Professional Documents

Culture Documents

Old Course Handout

Old Course Handout

Uploaded by

Chirag Bhanvadia0 ratings0% found this document useful (0 votes)

21 views3 pagesBits Piliani

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBits Piliani

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views3 pagesOld Course Handout

Old Course Handout

Uploaded by

Chirag BhanvadiaBits Piliani

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

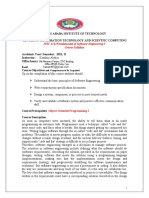

Birla Institute of Technology & Science, Pilani

Work-Integrated Learning Programmes Division

First Semester 20112012

Course Handout

Course No : ET ZC342

Course Title : Materials Management

Instructor : Amit Kumar Singh

Course Description

Integrated materials management, policy aspects, purchasing management, warehousing and storage of

inventory control systems, appraisal and control, just in time (JIT), automation in materials management.

Scope and Objective

At the end of the course, the student will be able to understand

Concepts and procedural aspects of the Integrated Materials Management

Purchasing, stores and warehousing concepts

Inventory management and cross functional areas using both qualitative and quantitative methods

Applications of computers in Materials Management

Prescribed Textbook

T1. Arnold, J.R. Tony & others, Introduction to Materials Management, Pearson Education, 6

th

Edition,

2007.

Reference Books

R1. Sunil Chopra & Peter Meindl, Supply Chain Management: Strategy, Planning and

Operation, Pearson Education, Third Edition 2007.

R2. Robert S. Russell, Bernard W.Taylor-II, Operations Management along the Supply Chain,

Wiley Publications, 6Th Ed

ET ZC342 (Course Handout) First Semester 2011-2012 Page 2

Plan of Self Study

Lecture

No.

Objective Topics Reference to

Text Book

1.

Introduction to Materials

Management

Introduction, Operating Environment, The

concept of supply chain, Material flow and

supply chain metrics

T1- Chapter 1

2.

Production Planning Systems Priority capacity relationship, manufacturing

planning and control system, SOP, MRP and

ERP

T1- Chapter 2

3.

Master Scheduling Relationship to production plan, Developing a

master production schedule, Production

planning, master scheduling and sales

T1- Chapter 3

4.

Material Requirements

Planning

Introduction to MRP, Bills of Material, MRP

process, Using the MRP plan

T1- Chapter 4

5.

Capacity Management Introduction, capacity planning, capacity

requirement planning, capacity available,

capacity required, scheduling orders, making the

plan

T1- Chapter 5

6.

Production Activity Control Introduction, Manufacturing systems, Data

Requirements, Scheduling, Scheduling

techniques, Scheduling bottlenecks, Theory of

constraints and drum buffer rope,

T1- Chapter 6

7.

Purchasing Introduction, objectives, cycle, establishing

specifications, functional specification

description, selecting suppliers, price

determination, Impact of MRP on purchasing

T1- Chapter 7

8 - 10

Forecasting

Introduction, Demand management and

forecasting, characteristics of demand,

principles of forecasting,

forecasting techniques, Tracking the forecast,

P/D Ratio

T1- Chapter 8 &

R1-R2

11-12

Inventory Fundamentals Introduction, Inventory and flow of material,

supply and demand patterns, Functions of

Inventories, Objectives of Inventory

management

Inventory costs, Financial statements and

inventory, Cash flow analysis, Area Inventory

control,

T1- Chapter 9 &

R1-R2

Syllabus for Mid-Semester Test (Closed Book): Topics in Lecture No. 1 to 12

ET ZC342 (Course Handout) First Semester 2011-2012 Page 3

Plan of Self Study

Lecture

No.

Objective Topics Reference to

Text Book

13

Order Quantities

Introduction, SKU, EOQ,

Variations of the EOQ model, Quantity

discounts, POQ

T1- Chapter 10 &

R1-R2

14-15

Independent Demand Ordering

Systems

Introduction, Order point system, Determining

safety stock, Determining service levels

Different forecast and lead time intervals,

Periodic review system, Distribution inventory

T1- Chapter 11 &

R1-R2

16.

Physical Inventory and

Warehouse Management

Introduction, Warehouse management, Physical

control and security, Inventory record accuracy,

T1- Chapter 12

17-18

Physical Distribution Introduction, Physical distribution system,

Legal types of carriage, Transportation cost

elements, Warehousing, Packaging, Material

Handling, Multi ware house systems

T1- Chapter 13

19-20

Products and Processes Need for new products, Product development

principles, Product specification and design,

process design, factors influencing process

design, Process systems, Selecting the process,

CPI,

T1- Chapter 14

21-22

Just-In-Time Manufacturing

and Lean Production

JIT philosophy, Waste, JIT environment,

Manufacturing planning and control in a JIT

environment, Lean production

T1- Chapter 15

23-24

Total Quality Management

Introduction, Quality cost concepts, Process

capability, Process control, Sample Inspection,

SO 9000, ISO 9000 series standards,

Benchmarking

T1- Chapter 16 &

R1-R2

Syllabus for Comprehensive Exam (Open Book): All topics given in Plan of Self Study

Evaluation Scheme:

EC

No.

Evaluation Component &

Type of Examination

Duration Weightage Day, Date, Session, Time

EC-1 Assignment/ Quiz TBA 10% TBA

EC-2 Mid-Semester Test

(Closed Book)*

2 Hours 30% Saturday, 03/09/2011 (FN)*

10 AM 12 Noon

EC-3 Comprehensive Exam

(Open Book)*

3 Hours 60% Saturday, 29/10/2011 (FN)*

9 AM 12 Noon

* Legend:

AN: AfterNoon Session; FN: ForeNoon Session; TBA : To be announced

Closed Book Test: No reference material of any kind will be permitted inside the exam hall.

Open Book Exam: Use of any printed / written reference material (books and notebooks) will be permitted inside the

exam hall. Loose sheets of paper will not be permitted. Computers of any kind will not be allowed inside the exam hall.

Use of calculators will be allowed in all exams. No exchange of any material will be allowed.

Instructor-in-Charge

You might also like

- Software Process and Project Management PDFDocument3 pagesSoftware Process and Project Management PDFMa AshrafNo ratings yet

- Information Technology Project Management Interview Questions: IT Project Management and Project Management Interview Questions, Answers, and ExplanationsFrom EverandInformation Technology Project Management Interview Questions: IT Project Management and Project Management Interview Questions, Answers, and ExplanationsRating: 4 out of 5 stars4/5 (4)

- EE4001 Software Engineering - OBTLDocument5 pagesEE4001 Software Engineering - OBTLAaron TanNo ratings yet

- Software EngineeringDocument3 pagesSoftware EngineeringDebanjan ChaudhuriNo ratings yet

- IT6T1Document2 pagesIT6T1Vyshnavi ThottempudiNo ratings yet

- Software Design and Architecture SWE-501Document2 pagesSoftware Design and Architecture SWE-501Faseeh SultanNo ratings yet

- Vtu Se SyllabusDocument34 pagesVtu Se SyllabusoceanparkkNo ratings yet

- 6th Sem SyllabusDocument41 pages6th Sem Syllabusdspreddy2003No ratings yet

- 6th Sem 1 CssyllDocument13 pages6th Sem 1 CssyllPrashant SherikarNo ratings yet

- 21 SchemeDocument4 pages21 SchemeraghuaceNo ratings yet

- DCSN200 Operations Management Spring 2012Document8 pagesDCSN200 Operations Management Spring 2012Maya Hariri HallabNo ratings yet

- SPM-M.techDocument19 pagesSPM-M.techNaga Phaniraj YechuriNo ratings yet

- Aimlsyll RemovedDocument13 pagesAimlsyll RemovedDeviprasad N ShettyNo ratings yet

- SS ZGDocument8 pagesSS ZGSaket ShrivastavaNo ratings yet

- Bacs3413 Project II 22.1.16Document4 pagesBacs3413 Project II 22.1.16Rexl RxzNo ratings yet

- Object Oriented Software Engineering ProjectDocument4 pagesObject Oriented Software Engineering Project2K18/SE/069 JAI CHAUDHRYNo ratings yet

- CSEB414/CSEB444 Advanced Soft. Engineering: Lecturer: Office: Telephone: E-Mail: Website Course OverviewDocument4 pagesCSEB414/CSEB444 Advanced Soft. Engineering: Lecturer: Office: Telephone: E-Mail: Website Course OverviewDarren GeeNo ratings yet

- SPM 3-I Couse File FormatDocument18 pagesSPM 3-I Couse File Formatnvsrinivasan1991No ratings yet

- My Syll12Document5 pagesMy Syll12Baljinder KambojNo ratings yet

- MGM'S: Laboratory ManualDocument34 pagesMGM'S: Laboratory ManualrameshNo ratings yet

- Sppu Be Computer 2015 StqaDocument2 pagesSppu Be Computer 2015 StqaSwapnil Shinde0% (1)

- CSC 263Document4 pagesCSC 263guiragossianstephanieNo ratings yet

- BSC Final Year Project-Teachers CBT Testing Centre ApplicationDocument128 pagesBSC Final Year Project-Teachers CBT Testing Centre ApplicationRennie Ramlochan100% (1)

- My SyllDocument5 pagesMy SyllBaljinder KambojNo ratings yet

- CS 360-Software Engineering-Hamid Abdul BasitDocument4 pagesCS 360-Software Engineering-Hamid Abdul BasitZia AzamNo ratings yet

- CN7021 - Advanced Software EngineeringDocument3 pagesCN7021 - Advanced Software EngineeringOgbonna VitalisNo ratings yet

- CSE - 3637 Lecture PlanDocument2 pagesCSE - 3637 Lecture PlanCHILE KOTHANo ratings yet

- Fundamentals of Software Engineering Course Outline 2017Document4 pagesFundamentals of Software Engineering Course Outline 2017Priyanshu PathakNo ratings yet

- Software Project ManagDocument23 pagesSoftware Project ManagDeepak GourNo ratings yet

- Professional/academic Knowledge and SkillsDocument4 pagesProfessional/academic Knowledge and SkillsVikas NagareNo ratings yet

- MM ZG522Document5 pagesMM ZG522Krishna VamsiNo ratings yet

- Lecture 1Document18 pagesLecture 1malikbbbbbb86No ratings yet

- Project ManagementDocument2 pagesProject ManagementAmmiraju ChoudharyNo ratings yet

- Software SyllabusDocument3 pagesSoftware SyllabusELAINE M PAILY CSNo ratings yet

- 1-B.tech (Computer Science & Engg) 7th & 8th Sem.Document16 pages1-B.tech (Computer Science & Engg) 7th & 8th Sem.Rahul TyagiNo ratings yet

- Syllabus 6329Document7 pagesSyllabus 6329MsrNo ratings yet

- Industrial Course SyllabiDocument81 pagesIndustrial Course SyllabiIbrahim AlhowaishNo ratings yet

- Qec SeDocument2 pagesQec SefastfurqanNo ratings yet

- Software Engineering Lab Manual For GUDocument47 pagesSoftware Engineering Lab Manual For GUABCNo ratings yet

- 1 21cst601-SepmDocument3 pages1 21cst601-Sepmvarshithaga3052003No ratings yet

- SW - Eng Course OutlineDocument3 pagesSW - Eng Course Outlinemekides100% (1)

- SPM Course OutlinesDocument8 pagesSPM Course OutlinesMadeehah AatifNo ratings yet

- Architecture of Service Oriented Information Systems (ASOIS)Document2 pagesArchitecture of Service Oriented Information Systems (ASOIS)Fllore omgNo ratings yet

- Global Institute of TchnologyDocument6 pagesGlobal Institute of Tchnologykaps_er_3No ratings yet

- STM PDFDocument184 pagesSTM PDFSANDHYA MISHRANo ratings yet

- SSZG 515Document2 pagesSSZG 515dablugauravNo ratings yet

- Independent University, Bangladesh Department of Computer Science & Engineering Course OutlineDocument4 pagesIndependent University, Bangladesh Department of Computer Science & Engineering Course OutlineZulker NienNo ratings yet

- Course Plan of Object Oriented Software Engineering I Me CseDocument4 pagesCourse Plan of Object Oriented Software Engineering I Me CsesurendiranNo ratings yet

- Learning Outcomes of Introductory Engineering Courses: Student Percep-TionsDocument15 pagesLearning Outcomes of Introductory Engineering Courses: Student Percep-TionsGanesh BabuNo ratings yet

- Stqa Co 23-24Document10 pagesStqa Co 23-24Ruchira suryawanshiNo ratings yet

- ITC51 (Systems Analysis & Design)Document4 pagesITC51 (Systems Analysis & Design)ehhunterNo ratings yet

- ELE9304 Syllabus 18-19Document3 pagesELE9304 Syllabus 18-19umarsaboNo ratings yet

- Course Handout SADocument9 pagesCourse Handout SAValiveti KumariNo ratings yet

- Engineering Problem Solving (ENGR 196) : Credit Hours: Class HoursDocument8 pagesEngineering Problem Solving (ENGR 196) : Credit Hours: Class HoursWeiHongNo ratings yet

- Muffakham Jah College of Engineering and Technology Information Technology Department Course Handout 2013-2014Document2 pagesMuffakham Jah College of Engineering and Technology Information Technology Department Course Handout 2013-2014Sobhan DasariNo ratings yet

- The Complete Project Management Exam Checklist: 500 Practical Questions & Answers for Exam Preparation and Professional Certification: 500 Practical Questions & Answers for Exam Preparation and Professional CertificationFrom EverandThe Complete Project Management Exam Checklist: 500 Practical Questions & Answers for Exam Preparation and Professional Certification: 500 Practical Questions & Answers for Exam Preparation and Professional CertificationNo ratings yet

- Fundamentals of Software Engineering: Designed to provide an insight into the software engineering conceptsFrom EverandFundamentals of Software Engineering: Designed to provide an insight into the software engineering conceptsNo ratings yet