Professional Documents

Culture Documents

Smoke Detector

Uploaded by

atharvawazurkarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Smoke Detector

Uploaded by

atharvawazurkarCopyright:

Available Formats

RECTANGULAR LED DETECTOR HEAD

BASE

OPENING HERE

LONG ALIGNMENT MARK

SHORT ALIGNMENT MARK

Photoelectric Smoke/HEAT Detector

Installation Wiring Diagram

TYPICAL WIRING DIAGRAM

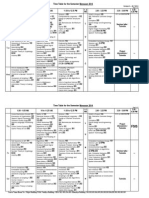

Figure 1(a) shows the typical wiring diagram of the

2-wire multiple-station smoke detector system.

INITIATING

LOOP

EN54 LISTED

COMPATIBLE

CONTROL

PANEL

+

-

FIRST DETECTOR BASE LAST DETECTOR BASE

EOL

RESISTOR

5 2 5 2

6 1 3 4 6 1 3 4

+ - +

REMOTE

INDICATOR

CLASS A OPTIONAL WIRING

NOTE: IF REMOTE INDICATOR IS NOT USED. POLARITY TO DETECTOR MAY BE REVERSED.

-

DO NOT PLACE LINKS BETWEEN THE WIRING POSITIONS

OF TERMINALS 2 AND 5 TO PROVIDE POWER

SUPERVISION

Figure 1(b) shows the typical wiring diagram of the

4-wire multiple-station smoke detector system.

DO NOT PLACE LINKS BETWEEN THE WIRING POSITIONS

OF TERMINALS 2 AND 5 TO PROVIDE POWER

SUPERVISION

WARNING

TO PREVENT DETECTOR CONTAMINATION AND

SUBSEQUENT WARRANTY CANCELLATION, THE

SMOKE DETECTOR MUST REMAIN COVERED UNTIL

THE AREA IS CLEAN AND DUST FREE.

INSTALLING THE BASE

1. To insure proper installation of the detector head to the

base, all the wires should be properly addressed at

installation:

(A) Position all the wires flat against terminals.

(B) Fasten the wires away from connector terminals.

2. If you use a jumper wire to connect the poles of

terminal 2 and 5 when testing the detector loop

continuity, be sure to remove the jumper wire prior to

the installation of the detector head.

3. The end-of-line device shown in fig. 1(a) and 1(b)

should be compatible with the control unit. The

end-of-line supervisory relay used should be rated for

the DC power voltage used.

4. Open area smoke detectors are intended for mounting

on a ceiling or a wall in accordance with the fire

standard in your country.

5. The base of the smoke detector can be mounted

directly onto an electrical junction box such as an

octagonal (75mm, 90mm or 100mm), a round (75mm),

or a square (100mm) box without using any type of

mechanical adapter.

INSTALLING THE HEAD

1. Align the components as shown in Figure 2.

2. Mate the detector head onto the base and twist

clockwise to secure it.

3. Do not install the detector head until the area is

thoroughly cleaned of construction debris, dusts, etc.

The maximum number of smoke detector installed in

the same loop is 30 units.

Fig. 2 Mating detector head onto base

ADJUSTING THE RELAY FOR NO/NC

The normal condition for the relay is normally open

(NO).

1. To adjust the normal condition of the relay to

normally closed (NC), insert a screwdriver into the

rectangular hole located on the side between the front

cover and base and rotate to remove the front cover.

2. Refer to figure 3. There is a jumper head next to the

relay on the PCB. Remove the jumper head and reinsert

it in the NC position.

3. Carefully replace the front cover.

Relay contact rating:

1A@30VDC,

0.5A@125VAC.

TESTING

1. All the alarm signal services, releasing device and

extinguisher system should be disengaged during the

test period and must be re-engaged immediately at the

conclusion of testing.

2. After energizing the detector head for approximately

one minute, check to see the indicator green LED

flashing once every 3~5 seconds. If green LED fails to

flash, it indicates the non-functioning of the detector or

faulty wiring. Re-check the wiring or replace the

detector if necessary.

3. Allow smoke from a cotton wick or a test smoke

aerosol to enter the detector-sensing chamber for at

least 10 seconds. When sufficient smoke has entered

the chamber, the detector will signal an alarm, this

being visible by a continuous illumination of the LED.

Reset each detector and/or control unit before

attempting to test any additional detectors in the same

zone. If the alarm fails in this step, it indicates a

defective unit, which requires service.

Fig. 3 Schematic of detector structure

When front cover is open.

SMOKE CHAMBER

LED

RELAY

JUMPER SETTING

VRC TEROFIRE PRODUCTS

42-44 Bromley Rd Congleton Cheshire UK

Post Code: CW12 1PT

Tel:44 (0)1260 297578 Fax:44(0)1260 290078

HEAT SENSOR TESTING

The detector to be tested should be subject to a flow of

warm air at a temperature of between 65C and 80C.

(This requirement can be met by some domestic hair

dryers).

Proceed as follows:

1. Switch on the warm airflow and check that temperature

is correct and stable.

2. From a distance of several inches, direct the airflow at

the guard protecting the thermistor. The detector

should alarm within 30 seconds.

3. Upon alarm immediately remove the heat source and

check that the red LED of the detector is illuminated.

Reset the detector from the control panel.

4.If detector fails to go into alarm mode within 30

seconds it is too insensitive and needs to be returned

to the distributor for servicing.

5. After testing, check that the system is set for normal

operation and notify the appropriate authorities that the

testing operation is complete and the system is active

again.

NOT SUITABLE FOR INSTALLATION IN AREAS

WHERE AIR VELOCITIES EXCEED 600 meters/min

MAINTENANCE

The recommended minimum requirement for detector

maintenance consists of an annual cleaning of dust from

the detector head by using a vacuum cleaner cleaning

program should be agreed to the individual environment

in conformance with EN 54-7:2000 and EN 54-5:2000

standards.

CAUTION: DO NOT ATTEMPT TO DISASSEMBLY OF THE

FACTORY SEALED SMOKE DETECTOR. THIS

ASSEMBLY IS SEALED FOR YOUR PROTECTION AND IS

NOT INTENDED TO BE OPENED FOR SERVICING BY

USERS. OPENING THE DETECTOR HEAD WILL VOID

THE WARRANTY.

REFERENCE TO THE TECHNICAL BULLETIN ISSUE NO.

EATB20010215 REV.B

SPECIFICATION

Model 2/4

wire

Ther

mal

Voltage

DC

Standby

Current

(Max.)

Alarm

Current

(Max.)

Surge

Current

(Max.)

Start-Up

Time

(Max.)

Permissible

Current

(Max.)

Frequency Alarm

Sound level

Alarm contact Base model

EN-54-7:2000

listed

10-0001 2 12~35V

35 A

70mA

40 A

60 Seconds 80mA 3-5 Seconds

P/N854001

EN-54-7:2000/

EN-54-5:2000 listed

10-0002 2 57C 12~35V

35 A

70mA

40 A

60 Seconds 80mA 3-5 Seconds

P/N854001

LIMITED WARRANTY STATEMENT

VRC TEROFIRE PRODUCTS represents that this product is free from defects in material and workmanship. And it will

repair or replace any product or part thereof which proves to be defective in workmanship or material for a period of

twelve (12) months from the date of purchase but not to exceed eighteen (18) months after shipment by the

manufacturer. For a full description of VRC TEROFIRE PRODUCTSS LIMITED WARRANTY, which, among other

things, limits the duration of warranties of merchantability and fitness for a particular purpose and excludes liability for

consequential damages. Please read the entire LIMITED WARRANTY on the VRC TEROFIRE PRODUCTS quotation.

Acceptance of order and/or original invoice which will become part of your sales agreement. Please contact VRC

TEROFIRE PRODUCTS directly for a return merchandise authorization (RMA) number before returning goods to the

factory address at 42-44 Bromley Rd Congleton Cheshire UK . Shipment must be prepaid and VRC TEROFIRE

PRODUCTS will repair or replace your returned detector.

ISSUE NO. MSD20010215 REV.A

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- MRTPDocument20 pagesMRTPStephen Crawford100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Winding Temperature IndicatorDocument9 pagesWinding Temperature IndicatorTruong Van Quang100% (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- VTT10000 Manual PDFDocument6 pagesVTT10000 Manual PDFalekyaNo ratings yet

- 601P Install ManualDocument2 pages601P Install ManualDanut Stefan100% (2)

- Installation Wiring Diagram for SD119 Series Smoke DetectorsDocument2 pagesInstallation Wiring Diagram for SD119 Series Smoke DetectorsVictor PatsiNo ratings yet

- 00 - MS - Fire Alarm System InstallationDocument10 pages00 - MS - Fire Alarm System Installationkikokiko KarimNo ratings yet

- VAR TEC FDR Series User ManualDocument2 pagesVAR TEC FDR Series User ManualmicrajacutNo ratings yet

- System Sensor 2151 & 2151T - Installation ManualDocument2 pagesSystem Sensor 2151 & 2151T - Installation ManualAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Heat Detector Maintenance Testing ProcedureDocument2 pagesHeat Detector Maintenance Testing ProcedureAlvin MiraNo ratings yet

- Installation Instructions: MFP RangeDocument12 pagesInstallation Instructions: MFP RangevinpugalNo ratings yet

- System Sensor CO1224T - 4-Wire CO Detector Installation ManualDocument4 pagesSystem Sensor CO1224T - 4-Wire CO Detector Installation ManualAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Seitron Beagle Instructions ManualDocument1 pageSeitron Beagle Instructions ManualAndrei MaresNo ratings yet

- Explosion-Proof Smoke Detector: GeneralDocument2 pagesExplosion-Proof Smoke Detector: GeneralBambang Sigit PriyantoNo ratings yet

- Combust Gas Detector Manual 4101-02B1Document15 pagesCombust Gas Detector Manual 4101-02B1eliasx1No ratings yet

- Installation Instructions: MFP RangeDocument12 pagesInstallation Instructions: MFP RangeSoheil GhasemiNo ratings yet

- System Sensor B112LP - Installation ManualDocument4 pagesSystem Sensor B112LP - Installation ManualAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- BOSCH Detector de Humo d7050 - InstallDocument8 pagesBOSCH Detector de Humo d7050 - Installwildor01No ratings yet

- 117 - 4417902 - Rev.0 - Instruction Manual AlarmScout 961-962 (Loop Powered) PDFDocument8 pages117 - 4417902 - Rev.0 - Instruction Manual AlarmScout 961-962 (Loop Powered) PDFFrancisco Rodriguez MartinezNo ratings yet

- LC-103PIMSK: Professional Passive Infrared & Microwave Detector With Anti-Mask With Pet ImmunityDocument2 pagesLC-103PIMSK: Professional Passive Infrared & Microwave Detector With Anti-Mask With Pet ImmunityAndrei PantaNo ratings yet

- BS-655/MAR: Optical Smoke DetectorDocument2 pagesBS-655/MAR: Optical Smoke DetectorakNo ratings yet

- FP Range Fire Alarm Installation GuideDocument12 pagesFP Range Fire Alarm Installation GuideJose CarmoNo ratings yet

- RF 360 Advanced Ceiling Mount PIR Installation Manual-1Document2 pagesRF 360 Advanced Ceiling Mount PIR Installation Manual-1Imi Michał SmulskiNo ratings yet

- I-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01Document2 pagesI-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01HiteshgangeleNo ratings yet

- Edwards 280 Heats Heat DetectorDocument2 pagesEdwards 280 Heats Heat Detectorbriguy4uNo ratings yet

- Manual Do Sensor de Incendio - Globalfire - AD - Series - ManualDocument2 pagesManual Do Sensor de Incendio - Globalfire - AD - Series - ManualValódia VictorinoNo ratings yet

- EUROGAS SERIES AUTOMATIC CONTROL SYSTEMS FOR GASEOUS FUELSDocument4 pagesEUROGAS SERIES AUTOMATIC CONTROL SYSTEMS FOR GASEOUS FUELSRonan CristhiamNo ratings yet

- R04 V-PS Photoelectric Smoke Detector Installation SheetDocument4 pagesR04 V-PS Photoelectric Smoke Detector Installation SheetDiegoNo ratings yet

- Conventional FireDocument5 pagesConventional FiremohammadNo ratings yet

- Accutek Manual PDFDocument30 pagesAccutek Manual PDFGustavo Espinosa MartinezNo ratings yet

- GE ESL500seriesSmokeDetectorInstallationManualDocument6 pagesGE ESL500seriesSmokeDetectorInstallationManualrommy214uNo ratings yet

- TSP-1 RevC 04-15Document8 pagesTSP-1 RevC 04-15boulacharNo ratings yet

- SM Ami-208mc (E)Document18 pagesSM Ami-208mc (E)DanielaCostaNo ratings yet

- Fenwall Ionization Smoke DetectorDocument4 pagesFenwall Ionization Smoke Detectormetal_dung2No ratings yet

- System Sensor D4S Data SheetDocument4 pagesSystem Sensor D4S Data SheetJMAC SupplyNo ratings yet

- 7ML19981GC61 1Document59 pages7ML19981GC61 1Andres ColladoNo ratings yet

- Technical ManualDocument45 pagesTechnical ManualOscares SnowNo ratings yet

- Rotary Encoder and Power Switch GuideDocument4 pagesRotary Encoder and Power Switch GuideshyhuNo ratings yet

- FPC 2 Panel PDFDocument11 pagesFPC 2 Panel PDFMiguel ContrerasNo ratings yet

- Mcdonnell & Miller: WarningDocument8 pagesMcdonnell & Miller: WarningALEXANDER VARELANo ratings yet

- SEC 3000 Instruction ManualDocument14 pagesSEC 3000 Instruction ManualPaulo YorgosNo ratings yet

- Addressable Smoke and Heat Detector Installation GuideDocument2 pagesAddressable Smoke and Heat Detector Installation GuideAdrian Oprisan100% (1)

- C-9105 Conventional Linear Beam Smoke Detector Installation and Operation ManualDocument14 pagesC-9105 Conventional Linear Beam Smoke Detector Installation and Operation ManualkatulaNo ratings yet

- Series: Photoelectric Smoke DetectorDocument4 pagesSeries: Photoelectric Smoke DetectorRuben MoralesNo ratings yet

- D355PL InstallationDocument4 pagesD355PL InstallationWilly LeonNo ratings yet

- Electro Industries ES-24-BR Electronic Slab Thermostat For Electric BoilersDocument10 pagesElectro Industries ES-24-BR Electronic Slab Thermostat For Electric Boilerse-ComfortUSANo ratings yet

- Intelligent BEAM ManualDocument14 pagesIntelligent BEAM ManualmthuyaNo ratings yet

- Honey Well 7800Document36 pagesHoney Well 7800robNo ratings yet

- Instruction Manual: Temperature Transducer For Pt100 Sensor With 4 - 20 Ma OutputDocument8 pagesInstruction Manual: Temperature Transducer For Pt100 Sensor With 4 - 20 Ma OutputBayu Dwi Rizkyadha PutraNo ratings yet

- Cu 104Document16 pagesCu 104PonyPantsNo ratings yet

- Lfe 50 N 7783 en 09052007Document14 pagesLfe 50 N 7783 en 09052007Thiago FernandesNo ratings yet

- PT295 LEL Sensor Rev 6Document31 pagesPT295 LEL Sensor Rev 6Hossam A.MoneimNo ratings yet

- Combustible Gas Transmitter 65-2400RK-05Document14 pagesCombustible Gas Transmitter 65-2400RK-05ابزار دقیقNo ratings yet

- SDS48 - Initial Start-Up and Service Checklist PDFDocument2 pagesSDS48 - Initial Start-Up and Service Checklist PDFПавелNo ratings yet

- SC 103Document8 pagesSC 103prihartono_diasNo ratings yet

- KX Eng PDFDocument4 pagesKX Eng PDFlinhpic99No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Viterbi-India Awards 2015Document2 pagesViterbi-India Awards 2015atharvawazurkarNo ratings yet

- Team - ID (CMT ID) Fill Here Project Title Fill Here College Name Fill Here Mentor Name Fill HereDocument1 pageTeam - ID (CMT ID) Fill Here Project Title Fill Here College Name Fill Here Mentor Name Fill HereatharvawazurkarNo ratings yet

- Code RobotDocument2 pagesCode RobotatharvawazurkarNo ratings yet

- FIR Filter AssignmentDocument1 pageFIR Filter AssignmentSai Vishnu RNo ratings yet

- Kit 110Document20 pagesKit 110atharvawazurkarNo ratings yet

- 8086 TheoryDocument8 pages8086 TheoryHardik DoshiNo ratings yet

- VerDocument3 pagesVerCelso Tame CubaNo ratings yet

- 06581534Document7 pages06581534atharvawazurkarNo ratings yet

- Code RobotDocument2 pagesCode RobotatharvawazurkarNo ratings yet

- An Object Oriented Approach To CAD Tool Control: Member, IEEE, and StephenDocument16 pagesAn Object Oriented Approach To CAD Tool Control: Member, IEEE, and StephenatharvawazurkarNo ratings yet

- 2ndmidsem11 SolnsDocument11 pages2ndmidsem11 SolnsatharvawazurkarNo ratings yet

- Consol Timetable M14-Ver3 222Document2 pagesConsol Timetable M14-Ver3 222atharvawazurkarNo ratings yet

- Digital Image Processing Assignment Quality Metrics and Contrast MeasuresDocument1 pageDigital Image Processing Assignment Quality Metrics and Contrast MeasuresatharvawazurkarNo ratings yet

- Curent FeedbackDocument7 pagesCurent FeedbackiragvNo ratings yet

- Read MeDocument4 pagesRead Meconnect2nsNo ratings yet

- Monsoon 2014Document1 pageMonsoon 2014atharvawazurkarNo ratings yet

- Monsoon 2013Document1 pageMonsoon 2013divyam1990No ratings yet

- End Semester Examination Time Table - Monsoon 2013: Date Time Courses Lab Exam-C Programming Lab Exam - C ProgrammingDocument1 pageEnd Semester Examination Time Table - Monsoon 2013: Date Time Courses Lab Exam-C Programming Lab Exam - C ProgrammingatharvawazurkarNo ratings yet

- Read MeDocument4 pagesRead Meconnect2nsNo ratings yet

- CourseOfferings M2014-Ver1Document13 pagesCourseOfferings M2014-Ver1atharvawazurkarNo ratings yet

- Merge Algorithms For Intelligent VehiclesDocument15 pagesMerge Algorithms For Intelligent Vehiclesconnect2nsNo ratings yet

- Compact Multi-Band Fractal AntennasDocument6 pagesCompact Multi-Band Fractal AntennasatharvawazurkarNo ratings yet

- Microwave and Millimetric-Wave Filters ProjectDocument9 pagesMicrowave and Millimetric-Wave Filters ProjectatharvawazurkarNo ratings yet

- Fractal WamiconDocument5 pagesFractal WamiconatharvawazurkarNo ratings yet