Professional Documents

Culture Documents

LNG Reliquifactio1

Uploaded by

Jitendra KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LNG Reliquifactio1

Uploaded by

Jitendra KumarCopyright:

Available Formats

LNG reliquifaction

Traditionally, LNG carriers have used the boil off from cargo as fuel for the propulsion. This led to the use

of steam plant as the preferred method as the combustion of this gas is simpler. In addition the steam

plant gives the option to safely deal wih excess boil off of gas during pasage or arrival in port without the

need to resort to venting.

The use of duel fuel burning diesel engines is becoming more in favour thus requiring

alternative methods to deal with the excess boil off.

ne method is reliquifaction commonlu seen in L!G shps but previously not sen in LNG due to

the very low saturation temperatures of LNG

Reliquifaction process

This generally ta"es the form of seperate reliquifaction and refrigeration units. The system uses Nitrogen

as the refrigerant in the reverse #rayton cycle$ a version of the cascae system in which several stages

% normally &' operate in series with the LNG. The final stage is a turbo expander in which the energy of

the Nitrogen is used to power the expander stage. Thus with the removal of energy from the nitrogen in

the form of wor" the temperature is low enough to liquify the LNG.

The entire asembly my be either totally enclosed in insulation with repairs only to be carried

out at predetermined times. r it may be enclosed in an insulated wor" house

It should be noted that hgh levels of nitrogen in the cargo can have a serious effect on the

viability of reliquifaction

The power absorbed by this unit is high thus ony recent increases in cargo prices has made it

economically viable. ( high voltage distribution system is required

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Overall Arrangement: Description of The Salient PartsDocument6 pagesOverall Arrangement: Description of The Salient PartsJitendra KumarNo ratings yet

- Overview of Microbiological AttackDocument10 pagesOverview of Microbiological AttackJitendra KumarNo ratings yet

- Oxygen AnalysersDocument2 pagesOxygen AnalysersJitendra KumarNo ratings yet

- Brochure o Pumps Deepwell Gas CarriersDocument4 pagesBrochure o Pumps Deepwell Gas CarriersJohn MarxisNo ratings yet

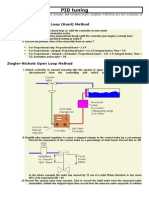

- PID TuningDocument4 pagesPID TuningJitendra Kumar100% (1)

- Parallel Operation of GeneratorsDocument5 pagesParallel Operation of GeneratorsJitendra KumarNo ratings yet

- Oil Distribution and Factors in Journal BearingsDocument2 pagesOil Distribution and Factors in Journal BearingsAnkit DedhiyaNo ratings yet

- Operation of A Centrifugal Oil PurifersDocument3 pagesOperation of A Centrifugal Oil PurifersJitendra KumarNo ratings yet

- Pilgrim NutDocument2 pagesPilgrim NutJitendra KumarNo ratings yet

- Oily Water SeperatorsDocument2 pagesOily Water SeperatorsJitendra KumarNo ratings yet

- Increasing Propulsive EfficiencyDocument6 pagesIncreasing Propulsive EfficiencyJitendra KumarNo ratings yet

- Oil WhirlDocument2 pagesOil WhirlJitendra KumarNo ratings yet

- Navigation LightingDocument1 pageNavigation LightingJitendra KumarNo ratings yet

- Microbes of Microbiological Attac1Document3 pagesMicrobes of Microbiological Attac1Jitendra KumarNo ratings yet

- Molybdenum DiSulphideDocument1 pageMolybdenum DiSulphideJitendra KumarNo ratings yet

- Marpol 73Document12 pagesMarpol 73Jitendra KumarNo ratings yet

- LNG Reliquifactio1Document1 pageLNG Reliquifactio1Jitendra KumarNo ratings yet

- Motor Ship Steam Plan1Document3 pagesMotor Ship Steam Plan1Jitendra KumarNo ratings yet

- Tooth Design: Forces Acting On Spur GearsDocument77 pagesTooth Design: Forces Acting On Spur GearsJitendra KumarNo ratings yet

- Metallurgical TestingDocument1 pageMetallurgical TestingJitendra KumarNo ratings yet

- Motor Ship Steam Plant ControlDocument1 pageMotor Ship Steam Plant ControlJitendra KumarNo ratings yet

- Lube Oil Requirements For Diesel EnginesDocument3 pagesLube Oil Requirements For Diesel EnginesJitendra KumarNo ratings yet

- Microbes of Microbiological Attac1Document3 pagesMicrobes of Microbiological Attac1Jitendra KumarNo ratings yet

- LNG Containment DesignsDocument3 pagesLNG Containment DesignsJitendra KumarNo ratings yet

- Liquified Gas CargoesDocument2 pagesLiquified Gas CargoesJitendra KumarNo ratings yet

- Mechanical GovernorsDocument1 pageMechanical GovernorsJitendra KumarNo ratings yet

- Materials Used in Ships Sea Water SystemsDocument1 pageMaterials Used in Ships Sea Water SystemsAnkit DedhiyaNo ratings yet

- Low Sulphur FuelsDocument1 pageLow Sulphur FuelsJitendra KumarNo ratings yet

- Lifting Using Accessories: Calculation of LoadDocument2 pagesLifting Using Accessories: Calculation of LoadJitendra KumarNo ratings yet

- Jacket Water SystemDocument2 pagesJacket Water SystemJitendra KumarNo ratings yet