Professional Documents

Culture Documents

Development of Australian Reinforcing Bar Standards

Uploaded by

Kevin Yew0 ratings0% found this document useful (0 votes)

8 views9 pagesAustralian Standards relating to reinforcing bars

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAustralian Standards relating to reinforcing bars

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views9 pagesDevelopment of Australian Reinforcing Bar Standards

Uploaded by

Kevin YewAustralian Standards relating to reinforcing bars

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

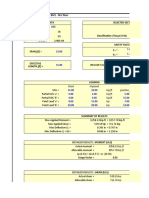

DEVELOPMENT OF AUSTRALIAN REINFORCING BAR STANDARDS

Hot Rolled Plain Round Reinforcing Bars

Std No Period Sizes Mechanical Properties Chemistry Identification Comments

A.S. A.81

Grade

designations

were:

Mild

Structural

Intermediate

Hard

1958 - 1965 Not Stated Mild Grade

Yield Strength: 205 MPa min

Tensile Strength: 380 - 480 MPa

Elongation: 20% on gauge length of

200mm, but less for bar diameters

above and below inch

Structural Grade

Yield Strength: 230 MPa min

Tensile Strength: 435 - 515 MPa

Elongation: 20% on gauge length of

200mm but less for bar diameters

above and below inch

Intermediate Grade

Yield Strength: 275 MPa min

Tensile Strength: 480 - 620 MPa

Elongation: 16% on gauge length of

200mm, but less for bar sizes above

and below inch.

Hard Grade

Yield Strength: 345 MPa min

Tensile Strength: 550 MPa min

Elongation: 10% on gauge length of

200mm, but less for bar diameters

above and below inch

Only requirements were:

S: .06% max

P: .06% max

Mild and Structural grades

could be assumed to have

welding equivalents to

structural steel (WTIA

Group 4 Steel)

Intermediate grade could

be assumed equivalent to

WTIA Group 5 Steels

Hard Grade could be

assumed equivalent to

WTIA Group 6 steel

On bundle tag only covering

makers name, trade mark,

grade of steel, and batch

number

A.S. A.81 1965 - 1973 Not stated, but

generally in

increments of

1/8 inch starting

at 3/8 inch

Yield Strength: 230 MPa min

Tensile Strength: 305 MPa

Elongation: 22% min on 5d

C: .30% max

C +Mn/6: .45% max

As produced by BHP,

equivalent to WTIA Group

4 Steel

On bundle tags only,

covering heat/batch number

and this Standard

Page 1 of 9 7/07/2006

Std No Period Sizes Mechanical Properties Chemistry Identification Comments

AS 1302 -

230R

1973 - 1977 Range of

diameters 10 -

50mm

Yield Strength: 230 MPa Min

Tensile Strength: 430 MPa min

Elongation: 22% min on 5d

Carbon: .30% max

C +Mn/6: .45% max

As produced by BHP,

equivalent to WTIA Group

4 Steel

On bundle tag only covering

heat / batch number and

grade of steel

AS 1302 -

230R

1977 - 1982 As above Yield Strength: 230 MPa min

Tensile Strength: 1.15xYS min

Elongation: 22% min on 5d

As above As above

AS 1302 -

230R

1982 - 1991 Range of

diameters 6.5 -

36mm

As above As above As above

AS 1302 -

250R

1991 - 2001 As above Yield Strength: 250 MPa min

Tensile Strength: 1.10xYS

Elongation: 22% on 5d

Carbon: .25% max

Carbon Equivalent defined

as:

C +Mn/6 +(Cr +Mo +

V)/5 +(Ni +Cu)/15

=.43% max

Equivalent to WTIA

Group 4 Steel

On bundle tag only covering

manufacturer, grade, this

Standard, heat/batch number

and mass

AS 3679 - 250 grade rounds are

deemed to comply with this

grade

AS 4671 2001 - Not stated Yield Strength: 300 MPa min

Tensile Strength: 440 MPa min

Elongation: 22% min on 5d

Carbon: .22% max

Carbon Equivalent defined

as:

C +Mn/6 +(Cr +Mo +

V)/5 +(Ni +Cu)/15

=.43% max

Equivalent to WTIA

Group 4 Steel

As above Supplied by OneSteel as

300PLUS (in accordance with

AS/NZS 3679.1)

Hot Rolled Deformed Bar Reinforcing Steels

Page 2 of 9 7/07/2006

Std No Period Sizes Mechanical Properties Chemistry Identification Comments

A.S. A.92

Grade

designations

were:

Mild

Structural

Intermediate

Hard

1958 - 1965 Bar numbers 3

to 11 where

each unit

represents 1/8

inch.

Effective range

10mm - 35mm

Mild Grade

Yield Strength: 205 MPa min

Tensile Strength: 380 - 480 MPa

Elongation: 20% on gauge length of

200mm, but less for bar diameters

above and below inch

Structural Grade

Yield Strength: 230 MPa min

Tensile Strength: 435 - 515 MPa

Elongation: 20% on gauge length of

200mm but less for bar diameters

above and below inch

Intermediate Grade

Yield Strength: 275 MPa min

Tensile Strength: 480 - 620 MPa

Elongation: 16% on gauge length of

200mm, but less for bar sizes above

and below inch.

Hard Grade

Yield Strength: 345 MPa min

Tensile Strength: 550 MPa min

Elongation: 10% on gauge length of

200mm, but less for bar diameters

above and below inch

Only requirements were:

S: .06% max

P: .06% max

Mild and Structural grades

could be assumed to have

welding equivalents to

structural steel (WTIA

Group 4 Steel)

Intermediate grade could

be assumed equivalent to

WTIA Group 5 Steels

Hard Grade could be

assumed equivalent to

WTIA Group 6 steel

On bundle tag only covering

makers name, trade mark,

grade of steel, and batch

number

A.S. A.92 1965 - 1973 As above Structural Grade

Yield Strength: 230 MPa min

Tensile Strength: 430 MPa min

Elongation: 22% min on 5d

Hard Grade

Yield Strength: 345 MPa min

Tensile Strength: 550 MPa

Elongation: 14% min on 5d

C: .30% max

C +Mn/6: .45% max

As produced by BHP,

equivalent to WTIA Group

4 Steel

On bundle tags only,

covering heat/batch number

and this Standard.

Hard grade to have

identification marks at

manufacturers discretion on

opposite sides of bar.

This was typically an

additional short longitudinal

rib joining two transverse

ribs

Std No Period Sizes Mechanical Properties Chemistry Identification Comments

Page 3 of 9 7/07/2006

AS 1302

230S

1973 1977 Not stated Yield Strength: 230 MPa min

Tensile Strength: 430 MPa min

Elongation: 22% on 5d

Carbon: .30% max

C +Mn/6: .45% max

As produced by BHP,

equivalent to WTIA Group

4 steel

On bundle tags only,

covering heat/batch number

and grade.

AS 1302 1977 - 1982 12mm to 36mm

in 4mm

increments.

40mm and

50mm subject to

enquiry.

Grade 230S

Yield Strength: 230 MPa min

Tensile Strength: 1.15 x YS min

Elongation: 22% on 5d

Grade 410Y

Yield Strength: 410 MPa min

Tensile Strength: 1.15 x YS

Elongation: 12% min on 5d

Grade 230S

Carbon: .30 max

C +Mn/6: .45% max

As produced by BHP,

equivalent to WTIA Group

4 Steel

Grade 410Y

Carbon: .35% max

C +Mn/6 =.60% max

As produced by BHP,

equivalent to WTIA Group

4 Steel

On bundle tag covering

manufacturer, grade, this

Standard, heat/batch number

and mass.

For grade 410Y only, a

continuous mark on

diametrically opposite

surfaces of the bar.

There was no large scale

production of grade 410Y in

this period

AS 1302 1982 - 1991 12mm to 36mm

in 4mm

increments.

40mm and

50mm subject to

enquiry.

Grade 230S

Yield Strength: 230 MPa min

Tensile Strength: 1.15 x YS min

Elongation: 22% on 5d

Grade 410Y

Yield Strength: 410 MPa min

Tensile Strength: 1.05 x YS

Elongation: 12% min on 5d

Grade 230S

Carbon: .30 max

C +Mn/6: .45% max

Grade 410Y

Carbon: .35% max

C +Mn/6 =.60% max

As produced by BHP,

equivalent to WTIA Group

4 Steel

On bundle tag only covering

heat / batch number and

grade of steel.

This marked the introduction of

TEMPCORE steel, and the

rapid phasing out of cold

twisted rebars

Page 4 of 9 7/07/2006

Std No Period Sizes Mechanical Properties Chemistry Identification Comments

AS 1302 Amdt 1983 As above As above Carbon: .22% max

Carbon Equivalent defined

as:

C +Mn/6 +(Cr +Mo +

V)/5 +(Ni +Cu)/15 =

.39% max

A distinctive deformation

pattern or other markings to

identify grade. This resulted

in use of the still current

crescent shaped transverse

ribs and the name

TEMPCORE on BHP

bars. This was later modified

to show individual

producing mill ID marks.

AS 1302 1991 - 2001 12mm to 36mm

in 4mm

increments.

40mm and

50mm subject to

enquiry.

Grade 250S

Yield Strength: 250 MPa min

Tensile Strength: 1.10 x YS min

Elongation: 22% on 5d

Grade 400Y

Yield Strength: 400 MPa min

Tensile Strength: 1.10 x YS

Elongation: 16% min on 5d

Grade 250S

Carbon: .25% max

Carbon Equivalent defined

as:

C +Mn/6 +(Cr +Mo +

V)/5 +(Ni +Cu)/15 =

.43% max

Equivalent to WTIA

Group 4 Steel

Grade 400Y

Carbon: .22% max

Carbon Equivalent defined

as:

C +Mn/6 +(Cr +Mo +

V)/5 +(Ni +Cu)/15 =

.39% max

On bundle tag only covering

manufacturer, grade, this

Standard, heat/batch number

and mass.

Bar markings at

manufacturers discretion to

identify grade of steel and

producing mill - see

TEMPCORE information.

Page 5 of 9 7/07/2006

Std No Period Sizes Mechanical Properties Chemistry Identification Comments

AS 4671 2001 - 12, 16, 20, 24,

32, 36mm

10mm also

available in coil.

40mm also

available in bar.

Grade 250N

Yield Strength: 250 MPa as lower

characteristic value.

Tensile Strength: 1.08 x YS

Elongation at maximum force

(Uniform elongation or Agt): 5%

Grade 500N

Yield Strength: 500 MPa as lower

characteristic value.

650 MPa as upper characteristic

value

Tensile Strength: 1.08 x YS

Elongation at maximum force

(Uniform elongation or Agt): 5%

Grade 250N

Carbon: .22% max

Carbon Equivalent defined

as:

C +Mn/6 +(Cr +Mo +

V)/5 +(Ni +Cu)/15 =

.43% max.

Equivalent to WTIA

Group 4 Steel

Grade 500N

Carbon: .22% max

Carbon Equivalent defined

as:

C +Mn/6 +(Cr +Mo +

V)/5 +(Ni +Cu)/15 =

.44% max.

Equivalent to WTIA

Group 4 Steel

Two or more longitudinal

marks in addition to

longitudinal ribs, or a

minimum of two short

transverse markings, or

alpha numeric characters

indicating steel grade

Page 6 of 9 7/07/2006

Cold Twisted Deformed Bar Reinforcing Steels

Standard Period Sizes Mechanical Properties Chemistry

Identification Comments

A.S. A.83 1958 - 1966 Not Specified For single bars >10mm (3/8 inch)

diameter.

Proof Stress: 410 MPa

Tensile Strength: 480 MPa

Elongation: 14% min on 8d

: 16% min on 4d

For twin bars >10mm (3/8 inch)

twisted together:

Proof Stress: 370 MPa

Tensile Strength: 435 MPa

Elongation: 14% min on 8d

16% min on 4d

Only requirements were:

S: .06% max

P: .06% max

As produced by BHP,

equivalent to WTIA Group

4 Steel

At manufacturers

discretion.

AS A83 1966 - 1973 Not restricted

but expressed in

bar numbers

where each unit

represents 1/8

inch of

diameter.

For bar sizes #3 and above (10mm

and above)

Proof Stress: 410 MPa

Tensile Strength: 480 MPa

Elongation: 14% min on 5d

C: .30% max

C +Mn/6: .45% max

As produced by BHP,

equivalent to WTIA Group

4 Steel

Marked or tagged to identify

conformance with this

specification

Square twisted

rebars also

covered by this

specification.

This grade was

sometimes

referred to as

CW60

indicating cold

twisted bar with

60 kips

minimum yield

strength

AS 1302 1973 - 1977 10mm and then

in 4mm

increments to

36mm.

Proof Stress: 410 MPa min

Tensile Strength: 480 MPa min

Elongation: 14% min on 5d

C: .30% max

C +Mn/6: .45% max

As produced by BHP,

equivalent to WTIA Group

4 Steel

On bundle tag only covering

heat / batch number and

grade of steel

Page 7 of 9 7/07/2006

Standard Period Sizes Properties Chemistry

Identification Comments

AS 1302 1977 - 1982 12mm to 36mm

in 4mm

increments

Proof Stress: 410 MPa min

Tensile Strength: 1.08 x PS

Elongation: 12% min on 5d

C: .30% max

C +Mn/6: .45% max

As produced by BHP,

equivalent to WTIA Group

4 Steel

Marked or tagged to identify

conformance with this

specification, and heat/batch

number

AS 1302 1982 - 1991 12mm to 36mm

in 4mm

increments

Proof Stress: 410 MPa min

Tensile Strength: 1.05 x PS

Elongation: 12% min on 5d

C: .30% max

C +Mn/6: .45% max

As produced by BHP,

equivalent to WTIA Group

4 Steel

Marked or tagged to identify

conformance with this

specification, and heat/batch

number

Cold twisted

bars were not

made in

Australia beyond

1983

Page 8 of 9 7/07/2006

Deformation Requirements and Dimensions.

The basic requirements for rib design, spacing, height and coverage have remained essentially unaltered since 1958. These requirements are similar to those for other major

international Reinforcing Bar Standards. The current standard (AS/NZS 4671:2001) includes a requirement to determine the specific projected area of ribs as a means of

demonstrating that the required bond with concrete will be achieved.

Hard Drawn Wire and Mesh

The material properties of hard drawn wire, and reinforcing mesh made from this wire, remained basically unaltered from 1958 until the 1990s, being:

Proof Stress: 450 MPa min

Tensile Strength: 500 MPa min.

During the 1990s, higher strength deformed wires were produced with strengths of:

Proof Stress: 500 MPa min

Tensile Strength: 550 MPa min.

The nominal sizes of these higher strength wires were proportionally reduced in line with the increase in strength.

With the publication of AS/NZS 4671 in 2001, reinforcing wire and mesh must achieve a proof stress of 500 MPa as a lower characteristic value. In addition, these products must

satisfy the following ductility measures:

Ratio (R

m

/R

e

): 1.03 min

Uniform Elongation (A

gt

): 1.5 % min.

Material Identification

Should you need to identify reinforcing steels where the origin, grade and strength levels are unknown, we can provide a very accurate estimate of properties and likely

specification. Simply cut a sample of length 25mm or greater. A longer sample would be preferable if heat (eg from oxy cutting of sample) has been applied. We will determine an

estimate of properties based on our chemical analysis, microstructure assessment and hardness level in the sample provided.

Please contact:

Greg Morris

OneSteel Market Mills

Tel : 02 4935 4424

Fax : 02 4935 4410

Page 9 of 9 7/07/2006

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cooling Tower Performance Test (Id CT) : Manual Input SheetDocument13 pagesCooling Tower Performance Test (Id CT) : Manual Input SheetSHIVAJI CHOUDHURY100% (1)

- Week 3 Two-Dimensional Conduction: Shape Factors and Dimensionless Conduction Heat RatesDocument7 pagesWeek 3 Two-Dimensional Conduction: Shape Factors and Dimensionless Conduction Heat RatesHammadNo ratings yet

- 2022 - ABS - 4. HVAC Systems - Heating and Air ConditioningDocument61 pages2022 - ABS - 4. HVAC Systems - Heating and Air ConditioningAbanoub SargiousNo ratings yet

- ETAG-020 Guideline Plastic Anchors Annex-CDocument13 pagesETAG-020 Guideline Plastic Anchors Annex-Cmicru85No ratings yet

- Assignment 3, 2010 - HYSYSDocument6 pagesAssignment 3, 2010 - HYSYSZhiyong Huang0% (1)

- Practical Boiler Operation Engineering and Power Plant-1 PDFDocument582 pagesPractical Boiler Operation Engineering and Power Plant-1 PDFDevendra Kumar Dewangan100% (1)

- 2002 Tunnel Fairhust CF CCTDocument65 pages2002 Tunnel Fairhust CF CCTkuduppanNo ratings yet

- Understanding NPSHDocument34 pagesUnderstanding NPSHeliyanto budiartoNo ratings yet

- Fixity of Piles in Liquefiable SoilsDocument9 pagesFixity of Piles in Liquefiable SoilsAnjumara HaiderNo ratings yet

- Thermodynamics: Solution Manual English Unit ProblemsDocument27 pagesThermodynamics: Solution Manual English Unit Problems06fmTCNo ratings yet

- Cementing OperationsDocument16 pagesCementing OperationsCronos100% (1)

- Heap Slope DesignDocument14 pagesHeap Slope DesignNoon Abdallah AbdalroufNo ratings yet

- Knuckle JointDocument20 pagesKnuckle JointROCKY DUBEYNo ratings yet

- VicoDocument17 pagesVicojustmenobleskNo ratings yet

- Influence of Atmospheric Stability On The Spatial Structure of TurbulenceDocument109 pagesInfluence of Atmospheric Stability On The Spatial Structure of TurbulenceKlaas KronaNo ratings yet

- New Trends in AcDocument11 pagesNew Trends in AcNallathambiNo ratings yet

- Ansys Manual Final Year Anna UniversityDocument32 pagesAnsys Manual Final Year Anna UniversityYukesh Kumar SinghNo ratings yet

- METU Chem. Eng. Dept. Ch.E. 410 Chem. Eng. Lab II Experiment 1.2. Tubular Viscometry (Visc)Document5 pagesMETU Chem. Eng. Dept. Ch.E. 410 Chem. Eng. Lab II Experiment 1.2. Tubular Viscometry (Visc)newtonNo ratings yet

- AMCA 801-01 (R2008) Fans Specification Guidelines PDFDocument61 pagesAMCA 801-01 (R2008) Fans Specification Guidelines PDFR L100% (1)

- FMDocument13 pagesFMP.v.KumarNo ratings yet

- CFD Simulation of Cross-Ventilation For A Generic IsolatedDocument14 pagesCFD Simulation of Cross-Ventilation For A Generic IsolatedMohamad HashemNo ratings yet

- Study On Deep BeamsDocument16 pagesStudy On Deep Beamsshailesh patilNo ratings yet

- TMMV08 Ass4 AB REVISION Pijbe382 Artma841 Janca142Document3 pagesTMMV08 Ass4 AB REVISION Pijbe382 Artma841 Janca142Arturo Mateos RodríguezNo ratings yet

- Acs Question Bank 19-20Document1 pageAcs Question Bank 19-20atika ingoleNo ratings yet

- SPE 36986 Relative Permeability in Coal: Reservoir Properties of CoalDocument6 pagesSPE 36986 Relative Permeability in Coal: Reservoir Properties of CoalWaleed Barakat MariaNo ratings yet

- Heat Throw WallsDocument20 pagesHeat Throw WallshusoNo ratings yet

- Heat Transfer ExxonMobilDocument30 pagesHeat Transfer ExxonMobilHernan CobaNo ratings yet

- Steel BeamDocument13 pagesSteel BeamRicardo Garcia IIINo ratings yet

- Heat Load EstimationDocument4 pagesHeat Load Estimationdhanu_lagwankarNo ratings yet