Professional Documents

Culture Documents

Protecting Motor Circuits

Uploaded by

georgel19800 ratings0% found this document useful (0 votes)

10 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views3 pagesProtecting Motor Circuits

Uploaded by

georgel1980Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Protecting motor circuits

Type 2 protection helps maintain productivity and prevent downtime

By Steven R. Goble

OTOR CIRCUITS form a

substantial part of any

commercial or industrial

installation. With greater

emphasis being placed on reduced down-

time and increased productivity, proper

application and selection of motor branch

circuit protective devices is essential.

Standard industry practice is to use com-

ponents listed by Underwriters Laborato-

ries, or certified by the Canadian Standard

Association, and applied according to the

National Electrical Code. However, U.L.,

CSA, and NEC testing and application

procedures are largely oriented toward

fire safety, with little, if any, concern

about maintaining productivity or pre-

venting downtime. Simply selecting the

branch circuit protective device to com-

ply with one of these codes or standards

may not provide an acceptable level of

protection.

Underwriters Laboratories has devel-

oped standards to verify that an electrical

product will not cause fire or electrical

shock hazards. UL 508 is the standard

used to evaluate the short circuit protec-

tion of industrial control equipment.

Section 58 of the Standard outlines the

testing requirements and criteria used to

determine if the test results are accept-

able. Short circuit test values given in

Table 58.2 of UL508 are used to establish

the short circuit rating for the contractor

and overload relay of motor starters. The

manufacturer must state whether this rat-

ing is restricted by a maximum fuse or

circuit breaker size in order to pass the

minimum short circuit test requirements.

Compliance to the standard allows

deformation of the enclosure, but the door

shall not be blown open and it shall be

possible to open the door after the test.

The contacts shall not disintegrate, but

welding of the contacts is considered

acceptable. When testing with fuses,

damage to the overload relay is not al-

lowed, and it must perform in accordance

with the calibration requirements. Tests

with circuit breakers allow the overload

relay to be damaged with burnout of the

current element completely acceptable.

For short circuit ratings in excess of the

levels listed in Table 58.2 of UL508, the

damage allowed is even more severe.

Welding or complete disintegration of

contacts is acceptable

and complete burnout

of the overload relay is

allowed. Therefore, a

user cannot be certain

that the motor starter

will not be damaged

just because it has been

U.L. Listed for use with

a specific branch circuit

protective device. U.L.

tests are for safety and

do not define the level

of damage allowed.

Selecting protective

devices

In selecting the branch

circuit protective de-

vice, the designer must

be aware of the limits

of the motor circuit

components, as follows

(see Fig. 1):

Excessive currents

from single phasing, overloading, and

locked rotor conditions cause motors to

overheat, leading to eventual failure.

Overload relays and branch circuit pro-

tective devices should be selected to open

the motor circuit before current levels

reach the heating curve (motor damage)

of the motor. The overload relay and

branch circuit protective devices must

also be able to withstand motor starting

current or, inrush current, which typi-

cally lasts for up to 10 sec, without trip-

ping prematurely (see Fig. 1).

Wire damage can oc-

cur under two condi-

tions. First, motor cir-

cuit conductors have a

short circuit withstand

rating that must not be

exceeded. If the branch

circuit protective device

is not capable of limit-

ing the short circuit

current to a value be-

low the wire withstand,

the wire may be dam-

aged, or destroyed.

Secondly, overheating

caused by overload

conditions which ex-

ceed the conductor

ampacity can lead to

wire damage, and con-

ceivably, a fire.

Contractor and over-

load relay short circuit

withstand ratings are

generally not available

from manufacturers.

The withstand capacity of these devices

varies as a function of physical size and

construction. Withstand ratings are

expressed in energy (given by the Joule

integral I

2

t) and peak current for various

levels of fault current. NEMA designed

products often have higher withstand ca-

pabilities than the newer IEC style motor

starters. Regardless of the style of con-

trol device used, the characteristics of the

branch circuit protective device must

ensure that the let-through energy and

peak current do not rise above the levels

M

CURRENT IN AMPERES

T

I

M

E

I

N

S

E

C

O

N

D

S

FIG. 1. Motor and Motor Circuit Damage Protection, 10H.P. @ 460V, 3 ph.

Motor

Damage

Contactor Breaking

Current

Crossover Range

(Ic = 7 10 Ie)

Overload

Relay

Motor

Start

#12 Wire

Damage

Thermal

Withstand

Limit

Contactor

Withstand

430-52.

MOTOR BRANCH CIRCUIT PROTECTION

Maximum rating or setting of protective devices+

FUSE CIRCUIT BREAKER*

Non-time Dual-element Instantaneous Inverse

Delay Time-delay Type Only Time Type

300% 175% 700% 250%

+See Article 430, Section 430-52, exceptions 1 thru 3.

*For latest information, check manufacturers data and/or Underwriters

Laboratories U.L. Standard 508 for damage and warning label requirements.

September 1991 CEE News

F E A T U R E

September 1991 CEE News

that the contractor and overload relay can

withstand.

Breaking capacity (current) is also of

significance. The branch circuit protec-

tive device must operate at all currents

above the contactor breaking capacity.

Sustained current exceeding the break-

ing capacity will cause destruction of the

contactor which could lead to a more

hazardous failure of the control equip-

ment. Therefore, the intersection of the

branch circuit protective device and

overload relay characteristic should not

exceed the breaking capacity of the

contactor. This intersection is known as

the crossover point (current). At cur-

rents immediately below the crossover

point, the overload relay trips and the

contactor is required to break the circuit.

Consequently, the crossover point

should not exceed the breaking capacity

of the contactor. For currents immedi-

ately above the crossover point, the

branch circuit protective device should

be sufficiently fast enough to avoid ther-

mal damage to the overload relay.

Selecting branch circuit protection

The branch circuit protective device

may be either a fuse or circuit breaker.

Section 430-52(a) (440-22a) of the NEC

requires that the branch circuit protective

device shall not exceed the values calcu-

lated in accordance with Table 430-152.

These values have been established to

insure applications are essentially free

from hazard, but do not define the level

of protection. The values given in Table

430-52 are maximum values and do not

preclude the application of lower sizes.

When selecting the protective device,

the following conditions must be satis-

fied to prevent damage to the motor cir-

cuit and minimize downtime in the event

of an overcurrent condition:

The time current characteristic must

be able to withstand the motor inrush

current. The branch circuit protective

device should also be capable of provid-

ing backup motor overload protection

for the overload relay. If contacts have

welded or the overload relay has been

miscalibrated, a second level of protec-

tion is provided for the motor and motor

circuit conductors.

The time-current characteristics must

be such that currents above the contactor

breaker capacity and the thermal with-

stand limit of the overload relay are

cleared.

The peak let-through current (Ip) and

the let-through energy (I

2

t) of the branch

circuit protective device must be low

enough to prevent damage to the contactor,

overload relay, and conductors. The let-

through characteristics must be sufficient

to protect the circuit components for all

levels of fault current. The maximum

acceptable Ip and I

2

t for fuses is limited by

U.L. and CSA for each fuse class. The

more current limiting the fuse, the lower

these values will be.

U.L. does not specify maximum Ip or I

2

t

for circuit breakers. Circuit breakers that

take 1/2 cycle or greater to clear a fault

may not limit the Ip or I

2

t values to levels

below the withstand capabilities of the

motor starter. To obtain this information

the circuit breaker manufacturer must be

contacted.

Preventing damage to starter

In order to properly select a branch cir-

cuit protective device that not only pro-

vides motor branch circuit protection, but

also protects the circuit components from

damage, the designer must look beyond

mere safety standards. Coordination of

the branch circuit protective device and

the motor starter is necessary to insure

that there will be no damage or danger to

either the starter or the surrounding equip-

ment. Unfortunately, the information

needed to thoroughly evaluate the coordi-

nation of the branch circuit components

is not readily available. There is, however,

an IEC (International Electrotechnical

Commission) Standard that offers guid-

ance in evaluating the level of damage

likely to occur during a short circuit with

various branch circuit protective devices.

IEC Publication 947, Low Voltage

Switchgear and Control, Part 4-1:

Contactors and Motor Starters, addresses

the coordination between the branch cir-

cuit protective device and the motor starter.

It also provides a method to measure the

performance of these devices should a

short circuit occur. IEC defines two levels

of protection (coordination) for the motor

starter under short circuit conditions:

Type 1. Considerable damage to the

contactor and overload relay is accept-

able. Replacement of components or a

completely new starter may be needed.

There shall be no discharge of parts

beyond the enclosure.

Type 2. No damage is allowed to either

the contactor or overload relay. Light

contact welding is allowed, but must be

easily separable.

Comparing branch circuit protective

devices

A comparison of the branch circuit de-

vices commonly used will give an idea of

the level of performance the user can

expect.

A motor circuit protector (MCP) is a

magnetic only (short circuit only) device

that will operate under short circuit con-

ditions in excess of its instantaneous trip

setting. To allow a motor to start, and

prevent nuisance tripping, typical trip set-

tings are 700% to 1300% of motor full

load current (FLA). This device typically

takes 1/2 cycle of short circuit current to

clear the circuit. Unless otherwise noted,

these are not considered to be current

CURRENT IN AMPERES

T

I

M

E

I

N

S

E

C

O

N

D

S

FIG. 2. Motor Circuit Protector Sized @ 700% FLA.

Motor

Damage

Contactor Breaking

Current

MCP (700% FLA)

Crossover Point

(Ic = 5.5 Ie)

Overload

Relay

Motor

Start

#12 Wire

Damage

Thermal

Withstand

Limit

Contactor

Withstand

CEE News September 1991

limiting devices. An MCP affords Type 1

protection under short circuit conditions

due to the 1/2 cycle or greater opening

time (note the intersection of the contactor

withstand curve with the MCPcurve. Fig.

2). Replacement of the motor starter can

be expected. MCPs provide no back-up

overload protection for the motor circuit.

If the relays are unable to operate in an

overload or single-phase condition, the

motor and other components can be sub-

jected to excessive heating.

Afast acting fuse (Fig. 3) has character-

istics that do not exhibit intentional, built-

in time delay during harmless inductive

surges (motor starting currents, trans-

former magnetizing current, etc.). Be-

cause of this lack of time delay, fast acting

fuses are typically sized at 300% of motor

FLAto prevent nuisance tripping on motor

start-up. However, unlike the MCP, they

can exhibit superior short circuit perform-

ance. When operating in their current

limiting range, these fuses can reduce the

damaging energies associated with short

circuits. If the characteristics are fast

enough, they can protect the motor circuit

components, and the motor starter. In

many cases, these fuses may provide

Type 2 protection for the starter.

Let-through energy for fast acting fuses,

although within Type 2 limits, will gener-

ally by higher than properly sized, lower

rated time delay fuses of the same class.

Fast acting fuses sized at these values

offer no back-up overload protection for

the motor circuit. If the relays are unable

to operate during an overload or single-

phase condition, the starter and other

components may be subjected to exces-

sive heating and damage.

A dual-element time-delay fuse (Fig.

4) is one whose characteristics have an in-

tentional, built-in delay to withstand

harmless inrush currents. Sizing dual-

element time-delay Class J fuses at 125%

of motor FLA, or next size larger if 125%

does not correspond to a manufacturers

standard fuse size, affords several distinct

protection advantages to the starter, motor

circuit, and motor.

They provide Type 2 protection under

short circuit conditions, due to their

excellent short circuit let-through values.

This type of protection does, by defini-

tion, require that the starter be reusable

following fuse replacement. Note that

relay calibration shall not be affected.

They provide practical, inexpensive back-

up overload protection for the motor cir-

cuit. If the relays are unable to operate in

an overload or single-phase condition,

properly sized fuses will open before the

motor damage curve is reached. This siz-

ing of fuses and relays is based on the

actual running current of the motor, if the

motor is not fully loaded, or the motor

nameplate currentwhichever is lower.

Several other benefits are established

when utilizing 125% sizing:

The dual-element time-delay design

allows the motor to start even though

125% sizing is used.

The motor circuit conductors ares pro-

tected from short circuit and overload

damage.

Contactor withstand and contactor heat-

ing curves are within the protection capa-

bilities of the fuse (which relates directly

to Type 2 protection).

The crossover point (Ic) is between the

optimum coordination limits of 7 to 10

times contactor ratings. For overloads up

to this value, the relay should operate

first. If the relays do not operate, for

whatever reason, the backup dual-ele-

ment time-delay Class J fuse will open

before the motor damage curve is reached.

For short circuits above this value, the

fuse short circuit element will operate,

protecting the motor starter and compo-

nents from damage.

Summary

When selecting the proper branch cir-

cuit protective device there are several

alternatives to choose from. The design-

er must evaluate what level of protection

is required to provide maximum safety,

productivity, and efficiency. Specifying

components tested to safety standards is

not enough and its not enough to follow

established application limits. The test

methods outlined in IEC 947-4-1 for

verification of coordination between

the starter and branch circuit protective

device can be used to determine the

performance level of the selected

components. I

Steven Goble is product manager, Elec-

trical, Bussmann, Cooper Industries,

St. Louis, MO.

CURRENT IN AMPERES

T

I

M

E

I

N

S

E

C

O

N

D

S

FIG. 3. Fast-Acting Fuse, IEC Type Sized @ 300% FLA.

Motor

Damage

Contactor Breaking

Current

Fast-Acting

Fuse (45A)

Crossover Range

(Ic = 9 Ie)

Overload

Relay

Motor

Start

#12 Wire

Damage

Thermal

Withstand

Limit

Contactor

Withstand

CURRENT IN AMPERES

T

I

M

E

I

N

S

E

C

O

N

D

S

FIG. 4. Dual-Element, Time-Delay Class J Fuse Sized @ 125% FLA.

Motor

Damage

Contactor Breaking

Current

Class J

Time-Delay

Fuse (17A)

Crossover Point

(Ic = 7 Ie)

Overload

Relay

Motor

Start

#12 Wire

Damage

Thermal

Withstand

Limit

Contactor

Withstand

You might also like

- Relay Selection GuideDocument39 pagesRelay Selection GuideSumer LandNo ratings yet

- Trefoil Formation Related IssuesDocument2 pagesTrefoil Formation Related IssuesdphegartyNo ratings yet

- Importance of X-R RatiosDocument6 pagesImportance of X-R RatiosNayreth MezonesNo ratings yet

- Termination Clearance PDFDocument4 pagesTermination Clearance PDFaramirezbenitesNo ratings yet

- Voltage Transformers Type UMZDocument25 pagesVoltage Transformers Type UMZpattarawatNo ratings yet

- 02 DT - Short CircuitDocument2 pages02 DT - Short CircuitMahyar MashayekhiNo ratings yet

- Effect of Cable Capacitance On Contactor Operation (Oct-Dec 06)Document4 pagesEffect of Cable Capacitance On Contactor Operation (Oct-Dec 06)santhosh100% (1)

- Industrial Control Transformers Catalog2005Document60 pagesIndustrial Control Transformers Catalog2005chinitnNo ratings yet

- Dokumen - Tips - Numerical Rho 3 Motor Protection Relay Easun R Current TransformerDocument4 pagesDokumen - Tips - Numerical Rho 3 Motor Protection Relay Easun R Current TransformerPAWAN RAJPUTNo ratings yet

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- Battery Sizing: From Open ElectricalDocument11 pagesBattery Sizing: From Open ElectricalBADRI VENKATESHNo ratings yet

- MCAGDocument5 pagesMCAGariptrNo ratings yet

- Motor ProtectionDocument58 pagesMotor ProtectionVenkat Subramanyam.CNo ratings yet

- Tripping Relay Bistable Relays RXMD 1 RXMD 2Document10 pagesTripping Relay Bistable Relays RXMD 1 RXMD 2M Kashif JunaidNo ratings yet

- AC Motor ProtectionDocument33 pagesAC Motor ProtectionLoretta KimNo ratings yet

- TR0902: Report On Matched-Melt Co-Ordination As Used For Selecting Wind Farm FusesDocument7 pagesTR0902: Report On Matched-Melt Co-Ordination As Used For Selecting Wind Farm FusesPCTMarketingNo ratings yet

- McompDocument9 pagesMcompSrikanth NakkaNo ratings yet

- Medium Voltage Induction Motor Protection and Diagnostics: Yi Du Pinjia Zhang Prof. Thomas G. HabetlerDocument61 pagesMedium Voltage Induction Motor Protection and Diagnostics: Yi Du Pinjia Zhang Prof. Thomas G. HabetlervladalucarDNo ratings yet

- HV CB For SubstationDocument28 pagesHV CB For SubstationjokotsNo ratings yet

- Impedance Correction FactorDocument7 pagesImpedance Correction FactorEngr Fahimuddin QureshiNo ratings yet

- Article On Transformer Neutral GroundingDocument4 pagesArticle On Transformer Neutral Groundingshanmars007100% (1)

- Schinder CBCTDocument10 pagesSchinder CBCTSunil KumarNo ratings yet

- Mcag 12Document6 pagesMcag 12big_lebowski100% (1)

- Power Quality and Harmonic Analysis in Three PhaseDocument7 pagesPower Quality and Harmonic Analysis in Three PhaseMarcos PessanhaNo ratings yet

- DGA or Dissolved Gas Analysis of Transformer OilDocument6 pagesDGA or Dissolved Gas Analysis of Transformer OilAmanda MarshallNo ratings yet

- HV Equipment Failure Data 2017Document164 pagesHV Equipment Failure Data 2017ipraoNo ratings yet

- Lock Out RelayDocument4 pagesLock Out RelayFatholla SalehiNo ratings yet

- Transformer Inrush Currents and Protection 2603 003 A00Document4 pagesTransformer Inrush Currents and Protection 2603 003 A00Joshi DhvanitNo ratings yet

- Types of Switching Surges Found in MV Motors Fed Via Cables and Switched by Vacuum Circuit BreakersDocument19 pagesTypes of Switching Surges Found in MV Motors Fed Via Cables and Switched by Vacuum Circuit BreakersRatoka LekhemaNo ratings yet

- Medium Voltage Capacitor Bank SpecificationsDocument4 pagesMedium Voltage Capacitor Bank SpecificationsAlexander WijesooriyaNo ratings yet

- CAG11Document2 pagesCAG11GuruNo ratings yet

- Sizing A MV Generator Circuit Breake1Document25 pagesSizing A MV Generator Circuit Breake1Afifah Zuhroh0% (1)

- Reverse PowerDocument6 pagesReverse PowerEdward DineshNo ratings yet

- Upgrading The ProtectionDocument4 pagesUpgrading The ProtectionMukesh KumarNo ratings yet

- BA300Document7 pagesBA300carthic1979No ratings yet

- Difference Between Vacuum Circuit Breaker & Vacuum ContactorDocument2 pagesDifference Between Vacuum Circuit Breaker & Vacuum ContactorMohan K67% (3)

- GE-Guide To Instantaneous SelectivityDocument19 pagesGE-Guide To Instantaneous SelectivityJOSE LUIS FALCON CHAVEZNo ratings yet

- Reduced Series ReactorDocument10 pagesReduced Series ReactorclicknagpalNo ratings yet

- Documents For Pmc/Owner'S Approval/Review/Records - Electrical Cooling Tower PackageDocument8 pagesDocuments For Pmc/Owner'S Approval/Review/Records - Electrical Cooling Tower PackageVivek MNo ratings yet

- 7-AZN-PDS-3501 - (20kV Switchgear (PDS) ) GA & SLD 24kV Switchgear SM6 - As BuiltDocument40 pages7-AZN-PDS-3501 - (20kV Switchgear (PDS) ) GA & SLD 24kV Switchgear SM6 - As BuiltRingoNo ratings yet

- Protection Coordination in MV Distribution System of Sri Lanka PDFDocument120 pagesProtection Coordination in MV Distribution System of Sri Lanka PDFJulioNo ratings yet

- 11kV SF6Document6 pages11kV SF6ahmadgce04No ratings yet

- GE Digital Energy Multilin: Fundamentals of Modern Protective RelayingDocument140 pagesGE Digital Energy Multilin: Fundamentals of Modern Protective RelayingClaudioNo ratings yet

- 36kV SF6 Gas Circuit Breaker Type SFG Mitsubishi ElectricDocument3 pages36kV SF6 Gas Circuit Breaker Type SFG Mitsubishi ElectricSunil G Parakkal100% (1)

- Fundamentals of Bus Bar Protection: GE MultilinDocument92 pagesFundamentals of Bus Bar Protection: GE Multilinmentong100% (1)

- Vagm 22Document4 pagesVagm 22AONLANo ratings yet

- Generator ReactancesDocument3 pagesGenerator ReactancesLora BishopNo ratings yet

- Busbar Diffrential Protection REB611 Tech ManualDocument380 pagesBusbar Diffrential Protection REB611 Tech Manualfiatraj1100% (1)

- 2014 Fist 4-1B 03062015 PDFDocument100 pages2014 Fist 4-1B 03062015 PDFShahid IqbalNo ratings yet

- 7SJ50x CatalogueDocument10 pages7SJ50x CatalogueManuel López Villaseñor100% (2)

- Abb Oltc Ordering Info PDFDocument13 pagesAbb Oltc Ordering Info PDFSellappan MuthusamyNo ratings yet

- Arc Control in Circuit Breakers: Low Contact Velocity 2nd EditionFrom EverandArc Control in Circuit Breakers: Low Contact Velocity 2nd EditionNo ratings yet

- Street Lighting Installation Worker: Passbooks Study GuideFrom EverandStreet Lighting Installation Worker: Passbooks Study GuideNo ratings yet

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- Coordination For Motor Protection: High Performance MCCBDocument4 pagesCoordination For Motor Protection: High Performance MCCBrobertovm2002No ratings yet

- Motor Circuit Protection Using Medium Voltage FusesDocument4 pagesMotor Circuit Protection Using Medium Voltage Fuseseastsider910No ratings yet

- 7XG3123 - ReyArc Catalogue SheetDocument12 pages7XG3123 - ReyArc Catalogue SheetChristian Vasquez MedranoNo ratings yet

- Echnical News: Improving Star-Delta ProtectionDocument4 pagesEchnical News: Improving Star-Delta ProtectionFuji Electric SMBENo ratings yet

- MN90T102Document13 pagesMN90T102dexterNo ratings yet

- S K Pillai A First Course On Electrical Drives PDFDocument242 pagesS K Pillai A First Course On Electrical Drives PDFSudhir SainiNo ratings yet

- P3003 1Document2 pagesP3003 1Sudhir SainiNo ratings yet

- Tans11 15Document5 pagesTans11 15Sudhir SainiNo ratings yet

- Power TransformerDocument43 pagesPower TransformerSudhir SainiNo ratings yet

- ECE4762011 - Lect9 Transformer PuDocument43 pagesECE4762011 - Lect9 Transformer PuSudhir SainiNo ratings yet

- Selected Motors of Fccu For Online Motor Signature AnalysisDocument1 pageSelected Motors of Fccu For Online Motor Signature AnalysisSudhir SainiNo ratings yet

- 07 - Hyd2.0 Installation PDFDocument85 pages07 - Hyd2.0 Installation PDFSudhir SainiNo ratings yet

- Standards IEEEDocument237 pagesStandards IEEESudhir Saini100% (1)

- CSQ-3 Users Manual 4189340263 UKDocument21 pagesCSQ-3 Users Manual 4189340263 UKSudhir SainiNo ratings yet

- The Complete Guide To Battery MonitoringDocument29 pagesThe Complete Guide To Battery MonitoringSudhir SainiNo ratings yet

- Solar PV Design ProblemDocument4 pagesSolar PV Design ProblemAjala Oladimeji DurotoluwaNo ratings yet

- Microsoft Word - TDDocument7 pagesMicrosoft Word - TDgoyal.167009No ratings yet

- Business Model PARAMAWE Solar Energy LTDDocument5 pagesBusiness Model PARAMAWE Solar Energy LTDALPHONCENo ratings yet

- Switching Actuator, 2-Channel Switching Actuator, 4-Channel: SA3-02M - SA3-04MDocument2 pagesSwitching Actuator, 2-Channel Switching Actuator, 4-Channel: SA3-02M - SA3-04MSam SamNo ratings yet

- HVDC StationDocument26 pagesHVDC StationmeraatNo ratings yet

- 4-EL Sewedy Cables Power-Cables-CatalogueDocument1 page4-EL Sewedy Cables Power-Cables-CatalogueKarim MakkiNo ratings yet

- Advanced Power Plant EngineeringDocument2 pagesAdvanced Power Plant EngineeringRaja RKNo ratings yet

- 132/33 KV Khulna Central-Grid SubstationDocument2 pages132/33 KV Khulna Central-Grid SubstationAnikk Das100% (1)

- Inverter 12VDC To 220VAC 100 Watt by Power Transistor 2N3055Document19 pagesInverter 12VDC To 220VAC 100 Watt by Power Transistor 2N3055Bank100% (1)

- Smart Grid Tirana Kristian - SevdariDocument23 pagesSmart Grid Tirana Kristian - SevdarikristiNo ratings yet

- Powerware 9355 20kva PDFDocument16 pagesPowerware 9355 20kva PDFGabino SNo ratings yet

- Ferraz A50P PDFDocument2 pagesFerraz A50P PDFMarcel BaqueNo ratings yet

- Kaco-Concept Cpss Bp50Document19 pagesKaco-Concept Cpss Bp50At YugovicNo ratings yet

- Solar Charge ControllerDocument2 pagesSolar Charge ControllerBrahmpal BhardwajNo ratings yet

- Infineon Thyristors and Diodes2009Document48 pagesInfineon Thyristors and Diodes2009LeonardoNo ratings yet

- (Steering Gear) TM-60 Check ProcedureDocument2 pages(Steering Gear) TM-60 Check ProcedureMikhail BagliukNo ratings yet

- BOE Review CommentDocument451 pagesBOE Review CommentGULF BUSINESS CONTRACTINGNo ratings yet

- 09e 49 00 A3 Sheet 01Document1 page09e 49 00 A3 Sheet 01Dar AkhtNo ratings yet

- TCS FunctionDocument2 pagesTCS FunctionVictor HutahaeanNo ratings yet

- Electrical System Design For High Rise BuildingDocument12 pagesElectrical System Design For High Rise Buildingbookbok100% (5)

- Ubt Rotary Ups Brochure en PDFDocument12 pagesUbt Rotary Ups Brochure en PDFRitaban222No ratings yet

- Working Sinewave InverterDocument10 pagesWorking Sinewave InverterxenotargetNo ratings yet

- Cinema Thetare Safety STD L & Work Shop Wiring andDocument23 pagesCinema Thetare Safety STD L & Work Shop Wiring andBadarul MuneerNo ratings yet

- Hot Runner KEBA2580 220VDocument19 pagesHot Runner KEBA2580 220VAarón DíazNo ratings yet

- PI-200, PI-400, PI-750, XI41B: Models / ModelosDocument31 pagesPI-200, PI-400, PI-750, XI41B: Models / ModelosRolando MaasNo ratings yet

- 3VT4 Molded Case PDFDocument17 pages3VT4 Molded Case PDFAnonymous clMeE4g70No ratings yet

- Industrial Batteries - Network Power Sonnenschein Solar Safe Storage Capacity For Renewable Energy. SpecificationsDocument4 pagesIndustrial Batteries - Network Power Sonnenschein Solar Safe Storage Capacity For Renewable Energy. Specificationssebax123No ratings yet

- GuideToSupplyMetering - (v7) - Nov 2016 PDFDocument25 pagesGuideToSupplyMetering - (v7) - Nov 2016 PDFLe'Novo FernandezNo ratings yet

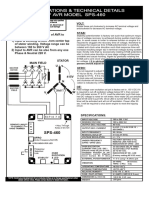

- Sps 460Document1 pageSps 460BrianHazeNo ratings yet