wall - Buckling - TubesDocument12 pagesQuay Walls - Combined - Wall - Buckling - TubesHugo LeiteNo ratings yet

- IS 4651 (Part 2) Ports & Harbours (For Earth Pressure Coefficients) PDFDocument12 pagesIS 4651 (Part 2) Ports & Harbours (For Earth Pressure Coefficients) PDFRoshanRSVNo ratings yet

- Looe Marina Presentation GROUP 2Document33 pagesLooe Marina Presentation GROUP 2Thomas ClarkNo ratings yet

- Introduction To Coastal Engineering 2010 - 2011: Unesco-IheDocument4 pagesIntroduction To Coastal Engineering 2010 - 2011: Unesco-IheDora LeNo ratings yet

- Pile Hammer SizingDocument3 pagesPile Hammer SizingIsabelle WongNo ratings yet

- Pavement TypesDocument20 pagesPavement TypesAnonymous 9iK0i8h0dPNo ratings yet

- Anticipated Sea-Level Rise Coastal Louisiana Technical Report Version 1.4Document121 pagesAnticipated Sea-Level Rise Coastal Louisiana Technical Report Version 1.4PaleogeneNo ratings yet

- Catalog Rakuna IVDocument8 pagesCatalog Rakuna IVJia Hann TanNo ratings yet

- Company Profile and Marine Guide - SILI PUMPDocument5 pagesCompany Profile and Marine Guide - SILI PUMPArrijal PratamaNo ratings yet

- PT Skema Energi Asia - Company Profile - Feb 2015Document7 pagesPT Skema Energi Asia - Company Profile - Feb 2015Gazali Ali100% (1)

- Final - Report - Part - 2 Breakwater EngineeringDocument76 pagesFinal - Report - Part - 2 Breakwater EngineeringBinSayeedNo ratings yet

- Blog Mechguru Com Machine Design Example of Concrete Anchor Bolt Design Calculation Part 6 Determining Concrete Breakout Strength of Anchor in ShearDocument7 pagesBlog Mechguru Com Machine Design Example of Concrete Anchor Bolt Design Calculation Part 6 Determining Concrete Breakout Strength of Anchor in ShearJoel TanNo ratings yet

- IS-4651 Part-3-1974Document31 pagesIS-4651 Part-3-1974Seetharam MahanthiNo ratings yet

- FenderTeam Product-Catalogue EnglishDocument100 pagesFenderTeam Product-Catalogue EnglishRodrigo Toro PavezNo ratings yet

- Beach NourishmentDocument16 pagesBeach NourishmentdodoNo ratings yet

- Bridge Manual Retaining Walls - Section 3.62 Page 3.2-2Document1 pageBridge Manual Retaining Walls - Section 3.62 Page 3.2-2lomoscribdNo ratings yet

- Design of Durbale Prestressed Concrete For Dabhol TrestleDocument10 pagesDesign of Durbale Prestressed Concrete For Dabhol TrestleKalipada SenNo ratings yet

- Report119 - Part5 of 5 InspectionsDocument11 pagesReport119 - Part5 of 5 InspectionshjdNo ratings yet

- S 08 Potongan As C, d,9 ModelDocument1 pageS 08 Potongan As C, d,9 Modelrofiqq4No ratings yet

- S-10 Detail Sambungan Baja-ModelDocument1 pageS-10 Detail Sambungan Baja-Modelrofiqq4No ratings yet

- Price KitazawaDocument9 pagesPrice Kitazawarofiqq4No ratings yet

- Jotun Thinner No. 10Document1 pageJotun Thinner No. 10rofiqq4No ratings yet

- 2012 Chem E Car Job Safety Form For IHLDocument13 pages2012 Chem E Car Job Safety Form For IHLrofiqq4No ratings yet