Professional Documents

Culture Documents

Deck - Wood

Deck - Wood

Uploaded by

Cristian RaduOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deck - Wood

Deck - Wood

Uploaded by

Cristian RaduCopyright:

Available Formats

deck

Georgia-Pacific

from

backyard projects

deck

MATERIALS LIST

5 1" x 6" x 8' treated lumber

98 2" x 4" x 8' treated lumber

5 2" x 6" x 8' treated lumber

2 2" x 8" x 8' treated lumber

9 2" x 8" x 12' treated lumber

1 2" x 8" x 16' treated lumber

1 2" x 10" x 12' treated lumber

3 2" x 10" x 16' treated lumber

2 2" x 12" x 12' treated lumber

1 2" x 12" x 16' treated lumber

3 4" x 4" x variable length treated lumber

18 hot-dipped galvanized or stainless steel

joist to beam framing anchors

32 hot-dipped galvanized or stainless steel

corner braces

50 2 1/2" hot-dipped galvanized or stainless

steel machine bolts, 1/4" diam., with

2 washers per bolt

40 4" hot-dipped galvanized or stainless steel

machine bolts, 3/8" diam., with 2 washers

per bolt

72 6 1/2" hot-dipped galvanized or stainless

steel machine bolts, 3/8" diam., with

2 washers per bolt

9 7 1/2" hot-dipped galvanized or stainless

steel machine bolts, 3/8" diam., with

2 washers per bolt

32 2" hot-dipped galvanized or stainless steel

lag screws, 1/4" diam., with 1 washer

per lag screw

18 4" hot-dipped galvanized or stainless steel

lag screws, 3/8" diam., with 1 washer

per lag screw

28 7" hot-dipped galvanized or stainless steel

lag screws, 3/8" diam., with 1 washer per

lag screw

20 lbs. 16d hot-dipped galvanized or stainless

steel nails

8 90 lb. sacks, prepackaged concrete mix

1 1/2 cubic ft. washed gravel

DECK

NOTE: For a free standing deck, one

additional beam assembly and

additional hand rails are required.

STEPS

2 1" x 6" x variable length treated lumber

4 1/2 per step -- 2" x 4" x 8' treated lumber

1/2 per baluster post -- 2" x 4" x 8' treated

lumber

Variable -- 2" x 4" x 10' treated lumber

(10' will do cleats for 4 steps)

2 2" x 6" x variable length treated lumber

1 2" x 8" x 8' treated lumber

2 2" x 12" x variable length treated lumber

1 4" x 4" x 8' treated lumber

8 4" galvanized corner braces

12 2 1/2" galvanized machine bolts, 1/4" diam.,

with 2 washers per bolt

4 per step -- 4" galvanized machine bolts, 1/4"

diam., with 2 washers per bolt

5 5 1/2" galvanized machine bolts, 3/8" diam.,

with 2 washers per bolt

2 per baluster -- 6 1/2" galvanized machine bolts,

3/8" diam., with 2 washers per bolt

8 2" galvanized lag screws, 1/4" diam., with

1 washer per bolt

TIP: Use water repellent or stain with water repellent

when your job is finished to help protect your

pressure treated wood from splitting, checking,

and warping.

NOTE: Deviations from or alterations to the deck plan

may affect structural stability. Consult with a local

designer before altering plan. All spans designed for

No. 2 or better Southern Pine.

NOTE: In some applications you may use screws

instead of nails for better holding power.

Georgia-Pacific Corporation makes no warranties expressed or implied

regarding this plan and specifically disclaims the warranties of merchant-

ability and fitness for a particular purpose. Check with an architect or a

building expert to make sure that this plan is appropriate to your situation

and meets local building codes. Read carefully the consumer information

sheet on pressure treated wood before starting construction.

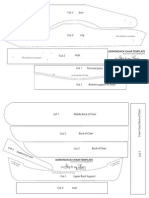

deck

2 x 4 Decking - nail with 16d, hot-dipped

galvanized nails

3/16" Spacing between decking

2 x 8 Joist with framing anchor at beam

Galvanized corner brace--each side of joist, 2" from

top of joist and header, bolt with 2 1/2" galv.

machine bolts, 1/4" diam., with 2 washers

2 x 8 Header--nail with 16d, hot-dipped galv. nails

2 x 12 Fascia--bolt to header with 4" galv . machine bolts,

3/8"diam., with 2 washers

2 x 10 Beam--attach with 3 - 7 1/2" galv.

machine bolts, 3/8" diam., with 2 washers

2 x 8 Ledger-- attach with 5-5 1/2" galv. machine bolts,

3/8" diam., with 2 washers, 10" o.c.

Ground level

4 x 4 Post--height varies, 1/3 of post must be below

ground level, with a minimum of 2 1/2' below ground

level - max. post height above ground level - 8'

Concrete footing

Washed gravel

2 x 12 Stringer--attach to ledger with 2" - 4"

corner braces and toenail to the ledger

- max. length 10'

NOTE: Allow a 1/4" joint between butt joints on the decking.

BEAM SECTION AT WALL

SECTION THRU RAIL

Existing structure

1/2" Joint at wall

2 x 4 Decking

3/16" Spacing

2

"

2 x 10 Spacer block

2 x 10 Beam--bolt thru spacer bloc

structural member in wall with a 7" galv

lag screw, 3/8" diam., with washer

- for masonry walls use galv. masonry

bolts and anchor, with washer

2 x 4 Ledger--bolt to beam

with 4" galv. lag screws,

3/8" diam., with washer Countersink lag screw

behind ledger

2 x 8 Joist

4" Galv. corner brace, each side of

joist - bolt to joist with 2 1/2" galv

machine bolts, 1/4" diam., with 2

washers, bolt to beam with 2" galv

lag screws, 1/4" diam, with washer

3

'

1

1

1

/

4

"

4

"

4

"

2"

2 x 6 Cap rail

1 x 6 Side rail

2 x 4 Baluster

3/16" Spacing

2 x 4 Decking

2 x 8 Joist

4" Corner bracer at joist

2 x 8 Header

6 1/2" Galv. machine bolt, 3/8" dia., with

2 washers, countersink head 1/2"

2 x 12 Facia

SECTION THRU LEDGER

2 x 4 Decking--nail thru outside of stringer

3/16" Spacing between decking

2 x 8 Ledger

2 x 12 Facia

2 x 8 Header

2 x 4 Decking

2 x 8 Joist

Galv. corner brace--each side of joist,

2" from top of joist and header

with 2 1/2" galv. machine bolts,

diam., with 2 washers

4" Galv. machine bolts

Attach 2 x 8 ledger with 5 - 5 1/2" galv

machine bolts, 3/8" diam., with 2 washers,

10" o.c., countersink boltheads 1/4"

2 x 4 Cleat

2 x 12 Stringer--attach to facia with two 4" corner braces

and toenail to ledger with 16d, hot-dipped galv. nails

6'

10'

12'

12"

2'

2'

2' o.c.

7' o.c.

12"

12"

12"

o.c

Miter joint

2 x 6 Cap rail

9'

16'

4' 3'

6'

1'6" 12"

1

2

"

2' o.c. 2'

6"

6

"

1

2

"

v

a

r

i

e

s

1/2" Joint between decking and wall

Possible location for deck - next to an existing door

6"

6"

3'9"

4 x 4 Footing

2 x 4 Decking

Steps - Number of steps must be

adjusted for the height differences

of each individual site

2 x 12 Stringer

2 x 8 Header

2 x 12 Fascia

2 x 10 Beams

Attach joist to beam with

framing anchors

4 x 4 Posts

2 x 8 Blocking

2 x 12 Facia

2 x 8 Joist

2 x 4 Baluster

Extend decking to edge of

joist - allow a 3/16" joint at

end of decking

Open space between spacer

blocks for drainage

2 x 4 Decking - alternate joints

2 x 10 Spacer block

Existing structure

2 x 4 Ledger

2 x 10 Beam

DECK PLAN

SECTION THRU STEPS, POST, & BEAM

varies

6"

4 x 4 Footing

- attach with

two 4" corner

braces

45 angle

2 x 4 Cleat - attach with

two 4" galv. machine

bolts, 1/4" diam., with 2

washers

5

1

/

2

"

15"

3"

4" 4" 7"

12" 6"

2'

v

a

r

i

e

s

3

"

6

"

2"

2 x 6 Cap rail

1 x 6 Side rail

2 x 4 Baluster

2 x 4 Baluster

12"

3'

2 x 4 Decking--

nail thru out-

side of stringer

Build Safely with Pressure-Treated Wood

Whether youre building a new planter or replacing your deck,

Georgia-Pacific pressure-treated wood is the high performance decking

choice. The projects you build with Georgia-Pacific pressure-treated

wood products should last a long time. So, it makes good sense to build

in a craftsmanlike manner. Here are some helpful tips to make your job

easier and look better.

For the latest information about pressure-treated wood, visit www.GP.com, or call 1-800-282-0600.

1.

Recommended

Fasteners.

2.

Nail bark

side up.

Always nail boards bark side up (annual rings arc upward) to

reduce cupping. Nail thin boards to thicker boards to help

maintain structural integrity.

3.

Drill pilot

holes.

Especially when nailing near the edge or end of a board, its a

good idea to drill pilot holes for your fasteners.

4.

Butt boards

tightly.

Butt decking boards together firmly. As drying occurs,

some shrinkage can be expected.

5.

Apply a

weather-

resistant

finish.

Any exposed wood, pressure treated or not, should be protected from

the weather. Application of a finish coat of clear or semi-transparent

water-repellent stain will help to minimize warping, checking, or

splitting. The finish coat should be applied immediately to untreated

wood and to pressure treated wood as soon as the surface is dry.

Did you

know?

Pressure-treated wood may

be painted or stained to

match any outdoor color

scheme. High-quality

latex-based paints and

oil or latex stains are

recommended. Make sure

the wood is dry and free

from surface deposits

before applying any

coating.

Water repellent coatings

can be applied to enhance

the long-term weathering

performance.

Only wood that is visibly

clean and free of surface

residue should be used for

patios, decks and

walkways.

To help maximize surface

protection and to keep

your wood looking better

longer, GP recommends

that a surface applied

water repellent be applied

every two years.

Safety Dispatch

Use only hot-dipped galvanized or stainless steel fasteners, connectors

and hardware to help safeguard the structural integrity of projects built

with ACQ treated wood.

As a minimum requirement for use with ACQ treated wood, hot-dipped

galvanized coated fasteners should conform to ASTM Standard A153

and hot-dipped galvanized coated connectors should conform to

ASTM Standard A653 (Class G-185). In demanding applications, such

as treated wood foundations and playground equipment, use of

stainless steel fasteners and connectors should be utilized and may,

in fact, be required by building codes.

Electroplated galvanized fasteners are not recognized as being

corrosion resistant for exterior applications. Aluminum should not be

used in direct contact with CCA or ACQ treated wood.

Safety First

Pressure-treated wood is easy to

work with. The following simple

safety procedures are recommended.

Do not burn treated wood. Toxic materials may be

produced as part of the smoke or ashes.

Clean up scraps & sawdust after construction and dispose by ordinary trash

collection.

Gloves should be worn to protect against splinters and abrasions.

A dust mask should be worn when sawing, machining or sanding any wood

to reduce the inhalation of wood dust. Whenever possible these operations

should be performed outdoors to avoid indoor accumulations of airborne

sawdust from treated wood.

Appropriate eye protection should be worn to reduce the potential for eye

injury from wood dust or particles and flying debris during machining and

construction.

After working with pressure-treated wood, thoroughly wash your hands and

exposed areas thoroughly with mild soap and water before eating, drinking

or using tobacco products.

Because preservatives or sawdust may accumulate on clothes, they should be

laundered before reuse. Wash work clothes separately from other clothing

or household items with which you may have contact.

Treated wood should not be used where it may come into direct or indirect

contact with drinking water, except for uses involving incidental contact

such as fresh water docks and bridges.

Q. What kinds of projects are ideal

for pressure-treated wood?

A. Choose GP pressure-treated

wood for decks, porches,

gazebos, planters, arbors and

other outdoor structures. Youll

enjoy the beauty of wood plus

long-lasting performance.

Q. How do I dispose of unused

wood?

A. Scraps and sawdust should be

disposed with ordinary trash. Do

not burn treated wood, as toxic

materials may be produced as

part of the smoke or ashes.

Q. What is ACQ?

A. Alkaline Copper Quaternary

(ACQ) is a chemical solution used

as a preservative treatment for

wood to help provide long-term

protection from rot, decay and

termites. The main active

ingredient in ACQ is copper,

which has long been established

as the most cost-effective

preservative component used in

preserving timber. Quat acts as

the co-biocide in the ACQ

preservative, providing additional

protection from decay fungi and

termite attack that copper alone

would not control. Copper and

quat solutions similar to ACQ

are used for the control of fungi

and bacteria in swimming pools

and spas.

Q. How long has ACQ been in use?

A. For more than a decade, ACQ has

been used in neighborhood

playgrounds, backyards and other

outdoor projects.

Q&A

2004 Georgia-Pacific Corporation. All rights reserved. Printed in USA.

3/04 Lit. Item #121160.

Use Site Precautions

ACQ treated wood may be used both inside

residences (should be clean and free of surface

residues) and outdoors. However, it should not

be used in or on sites where it could come into

contact with food, animal feed or drinking water.

Examples of such sites are as follows:

1. Structures for storage or handling animal feed,

(grain, silage, etc.) such as silos, feed troughs or

bunks.

2. Use as kitchen countertops or cutting boards.

3. Use in construction of those portions of

beehives which may come into contact with the

honey.

4. Structures that would be in direct or indirect

contact with drinking water, except for uses

involving incidental contact such as residential

fresh water docks and bridges. ACQ treated

lumber should not be used in salt-water

immersion applications.

5. Do not use ACQ treated lumber residues,

such as sawdust and shavings, as mulch.

Interested

in building

a porch swing?

See our

project plans at

www.gp.com/build.

You might also like

- Doormaking - A Do-It-Yourself GuideDocument202 pagesDoormaking - A Do-It-Yourself GuideFlo RenceNo ratings yet

- Parts List For 263 Pc. Mechanic's Tool Set #40263Document2 pagesParts List For 263 Pc. Mechanic's Tool Set #40263Juan KarLoz100% (2)

- Boral Installation MasonryGuideDocument25 pagesBoral Installation MasonryGuidem0172No ratings yet

- Domino Zigzag ChairDocument6 pagesDomino Zigzag ChairAlex Johnston0% (1)

- The Complete Outdoor Builder PDFDocument563 pagesThe Complete Outdoor Builder PDFAnonymous S3VjSTY100% (6)

- Solignum Colourless Wood PreservativeDocument2 pagesSolignum Colourless Wood Preservativebt17100% (4)

- TimberDocument35 pagesTimberMuskaan Chowdhary75% (8)

- SANS10005 (Amdt1)Document12 pagesSANS10005 (Amdt1)Johnnie StrydomNo ratings yet

- C 840 - 13 - Application and Finishing of Gypsum BoardDocument18 pagesC 840 - 13 - Application and Finishing of Gypsum BoardJose100% (3)

- Accoya Structural Design GuideDocument24 pagesAccoya Structural Design GuideMIlos AndricNo ratings yet

- Lean ToToolShedDocument17 pagesLean ToToolShedJeremy Smathers100% (2)

- Firewood GarbageShedDocument13 pagesFirewood GarbageShedJeremy SmathersNo ratings yet

- 8 X 10 Timber ShedDocument19 pages8 X 10 Timber ShedJeremy Smathers100% (1)

- Deck Construction GuideDocument13 pagesDeck Construction Guidefaxtackley100% (2)

- Occasional Table: Woodworks: Intermediate ProjectDocument7 pagesOccasional Table: Woodworks: Intermediate ProjectEucap MdzNo ratings yet

- Red Wing Steel Works 3x5 Heavy Duty Welding Table Plans PDFDocument7 pagesRed Wing Steel Works 3x5 Heavy Duty Welding Table Plans PDFDavid BondNo ratings yet

- Floor Covering Installer - October 2015Document52 pagesFloor Covering Installer - October 2015David KošićNo ratings yet

- Chief Architect x5 Users Guide House TutorialDocument42 pagesChief Architect x5 Users Guide House TutorialGema SuryaNo ratings yet

- Lowes Deck Design ForDocument13 pagesLowes Deck Design ForCarmen C BejaranNo ratings yet

- How To Make A Cornhole BoardDocument4 pagesHow To Make A Cornhole BoardAndré VeigaNo ratings yet

- Beach ChairDocument48 pagesBeach ChairEmilian BalutaNo ratings yet

- Wall Mounted Shoe RackDocument7 pagesWall Mounted Shoe RacksyafiqNo ratings yet

- Lowes Deck Plan 3Document15 pagesLowes Deck Plan 3Ant100% (2)

- All American TreehouseDocument50 pagesAll American Treehousecompulsorylogin50% (2)

- Beer CompletDocument45 pagesBeer CompletMurat KaraNo ratings yet

- Step of Concrete SlabDocument5 pagesStep of Concrete SlabMine MienNo ratings yet

- Planos para Gabinete Esquinero de MaderaDocument16 pagesPlanos para Gabinete Esquinero de MaderaIsmael Perez100% (2)

- OSHA 3157 - A Guide For Protecting Workers From Woodworking HazardsDocument74 pagesOSHA 3157 - A Guide For Protecting Workers From Woodworking HazardsWahed Mn ElnasNo ratings yet

- Architectural Designs:: 57 Danbury Road:: Wilton, CT 06897 USA & Canada 1-800-854-7852 or 1-877-229-2447:: International 262-521-4596Document23 pagesArchitectural Designs:: 57 Danbury Road:: Wilton, CT 06897 USA & Canada 1-800-854-7852 or 1-877-229-2447:: International 262-521-4596farhat4464No ratings yet

- How To Build A Double Chair Bench With TableDocument27 pagesHow To Build A Double Chair Bench With TablebearyuyuNo ratings yet

- Adirondack Chair TemplatesDocument7 pagesAdirondack Chair TemplatesDebbie MackNo ratings yet

- Drop Leaf TableDocument3 pagesDrop Leaf Table- yAy3e -No ratings yet

- Basic Steps For Building A DeckDocument5 pagesBasic Steps For Building A DeckRi SovannaphumiNo ratings yet

- Barn Door Baby GateDocument17 pagesBarn Door Baby GateNovitates1No ratings yet

- Planos Casa de JuegosDocument47 pagesPlanos Casa de Juegosdaniel estrada0% (1)

- Floating Shelf Drawer: An Out of The Woodwork Project PlanDocument23 pagesFloating Shelf Drawer: An Out of The Woodwork Project Planthanush_thampanNo ratings yet

- Adriondack Chair Template 2012Document2 pagesAdriondack Chair Template 2012pocetnikNo ratings yet

- A Circular Saw in The Furniture Shop-FinewoodworkingDocument4 pagesA Circular Saw in The Furniture Shop-Finewoodworkingkurt100% (1)

- Wall and CeilingDocument16 pagesWall and CeilingAbhishek JaniNo ratings yet

- Choosing Logs (Profiles & Packages)Document9 pagesChoosing Logs (Profiles & Packages)JP VersterNo ratings yet

- Backyard ProjectsDocument5 pagesBackyard Projects- yAy3e -No ratings yet

- Kreg Tool - Innovative Solutions For All of Your Woodworking and DIY Project NeedsDocument5 pagesKreg Tool - Innovative Solutions For All of Your Woodworking and DIY Project NeedsFernandoNo ratings yet

- 150 Cordwood CabinDocument4 pages150 Cordwood CabinEmmanuel BarbiniNo ratings yet

- Woodworking TeknikDocument11 pagesWoodworking TeknikRobbyRokhyadiNo ratings yet

- Ditra HandbookDocument36 pagesDitra HandbookghejanNo ratings yet

- A Complete Guide To Building Your Own Deck PDFDocument16 pagesA Complete Guide To Building Your Own Deck PDFremowood100% (1)

- Brick Veneer WallDocument16 pagesBrick Veneer Wallpilapil_jNo ratings yet

- Deluxe Router TableDocument27 pagesDeluxe Router TableNebojša JovanovNo ratings yet

- Woodsmith Magazine - Plans Now - Router Table ReviewDocument6 pagesWoodsmith Magazine - Plans Now - Router Table ReviewPaweł JamrożekNo ratings yet

- Roll Around Kitchen Cart: MLCS Items UsedDocument15 pagesRoll Around Kitchen Cart: MLCS Items UsedTETSUO111No ratings yet

- Advanced Project Oak Pie SafeDocument9 pagesAdvanced Project Oak Pie SafeMark_Voigt_4580No ratings yet

- Plans Triple Picture FrameDocument7 pagesPlans Triple Picture Framehmam_88100% (1)

- How To Make A Pine Cone Chandelier - 6 Steps (With Pictures)Document12 pagesHow To Make A Pine Cone Chandelier - 6 Steps (With Pictures)Marisa LopezNo ratings yet

- Murphy Bed InstDocument20 pagesMurphy Bed InstRobert ParkerNo ratings yet

- Hall TreeDocument6 pagesHall TreeDeb HallNo ratings yet

- RS1281 Utah URM GuideDocument130 pagesRS1281 Utah URM GuideAlyssa Roberts100% (1)

- MultiGrip PDFDocument4 pagesMultiGrip PDFluning liNo ratings yet

- Timber-Frame Garden Shed: Index Furnishings Outdoor Wood FurnishingsDocument7 pagesTimber-Frame Garden Shed: Index Furnishings Outdoor Wood Furnishingscarra80100% (1)

- Kitchen Planning Guide 2021Document7 pagesKitchen Planning Guide 2021Altair GomesNo ratings yet

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersFrom EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNo ratings yet

- Woodwork Joints: How They Are Set Out, How Made and Where UsedFrom EverandWoodwork Joints: How They Are Set Out, How Made and Where UsedNo ratings yet

- There Are Secrets to Tiling: The Best Way to Tile from Start to FinishFrom EverandThere Are Secrets to Tiling: The Best Way to Tile from Start to FinishNo ratings yet

- A Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.From EverandA Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.No ratings yet

- 2014shed 55065 GardenShed MatList WebDocument1 page2014shed 55065 GardenShed MatList Webrfjm28rxgdNo ratings yet

- 12 BY8 ShedplanDocument30 pages12 BY8 Shedplanhaheq100% (1)

- Ultimate Adjustable SawhorseDocument22 pagesUltimate Adjustable SawhorseNorbert VesztergomNo ratings yet

- Children's Bunkhouse LoftDocument7 pagesChildren's Bunkhouse Loft- yAy3e -100% (3)

- Chest of Drawers 2Document6 pagesChest of Drawers 2khunchaiyai100% (3)

- Crotch-Grained Chess Table: Walnut, PoplarDocument5 pagesCrotch-Grained Chess Table: Walnut, Poplarkhunchaiyai100% (2)

- Carved Fruit BowlDocument5 pagesCarved Fruit Bowlkhunchaiyai100% (1)

- Cherry End TableDocument5 pagesCherry End TablekhunchaiyaiNo ratings yet

- Bunk BedsDocument5 pagesBunk Bedskhunchaiyai100% (4)

- Chairside BookcaseDocument3 pagesChairside Bookcasekhunchaiyai100% (2)

- Bread BoxDocument3 pagesBread Box- yAy3e -No ratings yet

- Candle BoxDocument4 pagesCandle Box- yAy3e -No ratings yet

- Build A Toy BoxDocument10 pagesBuild A Toy BoxkhunchaiyaiNo ratings yet

- Book Case 2Document5 pagesBook Case 2khunchaiyai100% (1)

- Classic Bow SawDocument6 pagesClassic Bow Saw- yAy3e -No ratings yet

- Adjustable Plant ShelvesDocument3 pagesAdjustable Plant Shelves- yAy3e -No ratings yet

- NATSPEC Simple Domestic SpecificationDocument33 pagesNATSPEC Simple Domestic SpecificationBen BiiNo ratings yet

- Arsenic Fact SheetDocument1 pageArsenic Fact SheetEngineer MustafaNo ratings yet

- 007 DurabilityDocument28 pages007 Durabilityroy jackNo ratings yet

- Woodspec Final - Section ADocument45 pagesWoodspec Final - Section AtsousiNo ratings yet

- Materials & General Design Considerations Truss DesignDocument8 pagesMaterials & General Design Considerations Truss Designcivil_bookieNo ratings yet

- Week 3 Wood Processing (2) Specific Objectives: by The End of This Lesson, The StudentsDocument5 pagesWeek 3 Wood Processing (2) Specific Objectives: by The End of This Lesson, The StudentsNsikak InyangNo ratings yet

- Status of Timber Standardization in KenyaDocument7 pagesStatus of Timber Standardization in Kenyayrdgcgf5664No ratings yet

- Accoya-Collateral PerformanceTesting ENDocument24 pagesAccoya-Collateral PerformanceTesting ENj.saiyathNo ratings yet

- Timber Treatment Alternatives Organicnz Jul Aug 08Document4 pagesTimber Treatment Alternatives Organicnz Jul Aug 08Tina MacnicolNo ratings yet

- 2 07P01 PDFDocument28 pages2 07P01 PDFMike2322No ratings yet

- 09 Samss 002Document4 pages09 Samss 002Kalanithi KasirajanNo ratings yet

- D 1760 - 01 - Rde3njaDocument17 pagesD 1760 - 01 - Rde3njaPrastika Wahid SantosoNo ratings yet

- Is 9096 - 2006Document6 pagesIs 9096 - 2006Deepak Gadkari100% (1)

- Methods and Materials For Reducing Flammability Behaviour of Coir Fibre Based Composite Boards: A ReviewDocument9 pagesMethods and Materials For Reducing Flammability Behaviour of Coir Fibre Based Composite Boards: A ReviewsudhirNo ratings yet

- Conformed Set Division 6 - Wood and Plastics PDFDocument19 pagesConformed Set Division 6 - Wood and Plastics PDFNerinel CoronadoNo ratings yet

- RMS SpecificationDocument23 pagesRMS SpecificationXiaobing YangNo ratings yet

- Appendices Stop The RotDocument23 pagesAppendices Stop The RotAr Raj YamgarNo ratings yet

- A Handbook For The Sustainable Use of Timber in Construction Jim Coulson Full ChapterDocument67 pagesA Handbook For The Sustainable Use of Timber in Construction Jim Coulson Full Chapterlynn.anderson710100% (7)

- Thesis On Wood PreservationDocument5 pagesThesis On Wood Preservationjessicamoorereno100% (2)

- Fasteners For PlywoodDocument11 pagesFasteners For PlywoodfordesignNo ratings yet

- California Department of Boating and WaterwaysDocument47 pagesCalifornia Department of Boating and WaterwaysalaajabbarNo ratings yet

- Steel CatalogDocument102 pagesSteel CatalogАндрейNo ratings yet

- Wood - PlasticsDocument85 pagesWood - PlasticsKim Frances HerreraNo ratings yet

- NEA Memo To ECs No. 2018-033 - Conformity of Poles To NEA Standards As To Its Specifications and QualityDocument66 pagesNEA Memo To ECs No. 2018-033 - Conformity of Poles To NEA Standards As To Its Specifications and QualityOrville LokingNo ratings yet