Professional Documents

Culture Documents

Damper Catalog

Damper Catalog

Uploaded by

Marco Foglieri0 ratings0% found this document useful (0 votes)

3 views7 pagesxxxx

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentxxxx

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views7 pagesDamper Catalog

Damper Catalog

Uploaded by

Marco Foglierixxxx

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

VIBRATION DAMPERS

hereisnot adampingsolutionthat isthebest

T

here is not a damping solution that is the best

solution for all scenarios.

T

Meca offers three different damping solutions:

Damping Pads

Tuned Liquid Dampers (TLD)

Tuned Mass Dampers (TMD)

Vibration Damper:

p ( )

Each of these damping options have their advantages

and disadvantages, and so it takes a review of a

specific design and situation in order to determine the

best option for that stack.

Vibration Damper:

The vibration damper offers the most economical and effective way to handle the

problem of stack vibration. A properly designed and manufactured vibration damper

will significantly reduce the vibration amplitude and stress while increasing the life of

the stack.

Tacomo Narrows Bridge:

Stack Without a Damper Stack With a Damper

g

Perhaps the most famous case of

vortex shedding is the Tacomo

Narrows Bridge located in

Washington State. Built in 1940, it

failed less than 6 months after the

bridge was placed into service. At a

windspeedof only42mph(18.8

Vortex Shedding (Across Wind Vibration):

wind speed of only 42 mph (18.8

m/s) the bridge vibrated with

amplitudes as large as 28 ft (8.5 m).

Every stack has a critical wind speed at which vortex

Shedding occurs. Vortex Shedding is the instance

Where alternating vortices are generated on the down-

wind side of the stack, as shown in the figure. These

alternating vortices provide the driving force which

causes the structure to vibrate perpendicular to the

direction of the wind. When the critical wind speed

of the stack is reached, these forces can cause the stack

to resonate where large forces and deflections are

experienced.

Meca Enterprises, Inc. * 816 West Elgin St.* Broken Arrow, OK 74012

918-258-2913 office * 918-258-1057 Fax

www.mecaenterprises.com * support@mecaenterprises.com

Page 1 of 7

HELICAL STRAKES

Helical strakes are aerodynamic stabilizers which are sometimes used to reduce the forces

and deflections of the stack experienced due to vortex shedding. Strakes consist of three

(3) vanes which can be wrapped in a helical pattern on the upper 1/3 of the stack. They

have the appearance of a Snake which spirals around the stack. pp p

When strakes are added the drag coefficient of the stack is increased greatly. A smooth

cylinder will have a shape factor of 0.7, while the same stack with strakes will increase its

shape factor to 1.4. Consequently the load on the top 1/3 of the stack is doubled. Since a

stack is like a large cantilever beam, increasing the forces at the top by a factor of 2 will

increase the loads at the base by approximately 1.5. Similarly, the deflections will also

increase significantly.

Advantages:

1. Anyone can build them

Disadvantages:

1. Double the wind load on the upper 1/3

f th t k i i t k i ht

2. In some rare cases they provide the

most economical solution

of the stack, increasing stack weight

significantly

2. Nearly always more expensive than a

vibration damper

3. Complex geometry make fabrication

difficult

4 Caninterferewithother attachments 4. Can interfere with other attachments

(i.e. ladders, platforms, etc.)

5. Foundation and Anchor Bolts usually

increase in size

6. Do not work in the case of interfering

stacks

7. Some codes do not allow their use for

ScrutonNumber <8 (which covers

most stacks with vibration issues)

Meca Enterprises, Inc. * 816 West Elgin St.* Broken Arrow, OK 74012

918-258-2913 office * 918-258-1057 Fax

www.mecaenterprises.com * support@mecaenterprises.com

Page 2 of 7

DAMPING PADS FOR

STACKS STACKS

What is a damping pad?

A damping pad is a preformed laminated

fabric pad of manufactured material

composed of layers of tightly twisted, closely

Stack

Outer Shell

p y g y , y

woven lightweight material. Each layer is

made up of an elastomeric compound

containing mold and mildew inhibiting

agents.

What is it used for?

W h

Nut

Because steel smoke stacks have

relatively low inherent structural

damping, excessive top-of-stack

deflection can result at critical wind

speeds due to vortex shedding. To

What is it used for?

Washer

keep these deflections within

acceptable limits, a damping pad is

placed between the stack base plate

and concrete foundation and

conforms to the exact shape and size

of the base plate.

Damping

Pad

Baseplate

Grout

3/8 Leveling

Plate

Advantages

1. Do not increase wind loads

2. Creep effects are reduced to a limit

1. Can only withstand temperatures

upto200DegF (93DegC)

Plate

Disadvantages

p

of 5% of original thickness

3. Unusually high compressive strength

12,000 psi

4. Impervious to most oils and solvents

5. Resist effects of steam, water,

mildew and brine

up to 200 Deg F (93 Deg C)

2. Not always attractive to retrofit

existing stacks

Requires extra projection of

anchor bolts

Must lift stack and put

under

6. Can be used for temperatures ranging

7. From - 65

o

F (-54

o

C) to 200

o

F (93

o

C)

Meca Enterprises, Inc. * 816 West Elgin St.* Broken Arrow, OK 74012

918-258-2913 office * 918-258-1057 Fax

www.mecaenterprises.com * support@mecaenterprises.com

3. Slight increase in lateral deflection

Page 3 of 7

DAMPING PADS

FAQs FAQ s

How do Damping Pads Work?

It has been well documented that elastic foundations provide more structural damping

than rigid foundations. The damping pads introduce elasticity into the foundation which

i h i h l d i hi l i d d ib i li d increases the inherent structural damping. This results in reduced vibration amplitudes.

In fact, damping pads are listed in ASME-STS-1 as an acceptable means to dampen a

stack.

How Much Damping Can Be Achieved?

Field tests have been performed which indicate that critical damping values of up to 0.03

have been achieved. To be conservative, we recommend designs assume a critical

damping of 0.015.

Will This Cause the Stack to See Larger Lateral Deflections Due to

Along Wind Loads? Along Wind Loads?

The damping pads do introduce some elasticity into the base, but they are also very stiff.

There will be minimal impact on the lateral deflection due to along wind loads.

Do the Pads Hold up Over Time?

These pads have been in service for up to 30 years, with no reported problems.

Can Pads be Used on Existing Stacks? g

It is possible to use pads on existing stacks, but the stack must be raised in order to insert

a pad under the baseplate. Typically pads are 1 thick, so it must also be considered that

stack connections will be raised approximately 1.

Meca Enterprises, Inc. * 816 West Elgin St.* Broken Arrow, OK 74012

918-258-2913 office * 918-258-1057 Fax

www.mecaenterprises.com * support@mecaenterprises.com

Page 4 of 7

Tuned Liquid Damper

(TLD)

How does it work?

The TLD relies upon fluid to provide a

cost-effective method for damping. The

fluid is contained in an annular box,

which is provided near the top of the

TLD used as Platform

The TLD is unique in that it can also serve as a

platform. By simply adding posts and handrails to the

platform, the damper serves the dual purpose of Damper

andPlatform

stack. This box is specially designed to

maximize the damping effectiveness of

the fluid that is contained by the damper.

In addition, the design facilitates

redundancy so that the damper will

provide maximum reliability.

and Platform.

The platform can be designed to meet specific

requirements. As a standard, the damper itself is blasted

and painted (inorganic zinc primer), while the handrail,

mid-rail, and posts are galvanized.

Steel

Annular

Stack/

Chimney

Support

Brackets

Water &

Antifreeze

Tuned Liquid Damper (TLD)

Advantages:

1 Cantakedifferentshapesandsizes

Unique Configurations:

The TLD is very flexible and permits the most cost

effective solution for each job. Here are some examples

of some unique configurations that have been utilized.

Box

Brackets

1. Can take different shapes and sizes

2. Accommodates Ladders, Platforms

3. and Piping

4. Cost effective: Buy design only,

and build it locally

5. No moving parts

Disadvantages:

1. Special precautions when stack hot

2. Radiation shields needed on Flare

Stacks

3. Cant visually see lost liquid from

grade

Guyed Tower

G f

Damper

g

Damper under Platform

Gangway for

Multiple Stacks

Meca Enterprises, Inc. * 816 West Elgin St.* Broken Arrow, OK 74012

918-258-2913 office * 918-258-1057 Fax

www.mecaenterprises.com * support@mecaenterprises.com

Page 5 of 7

Tuned Liquid Damper (TLD)

FAQs FAQ s

Will the water freeze?

A mixture of water combined with antifreeze is recommended with each design. Combining water with

antifreeze will allow the damper to work well in very low ambient temperatures.

I h D hi d f ll f fl id? Is the Damper shipped full of fluid?

Typically the damper is shipped empty. The customer is then responsible for filling the damper with

the recommended mixture of water and antifreeze.

How will I know if the Damper is leaking fluid?

During fabrication a pressure test is performed to ensure that the damper will hold product under

atmospheric conditions. To date, Meca is unaware of any TLD leaking.

Will the fluid cause corrosion?

Some corrosion will be experienced, as is expected with all carbon steel. However, only modest

corrosion rates have been witnessed on damper installations.The only required maintenance on a p y q

damper is to check fluid level every 3 to 5 years.

What damping ratio should I expect with a damper?

Damping ratios up to 0.035 and up can be achieved, with the average being about 0.02. If needed, the

damper can be designed to provided much greater damping. The damper size and effective additional

damping are custom designed each time to provide the most economical solution.

What if I have a hot stack?

In the case where the stack shell is hot, >180 F (80 C), some special precautions must be taken. The

damper will be designed so that there is a gap between the shell and the damper, to essentially break

the thermal bridge. We do not want the damper to exceed the boiling point of water, which would

cause the damper to experience internal pressure. By breaking the thermal bridges we ensure that the

temperaturewill staybelowtheboilingpoint

Yes. The damper increases the damping in the structure, which is represented in many code by the

structural damping coefficient (Bs). Some Codes, such as ASME STS-1, take Bs into account when

calculating wind loads. If Bs increases, the wind forces will decrease. Often the decrease in wind

l d b i ifi h ff h f h d

temperature will stay below the boiling point.

Can a damper decrease my along wind loads?

loads can be significant enough to offset the cost of the damper.

Meca Enterprises, Inc. * 816 West Elgin St.* Broken Arrow, OK 74012

918-258-2913 office * 918-258-1057 Fax

www.mecaenterprises.com * support@mecaenterprises.com

Page 6 of 7

Tuned Mass Damper (TMD)

The Tuned Mass Dampers (TMDs) utilize mass to provide the damping. The dampers

are tuned to the natural frequency of the stack so that they are most effective at or near

thenatural frequencyof thestack

Tuned Mass Damper (TMD)

the natural frequency of the stack.

The Tuned Mass Damper consists of a cylindrical ring of steel mass, which is suspended

by cables. The ring is larger than the diameter of the stack, and is separated from the

stack with coils of cables which serve as springs.

Advantages:

1) All Mechanical Parts

2) No problem with high

temperatures

3) I df d i h

Disadvantages:

1) Must be full 360 Degrees

2) Needs to be near top of stack

3) Cannot serve dual purpose (i.e.

3) Inspected from grade with

Binoculars

4) Provides large structural damping

platform)

4) Sometimes interferes with ladders,

platforms and piping

Meca Enterprises, Inc. * 816 West Elgin St.* Broken Arrow, OK 74012

918-258-2913 office * 918-258-1057 Fax

www.mecaenterprises.com * support@mecaenterprises.com

Page 7 of 7

You might also like

- SNiP Vs EurocodeDocument105 pagesSNiP Vs EurocodeMarco FoglieriNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Dynamic Behaviour Under Wind Loading of Steel ChimneyDocument159 pagesDynamic Behaviour Under Wind Loading of Steel Chimneyzmtdialog100% (2)

- ASCE 7-98 Code Wind Loading AnalysisDocument34 pagesASCE 7-98 Code Wind Loading AnalysisPipim Pogi100% (1)

- Chapter 1+Casing+12Feb18Document47 pagesChapter 1+Casing+12Feb18Mohamad ZakwanNo ratings yet

- Saudi Arabia SeismicDocument1 pageSaudi Arabia SeismicMarco Foglieri100% (1)

- Wind Load On Saudi Arabia According To U B C 1997Document0 pagesWind Load On Saudi Arabia According To U B C 1997Marco Foglieri100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Description Assembly Order No. Static DataDocument29 pagesDescription Assembly Order No. Static DataMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 2132Document29 pagesW01 358 2132MROstop.comNo ratings yet

- Synchronous Lateral ExcitationDocument1 pageSynchronous Lateral ExcitationRabbie LeguizNo ratings yet

- W01 358 7304Document29 pagesW01 358 7304MROstop.comNo ratings yet

- W01 358 9603Document29 pagesW01 358 9603MROstop.comNo ratings yet

- W01 358 9048Document29 pagesW01 358 9048MROstop.comNo ratings yet

- W01 358 7742Document29 pagesW01 358 7742MROstop.comNo ratings yet

- W01 358 7091Document29 pagesW01 358 7091MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 7092Document29 pagesW01 358 7092MROstop.comNo ratings yet

- W01 358 8118Document29 pagesW01 358 8118MROstop.comNo ratings yet

- W01 358 7442Document29 pagesW01 358 7442MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 7047Document29 pagesW01 358 7047MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 7039Document29 pagesW01 358 7039MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Description Assembly Order No. Static DataDocument29 pagesDescription Assembly Order No. Static DataMROstop.comNo ratings yet

- W01 358 7830Document29 pagesW01 358 7830MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 7197Document29 pagesW01 358 7197MROstop.comNo ratings yet

- Triple Offset Butterfly ValvesDocument4 pagesTriple Offset Butterfly ValvesArunprasad MurugesanNo ratings yet

- 2003 Comp VRDocument8 pages2003 Comp VRMadJoe11No ratings yet

- W01 358 7561Document29 pagesW01 358 7561MROstop.comNo ratings yet

- Seven Years of Solid Results: Systems & PartsDocument5 pagesSeven Years of Solid Results: Systems & PartstorinomgNo ratings yet

- Sealing SolutionsDocument21 pagesSealing Solutionssaravan1891No ratings yet

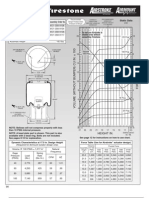

- Firestone Air Spring W02-358-3000Document29 pagesFirestone Air Spring W02-358-3000MROstop.comNo ratings yet

- Webinar 5 - Q&A ReportDocument11 pagesWebinar 5 - Q&A ReportrrprasathNo ratings yet

- Structural PDFDocument93 pagesStructural PDFSaqib imranNo ratings yet

- W01 358 9106Document29 pagesW01 358 9106MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order No.: Do Not Use Airstroke in Shaded Area Without Consulting FirestoneDocument29 pagesStatic Data Description Assembly Order No.: Do Not Use Airstroke in Shaded Area Without Consulting FirestoneMROstop.comNo ratings yet

- W01 358 6996Document29 pagesW01 358 6996MROstop.comNo ratings yet

- W01 358 7001Document29 pagesW01 358 7001MROstop.comNo ratings yet

- W01 358 9400Document29 pagesW01 358 9400MROstop.comNo ratings yet

- Firestone Air Spring W02-358-3004Document29 pagesFirestone Air Spring W02-358-3004MROstop.com100% (1)

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Canon Imageprograf Ipf610 Service Manual FreeDocument18 pagesCanon Imageprograf Ipf610 Service Manual FreeMarco FoglieriNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationMarco FoglieriNo ratings yet

- Idm June 2013 g21Document62 pagesIdm June 2013 g21Marco FoglieriNo ratings yet

- 1145-Fajfar TRST 2011Document33 pages1145-Fajfar TRST 2011Marco FoglieriNo ratings yet

- Chimneys - Damper CatalogDocument7 pagesChimneys - Damper CatalogMarco FoglieriNo ratings yet

- The Trouble With FiveDocument17 pagesThe Trouble With FiveMarco FoglieriNo ratings yet

- Technical Manual MP BasePLDocument118 pagesTechnical Manual MP BasePLMarco FoglieriNo ratings yet

- SNIP II 7 81 Seismic CodeDocument41 pagesSNIP II 7 81 Seismic CodeMarco FoglieriNo ratings yet

- The Trouble With FiveDocument17 pagesThe Trouble With FiveMarco FoglieriNo ratings yet