Professional Documents

Culture Documents

Paving Paths & Patios

Uploaded by

Rm1262Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paving Paths & Patios

Uploaded by

Rm1262Copyright:

Available Formats

1.

Introduction

Well constructed paths and patios will enhance any domestic

property or garden. They are practically free of maintenance,

and make a satisfying home improvement project.

This leaflet covers all types of paving laid with open joints on

either a mortar or a sand bed. It will give the homeowner or

DIY enthusiast guidance on selecting materials, preparing

the site and recommends methods of laying the paving.

The publication excludes interlocking paving blocks which

are laid very close together without open joints on a sand

bed. The Concrete Manufacturers Association publications

cover this type of paving.

2. General

The paving materials you choose will depend on cost,

personal preference and whether a formal or informal effect

will suit your home. Generally, the thicker the units, the

stronger the paving will be and the greater the loads the

paving will carry without distorting.

The finished paving must have a minimum slope of 1 in 50

for proper drainage. Paving must slope away from buildings.

Avoid low areas where water can collect.

3. Preparing the site

The ground below the paving

must be firm and stable so that

it does not settle unevenly with

time. It must have the same slope

as the finished paving.

Remove all roots and vegetable

matter from the site, and

preferably, the topsoil. Then trim

the bed to the correct level and

slope. Soft areas and areas that

have been filled must be well

stamped down with, for example,

a gumpole. If the fill is very dry,

mix in just enough water to

dampen it and then compact it.

Finally, recheck surface levels and slopes and correct them

if necessary.

4. Materials for the mortar bed

Cement

For the mortar bed always use cement which has an SABS

mark and complies with either SANS 50413-1 (masonry

cements) or SANS 50197-1(common cements). Use a 1: 5 mix

for masonry cements and a 1:6 mix for other cements.

Sand

A simple way of deciding whether a sand is suitable for

mortar is to mix 5 kg of cement with 25 kg of air dry sand

and then add enough water to produce a consistency suit-

able for mortar. If more than 6 litres of water is needed, the

sand is unsuitable.

5. Recommended methods of laying

Units less than 40 mm thick should always be laid on a bed

of mortar to give a total thickness of not less than 40 mm.

Thicker units may be laid on a sand bed.

paths & patios

Paving

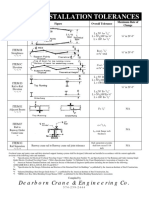

Type of paving Thickness of Units Method of Laying

Open-spaced bricks 50 mm or more Preferably on a sand bed:

otherwise on earth. Joints

10 mm wide, filled with mortar.

Concrete paving flags 35 to 50 mm On a sand bed with sand-filled

joints (paths); or on a mortar bed

with mortar-filled joints (patios).

Slate or slasto 35 to 40 mm On a mortar bed.

Joints filled with mortar.

Quarry or concrete tiles 20 to 25 mm On a mortar bed.

Joints filled with mortar.

Type of paving and methods of laying

If paving is laid on sand, a kerb should be provided to prevent outward movement.

6. Laying procedures

On mortar

Mix one part cement with six parts sand until the colour is

uniform and then add water slowly. You will need soft mortar

- about the consistence of toothpaste.

Alternatively the in situ soil can be stabilized as follows:

Loosen the top 50 mm of soil and then spread cement

at a rate of 1 bag / 8 m

2

.

Mix and add water until the mix has the consistence of

a smooth paste.

Lay small areas of about 1 m

2

at a time. Lay a bed of mortar

so that the paving plus mortar will be 40 mm or thicker. The

mortar layer thickness should not be less than 15 mm. Place

the paving units on the mortar, tap each one down firmly and

check that it is level and at the correct slope. The mortar will

rise a little into the joint between the units.

On sand

Spread a layer of loose sand 25 mm thick and level it off. Lay

the paving units on this and tap each one firmly into place

with, for example, a wooden mallet.

Check regularly that the paving is at the correct slope and

that the units are correctly lined up.

7. Jointing

With sand

Pour dry sand on the surface of the paving and brush it into

the spaces between the units. Then water it lightly to wash

the sand well down into the joints. The sand stabilises the

paving by limiting the movement of the units.

With mortar

For a jointing mortar mix one part cement thoroughly with

four parts sand, then add water slowly and mix to a soft

paste. Completely fill the joints with mortar.

If the units are laid on a mortar base, the joints should

preferably be filled within about two hours of laying the

mortar bedding. This will ensure a good bond between the

joint and bedding mortars.

Dry sand-cement mix (1 part cement, 3 parts sand) can

be brushed over the paving and lightly watered into place

provided that the surfaces of the units are smooth enough to

ensure that spillage on the surface can be removed entirely.

Use a wet cloth or brush to remove any mortar from the top

of the paving while it is still plastic: once it has hardened it is

difficult to remove.

Where large areas are paved with mortar-filled joints, it is

advisable to provide contraction joints at intervals of not

more than 2 metres. They should be about 10 mm wide,

extend right through the paving and be filled with sand.

8. Curing mortar

Cover paving that has been laid with mortar with wet sacking

or plastic sheeting for two or three days so that it does not

dry too quickly. Premature drying results in the mortar not

developing its full strength and the paving may crack.

Note: Methods of paving for driveways and other areas that

will be used by motor vehicles may differ from the above.

Consult relevant publications before building driveways or

other areas which may need to take heavier loads.

More information can be obtained from the Cement and

Concrete Institute (contact details below) and the Concrete

Manufacturers Association on e-mail cma@mweb.co.za or

the website at www.cma.org.za

Published by the Cement & Concrete Institute, Midrand, 1997, reprinted 2000, 2006.

Cement & Concrete Institute

PO Box 168, Halfway House, 1685

Tel (011) 315-0300 Fax (011) 315-0584

e-mail info@cnci.org.za website http://www.cnci.org.za

Cement & Concrete Institute

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Russell PHD 2015 Progressive Collapse of Reinforced Concrete Flat Slab StructuresDocument238 pagesRussell PHD 2015 Progressive Collapse of Reinforced Concrete Flat Slab StructuresRm1262No ratings yet

- Technoslide Elastomeric-Plain-Sliding-Bearings-For-Bridges-Structures-BrochureDocument13 pagesTechnoslide Elastomeric-Plain-Sliding-Bearings-For-Bridges-Structures-BrochureRm1262No ratings yet

- Henderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksDocument50 pagesHenderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksRm1262No ratings yet

- The Concrete Society - Fire DamageDocument6 pagesThe Concrete Society - Fire DamageRm1262No ratings yet

- Extend Abstract - 67792 - Joao GeadaDocument10 pagesExtend Abstract - 67792 - Joao GeadaRm1262No ratings yet

- IMIESA April 2021Document60 pagesIMIESA April 2021Rm1262No ratings yet

- Annerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireDocument6 pagesAnnerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireRm1262No ratings yet

- BinsDocument17 pagesBinsRm1262No ratings yet

- Crane Runway Installation Tolerances-BechtelDocument1 pageCrane Runway Installation Tolerances-BechtelRm1262No ratings yet

- UJ - EngineeringManagement 2020Document4 pagesUJ - EngineeringManagement 2020Rm12620% (1)

- Narayangharh-Mugling HighwayDocument85 pagesNarayangharh-Mugling HighwayRm1262No ratings yet

- Bituthene 3000-3000 HCDocument2 pagesBituthene 3000-3000 HCRm1262No ratings yet

- Sarens SarspinV.11.10.10Document4 pagesSarens SarspinV.11.10.10Rm1262No ratings yet

- SikaBond Rapid DPM PDSDocument4 pagesSikaBond Rapid DPM PDSRm1262No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ACR Methodology For The Conversion of High-Bleed Pneumatic Controllers in Oil and Natural Gas Systems v1.1Document33 pagesACR Methodology For The Conversion of High-Bleed Pneumatic Controllers in Oil and Natural Gas Systems v1.1mlkrembsNo ratings yet

- Aspect Oriented ArchitectureDocument43 pagesAspect Oriented ArchitectureerzhanbaiNo ratings yet

- Kendriya Vidyalaya, Tagore Garden Recruitment of Contractual Teachers For The Session 2013-14Document8 pagesKendriya Vidyalaya, Tagore Garden Recruitment of Contractual Teachers For The Session 2013-14ombidasarNo ratings yet

- Tips On Printing Half-Sheet PDF Booklets: 1. Print 1 Page of A Booklet To A Full Sheet of PaperDocument3 pagesTips On Printing Half-Sheet PDF Booklets: 1. Print 1 Page of A Booklet To A Full Sheet of Papermyco samNo ratings yet

- Opoc Engine ReportDocument34 pagesOpoc Engine Reportapi-32792277367% (3)

- Lexmark-E 321 Service ManualDocument184 pagesLexmark-E 321 Service ManualRemysNo ratings yet

- Surface Roughness TesterDocument1 pageSurface Roughness TesterRenju NairNo ratings yet

- Security Issues in Modern Automotive Systems: Patrick NischDocument6 pagesSecurity Issues in Modern Automotive Systems: Patrick NischEdson PatrícioNo ratings yet

- Unit - 1: (B) Difference Between Thermodynamcis and Heat TransferDocument66 pagesUnit - 1: (B) Difference Between Thermodynamcis and Heat TransferSayyadh Rahamath Baba100% (1)

- Domus Ventilation Guide 2019Document96 pagesDomus Ventilation Guide 2019Regie CayasNo ratings yet

- PrePeg XC110 210g 450gDocument3 pagesPrePeg XC110 210g 450gPrakashChouhanNo ratings yet

- Know The Escalation Matrix To ReportDocument1 pageKnow The Escalation Matrix To ReportHemal GandhiNo ratings yet

- Kota StationDocument5 pagesKota StationshashankjeeNo ratings yet

- Sneha Foundation PlusDocument17 pagesSneha Foundation PlusBikash KumarNo ratings yet

- 2011 Service Flex-Multi-Series mfl63744402 20120105132900Document87 pages2011 Service Flex-Multi-Series mfl63744402 20120105132900sajjad147No ratings yet

- Pamphlet On Maintenance and Overhauling of Lightning ArresterDocument10 pagesPamphlet On Maintenance and Overhauling of Lightning ArresterAjay Kumar PoulNo ratings yet

- FGRU URAN 08.12.2015 Rev.02Document3 pagesFGRU URAN 08.12.2015 Rev.02Hitendra PanchalNo ratings yet

- Flight Training Instruction: Naval Air Training CommandDocument174 pagesFlight Training Instruction: Naval Air Training CommandITLHAPN100% (1)

- Dbms Lab Manual-2013Document27 pagesDbms Lab Manual-2013Arham JainNo ratings yet

- Silver Nano ParticleDocument70 pagesSilver Nano Particleasad ullah100% (1)

- Masonry - Block Joint Mortar 15bDocument1 pageMasonry - Block Joint Mortar 15bmanish260320No ratings yet

- Lesson 1 DataDocument4 pagesLesson 1 Dataapi-435318918No ratings yet

- Ferro Manganese Slag PDFDocument2 pagesFerro Manganese Slag PDFDebraNo ratings yet

- VCEguide 300-360Document25 pagesVCEguide 300-360olam batorNo ratings yet

- Zf6 6r60 Zip BookletDocument8 pagesZf6 6r60 Zip BookletPablo Farfan Alvarez100% (1)

- IRGC (2021) - Spotlight - Risk Governance and The Rise of DeepfakesDocument4 pagesIRGC (2021) - Spotlight - Risk Governance and The Rise of DeepfakessaidNo ratings yet

- Sample Acceptable Use Policy From Southern Regional High SchoolDocument4 pagesSample Acceptable Use Policy From Southern Regional High Schoolapi-356000194No ratings yet

- Retail Generation ZDocument24 pagesRetail Generation ZSomanNo ratings yet

- NLPDocument20 pagesNLPAvishek01No ratings yet

- On The Job Winter 2013Document3 pagesOn The Job Winter 2013alanhynesNo ratings yet