Professional Documents

Culture Documents

Mantenimiento 6466 PDF

Uploaded by

marcosluna68Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mantenimiento 6466 PDF

Uploaded by

marcosluna68Copyright:

Available Formats

LARGE DIESEL ENGINES

John Deere

JO H N DEERE

Model No. Cyls. Bore (in.) Stroke (in.)

3164D 3 4.02 4.33

3179D 3 4.19 4.33

4219D 4 4.02 4.33

4239D 4 4.19 4.33

4239T 4 4.19 4.33

4276D 4 4.19 5.00

4276T 4 4.19 5.00

6329D 6 4.02 4.33

6359D 6 4.19 4.33

6359T 6 4.19 4.33

6404D 6 4.25 4 75

6404T 6 4.25 4.75

6404A 6 4.25 4.75

6414D 6 4.19 5.00

6414T 6 4.19 5.00

6466D 6 4.56 4 75

6466T 6 4.56 4.75

6466A 6 4.56 4.75

Engines are liquid cooled, in-line, four-

stroke, direct injection diesel engines.

Crankshaft rotation is counter-clock-

wise at pto (flywheel end of engine). Fir-

ing order is 1-2-3 for three cylinder

engines; 1-3-4-2 for four cylinder

engines; 1-5-3-6-2-4 for six cylinder

engines. Cylinders are numbered from

front to rear. Models 4239T, 4276T,

6359T, 6404T, 6414T and 6466T are

equipped with turbochargers. Models

6404A and 6466A are equipped with tur-

bocharger and intercooler.

Displ. (cu. in.)

1 6 4

1 7 9

2 1 9

2 3 9

2 3 9

2 7 6

2 7 6

3 2 9

3 5 9

3 5 9

4 0 4

4 0 4

4 0 4

4 1 4

4 1 4

4 6 6

4 6 6

4 6 6

MAINTENANCE

LUBRICATIO N

All Models

Recommended engine oil is SAE 5W

or SAE 5W-20 for temperatures below

-10F., SAE l ow or SAE lOW-30 for

temperatures between -10F. and 32F.

or SAE 30 for temperatures above

32F. API oil classification should be CD

for single viscosity oils and CC for multi-

viscosity oils.

Crankcase capacities for oil changes

are listed below. Due to production

changes in oil pans and the use of op-

tional oil pans on some engines, it is ad-

visable to check oil level on dipstick, as

crankcase is being filled, to prevent

underfilling or overfilling.

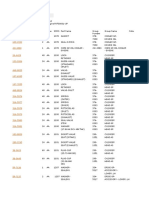

Crankcase Capacity (Qts.)

3164D,3179D *5.0std., *8.0opt.

4219D *5.0std.,*8.0opt.

4239D *8.0std.

4239T *14.0std.

4276D *8.0std.,*14.0opt.

4276T *13.0std.,*14.0opt.

6329D *11.0std.

6359D,6359T *17.0std.

6404D, 6404T, 6404A **15.0std.

6414D, 6414T . . . *17.0 std., n9. 0 opt

6466D, 6466T **16.0std.

6466A **18.0 std., **19.0 opt.

*Add one quart for filter change.

**Add two quarts for filter change.

Manufacturer recommends renewing

engine oil and oil filter after first 100

hours operation. Thereafter, renew

engine oil every 100 hours and oil filter

every 200 hours operation.

FUEL SYSTEM

All Models

_ FUEL FILTERS. A dual-stage fuel

filter (Fig. JDIA) is contained in a glass

sediment bowl (some models have two

filters). A drain plug is located in bottom

of filter body to drain v/ater or sediment

from filter bowl.

NO TE: The life of fuel filters depends on

the amount of contamination they must

remove from the fuel. If engine misfires or

ioss of power is evident, renew the fiiters.

In any event, fiiters shouid be renewed

every 500 hours or every year, whichever

comes first.

BLEED FUEL SYSTEM. When fuel

pump sediment bowl or fuel filter is

removed or engine runs out of fuel, refer

to Fig. JDIA and bleed air from fuel

system as follows: Loosen bleed screw

on top of filter body and actuate hand

primer lever of fuel lift pump until

bubble-free stream of fuel flows from

bleed screw, then tighten bleed screw.

Push primer lever down.

NO TE: if no resistance is fait when

pumping iever, turn crankshaft to reposi-

tion fuei pump cam.

On engines equipped with C.A.V.

Roto-Diesel injection pump, bleed air

from pump as follows: Loosen lower

bleed screw (1-Fig. JDl) and pump

primer lever until bubble-free stream of

fuel flows from bleed screw. Tighten

lower bleed screw and loosen upper

bleed screw (2) and repeat operation.

Fig. JD1-View of C.A.V. Roto-Dieset trtjection

pump showing tocation of bieed screws.

1. Lower bleed screw 2. Upper bleed screw

Fig. JDIA - View of two-stage fiiter and sedi-

ment bowi assembty typicat of type used on att

modets.

63

John Deere

LARGE DIESEL ENGINES

On 6404T, 6404A, 6466T and 6466A

engines equipped with Robert Bosch in-

jection pump, bleed air from pump as

follows: Loosen injection pump fuel

return line fitting (1-Fig. JD2) and

pump hand primer (2) until air-free fuel

flows from fitting.

On all models, bleed air from injector

pressure lines as follows: Loosen pres-

sure line connections at injectors about

one turn. Open throttle and crank

engine until fuel flows from loosened

connections, then tighten connections

and start engine.

Fig. JD2 To bteed air from Robert Bosch injec-

tion pump, ioosen fuel return line fitting (1) and

pump hand primer (2) untii air free fuei fiows

from fitting.

Fig. JD3-0n Roosa-Master injection pumps,

timing iines on cam ring and governor weight re-

tainer must be aiigned as shown with No. 1 pis-

ton at TDC compression stroke.

INJECTION PUMP STATIC TIM-

ING. Engines may be equipped with

C.A.V. Roto-Diesel injection pumps,

Roosa-Master JDB or DM series injec-

tion pumps or Robert Bosch multiple

plunger, inline injection pumps.

Static timing need not be checked in-

ternally on C.A.V. Roto-Diesel pump.

Pump will be in time with engine if tim-

ing gears are correctly timed and marks

on pump flange and engine front plate

are aligned.

On engines equipped with Roosa-

Master JDB or DM series injection

pump, check timing as follows: Shut off

fuel at fuel tank, then remove pump tim-

ing window cover. With number 1 piston

on compression stroke, rotate crank-

shaft until TDC mark on flywheel aligns

with pointer or until timing pin slides in-

to flywheel timing hole. Pump timing

marks on cam ring and governor weight

retainer should be aligned (Fig. JD3). If

adjustment is required, loosen pump

mounting stud nuts and turn pump body

until marks align, then tighten stud

nuts. Turn crankshaft in normal direc-

tions two revolutions and recheck timing

marks.

On engines equipped with Robert

Bosch pumps, check timing as follows:

Remove access plate from front of tim-

ing gear cover and remove timing hole

plug (Fig. JD4). With number 1 piston

on compression stroke, rotate crank-

shaft until TDC mark on flywheel aligns

with pointer or timing pin slides into fly-

wheel timing hole. The injection pump

drive hub mark should be aligned with

pointer mark. If adjustment is required,

loosen cap screws on pump drive gear

until drive hub can be moved in slotted

holes of drive gear. When timing marks

are aligned, re tighten cap screws to 35

ft.-lbs. torque. Rotate crankshaft two

complete revolutions and recheck timing

marks.

AIR CLEANER

All Models

All engines are equipped with dry

type, dual element air cleaner. The

safety (inner) element should be re-

newed if primary element is damjiged

and safety element is visibly dirty, ( r at

least once a year. DO NOT attempt to

clean the safety element.

The primary (outer) element caii be

cleaned by directing compressed air up

and down pleats from inside elen ent.

Air pressure must not exceed 30 pd at

nozzle. Element can also be cleaned us-

ing water in same manner as com-

pressed air. Water pressure must not

exceed 40 psi, and element must be (om-

pletely dry before reinstalling.

After cleaning, thoroughly inspect ele-

ment and sealing gasket for damage.

Renew primary filter element when ele-

ment is not responding to cleaning (in-

terval between cleanings becomes

short), or once a year.

COOLING SYSTEM

All Models

All engines are liquid cooled and

equipped with a water pump. Fan belt

tension is correct when a pressure ( f 20

pounds, halfway between pulleys, de-

flects belt 3/4-inch. When adjusting Delt,

pull on front alternator frame onl;^ If

equipped with two belts, always renew

belts as a matched set. Add a non-

chromate rust inhibitor every 500 hours

or every six months.

REPAIRS

CYLINDER HEAD

All Models

REMOVE AND REINSTALL. To

remove cylinder head, drain cooling

Fig. JD4-View of Robert

Bosch injection pump gear

and timing marks. With No. 1

piston at TDC compression

stroke, timing marks must

be aiigned.

system and disconnect battery ground

cable. Remove thermostat by-pass 1 ose,

upper radiator hose and water manifold.

Remove muffler and air intake pipe Un-

bolt and remove exhaust manifolc, in-

take manifold and intercooler (if e'|uip-

ped). Remove injector lines and injec-

tors. Unbolt and remove rocker arm

cover, rocker arm assembly and push

rods, then unbolt and remove cylinder

head.

NOTE: Do not turn crankshaft with cyl-

inder head removed unless cylinder

sleeves are secured with screws and

washers. Refer to Fig. JD18.

When reinstalling cylinder heac, in-

stall head gasket dry. Coat threads of

cylinder head cap screws with engii e oil

and be sure hardened flat washers are

installed under head of all cylinder lead

64

You might also like

- Mitsubishi 4g69 Engine ManualDocument66 pagesMitsubishi 4g69 Engine ManualAlbert Briceño75% (8)

- Derbi Technical Training 2010 (125 4T 4V)Document48 pagesDerbi Technical Training 2010 (125 4T 4V)Manualles73% (22)

- 770CH Diagramas PDFDocument6 pages770CH Diagramas PDFEdgar Martinez CarmonaNo ratings yet

- 7425 and 7525 Tractors Mexican Edition Introduction PDFDocument6 pages7425 and 7525 Tractors Mexican Edition Introduction PDFmiguelcastillo100% (1)

- Manual de Partes Kubota M108SDocument238 pagesManual de Partes Kubota M108Sjose del carmen rodriguez lobatoNo ratings yet

- Martillo Hidraulico Kent 4Document32 pagesMartillo Hidraulico Kent 4Jose Angel VGNo ratings yet

- Rock Ram 775Document33 pagesRock Ram 775Arnold CastroNo ratings yet

- 300D 310D and 315D Backhoe Loader IntroductionDocument7 pages300D 310D and 315D Backhoe Loader Introductionhenry ibañez100% (1)

- Newage MX341 Automatic Voltage Regulator PDFDocument6 pagesNewage MX341 Automatic Voltage Regulator PDFosanebi100% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6.7L DieselDocument94 pages6.7L DieselBrendan Brodie100% (15)

- 5VZ-FE Engine Timing BeltDocument4 pages5VZ-FE Engine Timing BeltAlexander B Quinto0% (1)

- SV208-SV210-SV212-SV216 - Case Rodo Vibratorio Manual de Operador (Inglés)Document226 pagesSV208-SV210-SV212-SV216 - Case Rodo Vibratorio Manual de Operador (Inglés)TERRACERIA SALVADOREÑANo ratings yet

- TR JD 6076 TSIDocument1 pageTR JD 6076 TSIJuanPabloCruz100% (1)

- Iveco Nef Engine F4ge0454c F4ge0484g Repair ManualDocument10 pagesIveco Nef Engine F4ge0454c F4ge0484g Repair ManualeliasNo ratings yet

- 920 & 930 WHEEL LOADERS POWER TRAIN Pruebas y AjustesDocument6 pages920 & 930 WHEEL LOADERS POWER TRAIN Pruebas y AjustesKarlOs Junco Sicha100% (1)

- VOLVO SD45D SINGLE-DRUM ROLLER Service Repair Manual PDFDocument15 pagesVOLVO SD45D SINGLE-DRUM ROLLER Service Repair Manual PDFfjjsjekdmme100% (1)

- Kubota V2607Document2 pagesKubota V2607Pablo Walper100% (3)

- Detroit Diesel 8.2 Liter Spec Sheet CollectionDocument6 pagesDetroit Diesel 8.2 Liter Spec Sheet CollectionAdrian Quintero100% (2)

- 770CH Diagramas PDFDocument6 pages770CH Diagramas PDFEdgar Martinez CarmonaNo ratings yet

- Rulo Ingersoll Rand Sd-Diagrama ElectricoDocument12 pagesRulo Ingersoll Rand Sd-Diagrama ElectricoCOBSA HuelvaNo ratings yet

- Parts Info 211-212-213-241-243 PDFDocument8 pagesParts Info 211-212-213-241-243 PDFmanutecnicoNo ratings yet

- 310J, 310SJ, 315SJ and 410J: As RequiredDocument2 pages310J, 310SJ, 315SJ and 410J: As Requiredhannelore.fineman8327100% (1)

- Manual lb75b PDFDocument178 pagesManual lb75b PDFnery ardila100% (1)

- John Deere Fuel Injection Pump Repair & InstallationDocument8 pagesJohn Deere Fuel Injection Pump Repair & Installationjohncouey67% (6)

- Yanmar TS 105 PDFDocument1 pageYanmar TS 105 PDFAhmad Ali Nursahidin100% (3)

- Preservation Storage For Reciprocating CompressorDocument7 pagesPreservation Storage For Reciprocating CompressorSubbarayan Saravanakumar100% (1)

- MM RT Flex96c - WECS 9520 - Dynex - 2014 04Document730 pagesMM RT Flex96c - WECS 9520 - Dynex - 2014 04Luci LucianNo ratings yet

- H1 Closed Circuit Axial Piston Pumps: Parts ManualDocument84 pagesH1 Closed Circuit Axial Piston Pumps: Parts Manualjoliveira_387024No ratings yet

- 416C, 426C, 428C, 436C and 438C Hydraulic System TroubleshootingDocument10 pages416C, 426C, 428C, 436C and 438C Hydraulic System TroubleshootingJose Antonio SalasNo ratings yet

- John Deere 6-466 Torque & Rebuild SpecificationsDocument1 pageJohn Deere 6-466 Torque & Rebuild Specificationsoswaldo palaciosNo ratings yet

- GTH 644 842 844Document282 pagesGTH 644 842 844maqvereNo ratings yet

- Desarmado & Armado Eje Trasero 426BDocument14 pagesDesarmado & Armado Eje Trasero 426BAbelardo Pina100% (1)

- Cummins L10 MotorDocument558 pagesCummins L10 MotorEliseo Ceniceros100% (1)

- Especificaciones de Apriete para Excavadora CAT 320DLDocument6 pagesEspecificaciones de Apriete para Excavadora CAT 320DLAlex JordánNo ratings yet

- TR JD 6068 PT TSI PDFDocument1 pageTR JD 6068 PT TSI PDFjorge luisNo ratings yet

- 310D Parts Manual MPTS ™.PDF Versión 1Document1,112 pages310D Parts Manual MPTS ™.PDF Versión 1Jacob Alberto Quispe Quispe100% (3)

- 420 E-HlsDocument18 pages420 E-HlsarnoldNo ratings yet

- Motor Yanmar l48v6 Compactador Mvh-150d2Document64 pagesMotor Yanmar l48v6 Compactador Mvh-150d2Mas Inyeccion ElectronicaNo ratings yet

- Calibracion de Valvulas John Deere 6090Document3 pagesCalibracion de Valvulas John Deere 6090青春只是一张黑白画。100% (1)

- Operacion de Sistemas 928F Contraeje PDFDocument43 pagesOperacion de Sistemas 928F Contraeje PDFBETOVN BETOVENNo ratings yet

- Sistemas de Tractor CASSA (Compatibility Mode)Document51 pagesSistemas de Tractor CASSA (Compatibility Mode)arnoldmecNo ratings yet

- Introduction and Customer Information: Right-Hand Side View of John Deere 710B Backhoe Loader (MANUFACTURED 1983-1988)Document15 pagesIntroduction and Customer Information: Right-Hand Side View of John Deere 710B Backhoe Loader (MANUFACTURED 1983-1988)Cristian Fernando Tarifa Martinez100% (1)

- John Deere 4039 TDocument63 pagesJohn Deere 4039 Tluna28106833% (3)

- Tabla de Presiones de Trans D6NDocument3 pagesTabla de Presiones de Trans D6NDavid manjarresNo ratings yet

- Especificaciones Técnicas Caja D6CDocument2 pagesEspecificaciones Técnicas Caja D6CAlfredo Guzmán100% (2)

- d8k Motor D342Document4 pagesd8k Motor D342Omar Suazo100% (1)

- TR JD 6068 PT TSIDocument1 pageTR JD 6068 PT TSICesar LeonNo ratings yet

- Manual de Parte - Genie GHT844Document264 pagesManual de Parte - Genie GHT844dcoronado0487100% (1)

- Motor 3126 Cat PDFDocument1 pageMotor 3126 Cat PDFDepto Limpia100% (1)

- Plano Electrico 420E PDFDocument4 pagesPlano Electrico 420E PDFivan rene villamizar villamizarNo ratings yet

- Manual de Reparacion Motores Iveco F4geDocument142 pagesManual de Reparacion Motores Iveco F4geRicardo Cunha50% (2)

- TMI - Motor 3046 - 5XK23708 - Equipo D3GDocument2 pagesTMI - Motor 3046 - 5XK23708 - Equipo D3GBETOVN BETOVENNo ratings yet

- Service Manual: SV208 SV210 SV212 SV216 Tier 3Document31 pagesService Manual: SV208 SV210 SV212 SV216 Tier 3Angel Ricardo Rodrogiez MalagonNo ratings yet

- Manual de Servicio KubotaDocument2 pagesManual de Servicio KubotacpaolinodNo ratings yet

- Catalogo de Partes Motores CATDocument10 pagesCatalogo de Partes Motores CATpablo100% (1)

- Propel SystemsDocument32 pagesPropel SystemsPerrote Caruso Perrito100% (1)

- Calibracion de Inyeccion D343 ENGINE CATERPILLARDocument1 pageCalibracion de Inyeccion D343 ENGINE CATERPILLARHector Alejandro Mosqueda Torres67% (3)

- 710G Technical ManualDocument679 pages710G Technical Manualjulio cesar cortez100% (1)

- 416B Backhoe Loader 8SG00001-11999 (MACHINE) POWERED BY 3054 Engine (SEBP2850 - 55) - Sistemas y Componentes1Document9 pages416B Backhoe Loader 8SG00001-11999 (MACHINE) POWERED BY 3054 Engine (SEBP2850 - 55) - Sistemas y Componentes1Arturo SanchezNo ratings yet

- Case 430 Skid SteerDocument1,300 pagesCase 430 Skid Steerlisandro fankhauser100% (1)

- Cummins QSB 4.5 - Service ManualDocument191 pagesCummins QSB 4.5 - Service ManualdiesmirnovNo ratings yet

- Instruction Manuel Ce v45-V55 MontabertDocument80 pagesInstruction Manuel Ce v45-V55 Montabertjacques PerronNo ratings yet

- Medidas y Torque Cilindros y BloqueDocument4 pagesMedidas y Torque Cilindros y BloqueIvan Castellanos100% (1)

- Eaton Fuller RTOF 11908LL Transmission Parts ManualDocument34 pagesEaton Fuller RTOF 11908LL Transmission Parts Manualramon hidalgoNo ratings yet

- Control de Trasm 410gDocument2 pagesControl de Trasm 410gdavidNo ratings yet

- Toyota Nico PDFDocument33 pagesToyota Nico PDFDaniel GarciaNo ratings yet

- Image Server HandlerDocument12 pagesImage Server Handlerbobcat1810No ratings yet

- b20z1 OverhaulDocument40 pagesb20z1 Overhaulvladimir hernandezNo ratings yet

- Cummins Speed ControllerDocument7 pagesCummins Speed Controllermarcosluna68100% (1)

- SX44Document4 pagesSX44Mk MakyNo ratings yet

- SX44Document4 pagesSX44Mk MakyNo ratings yet

- Especificaciones Tecnicas AVR Stamford SX440Document4 pagesEspecificaciones Tecnicas AVR Stamford SX440MH..2023No ratings yet

- Perkins 100 PDFDocument86 pagesPerkins 100 PDFmarcosluna68No ratings yet

- Course 1B. Unit Twenty: Affirmative Short AnswersDocument10 pagesCourse 1B. Unit Twenty: Affirmative Short Answersmarcosluna68No ratings yet

- Newage Sx440 Avr, Replacement: Same Fit Form and Function As The Original Newage SX440Document4 pagesNewage Sx440 Avr, Replacement: Same Fit Form and Function As The Original Newage SX440marcosluna68No ratings yet

- 424 Parts CarrierDocument173 pages424 Parts Carriermarcosluna68No ratings yet

- Spec Manager ClaveDocument1 pageSpec Manager Clavemarcosluna68No ratings yet

- Mechanical Tachometer Driv1 PDFDocument2 pagesMechanical Tachometer Driv1 PDFmarcosluna68No ratings yet

- The Codes Listed Are Sorted by PID.: PID FMI DDC Code # (Flashed) DescriptionDocument7 pagesThe Codes Listed Are Sorted by PID.: PID FMI DDC Code # (Flashed) Descriptionmarcosluna68No ratings yet

- Miguel Atlantico Center2Document1 pageMiguel Atlantico Center2marcosluna68No ratings yet

- Lube Oil Cooler PDFDocument4 pagesLube Oil Cooler PDFmarcosluna68No ratings yet

- Final Speech 2Document8 pagesFinal Speech 2marcosluna68No ratings yet

- Kit, Aux Pump MTGDocument2 pagesKit, Aux Pump MTGmarcosluna68No ratings yet

- Hello Welcome To My Final Speech: Luigi Leonardo Luna LozanoDocument8 pagesHello Welcome To My Final Speech: Luigi Leonardo Luna Lozanomarcosluna68No ratings yet

- 1 - 5302 - 858 - MO - 1003 Asia MotorDocument86 pages1 - 5302 - 858 - MO - 1003 Asia MotormarjanstipNo ratings yet

- Lube Oil Pump PDFDocument2 pagesLube Oil Pump PDFmarcosluna68No ratings yet

- Mechanical Tachometer Driv PDFDocument2 pagesMechanical Tachometer Driv PDFmarcosluna68No ratings yet

- 424 Parts CarrierDocument173 pages424 Parts Carriermarcosluna68No ratings yet

- Catálogo Electrónico de Partes Detalle de OpciónDocument2 pagesCatálogo Electrónico de Partes Detalle de Opciónmarcosluna68No ratings yet

- Oil Pan PDFDocument4 pagesOil Pan PDFmarcosluna68No ratings yet

- Catálogo Electrónico de Partes Detalle de OpciónDocument2 pagesCatálogo Electrónico de Partes Detalle de Opciónmarcosluna68No ratings yet

- Rocker Levers PDFDocument3 pagesRocker Levers PDFmarcosluna68No ratings yet

- Plumbing, Block VentDocument3 pagesPlumbing, Block Ventmarcosluna68No ratings yet

- Rear Engine Support PDFDocument2 pagesRear Engine Support PDFmarcosluna68No ratings yet

- 4Bt Engine Parts: Cummins Kang Machine Power Imp - Exp.Co.,LtdDocument41 pages4Bt Engine Parts: Cummins Kang Machine Power Imp - Exp.Co.,Ltdjack comboNo ratings yet

- Marine Engineering Progress in 1997: Annual ReviewDocument42 pagesMarine Engineering Progress in 1997: Annual Reviewнелля могурянNo ratings yet

- Procedimiento de Pulido CrankshaftsDocument19 pagesProcedimiento de Pulido CrankshaftsJavier Hector CayaNo ratings yet

- Product Download PDF 57172d4219c25Document57 pagesProduct Download PDF 57172d4219c25Nico Sugiarto Putra100% (7)

- Torsional Vibration Driveline PDFDocument189 pagesTorsional Vibration Driveline PDFanildhakeNo ratings yet

- Timing BeltDocument33 pagesTiming BeltAhmad Al DawayimaNo ratings yet

- PL80 S6D95L-1 22842-Or EG85Document50 pagesPL80 S6D95L-1 22842-Or EG85yosy prastiyo100% (1)

- MME-253 Melting and Casting: by Dr. Muhammad Zafar ZarifDocument21 pagesMME-253 Melting and Casting: by Dr. Muhammad Zafar ZarifSami UllahNo ratings yet

- PR6412 Computer Aided Machine Drawing Lab ManualDocument99 pagesPR6412 Computer Aided Machine Drawing Lab Manualvigneshkannaganesan75% (4)

- Fdocuments - in 2002 Mitsubishi Fuso Truck Fm657 Service Repair Manual 1595638455Document14 pagesFdocuments - in 2002 Mitsubishi Fuso Truck Fm657 Service Repair Manual 1595638455simonruiz1No ratings yet

- Reciprocating CompressorDocument7 pagesReciprocating CompressorAlphy Thomas100% (1)

- Perkins 4000 Series Engine Specialist Tools Parts List Part Number Description Use With Crankshaft and FlywheelDocument2 pagesPerkins 4000 Series Engine Specialist Tools Parts List Part Number Description Use With Crankshaft and Flywheelmahmoud khtaNo ratings yet

- In-Frame Overhaul Procedure: 3406E & C-15 Diesel Truck Engines Engine DesignDocument2 pagesIn-Frame Overhaul Procedure: 3406E & C-15 Diesel Truck Engines Engine Design李文琪100% (1)

- HH Catalog 2020 WebDocument44 pagesHH Catalog 2020 WebJoão JoséNo ratings yet

- 3408 3412Document27 pages3408 3412Gonzalo Villalobos Sanchez100% (4)

- Sakinah Hisham, K. Kadirgama, D. Ramasamy, M.M. Noor, A.K. Amirruddin, G. Najafi, M.M. RahmanDocument15 pagesSakinah Hisham, K. Kadirgama, D. Ramasamy, M.M. Noor, A.K. Amirruddin, G. Najafi, M.M. RahmanNiti KlinKaewNo ratings yet

- Fiat MotoareDocument33 pagesFiat MotoareSergiu GadaleanNo ratings yet

- Fiat ScudoDocument28 pagesFiat ScudobibNo ratings yet

- PXF00215 Basic PartsDocument12 pagesPXF00215 Basic PartsJose FavaNo ratings yet

- Analysis of Torsional Vibration in ICEDocument25 pagesAnalysis of Torsional Vibration in ICEgiulianoNo ratings yet

- Dirtbike - Streetbike - Atv-Utv - Watercraft - Snowmobile - 50CcDocument24 pagesDirtbike - Streetbike - Atv-Utv - Watercraft - Snowmobile - 50CcAlex CatoNo ratings yet

- Specifications: 4012-46A Industrial EngineDocument32 pagesSpecifications: 4012-46A Industrial EngineJacques Van NiekerkNo ratings yet

- Holding Down BoltsDocument5 pagesHolding Down BoltsRamneek Arora0% (1)

- 2014 Product CatalogDocument40 pages2014 Product CatalogandreinaNo ratings yet