Professional Documents

Culture Documents

Fe-C Phase Diagram

Fe-C Phase Diagram

Uploaded by

mffritzCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fe-C Phase Diagram

Fe-C Phase Diagram

Uploaded by

mffritzCopyright:

Available Formats

1

Fe-C Phase Diagram

2

At room temperature it exists as ferrite,

or iron.

Upon heating pure Iron experiences two

changes in crystal structure.

When we heat it to 912C it experiences a

polymorphic transformation to austenite,

or iron

At 1394C austenite reverts back to a BCC

phase called ferrite.

1394C

Ferrite

BCC

912C

iron

Austenite

FCC

25C

Ferrite

BCC

1538C

Melts

Pure Iron

2

3

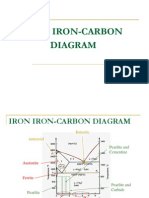

Fe-Fe

3

C Phase Diagram

Only part of the phase

diagram is shown.

The left axis is pure

iron.

On the right the phase

diagram only extends

to 6.70 wt%C

At this concentration

the intermediate

compound iron

carbide, or cementite

(Fe

3

C) is formed

4

Austenite

+ Fe

3

C

Development of Microstructures in Iron-Carbon

Alloys

(Pearlite) 3C Fe +

Various microstructures can be

produced in steel alloys

depending on

carbon content

heat treatment

Equilibrium (slow) cooling from

the region through the eutectoid

composition of 0.76 wt% C

% and Fe

3

C in eutectoid pearlite

3

5

Formation of Pearlite

Micrograph of eutectoid

steel, showing pearlite

microstructure.

Schematic representation of

the formation of pearlite

from austenite

0.76 wt% C

0.022 wt%C

6.7 wt%C

6

Hypo-eutectoid Composition (wt% C <0.76)

+

Upon cooling enter a two-phase

region

Composition 0.002 and 0.76 wt% C

Below 727C the remaining austenite

transforms to pearlite

C Fe3 +

4

Hypo-eutectoid Composition (0.38 wt% C)

White regions:

Proeutectoid

Ferrite

Dark regions:

Pearlite

Close-spaced

layers

Unresolved at this

magnification

Pearlite

wider-spaced

layers

91 m

8

Computing the relative amounts of

proeutectoid and pearlite

Similar to previous lecture.

Use the Lever Rule in

conjunction with a tie line

For hypoeutectic composition

C'

0,

fractions of pro-eutectic ,

and pearlite are:

(total) and Fe

3

C

5

9

Computing the relative amounts of

proeutectoid and pearlite

For hypereutectic composition

C'

1

(total) and Fe

3

C

10

Hyper-eutectoid Composition (wt% C >0.76)

Upon cooling enter a two-phase

region

Composition between 0.76 and 2.14

wt% C

The pro-eutectoid cementite phase has

begun to form along the grain

boundaries

C Fe3 +

6

11

Hyper-eutectoid Composition (1.40 wt% C)

White Pro-

eutectoid cementite

network

Pearlite colonies

30 m

12

Mechanical Properties of Steels

The mechanical properties of steel are largely

dictated by the phase transformations they undergo

upon cooling

If we heat steel to the single phase austenite

region and vary the cooling rate we can control the

microstructure.

Understanding phase transformations of metallic

alloys

7

13

Example: Railway Rails

Eutectoid composition of 0.76 wt%C

100% Pearlite structure

Pearlite is a natural composite

The strength of Pearlite is dictated by its

interlaminar spacing, S (m)

1

4 . 46 140

+ = S y

S

Increased cooling rates

14

Pearlite

Coarse Pearlite Fine Pearlite

8

15

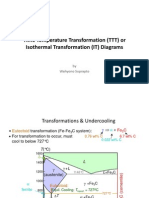

The rate of transformation

of the austenite to pearlite

is dependent on

temperature

This temperature

dependence can be plotted

as % transformation vs.

log. time

Isothermal Transformation Diagrams

Data was collected for

each curve, after rapid

cooling of 100% austenite

to the temperature

indicated

temperature was then

keep constant

throughout the course of

the reaction

16

More convenient to

represent time-

temperature dependence

isothermal

transformation diagram

generated from the %

transformation-versus-

log. times measurements

Note the eutectoid

temperature (727C)

Many tests conducted to

these construct curves.

Isothermal Transformation Diagrams

9

17

Isothermal Transformation Diagrams

18

Spheroidite

Hold steel at high temperature

Large drop in strength occurs

But ductility is greatly

increased

30 m

10

19

Formation of Martensite

Non-Equilibrium Cooling

Carbon must diffuse (move)

in order to form pearlite

Diffusion takes time +

temperature

If the sample is quenched

(plunged into water)

A supersaturated and

unstable structure is formed.

20

Characteristics of Martensite Transformation

Occurs by a non-diffusional process

Transformation occurs extremely fast, i.e. at the

speed of sound

Transformation occurs at temperatures well below

eutectoid temperature

Martensite is very hard (i.e. high

y

) but is

completely brittle

Not useful as an engineering material

Must be tempered

11

21

Martensite

Quench

Needle shaped

White areas austenite

quenched too fast

Tempered

564C

small particles cementite

matrix is ferrite

24.6 m 2 m

Effect of Carbon Content on Hardness

Brinell Hardness 0 - 320 Brinell Hardness 0 - 750

12

23

Effect of Carbon Content on Yield and

Tensile Strength

You might also like

- Microstructure of Metal MaterialsDocument70 pagesMicrostructure of Metal MaterialsEddyWang100% (14)

- ASTM E407-07 Standard Practice For Microetching Metals and AlloysDocument22 pagesASTM E407-07 Standard Practice For Microetching Metals and AlloysRifqiMahendraPutra100% (3)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- Fe C Phase DiagramDocument12 pagesFe C Phase DiagramDwi Cahyo NugrohoNo ratings yet

- Cast Iron Phase DiagramDocument97 pagesCast Iron Phase DiagramBhargav Suvagiya100% (1)

- 1 - Heat TreatmentDocument61 pages1 - Heat TreatmentMohamed Karim MohamedNo ratings yet

- TTT and CCT DiagramDocument24 pagesTTT and CCT DiagramArun Raj A C100% (2)

- TTT N AvramiDocument40 pagesTTT N AvramiAmirul AminNo ratings yet

- 03 - Iron - Iron CarbideDocument35 pages03 - Iron - Iron CarbidebotobotoakbarNo ratings yet

- TTT Phase DiagramDocument9 pagesTTT Phase Diagramhari krishnaNo ratings yet

- Publication 4 11889 199Document9 pagesPublication 4 11889 199Mulia AridhoNo ratings yet

- TTT CurvesDocument4 pagesTTT Curvesmanas310jntuhNo ratings yet

- FeC and TTT DiagramsDocument12 pagesFeC and TTT DiagramsMohamed El-WakilNo ratings yet

- EN1101 - MJE - Part 10 - Steel Phase Diagrams - LCDocument13 pagesEN1101 - MJE - Part 10 - Steel Phase Diagrams - LCnwankwo chubyNo ratings yet

- TTT DiagramDocument19 pagesTTT DiagramShah SaudNo ratings yet

- TTTDocument7 pagesTTTMuhammad Hery Al-GhiffaryNo ratings yet

- Review MetalDocument38 pagesReview MetalnisannisaNo ratings yet

- Fe-C Phase Transformations and Hardening of Steel, ContinuedDocument21 pagesFe-C Phase Transformations and Hardening of Steel, ContinuedchenshicatherineNo ratings yet

- The Iron-Iron Carbide Equilibrium DiagramDocument15 pagesThe Iron-Iron Carbide Equilibrium DiagramjhangeerNo ratings yet

- 1 - Heat TreatmentDocument61 pages1 - Heat TreatmentMohamed El SayadNo ratings yet

- Eng Mat Chapter 4Document126 pagesEng Mat Chapter 4VC Chua Yee LeongNo ratings yet

- Lecture Chapter 4 Phase Transformation and Metal AlloysDocument79 pagesLecture Chapter 4 Phase Transformation and Metal AlloysWinni TanNo ratings yet

- Engineering Material-II: Iron Carbide Phase DiagramDocument16 pagesEngineering Material-II: Iron Carbide Phase DiagramAla ZiNo ratings yet

- TTT 11Document55 pagesTTT 11MrDOTNo ratings yet

- Iron - Carbon Phase DiagramDocument33 pagesIron - Carbon Phase Diagramvishnu anand100% (2)

- TTT NotesDocument41 pagesTTT NotesshivanigopiNo ratings yet

- TTTDocument13 pagesTTTharitha gorijalaNo ratings yet

- Materials of Construction and Selection: Faculty of Chemical Engineering Universiti Teknologi MaraDocument80 pagesMaterials of Construction and Selection: Faculty of Chemical Engineering Universiti Teknologi MaraAisyah Addia AzizanNo ratings yet

- EMM LectureDocument38 pagesEMM Lecturelatendra kumar srivastavNo ratings yet

- Heat Treatment Part 1Document32 pagesHeat Treatment Part 1Naman DaveNo ratings yet

- Grey Cast IronDocument97 pagesGrey Cast IronSiddharth GuptaNo ratings yet

- Phase Transformations: Ferrite - BCCDocument65 pagesPhase Transformations: Ferrite - BCCAhsan JunaidNo ratings yet

- Heat TreatmentDocument56 pagesHeat TreatmentAakarsh RastogiNo ratings yet

- 4Document63 pages4ARJUN PESARU 19BME0161No ratings yet

- Heat Treatment - Critical Temperatures - Transformation On Heating / CoolingDocument23 pagesHeat Treatment - Critical Temperatures - Transformation On Heating / Coolingsamurai7_77No ratings yet

- Ch-8 Compatibility ModeDocument58 pagesCh-8 Compatibility Modedreamgurl9011No ratings yet

- Presentation On Heat TreatmentDocument43 pagesPresentation On Heat Treatmentgosaye desalegnNo ratings yet

- Professor Joe Greene Csu, ChicoDocument20 pagesProfessor Joe Greene Csu, ChicotripsachinNo ratings yet

- Iron-Carbon DiagramDocument3 pagesIron-Carbon DiagramnaniNo ratings yet

- 06-Iron (Fe) - Iron Carbide (Fe3C) Phase DiagramDocument42 pages06-Iron (Fe) - Iron Carbide (Fe3C) Phase DiagramTalaat Ahmed Mohamed El-Benawy100% (2)

- 3 Fe-Fe3C Phase DiagramDocument33 pages3 Fe-Fe3C Phase DiagramRajat Mishra100% (1)

- FALLSEM2019-20 MEE1005 ETH VL2019201001078 Reference Material I 29-Aug-2019 Fe-Fe3C Phase DiagramDocument33 pagesFALLSEM2019-20 MEE1005 ETH VL2019201001078 Reference Material I 29-Aug-2019 Fe-Fe3C Phase DiagramFazal KhanNo ratings yet

- Lec 7 Fe C DiagramDocument45 pagesLec 7 Fe C DiagramAdnan MehmoodNo ratings yet

- Heat Treatment Lecture NotesDocument48 pagesHeat Treatment Lecture Notes22210021 TANWADE RUTURAJ RAVINDRANo ratings yet

- Heat Treatment of SteelsDocument41 pagesHeat Treatment of Steelsyaswanth1992No ratings yet

- Heat Treatment of Steel PDFDocument8 pagesHeat Treatment of Steel PDFkaviatchennai100% (2)

- Time Temperature Transformation (TTT) or IsothermalDocument26 pagesTime Temperature Transformation (TTT) or IsothermalAfredo TrilasetyaNo ratings yet

- IRON - CARBON DiagramDocument15 pagesIRON - CARBON Diagramgadde39100% (2)

- Iron Carbon Diagram 6Document15 pagesIron Carbon Diagram 6Harris DarNo ratings yet

- Heat TreatmentDocument34 pagesHeat Treatmentrahul72No ratings yet

- TTT DiagramDocument26 pagesTTT Diagrammeckup123No ratings yet

- Carbon Steels: ME 215/205:materials Science LaboratoryDocument9 pagesCarbon Steels: ME 215/205:materials Science Laboratoryfaizan997No ratings yet

- Chapter 5 ContDocument39 pagesChapter 5 ContShishajimooNo ratings yet

- 8.heat TreatmentDocument7 pages8.heat Treatmentrohan_n_desai100% (2)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Welding Inspection, Steels Multi - Choice Question Paper (MFY-007)Document7 pagesWelding Inspection, Steels Multi - Choice Question Paper (MFY-007)Moses_JakkalaNo ratings yet

- Inverse Heat ConductionDocument23 pagesInverse Heat ConductionhsemargNo ratings yet

- Hardenability of Steel PDFDocument59 pagesHardenability of Steel PDFMOHAC KILICASLANNo ratings yet

- Ni HardMaterialDataandApplications 11017 PDFDocument28 pagesNi HardMaterialDataandApplications 11017 PDFhesamalaNo ratings yet

- Valvulas 41000 MasoneilanDocument35 pagesValvulas 41000 MasoneilanGabriel VelardeNo ratings yet

- Material Metallurgy - MCQDocument45 pagesMaterial Metallurgy - MCQSushant GhurupNo ratings yet

- Welding of Ferritic CreepDocument3 pagesWelding of Ferritic CreepMuhammed SulfeekNo ratings yet

- Microstructure of Rapidly Solidified Cu-Al-Ni Shape Memory Alloy RibbonsDocument10 pagesMicrostructure of Rapidly Solidified Cu-Al-Ni Shape Memory Alloy RibbonsMarité MalachevskyNo ratings yet

- Eff Ect of Heat Treatment Parameters On Material Properties of AISI 4140 SteelDocument3 pagesEff Ect of Heat Treatment Parameters On Material Properties of AISI 4140 SteelMatheus Paes PeçanhaNo ratings yet

- The Kinetics of Isothermal Martensitic Transformation of Zirconia Containing A Small Amount of YttriaDocument7 pagesThe Kinetics of Isothermal Martensitic Transformation of Zirconia Containing A Small Amount of YttriaShameekaNo ratings yet

- Lista MateriałówDocument7 pagesLista MateriałówVanessa KowalskaNo ratings yet

- Forming Limit Diagram of Advanced High Strength Steels (AHSS) BasedDocument7 pagesForming Limit Diagram of Advanced High Strength Steels (AHSS) BasedAnup AwateNo ratings yet

- International Journal of Plasticity: Rolf Mahnken, Andreas Schneidt, Thomas AntretterDocument22 pagesInternational Journal of Plasticity: Rolf Mahnken, Andreas Schneidt, Thomas AntretterKhouloud GharbiNo ratings yet

- Critical Review of Hot Stamping Technology For Automotive SteelsDocument13 pagesCritical Review of Hot Stamping Technology For Automotive SteelsFernando BarreraNo ratings yet

- Sub Zero Treatment FinalDocument20 pagesSub Zero Treatment FinalcristisoimosanNo ratings yet

- Material Science and Engineering Ch. 11 SolDocument56 pagesMaterial Science and Engineering Ch. 11 SolPatrick Gibson100% (1)

- Kaljenje I Drugo Po Boji Teorija MalaDocument7 pagesKaljenje I Drugo Po Boji Teorija MalaAnonymous dmhNTyNo ratings yet

- AISI 4340 HSLA Under Quenched and Tempered Conditions PDFDocument9 pagesAISI 4340 HSLA Under Quenched and Tempered Conditions PDFMs3a ProduksiNo ratings yet

- Etchant Composition Conc. Conditions Comments Kalling's No. 1Document1 pageEtchant Composition Conc. Conditions Comments Kalling's No. 1Nick LaveryNo ratings yet

- What Is A Jominy End Quench Test?Document18 pagesWhat Is A Jominy End Quench Test?faqhrulNo ratings yet

- Heat TreatmentDocument30 pagesHeat TreatmentDr-Bharath Vedashantha MurthyNo ratings yet

- The Jominy End Quench TestDocument4 pagesThe Jominy End Quench TestFaiz AmeeriNo ratings yet

- Metallurgical Characterization of M-Wire Nickel-Titanium Shape Memory Alloy Used For Endodontic Rotary Instruments During Low-CDocument3 pagesMetallurgical Characterization of M-Wire Nickel-Titanium Shape Memory Alloy Used For Endodontic Rotary Instruments During Low-C4umNo ratings yet

- Cle-Line CLF Catalog Rev1016Document127 pagesCle-Line CLF Catalog Rev1016Gilberto GarciaNo ratings yet

- The Morphology, Crystallography, and Chemistry of Phases in As-Cast Nickel-Aluminum BronzeDocument9 pagesThe Morphology, Crystallography, and Chemistry of Phases in As-Cast Nickel-Aluminum BronzeKay WhiteNo ratings yet

- Schaffler Diagram For High MN SteelsDocument4 pagesSchaffler Diagram For High MN SteelsEliel OrtizNo ratings yet

- A 1033 - 04 Qtewmzm - PDFDocument14 pagesA 1033 - 04 Qtewmzm - PDFTiến Lượng NguyễnNo ratings yet

- A Study of Austenite Precipitate Growth in Duplex Stainless Steel PDFDocument31 pagesA Study of Austenite Precipitate Growth in Duplex Stainless Steel PDFHarold Armando Muñoz100% (2)