Professional Documents

Culture Documents

Operation Management Workbook For Students

Operation Management Workbook For Students

Uploaded by

lravi4uOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operation Management Workbook For Students

Operation Management Workbook For Students

Uploaded by

lravi4uCopyright:

Available Formats

Operations Management

2

nd

Edition

WORKBOOK

Icfai Center for Management Research

Road # 3, Banjara Hills, Hyderabad 500 034

ISBN 81-314-1126-5

Ref. No. OM WB 03 2K7 35

For any clarification regarding this book, students may please write to Icfai giving the above

reference, and page number.

While every possible care has been taken in preparing this book, Icfai welcomes suggestions

from students for improvement in future editions.

Icfai, March 2007. All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, used

in a spreadsheet, or transmitted in any form or by any means electronic,

mechanical, photocopying or otherwise without prior permission in writing from

Icfai.

Operations Management (2

nd

Edition) Workbook

Contents

Part A

Multiple Choice Questions 3-67

Multiple Choice Answers and Explanations 71-136

Part B

Paper I

Paper I Model Test 1 139-148

Paper I Model Test 2 149-159

Paper I Model Test 1 Answers and Explanations 163-172

Paper I Model Test 2 Answers and Explanations 173-184

Paper II

Paper II Model Test 1 187-196

Paper II Model Test 2 197-207

Paper II Model Test 1 Answers and Explanations 211-221

Paper II Model Test 2 Answers and Explanations 222-231

iv

Detailed Contents

Part One: Introduction to Operations Management

1. OPERATIONS MANAGEMENT AN OVERVIEW

Operations Management Decisions

The Historical Evolution of Operations Management

Computers and Advanced Operations Technology

2. OPERATIONS STRATEGY

Operations Strategy as a Competitive Weapon

Elements of Operations Strategy

Developing an Operations Strategy

Financial and Economic Analysis in Operations

3. FORECASTING DEMAND

Forecasting in Operations

Forecast Components

Demand Forecasting Process

Forecasting Methods

Selecting a Forecasting Method

Measures of Forecasting Accuracy

Monitoring and Controlling Forecasts

Part Two: Design of Facilities and Jobs

4. ALLOCATING RESOURCES TO STRATEGIC ALTERNATIVES

Allocation Decisions in Operations Strategy

Linear Programming in Operations Management

Formulation of Linear Programming Problems

Solution of Linear Programming Problems

The Transportation Problem in Linear Programming

5. DESIGN OF PRODUCTION PROCESSES

Process Planning and Design

Major Factors Affecting Process Design Decisions

Types of Process Designs

Process Planning Aids

Selecting the Type of Process Design

v

6. FACILITY LOCATION AND LAYOUT

Importance of Location

Factors Affecting the Location Decisions

General Steps in Location Selection and Location Decision Process

Location Evaluation Methods

Locating Service Facilities

Facility Layout

Basic Layout Formats

Developing a Process Layout

Developing a Product Layout

Developing a Cellular Manufacturing Layout

Japanese Approaches and Trends in Manufacturing Layouts

Service Facility Layouts

7. JOB DESIGN

Job Design Fundamentals

Considerations in Job Design

Work Environment

Uses of Job Design

8. WORK MEASUREMENT

Uses of Setting Work Standards

Work Measurement Techniques

Part Three: Operations Planning and Control

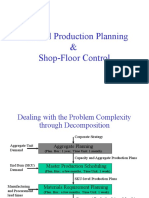

9. AGGREGATE PLANNING AND CAPACITY PLANNING

Overview of Planning Activities

The Aggregate Planning Process

Strategies for Developing Aggregate Plans

Aggregate Planning Techniques

Master Production Schedule

Implementing Aggregate Plans and Master Schedules

Capacity Planning

10. FUNDAMENTALS OF INVENTORY CONTROL

Purpose of Inventories

Inventory Costs

Inventory Systems

Economic Order Quantity Model

Inventory Classifications Models

vi

11. PURCHASE MANAGEMENT

Importance of Purchasing

Organizing Purchasing

Responsibilities of a Purchasing Manager

Purchasing Process

Duties of Buyers

Make-or-Buy Decisions

Ethics in Buying

12. MATERIALS MANAGEMENT

Necessity of Materials Management

Functions of Materials Management

Materials Management Technology

Materials Management Techniques

13. MATERIALS REQUIREMENT PLANNING

Fundamentals of Materials Requirement Planning

Components of an MRP System

Advantages and Disadvantages of an MRP System

Problems in Implementing MRP Systems

Manufacturing Resource Planning (MRP II)

14. OPERATIONS SCHEDULING

Purpose of Scheduling

Scheduling Methods

Scheduling Activities

Scheduling by Type of Operations

Scheduling Personnel in Service Operations

Scheduling Techniques

15. ENTERPRISE RESOURCE PLANNING

Evolution of ERP

Business Process Reengineering

Business Modeling for ERP

ERP Implementation

ERP and Competitive Advantage

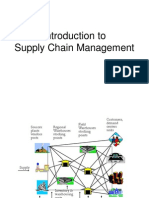

16. SUPPLY CHAIN MANAGEMENT

Business Drivers in Supply Chain Performance

Principles of Supply Chain Management

Forces Shaping Supply Chain Management

Supply Chain Management Framework

Customer Focus in Supply Chain Management

Electronic Supply Chain Management

vii

17. JUST-IN-TIME (JIT) MANUFACTURING SYSTEM

The Concept of the JIT System

Advantages of JIT Systems

Characteristics of JIT Systems

18. PRODUCTIVITY AND QUALITY MANAGEMENT

Productivity

The Strategic Role of Quality

Role of Inspection in Quality Control

The Cost of Quality

Statistical Concepts in Quality Control

Computers in Quality Control

Concept of TQM

19. FACILITIES AND MAINTENANCE MANAGEMENT

Facilities Management

Necessity of Maintenance Management

Types of Maintenance

Economics of Maintenance

Evaluation of Preventive Maintenance Policies

Maintenance Planning

Modern Approaches to Preventive Maintenance

Recent Trends in Maintenance

20. PROJECT MANAGEMENT

Necessity of Project Management

Network Modeling

Project Planning Methods

Project Crashing

Part Four: Technology and Globalization in Operations Management

21. TRENDS IN OPERATIONS TECHNOLOGY

Automation

Overview of Manufacturing Activities

Artificial Intelligence (AI)

Electronic Data Interchange (EDI)

22. GLOBALIZATION AND OPERATIONS MANAGEMENT

Significance of Globalization

Sources of Global Competitive Advantage

Difficulties in Managing Globalization

Changes in Operations Strategy Necessary due to Globalization

Managing Globalization

Operations in Global Business Strategy

Part A Multiple Choice Questions: Relevant Chapters

Chapters Title Multiple Choice Questions

Chapter 1 Operations Management An Overview 1-16

Chapter 2 Operations Strategy 17-40

Chapter 3 Forecasting Demand 41-86

Chapter 4 Allocating Resources to Strategic Alternatives 87-113

Chapter 5 Design of Production Processes 114-140

Chapter 6 Facility Location and Layout 141-186

Chapter 7 Job Design 187-200

Chapter 8 Work Measurement 201-216

Chapter 9 Aggregate Planning and Capacity Planning 217-243

Chapter 10 Fundamentals of Inventory Control 244-278

Chapter 11 Purchase Management 279-300

Chapter 12 Materials Management 301-333

Chapter 13 Materials Requirement Planning 334-360

Chapter 14 Operations Scheduling 361-408

Chapter 15 Enterprise Resource Planning 409-425

Chapter 16 Supply Chain Management 426-443

Chapter 17 Just-In-Time (JIT) Manufacturing System 444-460

Chapter 18 Productivity and Quality Management 461-493

Chapter 19 Facilities and Maintenance Management 494-529

Chapter 20 Project Management 530-557

Chapter 21 Trends in Operations Technology 558-582

Chapter 22 Globalization and Operations Management 583-600

This section consists of multiple-choice questions that test the students

understanding of the basic concepts discussed in the textbook. Answering these

questions will help students quickly recollect the theories theyve learnt and apply

them to real-life business situations.

Part A: Multiple Choice Questions

1. On the basis of Hawthorne studies, Elton

Mayo and his team concluded that

________had a major impact on employee

productivity.

a. Physical work conditions

b. Importance and recognition given to

employees

c. Job content

d. Fear of losing job

2. Which company first adopted the concept

of scientific management in the assembly

line production system?

a. General electric

b. Ford motors

c. General motors

d. Westinghouse

3. The computerization of operations began

when the first computer was installed in

General Electric Appliance Park in 1954.

What was the basic objective of computer

applications then?

a. Reducing manpower

b. Reducing clerical costs

c. Enhancing worker safety

d. Increasing production

4. Operations management involves the

functions of planning, organizing,

controlling etc, in production systems. The

activity of encouraging employees through

praise, recognition and other intangibles is

part of which function?

a. Controlling

b. Motivating

c. Coordinating

d. Organizing

5. Decisions on production and process

design, facility location and layout etc, are

part of which decision category?

a. Strategic decisions

b. Tactical decisions

c. Operational decisions

d. All of the above

6. Which of the following decision do not

fall within the basic scope of operations

management?

a. Analyzing the firms financial position

b. Designing a new assembly line

c. Determining the location of a new

distribution center

d. Improving product quality

7. Division of labor or specialization is an

outcome of ____________.

a. Industrial revolution

b. World War II

c. Scientific management

d. Computerization of production systems

8. The decision of an operations manager

about what products to make and when is

part of which function?

a. Organizing

b. Directing

c. Planning

d. Coordinating

9. The decisions that operations managers

take can be broadly classified into various

categories. What is the usual time-frame

for tactical decisions?

a. Seven years or more

b. One or two years

c. Two to four months

d. A couple of weeks

10. Operations Management deals with which

of the following?

a. Design of products

b. Design of services

c. Acquisition of resources

d. All of the above

11. Operations Management involves the

activities of planning, organizing,

controlling, directing, and coordinating in

production systems. These systems convert

resource inputs into products or services.

Centralization and/or decentralization of

operations fall under which of the

following activities?

Part A: Multiple Choice Questions

Operations Management

4

a. Planning

b. Organizing

c. Directing

d. Controlling

12. The term Production Management was

replaced by a more general term

Operations Management in the 1970s.

What led to the enlargement of the field

and use of the new term?

i. Inclusion of purchasing function

ii. Inclusion of dispatch and other related

activities

iii. Inclusion of services related concepts and

procedures

iv. Inclusion of manufacturing technologies

a. i, ii, iii

b. iii, iii, iv

c. i, iii, iv

d. i, ii, iii, iv

13. Operations Research uses mathematical

techniques to solve complex problems.

When was the concept of operations

research first introduced?

a. In the early 1940s during World War II

b. In the late 1920s during Hawthorne studies

c. In 1911 for the moving assembly line

production by Ford

d. In the 1880s at Midvale Steel Works

14. Who was involved in the Hawthorne

experiments at the Western Electric plant?

a. Frederick Taylor

b. Henry Ford

c. Elton Mayo

d. Adam Smith

15. Which of the following technologies helps

perform tasks that are repetitive or

hazardous for a human being to perform?

a. CAD

b. FMS

c. Expert systems

d. Moving assembly line

16. Computerization has significantly

improved the production process. Which

of the following is not an advantage of

computerization in the production process?

a. Rise in quality of products

b. Reduction in labor costs

c. Higher maintenance costs

d. Greater efficiency of the production

process

17. Which of the following are among the key

objectives of an operations manager?

i. Maximizing customer satisfaction

ii. Minimizing inventory

iii. Maximizing resource utilization

a. i & ii

b. ii & iii

c. i & iii

d. i, ii & iii

18. Product design is one of the factors that an

operations manager must consider while

designing a production system. Product

design can be based on a customized or a

standard production design system. What

does a customized product design system

primarily focus on?

a. Quality and on-time delivery

b. Reducing costs

c. Costs and quality

d. Mass production

19. Which of the following is not categorized

among indirect costs?

a. Administrative costs

b. Maintenance costs

c. Labor costs

d. Rentals

20. Who generally develops corporate

objectives that are unique to each

organization?

a. Frontline managers

b. Top-level managers

c. Middle level managers

d. Production supervisors

21. What factors must managers consider

while formulating corporate objectives?

a. Market conditions

b. Political environment

c. Economic environment

d. All of the above

Part A

5

22. Rainbow Electronics manufactures a

limited number of models of television

sets. What kind of product design system

does the company have?

a. Customized production design

b. Standardized product design

c. Stock-to-order

d. Assemble-to-order

23. Feasibility studies are part of the new

product development process. The

feasibility test generally focuses on which

of the following aspects?

i. Technical feasibility

ii. Marketing feasibility

iii. Economic feasibility

iv. Production feasibility

a. i & ii

b. ii & iii

c. i & iii

d. iii & iv

24. Large organizations are often divided into

separate operating divisions that operate as

autonomous business units with

independent control. What are such units

called?

a. Subsidiary units

b. Strategic business units

c. Franchise centers

d. Sister concerns

25. Nucor, a steel producer, competes

successfully with larger integrated steel

producers by processing steel scrap rather

than producing steel from iron ore. What

advantage does the company gain through

this kind of production process?

a. Production flexibility

b. Better quality

c. Lower costs

d. Batch process facility

26. Selecting product design, production

system, and inventory policy for finished

goods fall under which component of

operations strategy?

a. Designing the production system

b. Product/service design and development

c. Technology selection and process

development

d. Allocation of resources to strategic

alternatives

27. Which among the following products are

generally customized as per user

requirements?

i. Industrial boilers

ii. Turbines

iii. Televisions

iv. Ceiling fans

a. i and ii

b. ii and iii

c. iii and iv

d. iv and i

28. Which stage of the product life cycle is

characterized by exponential growth of

sales volume?

a. Introduction stage

b. Growth stage

c. Maturity stage

d. Decline stage

29. Pick the statement that pertains to the

relationship between the role of operations

department and the product life cycle.

a. The role of operations department

increases as the product moves up the

lifecycle

b. The role of operations department

decreases as the product moves up the

lifecycle

c. There is no change in the role of

operations department across the lifecycle

d. The role of operations department

increases or decreases as the product

moves up the lifecycle

30. What is the basic use of a prototype during

the new product development process?

a. A prototype is used to test the technical

and economical feasibility

b. A prototype helps test the product

performance under standard conditions

c. A prototype is developed as part of test

marketing

d. None of the above

Operations Management

6

31. Availability of raw materials and nearness

to markets are some of the factors that are

considered while making decisions

regarding plant location. Which

component of operations strategy deals

with decisions such as plant location?

a. Allocation of resources to strategic

alternatives

b. Technology selection and process

development

c. Product design and development

d. Facility planning

32. Developing an operations strategy is an

important function of an operations

manager. The operations strategy should

basically be in accordance with which of

the following?

a. Organization strategy

b. Marketing strategy

c. Competitor strategy

d. Both a and c

33. How is strategic planning different from

operations planning?

a. Strategic planning is concerned with long-

term planning while operational planning

involves short-term day-to-day planning

b. Strategic planning is concerned with short-

term day-to-day planning while

operational planning involves long-term

planning

c. Operational planning involves selection of

target markets and distribution channels

d. Both strategic planning and operational

planning are long-term in nature

34. Which of the following is not a

characteristic of operations strategy?

a. It should be fixed so as to support a

product through its entire lifecycle

b. It should accommodate future changes in

market demand

c. It should focus on having short-term

operational superiority over competitors

d. It should be consistent with strategies in

other functional areas such as marketing,

finance and human resources

35. HDFC Bank offers deposits, loans,

insurance products, mutual funds, trading

in stocks, etc, under one roof and positions

itself as a financial supermarket. Which

type of competitive advantage strategy

does the bank seek to focus on?

a. Quality

b. Product variety

c. Convenience

d. Low cost

(Questions 36 to 39) The given data below

shows the initial investment of three projects

and their payback periods. Use this data to

answer the following four questions.

Project Initial

investment

Expected annual

income from the

project

A Rs.10,00,000 Rs.2,00,000

B Rs.12,00,000 Rs.2,50,000

C Rs.8,00,000 Rs.1,50,000

36. Calculate the payback period for Project A

a. 5 years

b. 4 years

c. 3 years

d. 6 years

37. What is the payback period for Project B?

a. 5.0 years

b. 4.8 years

c. 3.8 years

d. 4.5 years

38. Calculate the payback period for Project C.

a. 5.0 years

b. 4.8 years

c. 5.3 years

d. 4.5 years

39. Based on the results for product A, B and

C, which is the best investment in terms of

faster returns?

a. Project A

b. Project B

c. Project C

d. Either project A or C

40. Allocation of resources to strategic

alternatives is a component of operations

strategy. What is the main objective of this

component?

a. To minimize efficiency

b. Optimize the use of resources for best

strategic use

Part A

7

c. Ensure capacity expansion

d. Maintain proximity to resources

41. Demand for a commodity is most likely to

depend upon which of the following?

i. The price of the commodity

ii. The prices of the available complimentary

goods

iii. The customer tastes and preferences

iv. Price of substitutes

a. i and ii

b. ii and iii

c. i, ii, and iii

d. i, ii, iii, and iv

42. _________is the ability of an organization

to adjust quickly to true changes in the

base level of demand.

a. Stability

b. Responsiveness

c. Repetitiveness

d. Controlling

43. The numerical difference between forecast

demand and actual demand is called

___________.

a. Standard deviation

b. Forecast error

c. Forecast variance

d. Forecast noise

44. A forecast made by using exponential

smoothing was found to be over-optimistic

to the most recent trends in demand.

Which of the following is the most suitable

corrective action possible to make the

forecast more realistic?

a. Increase the value of

b. Decrease the value of

c. Shift to some other forecasting method

d. Ensure that remains constant

45. If the demand for a product is stable and is

representative of the future, what should

be the value of used to forecast the

demand for the product?

a. Low

b. High

c. Medium

d. Can take any value

46. Organizations generally use demand

forecasts to develop which of the

following plans?

a. Financial plans

b. Facilities plans

c. Marketing plans

d. All of the above

47. Which of the following methods is

judgmental and subjective in nature and

based on the estimates and opinions of

individuals?

a. Time series methods

b. Delphi method

c. Exponential smoothing

d. Regression analysis

48. Which of the following statements is not

true about demand?

a. Dependent demand is forecasted

b. If a manufacturer produces tires, the

demand for the tires is a dependent

demand

c. MRP systems help determine demand for

items with dependent demand

d. Exponential smoothing is used to

determine independent demand

49. Which of the following statements about

demand forecasting is not true?

a. Forecasts are more accurate for shorter

time horizons

b. Regression analysis produces more

accurate forecasts than moving average

c. A 6-month moving average forecast is

more accurate than a 3-month moving

average forecast

d. Forecasts are created using only

quantitative data

50. Identify the statistical techniques that use

historical data collected over a period of

time to predict future demand.

a. Time-series methods

b. Qualitative methods

c. Nonparametric methods

d. Causal methods

Operations Management

8

51. Which of the following is not considered

by operations managers before selecting a

method for forecasting the future demand?

a. Cost and accuracy

b. Data availability

c. Projected time span

d. Plant capacity

52. Which of the following measures provide

information on the extent of forecast error

in relative terms?

a. Mean absolute deviation

b. Mean square error

c. Mean forecast error

d. Mean absolute percentage error

53. Which of the following decisions

undertaken by operations managers does

not generally require long-range forecast?

a. Capacity planning

b. New product development

c. Spare parts inventory

d. Capital funds

54. Demand for a product is influenced by

many factors. Which of the following is

not a factor that influences product

demand?

a. Price of the product

b. Price of the substitutes

c. Income levels of the consumers

d. Extent of accuracy of demand forecasts

55. Which of the following is not a

consequence of underestimation of

demand?

a. Increase in supply lead time

b. Increase in loss of orders

c. Increase in customer switching

d. Increased locking up of working capital as

inventory

56. Which of the following demand estimates

are very detailed and used to plan and

schedule production operations?

a. Short-term demand

b. Medium-term demand

c. Long-term demand

d. All of the above

57. Raw materials demand forecast is derived

from which of the following type of

forecast?

a. Short-term demand forecast

b. Aggregate product demand forecast

c. Labor demand forecast

d. All of the above

58. Forecasting demand has a direct impact on

which of the following two functions of

management.

a. Planning and organizing

b. Directing and control

c. Organizing and staffing

d. Planning and controlling

59. In Delphi method, independent opinions

and predictions are made by a panel of

experts and summarized by a competent

mediator. The success of this method is

not dependent on which of the following?

a. The presence of a socially dominant

individual

b. The geographical distance between the

experts

c. Tendency towards groupthink

d. Competency of coordinator

60. The demand for generator sets for twelve

consecutive months from January to

December is given as 78, 80, 85, 82, 84,

85, 87, 88, 86, 89, 86, 87. Calculate the

approximate demand for January of the

next year using the simple moving

averages method. Assume the time period

to be a six month moving average.

a. 82

b. 83

c. 86

d. 87

61. The sum of weights used in weighted

moving average method should be equal to

_________.

a. 1

b. 10

c. 100

d. Zero

62. How are weights in the weighted moving

average method calculated?

Part A

9

a. Simple moving average method

b. Future forecast

c. Trial & error

d. Exponential smoothing

63. Which of the following forecasting

methods are used when the demand for a

product is influenced by seasonal

tendencies?

a. Delphi method

b. Simple moving average method

c. Exponential smoothing

d. All of the above

64. Which of the following is not a benefit

that an operations manager gains when

using the exponential smoothing method?

a. Easy availability of standard software

packages

b. Less computational requirements

c. Larger data storage space

d. Greater accuracy in forecasts

65. Maximum weightage is given in the

exponential smoothing method for demand

values in which of the following time

periods?

a. Latest time period

b. Earliest time period

c. Average of latest and oldest time periods

d. Sum of latest and oldest time periods

66. What is the formula for calculating the

weighted moving average?

a. WMA

t

=

=

n

1 t

t t

A C

b. WMA

t+1

=

=

n

1 t

t t

A C

c. WMA

t+1

=

+

=

1 n

1 t

t t

A C

d. WMA

t-1

=

=

1 - n

1 t

t t

A C

67. Why is the constant used in exponential

smoothing method?

i. To show effects of past demand

ii. To smooth out the effects of any noise

iii. To predict future trends in demand

a. Only i

b. Only ii

c. i and ii

d. i, ii, and iii

68. In the equation Y = a + bX, what is a

termed as?

a. Value of the dependent variable

b. Value of the independent variable

c. Slope of the line

d. Y intercept or constant value

69. What is the relation between the slope of

the line and the trend line in regression

analysis?

a. If the slope is positive, then the trend line

increases positively

b. If the slope is positive, then the trend line

decreases negatively

c. There is no relationship between the slope

and the trend line

d. If the slope is negative, then the trend line

increases positively

70. If the sales of a refrigerator model rose

from 15000 units to 20000 units between

two consecutive time periods due to 5%

increase in advertising expenditure. What

is the value of the slope?

a. 33.33

b. 6.67

c. 3.33

d. 250

71. Short-range decisions vary from

purchasing, job scheduling, and project

assignment to machine scheduling. Which

of the following forecasting methods can

be used for such decisions?

a. Exponential smoothing

b. Linear regression analysis

c. Multiple regression analysis

d. Delphi method

72. Identify the forecasting method that can be

used when data collection proves very

expensive.

a. Moving averages method

b. Delphi method

Operations Management

10

c. Regression analysis

d. Exponential smoothing

73. Which of the following forecasting

methods give 100% accurate forecasts?

a. Qualitative methods

b. Time series methods

c. Causal methods

d. None of the above

74. Identify the relationship between cost of

forecasting and accuracy of forecasting.

a. Cost is directly proportional to extent of

accuracy

b. Cost is indirectly proportional to extent of

accuracy

c. Accuracy is independent of costs

d. Cost is inversely proportional to extent of

accuracy

(Questions 75 to 79) Use the data given in the

table below to answer the following five

questions related to forecast errors.

Demand Forecast Actual Demand

500 510

510 510

520 515

540 550

550 545

75. Calculate the Mean Absolute Deviation

(MAD).

a. 5

b. 6

c. 30

d. 20

76. The Mean Square Error (MSE) for the

given data is ______________.

a. 250

b. 100

c. 50

d. 75

77. Calculate the mean forecast error.

a. 2

b. 10

c. 7

d. 5

78. Mean Absolute Percentage Error (MAPE)

for the given data is __________.

a. 5.72

b. 3.14

c. 1.14

d. 2.56

79. Calculate the Tracking Signal (TS).

a. 1.67

b. 2.67

c. 3.67

d. 4.67

80. For forecasting purposes, firms need to

take into consideration various factors or

components. Which of the following is

associated with average sales over a given

period of time?

a. Trend component

b. Seasonal component

c. Cyclical component

d. Base demand

81. The demand for luxury products may be

linked with the business cycle, as sales

usually increase during the boom phase

and slow-down during recession. What

component of forecasting is described

here?

a. Trend component

b. Seasonal component

c. Cyclical component

d. Base demand

82. When LG increased the advertising budget

by 40%, the sales of its televisions

doubled. On this basis, LG prepared an

aggressive demand forecast for the next

year. What component of demand did LG

consider as part of its forecast?

a. Cyclical component

b. Promotional component

c. Trend component

d. Irregular component

83. Which of the following is an example of

the trend component of forecast?

Part A

11

a. The demand for gold has reduced as the

price of gold has increased

b. The promotional expenditure of Airtels

GSM service was hiked based on demand

forecast

c. The demand for camera mobile phones in

India has increased steeply since 2001

d. The demand for wrist watches has been

fluctuating for quite some time

84. Identify the correct sequence of steps taken

as part of the demand forecasting process.

a. Identify influencing factors understand

objectives identify customer segments

select forecasting technique

b. Identify influencing factors identify

customer segments understand objectives

select forecasting technique

c. Identify customer segments understand

objectives identify influencing factors

select forecasting technique

d. Understand objectives identify

influencing factors identify customer

segments select forecasting technique

85. Which of the following demand

forecasting techniques is divided into static

and adaptive methods?

a. Qualitative methods

b. Time series methods

c. Causal methods

d. All of the above

86. Trend and seasonal components play an

important role in demand forecasting. In

which of the following forecasting

methods are estimates of trend and

seasonal components assumed to not vary

from year to year?

a. Exponential smoothing

b. Static forecasting method

c. Regression analysis

d. Simple moving average

87. Constrained optimization models are

useful techniques enabling operations

managers to compute the amount of

resources to be allocated to each strategic

alternative. Which of the following is not a

benefit of using a constrained optimization

model?

a. Feasible solutions are reduced to

manageable numbers

b. Provides optimal solution for the whole

organization

c. Enables decision-makers to perform what-

if analysis

d. Provides optimal solutions that are always

practical

88. Constrained optimization models consist

of three major components. Which of the

following is not a component of these

models?

a. Decision variables

b. Nature of demand

c. Objective functions

d. Constraints

89. Linear programming is a mathematical

constrained optimization model used to

maximize or minimize the linear functions

of a large number of variables, subject to

certain constraints. Linear programming

cannot help obtain solutions for which of

the following?

a. Profitability

b. Cost effectiveness

c. Motivation

d. Productivity

90. Identify the term that describes the

solution satisfying all the restrictions of a

linear programming problem.

a. Initial solution

b. Basic solution

c. Feasible solution

d. Final solution

91. In linear programming, a statement such as

the number of labor hours available is

600 is identified as a ___________.

a. Constraint

b. Slack variable

c. Objective function

d. Decision variable

92. Identify the mathematical technique used

to determine the optimal utilization of

resources in an organization.

Operations Management

12

a. Exponential smoothing

b. Regression analysis

c. Linear programming

d. Decision tree analysis

93. When arriving at production plan decisions

by using linear programming, which of the

following is not considered a constraint?

a. Market

b. Capacity

c. Destination requirements

d. Inventory space

(Questions 94 to 98) Atul Tele-Products

manufactures two telephone models using two

different raw material grades. One (x) is of

superior quality and the other (y) inferior

(second grade). The profit per unit for the

model using superior quality raw material is

Rs.200 and that of the other is Rs150. The

maximum demand for both telephones is 600

units. Production should not exceed demand

and total machine time available for both types

of telephones together is 650 hours. Besides,

one superior quality telephone can be produced

in two hours while one unit of inferior quality

telephone can be produced every hour. Answer

the following five questions using the

information given above.

94. If Atul Tele-Products wants to maximize

profits, what should be the objective

function?

a. Maximize Z = 2x + 4y

b. Maximize Z = 200x + 150y

c. Maximize Z = 600x + 650y

d. Maximize Z = 2x + y

95. What is the constraint on machine hours?

a. 2x + y 650

b. x + 2y 650

c. 2x + y 600

d. x + 2y 600

96. What is the constraint on demand?

a. 2x + y 600

b. x + 2y 600

c. x + y 650

d. x + y 600

97. If the number of superior quality

telephones produced in a month is 200 and

inferior quality telephones is 200, then

what is the maximum profit (in rupees)

that the company gets?

a. Rs. 75000

b. Rs. 70000

c. Rs. 76500

d. Rs. 78500

98. What is the appropriate production

combination for the two models to gain

maximum profits?

a. x = 300, y = 300

b. x = 600, y = 0

c. x = 250, y = 100

d. x = 200, y = 200

99. While constructing a linear programming

problem, certain assumptions are made.

Which of these is not such an assumption?

a. Proportionality

b. Optimality

c. Divisibility

d. Additivity

100. If the objective function is a maximizing

function, which of the following can be

considered for it?

a. Profits

b. Inventory

c. Advertising expenditure

d. Production costs

(Questions 101 to 104) The diagram represents

the solution for a linear programming problem

where ABCS is the feasible region. Use the

diagram to answer the following four

questions.

Part A

13

101. Identify the constraint represented by the

line passing through the coordinates

(40, 0) and (0,60).

a. x + y = 40

b. 2x +3y = 120

c. 3x + 2y = 120

d. x + y = 60

102. Identify the corner points of the feasible

region from the above diagram.

a. (0,0), (80,0), (60,0), (40,0)

b. (40,0), (80,0), (60,80), (60,0)

c. (40,0), (80,0), (80,60), (60,0)

d. (0,60), (40,0), (80,0), (80,60)

103. What is the equation of the line passing

through (80,0)?

a. x = 80

b. y = 80

c. x + y = 80

d. x - y = 80

104. Find the minimum value of the objective

function where minimize Z = 20x + 35y.

a. 2100

b. 1600

c. 800

d. 3700

105. Which of the following statements is not

characteristic of linear programming?

a. The linear programming problem should

have a well-defined single objective to

achieve

b. The objective function and constraints of

the linear programming problem must be

linear functions

c. Decision variables of the linear

programming problem should be

continuous in nature

d. The resources considered in the linear

programming problem should have

unlimited supply

106. Identify the correct sequence of steps to

formulate a linear programming problem.

i. Identify the objective function

ii. Identify decision variables

iii. Identify constraints

a. ii, i, and iii

b. i, ii, and iii

c. iii, ii, and i

d. ii, iii, and i

107. Where does the optimum solution lie on

the graph in the graphical method of

solving a linear programming problem?

C

B

A

20

Y

O (0,0)

20

60

80

40

80 X

60

40

S

120

100 120

100

D

Operations Management

14

a. On the X axis

b. On the Y axis

c. In the feasible region

d. Outside the feasible region

108. In the simplex method of solving a linear

programming problem, the lesser than or

equal to inequality is converted into

equality by ___________ to the left hand

side of the inequality.

a. Adding a slack variable

b. Subtracting a slack variable

c. Adding a function

d. Subtracting a function

109. The sequence of steps in moving from one

basic solution to another in a simplex

method is known as ____________.

a. Integration

b. Iteration

c. Allocation

d. Summation

110. Identify the typical objective function of a

transportation problem.

a. To minimize the sum of all quantities

transported

b. To minimize the sum of all production

costs

c. To minimize the sum of all transportation

costs

d. All of the above

111. Which among the following is not a

method used in developing an initial

feasible solution for a transportation

problem?

a. North-West corner method

b. Least cost method

c. Vogels approximation method

d. Stepping stone method

112. Of all the methods used to determine the

initial feasible solution in transportation

problems, which is said to be most

effective?

a. North-West corner method

b. Lest cost method

c. Vogels approximation method

d. Both a & b

113. The concept of linear programming does

not consider any synergetic effects among

decision variables while calculating their

total value for the objective function or the

constraints they are associated with. This

is part of which assumption of linear

programming?

a. Proportionality

b. Additivity

c. Divisibility

d. Certainty

114. Onio Designs provides industrial designing

services to various automobile companies

in India. This is an example of

___________.

a. Job shop production

b. Batch manufacturing

c. Standardized service

d. Customized service

115. In the emerging business scenario, it has

become essential for operations managers

to manage the structure of their

organizations, not merely their operations.

What does the term structure include?

a. Number of plants and their individual

capacities

b. Choices in equipment and process

technology

c. Production control and workforce

management

d. All of the above

116. Keeping other things constant, when the

price of a commodity decreases, the

demand for the commodity __________.

a. Does not change

b. Increases continuously

c. Increases to a certain level

d. Decreases

117. To attain its objective of profit

maximization, L&T decided to acquire a

mine in Australia thereby owning sources

of raw material supplies. What is this

process of expanding ownership called?

a. Horizontal integration

b. Forward integration

c. Backward integration

d. Diagonal integration

Part A

15

118. The factor that is not considered by

operations managers while making their

decisions on backward integration.

a. Level of training for distributor employees

b. Capabilities to consume and market the

products

c. Anticipate changes in net return on assets

d. Availability of funds

119. What are the basic objectives of process

planning and design?

i. To produce products with desired quality

ii. To produce products at the right time

iii. To produce products in required quantities

iv. To produce products below competitor

prices

a. i and ii

b. i and iii

c. ii, iii, and iv

d. i, ii, and iii

120. Organizations must be flexible to increase

or maintain their market share. The ability

of the production system to shift quickly

from producing one product to another is

called _____________.

a. Product flexibility

b. Demand flexibility

c. Volume flexibility

d. Customer flexibility

121. In an assembly chart, the process of

inspection is generally represented by a

__________.

a. Square

b. Circle

c. Triangle

d. Pentagon

122. Which of the following is not an

advantage of process-focused production?

a. Small work-in-process inventory

b. Less manufacturing cycle time

c. Low initial investment

d. Better product mix available to meet

customer demand

123. Which of the following is not an

advantage of the product focused

production system?

a. Lower unit costs

b. Lower initial investments

c. Ease of planning

d. Reduced worker training

124. ABC Corp. to match the diversity in

customer orders wants to produce products

in small batches. Which type of process

design would be economically feasible for

ABC?

a. Assembly line

b. Continuous processing

c. Discrete unit processing

d. Job shop process

125. Which of the following forms the basis for

designing factory buildings and facility

layouts?

a. Operations strategy

b. Production planning

c. Process planning

d. Product design

126. When Hindustan Smelters Ltd. decided to

manufacture lead ingots, the management

decided to develop a process plan for the

same. Which of the following factors

should the operations manager at

Hindustan Smelters Ltd. keep in mind

when developing a process plan?

a. Nature of demand

b. Degree of vertical integration

c. Employee skill level requirements

d. Quality level and degree of customer

contact

127. Demand for Pepsi cola is seasonal. It has a

very high demand during summer and

minimal demand during winter season.

Which of the following assumptions is

false with respect to the seasonality of

demand of Pepsi cola?

a. As demand is seasonal Pepsi cola should

not be produced in winter season

b. Pepsi cola should be produced throughout

the year but with varying outputs

c. Finished goods inventory must be stocked

to meet high demand during summer

d. All the above statements are false.

Operations Management

16

128. Which of the following is not a factor

affecting backward integration?

a. Cost of producing components versus cost

of buying them

b. Investments necessary to produce

components in-house

c. Anticipated changes in net return on

assets, if production of components is

undertaken

d. Ability of the organization to market its

products

129. Identify which of the following is not an

advantage of vertical integration.

a. It reduces the over-dependency on the

purchasing function

b. It helps decentralize the overheads

c. It helps in pooling the R&D and design

efforts

d. It helps in achieving economies of scale

130. Assume that Eastside, a readymade

garment retailer, acquired a textile mill to

produce different fabrics. What kind of

integration strategy has the retailer

adopted?

a. Forward integration

b. Backward integration

c. Horizontal integration

d. Lateral integration

131. There are various types of process designs

that are generally used by organizations. In

which type of process design, products or

services tend to flow along linear paths

without backtracking or sidetracking?

a. Product-focused systems

b. Process-focused systems

c. Group technology

d. All the above

132. Steel and Chemical industries generally

implement which type of process design?

a. Discreet unit manufacturing

b. Process manufacturing

c. Job shop process

d. Both a & c

133. Which of the following process design

systems entail high initial investment?

a. Product-focused systems

b. Process-focused systems

c. Group technology

d. All of the above

134. What are the characteristics of process

focused systems?

i. Operations are grouped according to the

type of processes

ii. Production is performed on products on a

start and stop basis

iii. Products move from department to

department in batches

iv. Products are produced irrespective of

diversity in customer orders

a. i and ii

b. iii and iv

c. i, ii, and iii

d. ii, iii, and iv

135. Coding of parts in a manufacturing plant is

done to ensure the identification of each

part and its characteristics. What is the

difficulty in adopting this approach?

a. It provides a clear picture of the steps

involved in producing the part

b. It results in standardization of part design

c. It leads to grouping of the parts into

families

d. It requires high employee skills

136. Which of the following is not an

advantage of cellular manufacturing?

a. Lesser machine changeover time

b. Lower cost of training

c. Reduction in material handling costs

d. Increase in the in-process inventory

137. Which of the following types of charts

indicate operations by circles and

inspections by squares?

a. Assembly charts

b. Gantt charts

c. Flow charts

d. None of the above

138. Which type of production systems has high

diversity in product design and small batch

size?

Part A

17

a. Job shop production systems

b. Cellular manufacturing systems

c. Batch production systems

d. Product focused systems

139. Which of the following is not true about a

product-focused system?

a. Presence of initial fixed costs

b. Presence of low variable costs

c. The total cost of production increases as

the output volume increases

d. Low variations in products

140. In what way is a typical product-focused

system distinct when compared to a

process focused system?

a. Lower fixed costs and higher variable

costs

b. Higher fixed costs and lower variable

costs

c. Higher fixed costs and higher variable

costs

d. Lower fixed costs and lower variable costs

141. Which of the following reasons persuade

companies to set up facilities in export

promotion zones, technology parks and

industrial estates?

i. Tax holidays and exemption from import-

export barriers

ii. Availability of infrastructure

iii. Low loan interest rates

iv. Low cost of manpower

a. i and iv

b. ii, iii, iv

c. i, ii, iii

d. ii and iv

142. Which of the following is a major factor in

selection of a location for an aluminum

factory?

a. Proximity to final consumer

b. Proximity to input sources

c. Proximity to sea port

d. All of the above

143. For which of the following industries is

proximity to markets a must?

a. Telecom industry

b. Textile industry

c. Healthcare industry

d. Call center

144. What do you understand by the term

facility layout?

a. A list of facilities provided by the

organization to the consumers

b. The physical distribution of various

departments for ease in production

c. The location of employees inside the

organization

d. Layout of safety equipment in an

organization

145. Layouts are differentiated by the types of

workflow they entail. Workflow in turn is

dictated by the nature of the product.

Which of the following statements is true

about product layout?

a. Equipment is dedicated to the manufacture

of a narrow product line

b. Equipment is flexible to produce a wide

range of products

c. Material handling cost increases

significantly

d. It is used for manufacturing customized

products

146. Which of the following involves the use of

layout planning tools like templates and

two-dimensional cut-outs of equipment

drawn to scale?

a. Graphic and schematic analysis

b. Load distance model

c. Computer models

d. CRAFT model

147. Cotton yarn manufacturing units are

generally concentrated in select areas of

the country as yarn production requires

certain ideal levels of humidity. What

factor influences selection of plant location

in this case?

a. Site cost

b. Conducive politico-economic situation

c. Suitability of climate

d. Availability of amenities

148. Which of the following is not a primary

objective of facility location and layout

decisions?

Operations Management

18

a. To set up a plant of the right size and right

design

b. To serve the customer better

c. To optimize production cost

d. To use best available technology

149. Which of the following is not an

advantage of selecting an optimum

location for a plant?

a. Reduction of transportation costs of raw

material and finished goods

b. Competitive advantage due to proximity to

market

c. Low labor-cost

d. Cost of technology

150. Which of the following types of layout is

used when the product manufactured is

bulky, heavy or fragile?

a. Product layout

b. Process layout

c. Fixed position layout

d. Group technology layout

151. Which of the following techniques is not

associated with taking suitable location

decisions?

a. Cost-profit-volume analysis

b. Factor analysis

c. Linear programming

d. CRAFT analysis

152. Which of the following organizations

selects a particular location from a market-

oriented approach?

a. A retailer

b. A manufacturer

c. A software development center

d. A content development center

153. Which of the following is not a type of

facility layout?

a. Process layout

b. Product layout

c. Employee layout

d. Hybrid layout

154. It is also called the cellular manufacturing

layout. Identify the layout from the

following.

a. Process layout

b. Grouping technology layout

c. Fixed position layout

d. Hybrid layout

155. In which of the following situations is

there no need for selecting a facility

location?

a. When a business has just started

b. When expansion of the existing plant is

possible

c. When a business wants to establish new

branches/plants

d. When government regulations mandate

that the business has to shift its location

156. Firms conduct facility location analysis

where they evaluate different locations and

finally choose an optimum location to start

operations. Arrange the following

activities related to facility location

planning in a logical sequence.

i. Design layout

ii. Select location

iii. Search for a location

iv. Revise layout

a. i, ii, iii, iv

b. ii, iii, i, iv

c. iii, ii, i, iv

d. iv, iii, ii, i

157. Rahul wanted to set up a small scale

printing press to print books for

individuals interested in publishing their

work for a small audience. Which is the

right location for Rahul to establish a

printing press to cater to this kind of

market?

a. Near paper mills

b. In a town/city

c. In a village where cost of labor is cheap

d. Near the manufacturer of printing

machines

158. There are many factors affecting the

selection of a facility location. Which of

the following factors would deter a firm

from setting up operations in a particular

location?

a. Low labor costs

b. High transportation costs

c. Availability of public utility services

d. Benefit of tax holidays

Part A

19

159. The basic raw material for a cement

manufacturing unit is limestone and the

major consumers are the government, real

estate and individual consumers. Which is

the best possible location to build a cement

plant?

a. Close to sea port

b. Close to cities where consumption is high

c. Close to the raw material source

d. Within special economic zones or export

processing zones

160. Process layouts are also known as ______.

a. Functional layouts

b. Fixed position layout

c. Flow-shop layouts

d. Straight-line layouts

161. Many auto-ancillary units have set up

facilities close to facilities of auto majors

like Hyundai and Ford near Chennai.

Which of the following factors would have

primarily led to this decision?

a. Site cost

b. Proximity to markets

c. Need for safety requirements

d. Availability of services like electricity,

drainage, and waste disposal

162. Which of the following is not considered a

benefit derived by companies setting up

operations in special export zones (SEZ)?

a. Good infrastructure support

b. Tax holidays

c. Low interest loans

d. Availability of prime real estate

163. Companies can follow certain guidelines

when trying to analyze possible locations

and identify an optimal one since it is

expensive and time-consuming. What is

the correct sequence of guidelines a

company can follow when evaluating

locations?

a. Define location objectives relate

objectives to criteria Identify relevant

decision criteria evaluate alternative

locations select the best location

b. Identify relevant decision criteria define

location objectives relate objectives to

criteria evaluate alternative locations

select the best location

c. Define location objectives identify

relevant decision criteria relate

objectives to the criteria evaluate

alternative locations select the best

location

d. Define location objectives identify

relevant decision criteria evaluate

alternative locations relate objectives to

criteria select the best location

164. Though there is no standard procedure,

certain guidelines can be used for making

a location decision. The first guideline is to

define location objectives. Whose views

and requirements are not considered when

defining them?

Cost Volume Relationships of Two Locations

V

0

Volume of sales

C

o

s

t

Revenue

TC

2

TC

1

FC

1

FC

2

Operations Management

20

a. Owners and promoters

b. Employees

c. Customers

d. Competitors

(Questions 165 & 166) The above figure

presents cost-volume-profit analysis. Based on

the figure, answer the following two questions.

165. Which of the following is similar for the

two locations?

a. Revenue

b. Fixed cost

c. Variable cost

d. Total cost

166. If fixed cost at a location is Rs.500,000,

variable cost per unit Rs.30, and price per

unit Rs.50. Calculate the number of units a

firm should produce to break even?

a. 20,000

b. 10,000

c. 25,000

d. 15,000

(Questions 167 to 169) The table below gives

details about fixed costs and variable costs for

three different locations. Answer the following

three questions using information given in the

table.

Location Fixed cost /Yr Variable cost /

Unit

Chandigarh Rs. 4,00,000 300

Gurgaon Rs. 4,50,000 285

Delhi Rs. 5,00,000 275

167. Which of the following locations would

have the highest total cost per year if

annual output of a firm located there is

1000 units?

a. Chandigarh

b. Gurgaon

c. Delhi

d. Both Delhi and Gurgaon

168. Which of the following locations would

have the highest annual profit if the annual

production is 1000 units and selling price

per unit is Rs.1000?

a. Chandigarh

b. Gurgaon

c. Delhi

d. Both Chandigarh and Gurgaon

169. Which plant location would you select if

you were the authority to make the final

decision?

a. Chandigarh

b. Gurgaon

c. Delhi

d. Any of the above

170. Which of the following is not an

advantage of a good layout?

a. It reduces material handling costs

b. It reduces congestion in the plant

c. It reduces space utilization

d. It increases machine utilization

171. Under which type of layout are similar

machines and equipment grouped to carry

out the production process.

a. Process layout

b. Product layout

c. Fixed position layout

d. Hybrid layout

172. What type of machine is used in a process

layout?

a. Specially designed machines

b. General purpose machines

c. Machines that help manufacture

standardized products

d. All of the above

173. Which of the following is an advantage of

process layouts?

a. Increased production time

b. Increased work-in-progress

c. Increased accumulation of work

d. Increased utilization of men and material

174. Which type of layout is designed to

produce standardized products?

a. Process layout

b. Product layout

c. Fixed position layout

d. Hybrid layout

Part A

21

175. Which of the following manufacturing

processes requires using a fixed position

layout?

a. Petroleum distillation

b. Beer manufacturing

c. Ship-building

d. Cement manufacturing

176. In a fabrication and assembly plant,

fabrication is done on __________ layout

while assembly is done on

______________ layout.

a. Product, process

b. Process, product

c. Product, fixed position

d. Fixed position, product

177. Managers can use various models like

mathematical models, computer models,

and physical models to develop a process

layout. Which among the following helps

find the best process layout by evaluating

thousands of alternative layouts very

quickly?

a. Graphic and schematic analysis

b. CRAFT model

c. Load distance model

d. Line balancing

178. Different types of products are

manufactured using a process layout. As

workflow differs from product to product,

managers focus on minimizing the

movement of materials as it can hike

material movement costs. Which of the

following models aims at minimizing these

costs?

a. Graphic and schematic analysis

b. CRAFT model

c. Load distance model

d. Line balancing

179. In which of the following countries were

compact production layouts developed due

to space constraints?

a. USA

b. Japan

c. India

d. China

180. Match the following models used to

develop layouts with their respective

features.

i. CRAFT model

ii. Load distance model

iii. Line balancing

iv. Graphic & schematic analysis

p. Used for studying workflow in an

assembly line

q. Evaluates thousands of alternative layouts

in a short period

r. Analyses and minimizes material

movements costs in a plant

s. Two dimensional drawings are used to

determine the best layout

a. i/p, ii/q, iii/r, iv/s

b. i/q, ii/p, iii/r, iv/s

c. i/r, ii/q, iii/p, iv/s

d. i/q, ii/r, iii/p, iv/s

181. Different types of layout of service

facilities exist based on degrees of

customer contact. In which of the

following layouts is internal work of

employees given secondary importance?

a. Layouts focusing on customer receiving

and servicing

b. Layouts focusing on technology

c. Layouts focusing on physical materials

processing

d. Layouts focusing on production efficiency

182. Which of the following service providers

uses both customer focus layouts and

process focus layouts as part of its service

facility layout?

a. Banks

b. Hospitals

c. Restaurants

d. Call center

183. The following table gives the volume of

quantities to be shipped to four markets.

The X and Y coordinate values of the

location that would help minimize

transportation costs are also given. Use the

center of gravity method to identify

coordinates for the optimal location to set

up a warehouse to service the four markets

with minimal transportation costs.

Operations Management

22

Distribution

Center

X Y VOLUME

(000)

A 4 4 60

B 12 6 90

C 10 14 110

D 5 13 100

a. 10.75, 9.06

b. 10.05, 8.11

c. 9.06. 10.75

d. 8.11, 10.06

184. Which of the following is not a location

evaluation method?

a. Point rate method

b. Center of gravity method

c. Analytic Delphi method

d. Historical analogy method

185. Analytic Delphi Method helps managers

take complex multi-location decisions.

Give the correct sequence of steps to be

taken as part of such location decisions.

a. Form panels - Identify trends and

opportunities - Determine directions and

strategic goals of the organization -

Develop alternatives - Prioritize

alternatives

b. Identify trends and opportunities -

Determine directions and strategic goals of

the organization - Form panels - Develop

alternatives - Prioritize alternatives

c. Identify trends and opportunities - Form

panels - Determine directions and strategic

goals of organization - Prioritize

alternatives - Develop alternatives

d. Form panels - Determine directions and

strategic goals of the organization -

Prioritize alternatives - Develop

alternatives - Identify trends and

opportunities

186. Linear Decision Rules (LDRs) are a set of

equations for calculating the optimal

workforce, aggregate output rate and

inventory level for each time period in a

planning horizon. Which of the following

is not true about LDRs?

a. They provide optimum solutions for the

problems

b. They eliminate trial and error

computations

c. They consider non linear cost relationships

d. They can be generalized to all

organizations

187. ________ is the basis for job analysis, job

description and job specification.

a. Job rotation

b. Job design

c. Job enrichment

d. Job enlargement

188. ________ describes the tasks, duties and

responsibilities of a job.

a. Job analysis

b. Job enrichment

c. Job description

d. Empowerment

189. ___________ investigates job content, the

physical conditions in which the job is

carried out, and qualifications necessary to

carry out job responsibilities.

a. Job description

b. Job analysis

c. Job profile

d. Job specification

190. What does an effective job design ensure?

a. Employees are paid above expectations

b. Jobs are consistent with organizational

goals

c. Proper measurement of work done by each

employee

d. All the above

191. The Job Characteristics Model developed

by Richard Hackman and Greg Oldham

includes five characteristics. They are skill

variety, task identity, task significance,

autonomy and feedback. Match the

following terms with their respective

description.

i. Skill variety

ii. Task significance

iii. Autonomy

iv. Feedback

p. Influence of job on individuals inside &

outside the organization

q. Flexibility, independence, and discretion in

the job

Part A

23

r. Skill sets and abilities needed for the job

s. Extent of information given to employees

on their performance

a. i/q, ii/p, iii/s, iv/r

b. i/p, ii/q, iii/r, iv/s

c. i/r, ii/q, iii/p, iv/s

d. i/r, ii/p, iii/q, iv/s

192. Which of the following is not a

consequence of a good job design?

a. Improved efficiency

b. Improved productivity

c. Increase in worker inputs

d. Increase in motivation

193. The job design developed should be

feasible for employees as well as the

organization. Feasibility is required in

which of the following areas?

i. Technical feasibility

ii. Economic feasibility

iii. Political feasibility

iv. Behavioral feasibility

a. i, ii, iv

b. i, iii, iv

c. i, ii, iii

d. ii, iii, iv

194. What do you understand by the term job

content?

a. It gives the detailed set of activities to be

performed on the job

b. It describes the physical conditions in

which the job is done and qualifications

for the job.

c. It describes the duties and responsibilities

of a job.

d. All of the above

195. Job content is the key to job design as it

influences other aspects of human resource

management. Job content helps clarify

which of the following aspects?

i. Qualifications

ii. Skill sets

iii. Nature of training programs

iv Level of motivation

a. i and ii

b. iii and iv

c. i, ii, and iii

d. i, ii, iii, iv

196. Job specialization at work has many

advantages for the organization. Which of

the following is not an advantage resulting

from this?

a. Ease in recruiting new workers because

fewer skills are required

b. Lower production time and higher

productivity levels

c. Lower flexibility in job rotation

d. Larger scope for mechanization or

automation of processes

197. Which of the following is an advantage of

work specialization for a manager?

a. Lower work satisfaction

b. Ease of supervision and training workers

c. Reduced scope for improvement because

of limited perspective of workers

d. Hidden costs of worker dissatisfaction

resulting from absenteeism and high

employee turnover

198. Which of the following types of

compensation is a basic need and is not a

tool used for employee motivation?

i. Fixed salary

ii. Promotion

iii. Health insurance

iv. Bonus

a. Only i

b. ii, iii and iv

c. i, iii and iv

d. i, ii, iii, iv

199. Which of the following is a form of

monetary benefit given to employees in an

organization?

a. Rewards

b. Titles

c. Promotions

d. Low interest loans

200. Identify the correct sequence of activities

to be performed by the human resource

manager.

Operations Management

24

i. Job analysis

ii. Job description

iii. Job design

a. i, ii, iii

b. ii, iii, i

c. i, iii, ii

d. iii, i, ii

201. The different techniques used in work

measurement are time study, historical

analysis, standard data, work sampling,

and predetermined motion time data

systems. Each has a different way of

measuring time. How is it done in time

study?

a. Using standard table

b. Using past record

c. Using stop watch

d. Using formula

202. Which of the following are benefits of

setting work standards?

i. It helps improve machine utilization by

reducing idle time

ii. It helps compare efficiency of different

work methods

iii. It helps a manager delegate work to all

employees

iv. It provides benchmarks for evaluating

workers performance

a. i and ii

b. i and iii

c. i, ii and iv

d. i, ii, and iii

203. Which of the following work measurement

methods does not use historical or stored

data but uses several random observations

in the work environment?

a. Standard data technique

b. Predetermined motion time study

c. Work sampling

d. Historical analysis

204. Which of the following is not a technique

used for setting work standards?

a. Time study

b. Work sampling

c. Delphi method

d. Predetermined motion time systems

205. Which of the following statements gives

an incorrect description of a feature of

time study?

a. The average of observations made always

represents time required to perform each

elemental task

b. Workers behave differently than usual

while conducting a time study

c. Observations are recorded repeatedly

across several workers to arrive at the

standard time

d. Normal time is the product of average

cycle time and worker rating

206. Which of the following is not an

allowance considered under the time study

technique of work measurement?

a. Contingency allowance

b. Interference allowance

c. Dearness allowance

d. Relaxation allowance

(Questions 207 & 208) A time study of a

production worker in a component

manufacturing plant produced the following

results: Cycle time = 3.75 minutes; worker

performance rating = 90 percent. Answer the

following two questions using this information.

207. Calculate the normal time for the job.

a. 3.75 minutes

b. 3.375 minutes

c. 3.455 minutes

d. 3.565 minutes

208. If allowances are 12 per cent of the job

time, calculate the standard time required

for the job.

a. 3.375 minutes

b. 3.775 minutes

c. 3.835 minutes

d. 3.965 minutes

209. Identify the technique of setting work

standards that uses recorded standard time

data for each of the basic motions

associated with performing a task and

summing them up to determine the time

required to perform the whole task.

Part A

25

a. Time study

b. Pre-determined Motion Time Study

c. Standard data

d. Historical analysis

210. Which of the following statements

correctly describes the difference between

Standard Data Technique and Pre-

determined Motion Time Study in work

measurement?

a. PMTS has to be measured by taking

observations while Standard Data provides

standard times for common movements

b. Standard data provides time for basic

movements while PMTS provides time for

job-specific motions

c. PMTS provides time for basic motions

while Standard Data provides time for job-

specific motions

d. PMTS has to be measured by looking at

the standard table while Standard Data

technique uses observations

211. ___________ is a technique of analyzing

work by making several observations,

usually at random, to see the relative

frequency with which various elemental

activities take place.

a. Time study

b. Standard data

c. Historical analysis

d. Work sampling

212. One of the primary applications of work

sampling is to find the percentage of time

an employee or equipment was occupied,

or left idle. What is the name given to this

application of work sampling?

a. Ratio delay

b. Performance measurement

c. Time standards

d. Employee self-timing

213. Which of the following primary

applications of work sampling are used to