Professional Documents

Culture Documents

Machining Interchangeable Parts Mechanisms Forging Casting Machining

Uploaded by

Qamar ZamansOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machining Interchangeable Parts Mechanisms Forging Casting Machining

Uploaded by

Qamar ZamansCopyright:

Available Formats

Prior to the industrialization of machining and the development of interchangeable parts during the

19th century, filing was much more important in the construction of mechanisms. Component parts

were roughly shaped by forging, casting, and by primitive machining operations. These components

were then individually hand-fit for assembly by careful and deliberate filing. The potential precision of

such fitting is much higher than generally assumed, but the components of such hand-fit assemblies

are decidedly not interchangeable with those from another assembly. Locks, clocks,

and firearms (flintlocks and earlier) were manufactured in this way for centuries before the Industrial

Revolution.

Machining in the mid-19th century was heavily dependent on filing, because milling practice was

slowly evolving out of its infancy. As late as the early 20th century, manufacturing often involved

filing parts to precise shape and size. In today's manufacturing environment, milling and grinding

have generally replaced this type of work, and filing (when it occurs at all) usually tends to be

for deburring only. Skillful filing to shape and size is still a part of diemaking, moldmaking,

toolmaking, etc., but even in those fields, the goal is usually to avoid handwork when possible

You might also like

- CNC ReportDocument39 pagesCNC Reportrasaiya69% (13)

- Terminology Tool and DieDocument2 pagesTerminology Tool and DieCleng LaynesNo ratings yet

- RivetingDocument32 pagesRivetingJOYCE ONYEAGORONo ratings yet

- 1 s2.0 S089069550300172X Main - FlowformingDocument17 pages1 s2.0 S089069550300172X Main - FlowformingAnil JainNo ratings yet

- A Review of Spinning, Shear Forming and Ow Forming ProcessesDocument18 pagesA Review of Spinning, Shear Forming and Ow Forming ProcessesQuy SopNo ratings yet

- History Machine DesignDocument2 pagesHistory Machine Designram prasadNo ratings yet

- The Inaugural Issue ofDocument2 pagesThe Inaugural Issue ofMonika KshNo ratings yet

- CH 21Document1 pageCH 21Syed Anas SohailNo ratings yet

- Machine (Machined, Machining) Did Not Yet Exist.: MachinistDocument1 pageMachine (Machined, Machining) Did Not Yet Exist.: MachinistGokul PrabuNo ratings yet

- Essay - History of The Wood ScrewDocument7 pagesEssay - History of The Wood ScrewLeo BjorkegrenNo ratings yet

- Us Designingsheetmetal wp-4Document8 pagesUs Designingsheetmetal wp-4Nguyễn Hữu Quốc KhánhNo ratings yet

- DEAMER Peggy CraftOnDemand 2015Document5 pagesDEAMER Peggy CraftOnDemand 2015Paul DeFazioNo ratings yet

- Engineering The Future: 11.1 ChangeDocument11 pagesEngineering The Future: 11.1 ChangeAyman_Elmasry_9107No ratings yet

- Chapter Two: Nontraditional Machining Principles Objectives in This Chapter You Will Grasp AboutDocument76 pagesChapter Two: Nontraditional Machining Principles Objectives in This Chapter You Will Grasp AboutAla ZiNo ratings yet

- DCP291 Design and Fabrication of Forging Die For Door ClampingDocument3 pagesDCP291 Design and Fabrication of Forging Die For Door ClampingANAND KRISHNANNo ratings yet

- Applications: Linear PlaningDocument2 pagesApplications: Linear PlaningMarlLo MarapaoNo ratings yet

- Interchangeable Parts: Interchangeable Parts Are Parts (Components) That Are, For Practical Purposes, Identical. TheyDocument11 pagesInterchangeable Parts: Interchangeable Parts Are Parts (Components) That Are, For Practical Purposes, Identical. TheyNekia9imeNo ratings yet

- Home Instruction for Sheet Metal Workers - Based on a Series of Articles Originally Published in 'Metal Worker, Plumber and Steam Fitter'From EverandHome Instruction for Sheet Metal Workers - Based on a Series of Articles Originally Published in 'Metal Worker, Plumber and Steam Fitter'No ratings yet

- Milling MachineDocument47 pagesMilling MachineCt Costales DangaranNo ratings yet

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsFrom EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsRating: 5 out of 5 stars5/5 (1)

- Scroll Saw Basics (1991) PDFDocument132 pagesScroll Saw Basics (1991) PDFJoseph Romero83% (6)

- 19ME302 - Module 1 NotesDocument41 pages19ME302 - Module 1 NotesLikhith Kumar NNo ratings yet

- The Blacksmith's Craft - An Introduction To Smithing For Apprentices And CraftsmenFrom EverandThe Blacksmith's Craft - An Introduction To Smithing For Apprentices And CraftsmenNo ratings yet

- Document 1Document5 pagesDocument 122.Võ Thành PhongNo ratings yet

- Architecture ManagementDocument12 pagesArchitecture ManagementBUDIONGAN, GUINDELYNNo ratings yet

- Elli Fritt 1993Document12 pagesElli Fritt 1993ShubhamNo ratings yet

- Die Grinder: Die Grinders and Rotary Tools Are Handheld Power Tools Used For Grinding, Sanding, Honing, PolishingDocument1 pageDie Grinder: Die Grinders and Rotary Tools Are Handheld Power Tools Used For Grinding, Sanding, Honing, PolishingHumberto Rivera SoriaNo ratings yet

- Recent Development Trends in Metal Forming: SciencedirectDocument44 pagesRecent Development Trends in Metal Forming: SciencedirectYasser BouktirNo ratings yet

- Nut and BoltDocument24 pagesNut and BoltKiran HivareNo ratings yet

- CEM1 Week1 PDFDocument17 pagesCEM1 Week1 PDFJhune UrabaNo ratings yet

- Edge Folding MachineDocument49 pagesEdge Folding MachineAakash Dindigul100% (1)

- Nuts and BoltsDocument7 pagesNuts and BoltsMuDasirNo ratings yet

- Module in Industrial Arts 1Document76 pagesModule in Industrial Arts 1Kevin Nichols Abacan100% (1)

- Machine ToolsDocument2 pagesMachine Toolsyachka228325No ratings yet

- ScrewdriverDocument10 pagesScrewdriverroberto jimenezNo ratings yet

- Screwdriver: Tool ScrewsDocument4 pagesScrewdriver: Tool Screwscotton byNo ratings yet

- The Change of The Blacksmith James Williams 1Document5 pagesThe Change of The Blacksmith James Williams 1api-736014651No ratings yet

- Ironwork - Part II - Being a Continuation of the First Handbook, and Comprising from the Close of the Mediaeval Period to the End of the Eighteenth Century, Excluding English WorkFrom EverandIronwork - Part II - Being a Continuation of the First Handbook, and Comprising from the Close of the Mediaeval Period to the End of the Eighteenth Century, Excluding English WorkNo ratings yet

- Wrought Ironwork - A Manual of Instruction for Rural CraftsmenFrom EverandWrought Ironwork - A Manual of Instruction for Rural CraftsmenRating: 5 out of 5 stars5/5 (1)

- 05 - Milling Operations in The LatheDocument125 pages05 - Milling Operations in The Lathej43951048No ratings yet

- The History of DFM : Eli WhitneyDocument6 pagesThe History of DFM : Eli Whitneyccaballerog206No ratings yet

- 11 Chapter 1Document32 pages11 Chapter 1G00GLRNo ratings yet

- Machining: 1 History and TerminologyDocument6 pagesMachining: 1 History and Terminologyanant2409No ratings yet

- Investment Casting PDFDocument2 pagesInvestment Casting PDFShailesh Dhomne100% (1)

- ForjingDocument4 pagesForjingolyad ahmedinNo ratings yet

- Gillette ReportDocument48 pagesGillette Reporthaider_shah882267100% (1)

- Press Working of Me 00 SmitDocument308 pagesPress Working of Me 00 SmitDonT_RNNo ratings yet

- Rough Music and Factory Protest in Post-1945 Italy: by Guest On 27 September 2017Document41 pagesRough Music and Factory Protest in Post-1945 Italy: by Guest On 27 September 2017serenity_802No ratings yet

- FinalDocument66 pagesFinalBasu KumashiNo ratings yet

- Wheellock PlansDocument59 pagesWheellock PlansPuturrú De Fuá100% (2)

- MAT CH II IntroDocument25 pagesMAT CH II IntroMilion dugumaNo ratings yet

- Robotic Craft: - Mark MiodownikDocument1 pageRobotic Craft: - Mark MiodownikMario Gregorio MartínezNo ratings yet

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationFrom EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationRating: 4 out of 5 stars4/5 (14)

- The Giza Power PlantDocument10 pagesThe Giza Power Plantinterstar100% (1)

- This Content Downloaded From 103.212.145.68 On Fri, 07 Apr 2023 06:19:02 UTCDocument16 pagesThis Content Downloaded From 103.212.145.68 On Fri, 07 Apr 2023 06:19:02 UTCpuneya sachdevaNo ratings yet

- White Black Yellow Modern Construction Company Presentation TemplateDocument28 pagesWhite Black Yellow Modern Construction Company Presentation TemplateEzekiel Barcelona BonaobraNo ratings yet

- تذکرہ جمیل PDFDocument151 pagesتذکرہ جمیل PDFQamar ZamansNo ratings yet

- Kashmir Issue by Dr. Farooq KhanDocument49 pagesKashmir Issue by Dr. Farooq KhanQamar ZamansNo ratings yet

- Assignment 2Document2 pagesAssignment 2Qamar ZamansNo ratings yet

- Course Outline - Pak StudiesDocument3 pagesCourse Outline - Pak StudiesQamar ZamansNo ratings yet

- Course Outline - Pak StudiesDocument3 pagesCourse Outline - Pak StudiesQamar ZamansNo ratings yet

- Assignment 2Document2 pagesAssignment 2Qamar ZamansNo ratings yet

- BitLocker Recovery Key 2FA57E2A A9EC 492F 8C42 E6FB45376145Document1 pageBitLocker Recovery Key 2FA57E2A A9EC 492F 8C42 E6FB45376145Qamar ZamansNo ratings yet

- Middle Ages Blacksmiths Hardened Trade Smiths Paris The Process Was A SecretDocument1 pageMiddle Ages Blacksmiths Hardened Trade Smiths Paris The Process Was A SecretQamar ZamansNo ratings yet

- Brandon PoulsonDocument1 pageBrandon PoulsonQamar ZamansNo ratings yet

- Cia AgentDocument1 pageCia AgentQamar ZamansNo ratings yet

- RemscheidDocument1 pageRemscheidQamar ZamansNo ratings yet

- Battle of Morotai: Pacific War Morotai Netherlands East Indies Allies Liberation of The Philippines JapaneseDocument1 pageBattle of Morotai: Pacific War Morotai Netherlands East Indies Allies Liberation of The Philippines JapaneseQamar ZamansNo ratings yet

- Rasping Emic Hand Axes Abrading Sandstone Lapping Wood SandDocument1 pageRasping Emic Hand Axes Abrading Sandstone Lapping Wood SandQamar ZamansNo ratings yet

- Rasping Emic Hand Axes Abrading Sandstone Lapping Wood SandDocument1 pageRasping Emic Hand Axes Abrading Sandstone Lapping Wood SandQamar ZamansNo ratings yet

- Metalworking Woodworking Tool Cut Hand Tool Steel Case Hardened Tang RaspDocument1 pageMetalworking Woodworking Tool Cut Hand Tool Steel Case Hardened Tang RaspQamar ZamansNo ratings yet

- Date Afor MailDocument17 pagesDate Afor MailQamar ZamansNo ratings yet

- NotificationvvbDocument1 pageNotificationvvbmahmoodanwar34No ratings yet

- هقفلا Al-Fiqh: َقفلا-Fiqh literally means to understand نهفلا.An example ofDocument59 pagesهقفلا Al-Fiqh: َقفلا-Fiqh literally means to understand نهفلا.An example ofAyman (Maryam)No ratings yet

- Reading Tips Never Read The Passage First Never Waste Your Time at Reading The Passage FirstDocument43 pagesReading Tips Never Read The Passage First Never Waste Your Time at Reading The Passage FirstQamar Zamans100% (1)

- LicenceDocument1 pageLicenceasad8111No ratings yet

- Date Afor MailDocument17 pagesDate Afor MailQamar ZamansNo ratings yet

- Date Afor MailDocument17 pagesDate Afor MailQamar ZamansNo ratings yet

- Paper English Class 9thDocument3 pagesPaper English Class 9thQamar Zamans100% (1)

- MphilDocument1 pageMphilQamar ZamansNo ratings yet

- Drilling Jigs Italiana FerramentaDocument34 pagesDrilling Jigs Italiana FerramentaOliver Augusto Fuentes LópezNo ratings yet

- Aashto M288-17 Product Selection GuideDocument1 pageAashto M288-17 Product Selection GuideDem DemNo ratings yet

- Shirokov 2020 IOP Conf. Ser. Mater. Sci. Eng. 775 012148Document8 pagesShirokov 2020 IOP Conf. Ser. Mater. Sci. Eng. 775 012148Tomás de AlmeidaNo ratings yet

- Nozzle Liners and Dip PipesDocument6 pagesNozzle Liners and Dip PipesHedi Ben MohamedNo ratings yet

- BLOBITECTUREDocument23 pagesBLOBITECTURESonal TarkasbandNo ratings yet

- (08100) - Concrete-Filled Tubular Members and Connections - Xiao-Ling Zhao, Lin-Hai Han and Hui LuDocument303 pages(08100) - Concrete-Filled Tubular Members and Connections - Xiao-Ling Zhao, Lin-Hai Han and Hui LuNantawut MuangjuangNo ratings yet

- Technical Performance Data SheetDocument2 pagesTechnical Performance Data SheetAthul T.NNo ratings yet

- Early Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementDocument3 pagesEarly Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementZain AbidiNo ratings yet

- Terry Adams Construction/ HVAC ResumeDocument3 pagesTerry Adams Construction/ HVAC ResumeTerry AdamsNo ratings yet

- Comparison of Oman Seismic Code For Buildings With International CounterpartsDocument12 pagesComparison of Oman Seismic Code For Buildings With International CounterpartskarlNo ratings yet

- ReferencesDocument3 pagesReferencesDharmendra PrajapatiNo ratings yet

- ICT Models Incluye KILLZONES INDEX y FOREX PDFDocument9 pagesICT Models Incluye KILLZONES INDEX y FOREX PDFferuz qazaqov100% (1)

- PP08 - Asep - NSCP 2015 Update On CH7 MasonryDocument13 pagesPP08 - Asep - NSCP 2015 Update On CH7 MasonryjimNo ratings yet

- Chapter 10 Foundations and Equipment PadsDocument30 pagesChapter 10 Foundations and Equipment PadsNyan LinNo ratings yet

- Seismic Bridge Design Mitigation Outline Part 3Document156 pagesSeismic Bridge Design Mitigation Outline Part 3Mike2322No ratings yet

- Presentation - Tilottoma - Anup MitraDocument80 pagesPresentation - Tilottoma - Anup MitraAnup Kumar MitraNo ratings yet

- Professionals Guide For Rebar Detailing 2018Document12 pagesProfessionals Guide For Rebar Detailing 2018Thiha KyawNo ratings yet

- GB 10-2019 Brochure Mapeguard Um-35 Web PDFDocument36 pagesGB 10-2019 Brochure Mapeguard Um-35 Web PDFInsafians PowerNo ratings yet

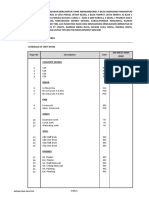

- JMJ Mega Bina (RM) Page No Description Unit: Redhuan/ipoh meru/SURDocument3 pagesJMJ Mega Bina (RM) Page No Description Unit: Redhuan/ipoh meru/SURAhmad RedhuanNo ratings yet

- Forms and Materials For Speedy Construction: Submitted by Mohd Kaif Vijay Kishor Kamal Kant Jitendra Saini Mudassir KhanDocument23 pagesForms and Materials For Speedy Construction: Submitted by Mohd Kaif Vijay Kishor Kamal Kant Jitendra Saini Mudassir KhanAr Jitendra KumarNo ratings yet

- 1.load CalculationDocument5 pages1.load Calculationvel suriyaNo ratings yet

- FEL Stages by Burns and MCDocument4 pagesFEL Stages by Burns and MCRahul KhandelwalNo ratings yet

- Method Statement For Building Work 20180816 PDFDocument16 pagesMethod Statement For Building Work 20180816 PDFPROJECT MANAGERNo ratings yet

- Bd-Ps1E: Pcefv-V39 Pcefv-V47 Pcefv-V55 Pcefv-V63 Pcefv-V71 Pcefv-V79Document14 pagesBd-Ps1E: Pcefv-V39 Pcefv-V47 Pcefv-V55 Pcefv-V63 Pcefv-V71 Pcefv-V79Marlon MartinezNo ratings yet

- COMPLET BLD 103.... SamuelDocument39 pagesCOMPLET BLD 103.... SamuelFadare SamuelNo ratings yet

- Project Work: Construction of Bridge No 352 (6 X 30.50M PSC Box Girder)Document44 pagesProject Work: Construction of Bridge No 352 (6 X 30.50M PSC Box Girder)shravan38No ratings yet

- Grinding Technology HPGRDocument6 pagesGrinding Technology HPGRworquera2507No ratings yet

- Pad Footing Design Based On ACI 318-14: Input Data Design SummaryDocument4 pagesPad Footing Design Based On ACI 318-14: Input Data Design SummaryBryan PerezNo ratings yet

- Specifications BOOKLET 3Document423 pagesSpecifications BOOKLET 3Ahmad OmarNo ratings yet

- HW Generator Denr FormDocument4 pagesHW Generator Denr FormDonna Liza FajardoNo ratings yet