Professional Documents

Culture Documents

Calculation of Gas Free Liquid Level

Uploaded by

Vibhuti Bhargava0 ratings0% found this document useful (0 votes)

17 views1 pageFoam Free level in CBM

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFoam Free level in CBM

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pageCalculation of Gas Free Liquid Level

Uploaded by

Vibhuti BhargavaFoam Free level in CBM

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Calculation of Gas free liquid level

Coal-Seam water level monitoring in CBM production is generally complicated by violent

degassing and foaming that can occur in monitoring wells when the critical pressure is achieved

(Ref: Montana Bureau of Mines and Geology, University of Montana, 2002).

The liquid column in most wells are aerated by the gas which is produced from the coal seams.

The gas flows up through the liquid column and vents at the surface of the well into the flow line

to the separator. If the gas production is small, the height of liquid column is increased very little

by existence of gas bubbles. However, if gas is produced in considerable amount, liquid column

can be aerated as much as five times of gas free liquid column. (Ref: Acoustic Determination of

Producing Bottomhole Pressure by Echometer).

From the work done by Walker, and further research of Gilbert a method was published to

determine gas free liquid column without waiting for fluid to get stabilized after closing the

casing annulus valve for a long period of time. In this method, casing valve is closed and a shot

for water level is taken. After waiting for few minutes (depending on wells ability to increase

casing annulus pressure by some significant amount) another shot is taken, which in turn

produces dp/dt gradient (Change in casing pressure with time). This gradient along with depth of

well (bottom-most perforation in CBM wells) calculates height of foam and gas-free liquid level

for the well as per the extrapolation derived from Gilberts Chart (1952).

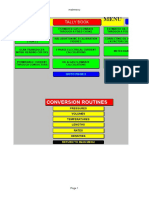

Our Software, which is used to analyse liquid level on daily basis has ability to calculate gas free

liquid level and hence can be used to calculate foam height and gas free liquid level.

You might also like

- Spe 15481 PaDocument10 pagesSpe 15481 PaVibhuti BhargavaNo ratings yet

- Determination of Acoustic Velocities For Natural GasDocument7 pagesDetermination of Acoustic Velocities For Natural GasVibhuti BhargavaNo ratings yet

- Hsehandbook 1Document11 pagesHsehandbook 1MartahanManurungNo ratings yet

- H Se HandbookDocument67 pagesH Se HandbookVibhuti BhargavaNo ratings yet

- Oil Gas Industry GuidelinesDocument90 pagesOil Gas Industry GuidelinesAdhia Prenata Putra HuzaNo ratings yet

- Oil Gas Industry GuidelinesDocument90 pagesOil Gas Industry GuidelinesAdhia Prenata Putra HuzaNo ratings yet

- GilbertDocument24 pagesGilbertVibhuti BhargavaNo ratings yet

- Espdesign-Si Units - XLS: Bar Max 3 L 2 L 3 3Document3 pagesEspdesign-Si Units - XLS: Bar Max 3 L 2 L 3 3Vibhuti BhargavaNo ratings yet

- Echometer Shut in Reservoir PressureDocument20 pagesEchometer Shut in Reservoir PressureVibhuti BhargavaNo ratings yet

- Welltest SpecialistsDocument9 pagesWelltest SpecialistsVibhuti BhargavaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NGP-001-PCS-15.03-0001!00!00 - Specification For Gas Engine Driven Reciprocating CompressorDocument39 pagesNGP-001-PCS-15.03-0001!00!00 - Specification For Gas Engine Driven Reciprocating Compressorm.shehreyar.khanNo ratings yet

- Atlascopco Oil DatasheetDocument2 pagesAtlascopco Oil DatasheetAmirmasoudNo ratings yet

- Invalco Brochure PDFDocument20 pagesInvalco Brochure PDFMargaret DaughertyNo ratings yet

- Oil SeparatorDocument2 pagesOil SeparatorOnofreNo ratings yet

- SP-1074 Pom PDFDocument24 pagesSP-1074 Pom PDFHari Prakash GrandheyNo ratings yet

- 99041-Prediction of Scale and CO2 Corrosion in Oil Field SystemsDocument16 pages99041-Prediction of Scale and CO2 Corrosion in Oil Field SystemsdhireshmahajanNo ratings yet

- OP Production and Test Separator TechSheet PeerlessDocument2 pagesOP Production and Test Separator TechSheet Peerlessحسيننننن حسينننننNo ratings yet

- Carrier XCT™7 - CO - VRF COMPACT VERSIONDocument69 pagesCarrier XCT™7 - CO - VRF COMPACT VERSIONChaminda Kumara100% (1)

- Hydrates: by Sherry Oyagha 28 August, 2020Document45 pagesHydrates: by Sherry Oyagha 28 August, 2020JesseNo ratings yet

- SeparatorsDocument50 pagesSeparatorsCVACAPNo ratings yet

- Vdocuments - MX Mineral Oil Centrifuge Ose 5-91-0374Document81 pagesVdocuments - MX Mineral Oil Centrifuge Ose 5-91-0374Miti RacuNo ratings yet

- Instruction BookDocument44 pagesInstruction BookMiharb FinouakefNo ratings yet

- Corrosion AllowanceDocument35 pagesCorrosion AllowanceReni Mutiara Sari50% (2)

- E 21.411 - Reciprocating CompressorDocument4 pagesE 21.411 - Reciprocating CompressorPhượng Nguyễn0% (1)

- Hydrocyclone FiltersDocument2 pagesHydrocyclone FiltersKapwell LimitedNo ratings yet

- OLGA 6.2 Release NoteDocument33 pagesOLGA 6.2 Release NoteelvithafNo ratings yet

- Bucket and Weir Type SeparatorDocument3 pagesBucket and Weir Type SeparatorAdewunmi OlufemiNo ratings yet

- Nodal Analysis IPIMSDocument80 pagesNodal Analysis IPIMShaiderNo ratings yet

- ASCOM General IntroductionDocument12 pagesASCOM General IntroductionperrychemNo ratings yet

- NTPCVBR1Document91 pagesNTPCVBR1DenkaNo ratings yet

- Gammon: Aqua-Glo Series V Water Detector Kit Operating Procedure ManualDocument8 pagesGammon: Aqua-Glo Series V Water Detector Kit Operating Procedure ManualMd Tahmidul IslamNo ratings yet

- PX 80VGV-14C - Service & Maintenance ManualDocument160 pagesPX 80VGV-14C - Service & Maintenance ManualCentrifugal SeparatorNo ratings yet

- Vertical Mill PDFDocument15 pagesVertical Mill PDFGregory100% (4)

- Tally BookDocument53 pagesTally BookAnyer SalazarNo ratings yet

- CMG Winpro 200910Document235 pagesCMG Winpro 200910swpuxiaofanNo ratings yet

- Manual Irn 7-15 PDFDocument37 pagesManual Irn 7-15 PDFairmacmex100% (1)

- Multi-Interface Level in Oil Tanks and Applications of Optical Fiber Sensors Leal-Junior2018 PDFDocument11 pagesMulti-Interface Level in Oil Tanks and Applications of Optical Fiber Sensors Leal-Junior2018 PDFEdda Andrade RosalesNo ratings yet

- Air Compressor PDS 100S PDFDocument65 pagesAir Compressor PDS 100S PDFTomy Efraim SitumorangNo ratings yet

- Steam Generator Installation ManualDocument110 pagesSteam Generator Installation ManuallucialucenasNo ratings yet

- Oil & Gas Upstream Production Facilities OverviewDocument49 pagesOil & Gas Upstream Production Facilities OverviewabdulzahraNo ratings yet